Abstract

Escherichia coli cells expressing mink (Mustela vison) growth hormone were grown in a batch fermentation process. The expression level was estimated to be 27% of the total cellular protein after 3 h of induction with 1 mM isopropyl β-d-thiogalactoside (IPTG). If the expression of mink growth hormone (mGH) was induced with 0.2 mM IPTG, the concentration of target protein was slightly lower and was found to be 23% at the same time after induction. mGH expressed as inclusion bodies was solubilized in 8 M urea and renatured by dilution protocol at a protein concentration of 1.4–2.1 mg/ml in the presence of glutathione pair in a final concentration of 11.3 mM. [GSH]/[GSSG] ratio equal to 2/1 was used. Two-step purification process comprising of ion-exchange chromatography on Q-Sepharose and hydrophobic chromatography on Phenyl-Sepharose was developed. Some 25–30 mg of highly purified and biologically active mGH was obtained from 4 g of biomass. The method presented in this study allows producing large quantities of mGH and considering initiation of scientific investigation on mGH effect on mink in vivo and availability in fur industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Growth hormone (GH) is a single-chain polypeptide hormone synthesized and secreted by the pituitary gland. Besides stimulating linear body growth, it also plays an important role in a variety of metabolic and physiological processes. Human GH (hGH) is the most investigated one. There are several forms of hGH, but the predominant one containing 191 amino acids residues and two disulfide bonds has a molecular mass of 22 kDa (Chawla et al. 1983; Li 1982).

Until the mid-1980s, the only source of hGH was from human cadaver tissue (Pearlman and Bewley 1993). However, the advent of recombinant DNA technology has allowed the production of large quantities of biologically active hGH (Goeddel et al. 1979; Olson et al. 1981). Recombinant hGH is still now largely used to treat GH-deficient short-stature children to final height and as therapy of adults with GH deficiency (Molitch et al. 2006; Laursen 2004).

Among the animal GHs, bovine (bGH) and porcine (pGH) hormones are the most investigated ones. They are both polypeptides with a molecular mass of 22 kDa and two disulfide bonds (Cardamone et al. 1995; Secchi and Borromeo 1997; Parkinson et al. 2000). They were cloned, and the production of recombinant, biologically active pig and bovine GHs (rpGH and rbGH) has made them one of the most promising proteins for improving the productivity of farmed animals (Woychik et al. 1982; Seeburg et al. 1983; George et al. 1985; Langley et al. 1987a,b; Crivelli et al. 1991; Wang et al. 1993). Both recombinant GHs are legally used in several countries (e.g., United States and Australia) (Sillence 2004): rbGH to stimulate milk production in dairy cows (Maierhofer et al. 1993; Beswick and Kennelly 1998) and rpGH to improve swine growth rate and to reduce fat deposition (Klindt et al. 1992, 1995).

There is very limited information on mink growth hormone (mGH). The mGH gene was cloned and sequenced (Harada et al. 1990; Shoji et al. 1990); the resulting protein contained four cysteine residues and potentially two disulfide bridges that might be formed based on the high level of sequence homology with other GHs.

In this study, we report the production of bioactive mGH in Escherichia coli using recombinant DNA technology. The availability of unlimited amounts of recombinant mGH will be valuable to further research on the physiological functions of GH in the mink. In particular, it will be interesting to study if this hormone has the same major role in normal epidermal homeostasis in the mink as in several other species (Edmondson et al. 2003) and, therefore, if mGH might be a useful support in fur production industry.

