Abstract

The decarboxylation of tyrosine by certain lactic acid bacteria leads to the undesirable presence of tyramine in fermented foods. Tyramine is the most frequent biogenic amine found in cheese and is also commonly found in other fermented foods and beverages. The tyramine-producing strain Enterococcus durans IPLA 655 was grown in a bioreactor under different conditions to determine the influence of carbon source, tyrosine and tyramine concentrations, and pH on tyramine production. The carbon source appeared to have no significant effect on the production of tyramine. In contrast, tyrosine was necessary for tyramine production, while the presence of tyramine itself in the growth medium inhibited such production. pH showed by far the greatest influence on tyramine synthesis; tyramine was produced in the greatest quantities at pH 5.0, although this was accompanied by a reduced growth rate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biogenic amines (BA), which are found in a number of foods, are organic bases with an aliphatic, aromatic, or heterocyclic structure. With the exception of the physiological polyamines, they are mainly produced by the microbial decarboxylation of amino acids (Silla Santos 1996). The consumption of foods with high BA concentrations can lead to different degrees of food intolerance. Even low BA concentrations can be problematic if the individual’s natural detoxification mechanisms are inhibited or deficient. Tyramine and histamine can evoke symptoms such as alterations in blood pressure, headache, urticaria, nausea, and vomiting (Shalaby 1996). Putrescine and cadaverine can also react with nitrite to form carcinogenic nitrosamines.

Fish, cheese, and wine are the foodstuffs most commonly associated with BA poisoning. In raw fish products, histamine is produced by Gram-negative bacteria, but in fermented products it is usually produced by lactic acid bacteria (LAB). LAB in fermented foods also produce tyramine, putrescine, and cadaverine, although it is important to highlight that the capacity to produce BA is highly strain-dependent.

The accumulation of BAs in foods requires the presence of microorganisms that produce specific amino acid decarboxylases. The availability of amino acid substrates and other variables such as temperature, pH, a w, redox potential, and NaCl concentration affect the synthesis of these enzymes and their activity (Suzzi and Gardini 2003). Decarboxylase enzymes may have been developed by bacteria to help them survive and grow in acidic environments (Bearson et al. 1997). They are, in fact, inactive at neutral and alkaline pH (Schelp et al. 2001), suggesting that pH plays an important role in BA production. Although the exact physiological role of BAs remains unknown, they may be involved in acid stress resistance (Gale 1946). However, the literature contains conflicting information in this regard. While some authors report a correlation between the reduced pH caused by lactic fermentation in sausages and BA production (Eitenmiller et al. 1978; Santos-Buelga et al. 1986), others conclude that the main biological feature influencing BA formation is simply the extended growth of BA-producing microorganisms (Gardini et al. 2001). Recently, Marcobal et al. (2006) studied the influence of pH, tyrosine, and pyridoxal-5-phosphate (PLP) on tyramine production by Enterococcus faecium and Lactobacillus brevis, and concluded that a low pH and a high tyrosine concentration favor its production by these strains.

Cheeses are among the fermented foods that accumulate the highest concentrations of BA, with LAB as (Enterococcus and Lactobacillus) the main microorganisms responsible. Higher BA concentrations are usually detected in cheeses made with raw milk than in those made with pasteurized milk. Certainly, enterococci are the predominant bacteria in fully ripened raw milk cheese (review: Foulquie Moreno et al. 2006).

Because tyramine is the most frequent BA found in cheese (Novella-Rodríguez et al. 2003) and can reach concentrations higher than 1 g/kg of cheese (Fernández et al. 2006), its production under different conditions was studied. The main aim of the present work was to determine the effect of pH on tyramine production by Enterococcus durans IPLA 655, one of the Enterococcus species most commonly isolated from raw milk cheeses (Delgado and Mayo 2004; Psoni et al. 2006). Experiments were performed in a bioreactor under controlled conditions of pH. The influence of the carbon source, substrate (tyrosine) concentration, and the concentration of tyramine itself on the growth of this bacterium and its production of tyramine was determined in batch cultures.

Materials and methods

Bacteria and culture conditions

E. durans IPLA 655, formerly Lactococcus lactis IPLA 655, was the tyramine-producing strain used in this work. The nontyramine-producing strain E. durans IPLA 655 tdcA, which has the tdcA gene truncated by the integration of a plasmid by homologous recombination (Fernández et al. 2004), was also used in one part of the study. Both strains were statically propagated at 30°C in M17 broth (Oxoid, Basingstoke, Hampshire, England) supplemented with 0.5% (w/v) glucose (GM17). When necessary, the culture medium was supplemented with tyrosine (10 mM) and pyridoxal-5-phosphate (PLP) (0.005% w/v). Other conditions are indicated in the text.

An overnight culture of E. durans IPLA 655 grown in GM17 and 10 mM tyrosine was washed and resuspended in the same volume of potassium phosphate buffer (50 mM pH 7.0) and used as an inoculum (1% v/v) in all fermentation assays. All such assays were performed in GM17 broth supplemented with 10 mM tyrosine.

Flasks containing 5 ml of culture medium were used for uncontrolled pH fermentations (30°C, 6 h). Under these conditions, four different carbon sources (glucose, lactose, sucrose, and galactose) at 10 g l−1 were assayed.

A concentration of 5 g l−1 glucose was chosen for further assays in which the effect of several concentrations of tyrosine (0, 0.5, 2.5, 5, 7.5, and 10 mM) and tyramine (0,1, 2, and 5 mM) on tyramine production were tested.

For batch fermentations at controlled pH, a 2-l bioreactor vessel (750 ml working volume) (Biostat B, Braun-Biotech, Melsungen, Germany) was employed. pH was measured using an InPro 3000/225 pH probe (Mettler-Toledo, France), and controlled by the automatic addition of 2 N NH4OH. The agitation speed was 30 rpm. Cultures were grown at different pH (uncontrolled, 5.0, 6.0, and 6.8) at 30°C for 24 h. No control of pO2 was undertaken. An overnight culture grown in the presence of 10 mM of tyrosine was used as the inoculum (1% v/v).

16S ribosomal RNA gene sequence-based strain classification

The gene encoding the 16S rRNA of the tyramine producing-strain from the IPLA (Instituto de Productos Lácteos de Asturias, CSIC, Spain) collection, originally classified as Lactococcus lactis IPLA 655 (Cuesta 1996) was PCR-amplified using the primers and conditions described by Edwards et al. (1989). The amplicon was purified using the GelElute PCR Clean-up Kit (Sigma-Genosys, Haverhill, UK) and the nucleotide sequence determined using an ABI Prism 373 A Strech automated sequencer [performed by the Servicio de Secuenciación Automática de DNA—the Automatic DNA Sequencing Service (CIB, CSIC, Spain)]. The sequence was compared with those in databases using the BLASTN program (Altschul et al. 1997).

Measurement of specific growth rate

The maximum specific growth rate (μ max) was determined experimentally in the exponential growth phase as: \(\mu _{{\max }} = \left. {{{\left[ {\ln {\left( {{X_{1} } \mathord{\left/ {\vphantom {{X_{1} } {X_{0} }}} \right. \kern-\nulldelimiterspace} {X_{0} }} \right)}} \right]}} \mathord{\left/ {\vphantom {{{\left[ {\ln {\left( {{X_{1} } \mathord{\left/ {\vphantom {{X_{1} } {X_{0} }}} \right. \kern-\nulldelimiterspace} {X_{0} }} \right)}} \right]}} {{\left( {t_{1} - t_{0} } \right)}}}} \right. \kern-\nulldelimiterspace} {{\left( {t_{1} - t_{0} } \right)}}} \right]\) s, where X 0 and X 1 are the biomass (g l−1) at times t 0 and t 1 (O’Sullivan and Condon 1999).

Analyses

Samples were taken aseptically at regular intervals, and bacterial growth monitored by absorbance at 600 nm using a Biophotometer (Eppendorf, Hamburg, Germany).