Materials and methods

Reagents

Reagents for sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) were purchased from Bio–Rad (Hercules, USA), and protein molecular weight markers were obtained from Pharmacia (Uppsala, Sweden) and MBI Fermentas (Vilnius, Lithuania). Q-Sepharose Fast Flow, Phenyl-Sepharose 6 Fast Flow (low sub), and Sephadex G-25 were from Amersham Biosciences (Uppsala, Sweden). Isopropyl β-d-thiogalactoside (IPTG) from MBI Fermentas and reduced and oxidized glutathione from Roche (Indianapolis, IN, USA) were used. All other chemicals were of analytical grade. In the text, pH values of Tris–HCl buffer solutions were indicated at 25°C. The mouse myeloid cell line FDC-P1 (Hapel et al. 1984), stably transfected with the full-length ovine GH receptor (oGHR), was kindly provided by Dr. James Beattie (Department of Bioscience, University of Strathclyde, Glasgow, UK). This clonal line (oGHR-FDC-P1) expresses approximately 2,200 receptors/cell with an affinity of 1.4 nM for bovine GH (Beattie et al. 1999). Tissue culture plastic was from Corning Lifescience (Schiphol-Rijk, The Netherlands), and culture medium and fetal calf serum (FCS) were from Euroclone (Milan, Italy). Antibiotics, MTT reagent (3-(4,5-dimethyl-thiazol-2yl)-2,5-diphenyl tetrazolium bromide) and mouse recombinant interleukin-3 (IL-3) were from Sigma (Milan, Italy). Recombinant porcine GH (rpGH) was from GroPep (Adelaide, Australia), and recombinant bovine GH (rbGH) was from Monsanto (St. Louis, MO, USA).

Microorganism

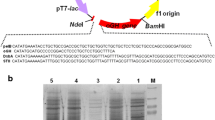

E. coli strain BL21 (DE3) harboring a pET21a+-based expression vector (NovaGen) was used for recombinant mGH production. A vector contains a strong phage T7 promoter and an mGH gene inserted into pET21a+ vector through NdeI and BamHI restriction endonucleases sites. A gene product is a 191-amino-acid-length polypeptide whose sequence refers to P19795 (amino acids 27 to 216) in Swiss-Prot database plus methionine at the first position of the N-end of protein.

Fermentation conditions

For large-scale production of mGH, recombinant E. coli cells were grown in a 15-l volume fermentor (LKB 1601 Ultroferm) with 10 l of working volume. Culture conserved in LB medium containing 15% of glycerol was used to produce inoculum by adding 250 μl of conserve to 1,000 ml of propagation medium (casein hydrolysate 10 g, yeast extract 5 g, NaCl 5 g) supplemented with 50 mg of ampicillin and incubated overnight at 37°C with shaking at 200 rpm. The fermentation was performed in 7 l of nutrient-rich medium (casein hydrolysate 180 g, yeast extract 50 g, NH4Cl 10 g) supplemented with 1 l of phosphate buffer pH 7.0 (Na2HPO4 × 12H2O 118.7 g, KH2PO4 45.4 g), 1 l of glucose solution (glucose 30 g, MgSO4 × 7H2O 5 g), 0.5 g of ampicillin, and 200 μl of 10% (v/v) antifoam agent (Antifoam 204, Sigma)/water mixture. The fermentation was carried out at 37°C with aeration, and the pH was maintained at 7.0 using 30% NaOH; oxygen saturation was approximately 20%. The culture growth was observed by measurement of an optical density at 600 nm wavelength (OD600) using an Ultrospec 4000 spectrophotometer (Pharmacia Biotech). All measurements were performed off-line by collecting samples of fermentation media at various time points postinoculation. Expression of mGH was induced at OD600 = 2.0 by adding into the fermentation medium IPTG solution to the final concentration of 1 or 0.2 mM. Samples after induction were taken every 40 min for SDS-PAGE analysis of protein expression. Cells were cultivated for 200 min after induction and then harvested by centrifugation at 5,000 × g for 15 min.