To determine the viable cell count, serial dilutions of culture samples were made in quarter-strength Ringer’s solution and deep plated in duplicate on GM17 agar and incubated for 48 h at 30°C.

The quantitative analysis of tyramine production was undertaken by reverse-phase high performance liquid chromatography (RP-HPLC) using a Waters liquid chromatograph controlled by Millenium 32 Software (Waters, Milford, MA, USA). The samples were prepared by centrifugation at 8,000×g for 10 min. The resulting supernatants were filtered using Millipore 0.2 μm filters and derivatized using dabsyl chloride, as described by Krause et al. (1995). Separations were performed using a Waters Nova-pack C18 column (150×3.9 mm). Usually, 10 μl of the derivatized sample was injected and detection performed at 436 nm. The solvent gradient and detection conditions were similar to those described by Krause et al. (1995).

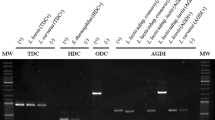

Tyrosine decarboxylase activity test

The relationship between tyrosine decarboxylase activity and pH was analyzed using the tyrosine decarboxylase activity test (Le Jeune et al. 1995). Cells from an overnight culture (108 cfu/ml) were harvested by centrifugation, washed twice, and ten-fold diluted in 30 mM potassium phosphate buffer (pH 5.0). The change in pH was measured over the incubation period (2 h at 30°C), in the presence and absence of 10 mM tyrosine.

Determination of organic acids and sugars by HPLC

Sugar and organic acid concentrations were determined using a chromatographic system composed of an Alliance 2690 module injector, a Photodiode Array PDA 996 detector, and a 410 Differential Refractometer detector, all controlled with Millennium 32 software (Waters, Milford, MA, USA). Supernatants (50 μl) were isocratically separated in a 300×7.8 mm HPX-87H Aminex ion-exchange column (Hewlett Packard, Palo Alto, CA, USA) protected by a cation H+ Microguard cartridge (BioRad, Laboratories, Richmond, CA, USA), at a flow rate of 0.7 ml/min and a temperature of 65°C. Sulfuric acid (3 mM) was used as the mobile phase. A PDA 996 detector at 210 nm was used to identify and quantify the organic acids detected, whereas the sugars were analyzed with a 410 Refractometer. Solutions of lactic and acetic acids, glucose, galactose, lactose, and sucrose were used as standards in the identification and quantification procedure.

Nucleotide sequence accession number

The nucleotide sequence reported in this study was submitted to EMBL Nucleotide Sequence Database under the accession no. AM292057.

Results

The tyramine producing-strain L. lactis IPLA 655 was reclassified as E. durans IPLA 655 based on its 16S rRNA sequence

The gene encoding the 16S rRNA of the tyramine-producing strain originally classified as L. lactis IPLA 655 (Cuesta 1996) was PCR-amplified and sequenced. The nucleotide sequence was compared with those in databases and found to be 100% identical to that of E. durans. Consistently, the strain was reclassified as E. durans IPLA 655.

Effect of different carbon sources on tyramine production

E. durans IPLA 655 was grown at 30°C for 6 h in M17 medium supplemented with 10 mM tyrosine (a tyramine precursor) and with glucose, sucrose, lactose, or galactose as carbon sources. The influence of the carbon source (10 g l−1) on growth and tyramine production was determined at the end of the incubation period (6 h). The experiments were done by duplicate and the differences were not significant. Table 1 summarizes the results obtained; similar growth rates were found with all carbon sources.

Under all the conditions assayed, at least 40% of the sugar was still available in the culture medium after 6 h of growth. E. durans IPLA 655 showed a homolactic metabolic pattern, with lactic acid as the main product of fermentation. The highest lactic acid concentration (5.3 g l−1) was recorded when the cells were grown with glucose as a carbon source. When lactose, galactose, and sucrose were used as carbon sources, the lactic acid concentrations reached were 4.8, 2.6, and 0.56 mg/ml, respectively. The final pH was also determined in the different media. As expected, the highest lactic acid concentration corresponded to the lowest pH measured (Table 1).

Differences in tyramine production were also detected and seemed to be related to the ability of the strain to grow and, consequently, reduce the pH. In fact, the lower the pH reached, the greater amount of tyramine produced. The cultures grown with glucose showed the greatest tyramine synthesis and the lowest pH. Those grown with sucrose produced the smallest quantities of tyramine and had the highest pH.

Effect of tyrosine and tyramine concentrations on tyramine production

E. durans IPLA 655 was grown at 30°C for 6 h in GM17. Several tyrosine concentrations (0, 0.5, 2.5, 5, 7.5, and 10 mM) were provided to determine their influence on tyramine production; similar optical density (OD) values were observed in the different cultures. In the absence of tyrosine, no tyramine was detected. Increasing tyrosine to 7.5 mM substantially increased the tyramine level in the culture supernatants. However, higher tyrosine concentrations led to no greater BA production (Table 2).

Different concentrations of tyramine (0, 1, 2, and 5 mM) were added to the culture medium in order to evaluate their effect on the production of tyramine itself. The bacterium was grown in GM17 supplemented with 10 mM of tyrosine and the indicated tyramine concentrations (Table 3). No differences in the OD value of the cultures were observed. The greater the tyramine concentration added to the culture medium, the smaller the tyramine production (Table 3). The experiments were done by duplicate and no significant differences were found.

Effect of pH on tyramine production

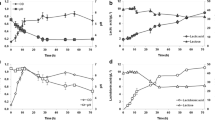

The influence of pH (uncontrolled, 5.0, 6.0, and 6.8) on bacterial growth and tyramine synthesis was determined in bioreactor batch cultures grown in GM17 broth supplemented with 10 mM tyrosine for 24 h at 30°C. Samples were taken at different times (Fig. 1). A clear influence on tyramine production was observed. Under the uncontrolled pH conditions (the initial pH was 6.8), tyramine was detected in the culture supernatants after 4 h of incubation and it continued to increase until the end of the incubation period (final content 6.2 mM; pH 5.8). In the cultures grown at pH 6.0 and 5.0, tyramine was detected after just 2 h of incubation. From 4 h onwards, a continuous increase in tyramine production was observed under the pH 6.0 and 5.0 conditions. A concentration of 16 mM was reached at the end of the incubation period at pH 5.0. It is noteworthy that under the pH 6.8 conditions, the quantity of tyramine produced was smaller (3.2 mM). It is to be expected that a suboptimum pH would affect bacterial growth. In fact, a clear difference in the μ max was seen between the cultures grown at pH 6.0 (0.81 h−1) and 5.0 (0.7 h−1) and those grown at pH 6.8 (1.22 h−1).

Effect of tyramine production on culture pH

To determine whether tyramine production by E. durans IPLA 655 had any effect on the culture pH, cells from an overnight culture grown in GM17 supplemented with 10 mM tyrosine were centrifuged and suspended in potassium phosphate assay buffer in the presence or absence of tyrosine. The effect of the tyramine-producing bacteria on pH was compared with that of the nonproducing strain E. durans IPLA 655 tdcA (Fig. 2).

In the presence of tyrosine, the tyramine-producing strain provoked an increase in pH. No pH variations were observed under any other conditions (Fig. 2). As expected, HPLC analysis of these samples showed that tyramine was only detected when the tyramine-producing strain was present.

Discussion

Different authors have reported that the production of BA in cheese is limited by the amount of precursor available (Ordoñez et al. 1997; Novella-Rodríguez et al. 2004; Fernández et al. 2006). Moreno-Arribas and Lonvaud-Funel (1999) showed that the tyrosine decarboxylase activity of L. brevis depended on the availability of tyrosine. In the present work, tyramine production by E. durans IPLA 655 in GM17 supplemented with different tyrosine concentrations was quantified (Table 2). Unsurprisingly, the presence of tyrosine was found to be necessary for tyramine synthesis, and a good correlation was seen between increased availability of this precursor (up to 7.5 mM) and tyramine production. A saturation effect was observed at higher concentrations, possibly related to the low solubility of tyrosine.