Refolding and purification of mGH

E. coli lysate was prepared as follows: 4 g of frozen biomass was homogenized in 40 ml of 0.1 M Tris–HCl buffer pH 7.2 containing 5 mM EDTA, and the cells were sonicated 5 min on ice using a Sonics Vibracell VCX 750. PMSF to a final concentration of 1 mM was added just before the sonication. The suspension of disrupted cells was centrifuged at 13,000 × g for 25 min at 4°C. The collected pellets of inclusion bodies were washed with an equal volume of water, then resuspended in 40 ml of washing solution (2 M urea, 1 M NaCl, 5 mM EDTA, 1 mM PMSF in 0.1 M Tris–HCl buffer pH 9.0) and centrifuged at 16,000 × g for 25 min at 4°C. Subsequently, the pellets were washed with water. Purified inclusion bodies were solubilized in 40 ml of 0.1 M Tris–HCl buffer pH 9.0 containing 8 M urea and 20 mM reduced glutathione with gentle stirring at 4°C for 15 min. The solution was centrifuged at 16,000 × g for 25 min at 4°C, and the resulting supernatant was diluted with 0.1 M Tris–HCl buffer pH 9.0 containing 6 mM oxidized glutathione to reduce the urea concentration to 3 M. The renaturation reaction was carried out for 20 h at 4°C with gentle stirring. Finally, the solution was centrifuged at 16,000 × g for 25 min at 4°C, and the chaotropic agent and thiol compounds were removed by size exclusion chromatography using a Sephadex G-25 gel filtration column (2.5 × 80.5 cm), equilibrated with 0.025 M Tris–HCl buffer pH 8.5 at a flow rate of 1.5 ml/min.

Fractions containing mGH were pooled and loaded on Q-Sepharose column (2.5 × 12 cm) previously equilibrated with 0.025 M Tris–HCl buffer pH 8.5 at a flow rate of 2 ml/min. Unbound proteins were washed out with the same buffer, and bound proteins were eluted with a linear salt gradient as follows: one bed volume of 0–0.15 M NaCl, two bed volumes of 0.15–0.3 M NaCl, and two bed volumes of 0.3–1 M NaCl in 0.025 M Tris–HCl buffer pH 8.5. Peak which appeared in the range of 0.3–1 M of NaCl and contained mGH was pooled. The salt concentration was adjusted approximately to 2 M, and the protein solution was applied on Phenyl-Sepharose column (1.5 × 13.5 cm) previously equilibrated with 0.025 M Tris–HCl buffer pH 8.5 containing 2 M NaCl at a flow rate of 1 ml/min. Unbound proteins were washed out with the same buffer, and bound proteins were eluted with ten bed volumes of linear NaCl gradient (0.8–0.2 M) in 0.025 M Tris–HCl buffer pH 8.5. Fractions containing mGH were pooled and stored at −20°C.

Analytical methods

The protein concentration was determined spectrophotometrically at 595 nm by the Bradford (1976) assay.

SDS-PAGE was carried out according to the method of Laemmli (1970). The acrylamide concentration of the resolving gel was 15%. Proteins were stained with Coomassie Brilliant Blue R-250 dye. The gels were scanned, and the percentage of mGH was estimated using the UN-SCAN-IT software (Silk Scientific, USA).

Cell lysates for protein expression examination were prepared from 1.4 ml of the culture. Cells were harvested by centrifugation at 10,500 × g for 15 min, and cell pellets were suspended in 0.1 ml of TE buffer (1 M Tris, 0.5 M EDTA, pH 8.0) with 1% SDS and heated at 95°C for 5 min. Then, the solution was diluted as many times as the number of the culture optical density units had been and mixed with fourfold concentrated gel sample buffer (0.025 M Tris–HCl pH 6.8, 2% SDS, 10% glycerol, 5% β-mercaptoethanol and 0.05% bromphenol blue in final concentrations). Samples were heated at 95°C for 5 min and loaded on SDS-PAGE gel.

Samples of purified mGH were analyzed by RP-HPLC using reversed-phase column Protein C4 (250 × 4.6 mm, Vydac); solvent A, 0.1% trifluoracetic acid in water; solvent B, 0.1% trifluoracetic acid in acetonitrile (HPLC gradient grade). The column was initially equilibrated with 9% B at a flow rate of 1 ml/min. After injection, a linear gradient of 9 to 41% B for 3 min, 41 to 49% B for 10 min, 49 to 58% B for 40 min, 58 to 68% B for 10 min, and 68 to 81% B for 1 min was applied. The absorbance was monitored at 215 nm using a Waters 2487 Dual λ absorbance detector. Data analysis was performed using Waters Breeze chromatography software. Samples after renaturation step were analyzed using reversed-phase column Hi-Pore RP-304 (250 × 4.6 mm, Bio–Rad). The column was also equilibrated with 9% B at a flow rate of 1 ml/min. A linear gradient of 9 to 41% B for 3 min, 41 to 49% B for 10 min, 49 to 64% B for 67 min, and 64 to 81% B for 1 min was applied.