The effect of tyramine itself in the culture medium was also assayed. As expected, the addition of tyramine led to a reduction in tyramine production. The inhibition of amino acid decarboxylation by histamine has also been studied. Coton et al. (1998) showed that this BA behaves as a competitive inhibitor of histidine decarboxylase in Leuconostoc oenos 9204. It has also been suggested that the histidine/histamine membrane antiport system is also inhibited by high histamine concentrations in this same strain (Rollan et al. 1995). Moreno-Arribas and Lonvaud-Funel (1999) showed that tyrosine decarboxylase activity in L. brevis IOEB9809 is reduced in the presence of tyramine. This might also explain the effect seen in E. durans IPLA 655.

Some amino acid degradation pathways, such as arginine deaminase, depends on the carbon source available being repressed by glucose (Poolman et al. 1987). It has been proposed that the expression of the hdc gene (which codes for histidine decarboxylase) in Lactobacillus hilgardii is under catabolic repression (Landete et al. 2003). However, little information is available on the effect of the carbon source and its concentration on tyrosine decarboxylation, although Connil et al. (2002) showed that increasing the glucose concentration does not greatly affect tyramine production in sterile-salmon extract. The present results, however, indicate that the nature of the carbon source does have a slight effect on tyramine production. Nevertheless, the differences in tyramine content detected in the culture supernatants might simply reflect that E. durans IPLA 655 prefers some carbon sources to others. Moreover, differences were observed in the pH when the different carbon sources were used. These data therefore seem to indicate that pH is a crucial factor in tyramine synthesis. This is in agreement with previous observations describing an acidic pH to be optimum for tyrosine decarboxylase (Moreno-Arribas and Lonvaud-Funel 1999). Some authors have described amino acid decarboxylation as one of the acid stress resistance mechanisms that control intracellular pH (Lin et al. 1996; Sanders et al. 1998). Recently, the influence of the pH of the medium on tyramine production was described in E. faecium and L. brevis (Marcobal et al. 2006). However, other authors indicate that the pH has no effect on tyramine production, a reduction in the culture pH simply reducing the growth rate and, in turn, the BA synthesis (Gardini et al. 2001). The present work—which is the first to study the growth of the tyramine-producing strain E. durans IPLA 655 under different controlled pH conditions—shows the influence of pH on BA synthesis. Moreover, a certain uncoupling between growth and tyramine synthesis seems to occur. In fact, the greatest tyramine production was observed in 24 h cultures at pH 5.0 and 6.0 (16 and 8 mM, respectively). These cultures clearly showed lower optical densities and growth rates throughout the incubation period than did cultures grown at pH 6.8 or under uncontrolled pH conditions. The tyramine content of the latter culture supernatants was also lower (3.2 and 6.2 mM, respectively). It should be noted that tyramine was detected very early in the growth curve (2 h) under acidic culture conditions. Under the other pH conditions (uncontrolled and pH 6.8) a delay in tyramine detection was noted; indeed, appreciable amounts of tyramine were only seen after 8 h of incubation. The present results therefore corroborate the dependence of tyramine synthesis by E. durans IPLA 655 on pH. This could be related to stronger expression of the decarboxylase and antiporter genes and/or to greater activity of the decarboxylase enzyme.

Overall, the present results contribute to a better understanding of the factors affecting BA production by LAB. The final aim of this kind of study is to determine the conditions that help avoid the accumulation of these toxic compounds in foods. This work shows that tyramine production by E. durans IPLA 655 is favored by high concentrations of the amino acid substrate tyrosine and by acidic pH. Such conditions would be difficult to prevent in fermented foods. In fact, in most types of cheese, they are even desirable because proteolysis (with the consequent liberation of free amino acids) and acidification are very important factors in the quality of the final product. Therefore, minimizing tyramine accumulation by changing the production conditions would seem not to be the answer. Rather, the solution is to prevent the appearance of tyramine-producing bacteria. In this respect, the use of pasteurized milk acquires special importance (Ordoñez et al. 1997; Novella-Rodriguez et al. 2004).

References

Altschul SF, Madden TL, Schaffer AA, Zhang J, Zhang Z, Miller W, Lipman DJ (1997) Gapped BLAST and PSI-BLAST: a new generation of protein database search programs. Nucleic Acids Res 25:3389–3402

Bearson S, Bearson B, Foster JW (1997) Acid stress responses in enterobacteria. FEMS Microbiol Lett 147:173–180

Connil N, Plissoneau L, Onno B, Pilet MF, Prevost H, Dousset X (2002) Growth of Carnobacterium divergens V41 and production of biogenic amines and divercin V41 in sterile cold-smoked salmon extract at varying temperatures, NaCl levels, and glucose concentrations. J Food Prot 65:333–338

Coton E, Rollan GC, Lonvaud-Funel A (1998) Histidine decarboxylase of Leuconostoc oenos 9204: purification, kinetic properties, cloning and nucleotide sequence of the hdc gene. J Appl Microbiol 84:143–151

Cuesta P (1996) Desarrollo de un cultivo iniciador para el queso Afuega’l Pitu. Ph.D. thesis, University of Oviedo, Oviedo, Spain

Delgado S, Mayo B (2004) Phenotypic and genetic diversity of Lactococcus lactis and Enterococcus spp. strains isolated from Northern Spain starter-free farmhouse cheeses. Int J Food Microbiol 90:309–319

Edwards U, Rogall T, Blocker H, Emde M, Bottger EC (1989) Isolation and direct complete nucleotide determination of entire genes. Characterization of a gene coding for 16S ribosomal RNA. Nucleic Acids Res 17:7843–7853

Eitenmiller RR, Koehler PE, Reagan JO (1978) Tyramine in fermented sausages: factors affecting formation of tyrosine and tyrosine decarboxylase. J Food Sci 43:689–693

Fernández M, Linares DM, Alvarez MA (2004) Sequencing of the tyrosine decarboxylase cluster of Lactococcus lactis IPLA 655 and the development of a PCR method for detecting tyrosine decarboxylating lactic acid bacteria. J Food Prot 67:2521–2529

Fernández M, Flórez AB, Linares DM, Mayo B, Alvarez MA (2006) Early PCR detection of tyramine-producing bacteria during cheese production. J Dairy Res 73:1–4

Foulquie Moreno MR, Sarantinopoulos P, Tsakalidou E, De Vuyst L (2006) The role and application of enterococci in food and health. Int J Food Microbiol 106:1–24

Gale EF (1946) Bacterial amino acid decarboxylases. Adv Enzymol 6:1–32

Gardini F, Martuscelli M, Caruso MC, Galgano F, Crudele MA, Favatti F, Guerzoni ME, Suzzi G (2001) Effects of pH, temperature and NaCl concentration on the growth kinetics, proteolytic activity and biogenic amine production of Enterococcus faecalis. Int J Food Microbiol 64:105–117

Krause I, Bockhardt A, Neckemann H, Henle T, Klostermeyer H (1995) Simultaneous determination of amino acids and biogenic amines by reversed-phase high performance liquid chromatography of the dabsyl derivatives. J Chromatogr A 715:67–79

Landete JM, Ferrer S, Pardo I (2003) Regulación genica y enzimatica de la histidina descarboxilasa (HDC) de Lactobacillus hilgardii Congreso Nacional de Microbiologia (P 42), p 314

Le Jeune C, Lonvaud-Funel A, ten Brink B, Hofstra H, van der Vossen JM (1995) Development of a detection system for histidine decarboxylating lactic acid bacteria based on DNA probes, PCR and activity test. J Appl Bacteriol 78:316–326