In vitro bioassay for mGH

The mGH biological activity was determined in vitro on oGHR-FDC-P1 cells as previously described (Beattie et al. 1999). Stimulation of oGHR-FDC-P1 cells was assessed using the MTT-formazan dye assay (Mosmann 1983). This assay monitors the stimulation of both metabolic and mitogenic activity in these cells.

Cells were grown in suspension and were maintained in RPMI 1640 containing 50 U/ml penicillin–streptomycin, 10% FCS, 2 mM glutamine, and 50 U/ml mouse recombinant IL-3.

For stimulation experiments, cells were diluted in RPMI 1640—0.5% FCS and dispensed into a 96-well microtiter plate (40,000 cells per well). Cells were treated with hormone solution appropriately diluted in RPMI 1640—0.5% FCS. After 24 h of incubation, 20 μl MTT at a concentration of 0.5 mg/ml in RPMI 1640 was added to each well, and after a further 3 h of incubation, cells were lysed with 150 μl 0.12 M HCl in isopropyl alcohol. The contents of microtiter wells were resuspended thoroughly by trituration, and absorbance in each well was determined at 540 nm.

Bioactive mGH was measured in triplicate at six dose levels, and the relative potencies were compared from the standard curve plotted using rpGH and rbGH.

Before statistical analysis, the dose–response curves obtained from the oGHR-FDC-P1 bioassay were log-dose-transformed. Curves were then linearized by plotting the maximal response relative to the log-dose of the protein concentration. The EC50 of the curves was defined as the amount of GH required to give 50% of the maximum response under the conditions established for the assay. Maximal response was defined as the top of the dose–response sigmoid curve plotted with increasing concentrations of each treatment. All preparations gave rise to the same maximal stimulation. Results were expressed as means±SD.

Parallelism of the response curves generated by the various GH preparations was determined by comparing the slopes of the fitted regression lines with a statistical method included in the GraphPad Prism software (GraphPad Software, San Diego, CA, USA).

Results

Expression of mGH in E. coli

E. coli BL21 (DE3) harboring the plasmid pET21a+/mGH was grown in batch fermentation process. The target protein was induced with 1 mM IPTG at OD600 = 2.0. The expression level of mGH was estimated by SDS-PAGE. A wide protein band of about 22 kDa was found in samples after induction (Fig. 1, lanes 3–7). It is evident that this protein is absent in the sample of uninduced cells (Fig. 1, lane 2). The kinetics of recombinant mGH biosynthesis and the time profile of cell density are presented in Fig. 2. The maximum expression level was at 120 min after induction. After this point, the expression level decreased and was about 27% of total cellular protein at 200 min after induction. If the expression of mGH was induced with 0.2 mM IPTG, the concentration of target protein was slightly lower and was found to be 23% at the same time after induction.

Recombinant mGH was expressed as insoluble protein and accumulated as inclusion bodies. The washed pellets were found to be pure enough and comprised of 80% mGH as judged by SDS-PAGE (Fig. 3). Therefore, it was used for further recovery of mGH.