Lin J, Smith MP, Chapin KC, Baik HS, Benett GN, Foster JW (1996) Mechanisms of acid resistance in enterohemorragic Escherichia coli. Appl Environ Microbiol 62:3094–3100

Marcobal A, Martin-Alvarez PJ, Moreno-Arribas MV, Muñoz R (2006) A multifactorial design for studying factors influencing growth and tyramine production of the lactic acid bacteria Lactobacillusbrevis CECT 4669 and Enterococcus faecium BIFI-58. Res Microbiol 157:417–424

Moreno-Arribas V, Lonvaud-Funel A (1999) Tyrosine decarboxylase activity of Lactobacillusbrevis IrOEB 9809 isolated from wine and L. brevis ATCC 367. FEMS Microbiol Lett 180:55–60

Novella-Rodríguez S, Veciana-Nogues MT, Izquierdo-Pulido M, Vidal-Carou MC (2003) Distribution of biogenic amines and polyamines in cheese. J Food Sci 68:750–755

Novella-Rodríguez S, Veciana-Nogues MT, Roig-Sagués AX, Trujillo-Mesa AJ, Vidal-Carou MC (2004) Evaluation of biogenic amines and microbial counts throughout the ripening of goat cheeses from pasteurized and raw milk. J Dairy Res 71:245–252

Ordoñez AI, Ibáñez FC, Torre P, Barcina Y (1997) Formation of biogenic amines in Idiazábal ewe’s-milk cheese: effect of ripening, pasteurization, and starter. J Food Prot 60:1371–1375

O’Sullivan E, Condon S (1999) Relationship between acid tolerance, cytoplasmic pH, and ATP and H+-ATPase levels in chemostat cultures of Lactococcus lactis. Appl Environ Microbiol 65:2287–2293

Poolman B, Driessen AJ, Konings WN (1987) Regulation of arginine-ornithine exchange and the arginine deiminase pathway in Streptococcus lactis. J Bacteriol 169:5597–5604

Psoni L, Kotzamanides C, Andrighetto C, Lombardi A, Tzanetakis N, Litopoulou-Tzanetaki E (2006) Genotypic and phenotypic heterogeneity in Enterococcus isolates from Batzos, a raw goat milk cheese. Int J Food Microbiol 119:109–120

Rollan GC, Coton E, Lonvaud-Funel A (1995) Histidine decarboxylase activity of Leuconostoc oenos 9204. Food Microbiol 12:455–461

Sanders JW, Leenhouts K, Burghoorn J, Brands JRl, Venema G, Kok J (1998) A chloride-inducible acid resistance mechanism in Lactococcus lactis and its regulation. Mol Microbiol 27:299–310

Santos-Buelga C, Peña-Egido MJ, Rivas-Gonzalo JC (1986) Changes in tyramine during Chorizo–sausages ripening. J Food Sci 51:518–527

Schelp E, Worley S, Monzingo AF, Ernst S, Robertus JD (2001) pH-induced structural changes regulate histidine decarboxylase activity in Lactobacillus 30a. J Mol Biol 306:727–732

Shalaby AR (1996) Significance of biogenic amines to food safety and human health. Food Res Int 29:675–690

Silla Santos MH (1996) Biogenic amines: their importance in foods. Int J Food Microbiol 29:213–231

Suzzi G, Gardini F (2003) Biogenic amines in dry fermented sausages: a review. Int J Food Microbiol 88:41–54

Acknowledgments

This research was funded by the Commission of the European Communities (QLK1-CT2002-02389). D. M. Linares was the recipient of a fellowship from the Spanish Ministry of Education and Science, and M. Fernández is a beneficiary of a I3P CSIC contract financed by the European Social Fund. We thank Adrian Burton for proofreading the English.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fernández, M., Linares, D.M., Rodríguez, A. et al. Factors affecting tyramine production in Enterococcus durans IPLA 655. Appl Microbiol Biotechnol 73, 1400–1406 (2007). https://doi.org/10.1007/s00253-006-0596-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0596-y