Refolding of mGH

Inclusion bodies were solubilized in 8 M urea to a final protein concentration of 3.7–5.6 mg/ml. The target protein was renatured by dilution protocol at pH 9.0 and at a protein concentration of 1.4–2.1 mg/ml. The concentration of chaotropic agent was decreased to 3 M. To form disulfide bonds, a mixture of reduced and oxidized glutathione was added to the renaturation buffer to a final concentration of 11.3 mM. [GSH]/[GSSG] ratio equal to 2/1 was used. The yield of mGH renaturation was determined by RP-HPLC and was equal to 49 ± 2% (mean±SD for three experiments is given) of all inclusion body proteins after 20 h at 4°C (Fig. 4). We considered that the main peak in RP-HPLC chromatogram corresponded to an oxidized form of mGH. To verify the retention time of oxidized mGH, we reduced the protein partially purified on Q-Sepharose with DTT (30 mM) at room temperature for 50 min and immediately analyzed by RP-HPLC. An oxidized form of mGH was eluted earlier than a reduced one, and a difference of 6.27 ± 0.87 min (mean±SD for four RP-HPLC elution profiles is given) was found between the elution times of both forms under chromatographic conditions described above. Therefore, in Fig. 4, the peaks with retention times of 36.243 and 42.096 min most likely correspond to oxidized and reduced forms, respectively. It is clear from SDS-PAGE analysis under reducing and nonreducing conditions that mGH aggregates, which have formed in refolding process via disulfide bonds, decrease the yield of target protein (Fig. 5, lanes 5 and 9). There are much more protein bands of various molecular mass in lane 9 (nonreducing conditions) than in lane 5 (reducing conditions). Moreover, it is observable in lane 9 that oxidized mGH and reduced mGH have a different mobility on the nonreducing SDS-PAGE. The apparent molecular mass of oxidized mGH is approximately 20 kDa while that of reduced mGH is >21 kDa. If the total amount of oxidized and reduced mGH were equated to 100%, the amount of oxidized mGH would be equal to 89 ± 3% (mean±SD for four experiments is given). It coincides with RP-HPLC analysis. If the area of peaks of oxidized and reduced mGH (Fig. 4, the peaks with the retention times of 36.243 and 42.096 min, respectively) were 100%, the renaturation yield would be 93 ± 2% (mean±SD for three experiments is given). It confirms that a large amount of aggregates but not of reduced form decreases the yield of renatured mGH.

SDS-PAGE (15%) analysis of mGH samples at various steps of purification. Lane 1 Protein markers; lanes 2 and 6 10 μg of highly purified mGH was loaded under reducing and nonreducing conditions, respectively; lanes 3 and 7 5 μg of highly purified mGH was loaded under reducing and nonreducing conditions, respectively; lanes 4 and 8 samples after Q-Sepharose under reducing and nonreducing conditions, respectively; lanes 5 and 9 samples after gel filtration under reducing and nonreducing conditions, respectively

Chromatographic purification of refolded mGH

After removal of low molecular mass compounds (3 M urea and glutathione pair) by gel filtration, the renatured protein was purified by ion-exchange chromatography on Q-Sepharose and following hydrophobic chromatography on Phenyl-Sepharose. The most part of disulfide-bonded aggregates formed during renaturation process were successfully removed by chromatography on Q-Sepharose (Fig. 5, lanes 4 and 8). mGH seemed to be pure by SDS-PAGE under reducing conditions (Fig. 5, lane 4). However, SDS-PAGE under nonreducing conditions showed some impurities (Fig. 5, lane 8). It was most likely dimeric and other oligomeric forms of mGH. The purity of mGH was 87 ± 4% (mean±SD for four experiments is given) as judged by SDS-PAGE under nonreducing conditions. The last step of purification applying hydrophobic chromatography on Phenyl-Sepharose results in highly purified mGH. No additional bands appeared in SDS-PAGE gel under reducing and nonreducing conditions (Fig. 5, lanes 2,3,6, and 7). The purity of mGH was ≥95% as judged by RP-HPLC (Fig. 6). The summary of mGH purification from 4 g of biomass is presented in Table 1.

Biological activity of purified mGH

The purified mGH resulted highly biologically active: the mitogenic and metabolic activity of oGHR-FDC-P1 cells were stimulated dose-dependently between 5 and 500 ng/ml (Fig. 7).

The response of oGHR-FDC-P1 cells to increasing concentrations of mGH, rbGH, and rpGH. Cells were treated for 24 h with GHs and the effects revealed by MTT assay as described in the “Materials and methods” section. The results are expressed with a normalized y-axis (i.e., percentage between top and bottom of the sigmoid dose–response curves). Values are the mean±SD of three replicates

Because a reference mGH preparation was not available (no pituitary or recombinant mink GH is available from the National Hormone & Peptide Program, Harbor-UCLA Medical Center, Torrance, USA or other sources), the bioactivity of the purified mGH was compared to that of rbGH and rpGH. The bovine hormone was used because it is almost a species-specific treatment for oGHR-FDC-P1: bGH differs from oGH for only two amino acids. The pig GH was used because among the known GHs, it has the highest sequence homology with mGH (98.4%) (Harada et al. 1990).

Mink, pig, and bovine GHs gave rise to the same maximal stimulation of oGHR-FDC-P1 cells, and there was no appreciable difference between the slopes of the lines after log transformation of the three dose–response curves. This indicates that mGH is a full agonist for the oGHR, with the same efficacy to stimulate oGHR-FDC-P1 of the other two mammalian recombinant GHs. Conversely, the EC50 of the three dose–response curves were significantly different (P < 0.01). The potency of mGH was the lowest (EC50 = 103.0 ± 9.3 ng/ml), being 63 and 8% of that of pig (EC50 = 65.3 ± 6.5 ng/ml) and bovine (EC50 = 8.0 ± 1.1 ng/ml) GHs, respectively.

Discussions

Expression of heterologous protein in E. coli allows its rapid and economical production in large amounts. However, some new problems arise, especially in case of inactive protein synthesis and inclusion body formation. Inclusion bodies need to be solubilized by denaturants, and target protein has to be refolded to its native biologically active conformation. In spite of this disadvantage and various scientific efforts to obtain soluble target protein in host E. coli strain, inclusion body formation is still considered as a convenient and effective way in recombinant protein production. Expression of target protein more than 30% of the total cellular protein, easy isolation of the inclusion bodies from cells, lower degradation of the expressed protein, high level of target protein homogeneity in inclusion bodies, and possibility to reduce the number of purification steps are usually indicated as the main advantages of inclusion body formation (Singh and Panda 2005).

mGH expressed in E. coli faces the same aggregation problems and accumulates as inclusion bodies. Our previous experiments showed that mGH tends to aggregate, and even in case of low expression level (approximately 2% of total cellular proteins), the formation of inclusion bodies was observed (Morkunas et al. 2005). In spite of the same expression system, similar cultivation conditions, and high-level pGH and mGH sequence homology of 98% (187/190aa), mGH expression level after 2 h of induction was approximately 5% lower compared with pGH (Baranauskaite et al. 2005). Moreover, in contrast to pGH, a sharp loss of expression level was observed. Plasmid instability and metabolite accumulation could be probable reasons of the reduction of target protein amount.

To renature mGH, the dilution of the denatured solution with renaturation buffer was chosen as one of the easiest ways especially in large-scale purification process (Clark 1998). The renaturation of mGH was performed in conditions successfully used for the refolding of pGH according to its very high sequence homology (Baranauskaite et al. 2005). To reduce the volume of renaturation solution, mGH was renatured at high protein concentration (1.4–2.1 mg/ml), the rather that optimization of pGH refolding conditions showed that a decrease in protein concentration did not substantially change the final result. pH was slightly alkaline because these conditions allow rapid disulfide-bond formation (Vallejo and Rinas 2004).

To purify mGH, two-step process comprising of ion-exchange chromatography on Q-Sepharose and hydrophobic chromatography on Phenyl-Sepharose was developed. Because the refolding of disulfide-bonded proteins is in competition with its aggregation, it is of great importance to find effective step for target protein monomer separation from dimer and other oligomers. In the case of recombinant GHs, monomeric and other oligomeric forms differ in their hydrophobic affinity to Phenyl-Sepharose. This approach was successfully used not only for mGH but also for pGH monomer separation from other forms (Sereikaite and Bumelis 2006). The chromatographic cycle results in rather high yield of target protein. It was obtained approximately 15% of refolded and purified mGH from all solubilized inclusion body proteins.

The purified mGH resulted to be highly biologically active in vitro, stimulating cell proliferation down to the 5 ng/ml dose. Recombinant mGH had equal efficacy (i.e., same maximal response and parallel S-curves) but lower potency (i.e., higher dose needed to cause 50% of the maximal response) of recombinant porcine and bovine GHs in the oGHR-FDC-P1 cell bioassay.

The fact that the three hormones had the same efficacies indicates that mGH is a full agonist of the oGHR, causing the receptor to change to an active conformation as well as the bovine and porcine GHs.

The different potencies of the three GHs likely are the consequences of different affinities for the oGHR expressed on the FDC-P1 cell membrane. The highest affinity of bGH can be expected: bGH differs from the species-specific oGH for just two amino acids, while mGH and rpGH show 29 and 24 amino acid substitutions.

Conversely, we have no explanation of why mGH was 37% less potent than pGH. Mink and pig GHs are highly homologous (98.4% sequence homology) and are both nonspecies-specific agonists for the oGHR. Nevertheless, the relative potency of mGH was calculated by comparing the EC50, which is not the same as the K d for binding of an agonist to its receptor. Several factors can contribute to the affinity of a hormone to its receptor, and further investigations with species-specific mink GHR (i.e., mink liver cell membranes) are required to have a direct measure of the K d of the purified recombinant mGH to its receptor.

In conclusion, the method presented in this study allows producing large quantities of mGH and considering initiation of scientific investigation on mGH effect on mink in vivo and availability in fur industry.

References

Baranauskaite L, Sereikaite J, Gedminiene G, Bumeliene Z, Bumelis V-A (2005) Refolding of porcine growth hormone from inclusion bodies of Escherichia coli. Biocatal Biotransform 23:185–189

Beswick NS, Kennelly JJ (1998) The influence of bovine growth hormone and growth hormone releasing factor on acetyl-CoA carboxylase and fatty acid synthase in primiparous Holstein cows. Comp Biochem Physiol C Pharmacol Toxicol Endocrinol 120:241–249

Beattie J, Borromeo V, Bramani S, Secchi C, Baumbach WR, Mockridge J (1999) Effects of complexation with in vivo enhancing monoclonal antibodies on activity of growth hormone in two responsive cell culture systems. J Mol Endocrinol 23:307–313

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Cardamone M, Puri NK, Brandon MR (1995) Comparing the refolding and reoxidation of recombinant porcine growth hormone from a urea denaturated state and from Escherichia coli inclusion bodies. Biochemistry 34:5773–5794

Chawla RK, Parks JS, Rudman D (1983) Structural variants of human growth hormone: biochemical, genetic, and clinical aspects. Annu Rev Med 34:519–547

Clark ED (1998) Refolding of recombinant proteins. Curr Opin Biotechnol 9:157–163

Crivelli E, Cardamone M, Puri NK (1991) A single step method for the solubilization and refolding of recombinant protein from E. coli inclusion bodies. Aust J Biotechnol 5:78–80

Edmondson SR, Thumiger SP, Werther GA, Wraight CJ (2003) Epidermal homeostasis: the role of the growth hormone and insulin-like growth factor systems. Endocrine Reviews 24:737–764

George HJ, L’Italien JJ, Pilacinski WP, Glassman DL, Krzyzek RA (1985) High-level expression in Escherichia coli of biologically active bovine growth hormone. DNA 4:273–281

Goeddel DV, Heyneker HL, Hozumi T, Arentzen R, Hakura K, Yansura DG, Ross MJ, Miozzari G, Crea R, Seeburg PM (1979) Direct expression in Escherichia coli of a DNA sequence coding for human growth hormone. Nature 281:544–548

Hapel AJ, Warren HS, Hume DA (1984) Different colony-stimulating factors are detected by the “interleukin-3”-dependent cell lines FDC-Pl and 32D cl-23. Blood 64:786–790

Harada Y, Tatsumi H, Nakano E, Umezu M (1990) Cloning and sequence analysis of mink growth hormone cDNA. Biochem Biophys Res Commun 173:1200–1204

Klindt J, Buonomo FC, Yen JT (1992) Administration of porcine somatotropin by sustained-release implant: growth and endocrine responses in genetically lean and obese barrows and gilts. J Anim Sci 70:3721–3733

Klindt J, Buonomo FC, Yen JT (1995) Administration of porcine somatotropin by sustained-release implant: growth, carcass and sensory responses in crossbred and genetically lean and obese boars and gilts. J Anim Sci 73:1327–1339

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 47:680–685

Langley KE, Berg TF, Strickland TW, Fenton DM, Boone TC, Wypych J (1987a) Recombinant-DNA-derived bovine growth hormone from Escherichia coli. 1. Demonstration that the hormone is expressed in reduced form, and isolation of the hormone in oxidized, native form. Eur J Biochem 163:313–321

Langley KE, Lai PH, Wypych J, Everett RR, Berg TF, Krabill LF, Davis JM, Souza LM (1987b) Recombinant-DNA-derived bovine growth hormone from Escherichia coli. 2. Biochemical, biophysical, immunological and biological comparison with the pituitary hormone. Eur J Biochem 163:323–330

Laursen T (2004) Clinical pharmacological aspects of growth hormone administration. Growth Horm IGF Res 14:16–44

Li CH (1982) Human growth hormone: 1974–1981. Mol Cell Biochem 46:31–41

Maierhofer R, Kirchgessner M, Schwarz FJ, Eidelsburger U (1993) The effect of bovine growth hormone on the production criteria of dairy cows during summer feeding with grass. 2. Milk yield, milk composition and live weight. Arch Tierernahr 44:357–367

Molitch ME, Clemmons DR, Malozowski S, Merriam GR, Shalet SM, Vance ML (2006) Evaluation and treatment of adult growth hormone deficiency: an endocrine society clinical practice guideline. J Clin Endocrinol Metab 91:1621–1634

Morkunas M, Alisauskaite S, Sereikaite J, Bumelis V-A (2005) Influence of growth limiting factors on recombinant growth hormone expression in E. coli. J Biotechnol 118:S83

Mosmann T (1983) Rapid colorimetric assay for cellular growth and survival: application to proliferation and cytotoxicity assays. J Immunol Methods 65:55–63

Olson KC, Fenno J, Lin N, Harkins RN, Snider C, Kohr WH, Ross MJ, Fodge D, Prender G, Stebbing N (1981) Purified human growth hormone from E. coli is biologically active. Nature 293:408–411

Parkinson EJ, Morris MB, Bastiras S (2000) Acid denaturation of recombinant porcine growth hormone: formation and self-association of folding intermediates. Biochemistry 39:12345–12354

Pearlman R, Bewley TA (1993) Stability and characterization of human growth hormone, In: Wang YJ, Pearlman R (eds) Stability and characterization of protein and peptide drugs: case histories. Plenum, New York, pp 1–58

Secchi C, Borromeo V (1997) Structure and function of bovine growth hormone. Bovine growth hormone as an experimental model for studies of protein–protein interactions. J Chromatogr B Biomed Sci Appl 688:161–177

Seeburg PH, Sias S, Adelman J, de Boer HA, Hayflick J, Jhurani P, Goeddel DV, Heyneker HL (1983) Efficient bacterial expression of bovine and porcine growth hormones. DNA 2:37–45

Sereikaite J, Bumelis V-A (2006) Separation of recombinant porcine growth hormone monomer from dimer and other oligomers in production process from E. coli inclusion bodies. Biologija 3:67–69

Shoji K, Ohara E, Watahiki M, Yoneda (1990) Cloning and nucleotide sequence of a cDNA encoding the mink growth hormone. Nucleic Acids Res 18: 6424

Sillence MN (2004) Technologies for the control of fat and lean deposition in livestock. Vet J 167: 242–257

Singh SM, Panda AK (2005) Solubilization and refolding of bacterial inclusion body proteins. J Biosci Bioeng 99: 303–310

Vallejo LF, Rinas U (2004) Strategies for recovery of active proteins through refolding of bacterial inclusion body proteins. Microb Cell Fact 3:11

Wang H, O’Mahony DJ, McConnell DJ, Qi SZ (1993) Optimization of the synthesis of porcine somatotropin in Escherichia coli. Appl Microbiol Biotechnol 39:324–328

Woychik RP, Camper SA, Lyons RH, Horowitz S, Goodwin EC, Rottman FM (1982) Cloning and nucleotide sequencing of the bovine growth hormone gene. Nucleic Acids Res 10: 7197–7210

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sereikaite, J., Statkute, A., Morkunas, M. et al. Production of recombinant mink growth hormone in E. coli . Appl Microbiol Biotechnol 74, 316–323 (2007). https://doi.org/10.1007/s00253-006-0673-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0673-2