Abstract

Desulfitobacterium hafniense strain DCB2 generates electricity in microbial fuel cells (MFCs) when humic acids or the humate analog anthraquinone-2,6-disulfonate (AQDS) is added as an electron-carrying mediator. When utilizing formate as fuel, the Gram-positive, spore-forming bacterium generated up to 400 mW/m2 of cathode surface area in a single-chamber MFC with a platinum-containing air-fed cathode. Hydrogen, lactate, pyruvate, and ethanol supported electricity generation, but acetate, propionate, and butyrate did not. Scanning electron microscopy indicated that strain DCB2 colonized the surface of a current-generating anode but not of an unconnected electrode. The electricity was recovered fully within minutes after the exchange of the medium in the anode chamber and within a week after an exposure of a colonized anode to 90°C for 20 min. Of the six strains of Desulfitobacteria tested, all of which would reduce AQDS, only D. hafniense strain DCB2 continued to reduce AQDS and generate electricity for more than 24 h, indicating that reduction of the humate analog alone is insufficient to sustain electrode reduction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microorganisms can convert the chemical energy stored in organic compounds into electricity when incubated in microbial fuel cells (MFCs). Lovley recently published a comprehensive review of this subject (Lovley 2006). Potentially, bacteria in MFCs could be used to power microelectronic devices, produce electricity at remote locations, and generate electricity during the consumption of waste. The basic design of an MFC includes an anode connected to a cathode with a fixed external resistance placed in line. The anode is maintained in an anoxic environment while the cathode is exposed to an oxidizing agent such as ferricyanide or more commonly oxygen. One of the simplest designs is the placement of the anode into anaerobic sediment and connecting it to a cathode in the overlying oxygenated water (Reimers et al. 2001; Tender et al. 2002). Electrons released during biological consumption of reduced organic and inorganic compounds travel the wire while a current of protons migrates from the anode to the cathode via the sediment and water. In the absence of sediment, a polymer electrolyte or proton exchange membrane (PEM) is usually used to separate the anode from the cathode. PEMs have been used to construct dual and single-chamber MFCs; in the latter case, the PEM is often fused to a cathode bathed in air on one side. The power output of an MFC can be enhanced by the application of a catalyst to the cathode to facilitate the reduction of oxygen. Platinum is commonly used in this way (Liu and Logan 2004), but iron(II) phthalocyanine and cobalt tetramethoxyphenylporphyrin have recently been shown to work nearly as well (Cheng et al. 2006; Zhao et al. 2005) and are far less expensive. Regardless of the design of the MFC, anoxic conditions within the anode chamber favor electricity production by sustaining anaerobic growth and metabolism while avoiding microbial and abiotic consumption of the fuels coupled to oxygen reduction in the anode chamber.

The physical components of MFCs are critical to the optimization of electricity generation, but microbes are the catalysts of anode reduction and much of the microbial world remains to be examined in relation to electrode reduction. Escherichia coli, a research workhorse of microbiologists, will generate a current in an MFC when an artificial, soluble, electron-carrying mediator such as methylene blue or neutral red is present (Park and Zeikus 2000; Park and Zeikus 2003). The term mediatorless electrode reduction has been used to describe the generation of electricity by bacteria without the addition of an exogenous electron-carrying mediator to the fuel cell. Microorganisms capable of doing this include Shewanella putrefaciens (Kim et al. 2002), Geobacter metallireducens (Bond et al. 2002), Geobacter sulfurreducens (Bond and Lovley 2003), Rhodoferax ferrireducens (Chaudhuri and Lovley 2003), and some other Gram-negative bacteria that are known to reduce humates or Fe(III) (Holmes et al. 2004a–c). The mechanism behind mediatorless electrode reduction remains under study, but it is clear that endogenous mediators, which may include outer membrane proteins and pili in the case of G. sulfurreducens (Lovley 2006; Reguera et al. 2005), are required to complete the task of generating a current. Alternatively, production of soluble mediators by the bacteria themselves has been shown to support electricity generation in an MFC (Bond and Lovley 2005; Rabaey et al. 2004, 2005). For example, Pseudomonas aeruginosa strain KRP1 will produce phenazines and use them as electron-carrying shuttles for electrode reduction (Rabaey et al. 2005). These investigators also demonstrated that electricity is generated when pyocyanin, produced by the Gram-negative P. aeruginosa, is added to MFCs inoculated with Gram-negative Enterococcus faecium strain KRA3 or the Gram-positive, nonspore-forming Lactobacillus amylovorus strain LM1.

Overall, the aforementioned studies confirm the existence of a diverse group of bacteria capable of generating electricity, but most of the electricity-producing bacteria studied to date have been Gram-negative, nonspore-forming bacteria. An examination of the microbial community from an electricity-generating anode placed in marine sediment showed an increase in the number of 16S rRNA genes from Gram-positive bacteria cloned from the biofilm on a connected (current-generating) vs unconnected anode (Bond et al. 2002). We wished to determine if Gram-positive Desulfitobacterium spp. commonly found in aquatic sediments could be used to generate electricity when incubated in a fuel cell. The Desulfitobacteria are spore-forming, freshwater, rod-shaped bacteria and are members of the Firmicutes, as is Clostridium butyricum strain EG3, which is reported to generate electricity when incubated in a fuel cell (Park et al. 2001). They are metabolically versatile capable of using many different electron donors (e.g., short chain fatty acids and alcohols) and acceptors such as chlorinated compounds, nitrate, sulfuroxy anions, metals, and humates (Finneran et al. 2002). Furthermore, the Desulfitobacteria are spore-forming microorganisms capable of surviving exposure to extremes in temperature and desiccation, a feature that may prove useful in the optimization and application of MFCs. The goals of this study were to determine if the Desulfitobacteria could be used to generate electricity, if growth of the organisms would couple to electrode reduction, and if an exogenous electron-carrying mediator is necessary for the generation of a current.

Materials and methods

Culture conditions

Desulfitobacterium hafniense strain DCB2 (DSM 10664), D. hafniense strain PCP1 (ATCC 700357), D. hafniense strain DP7 (DSM 13498), Desulfitobacterium dehalogenans strain JW/DU1 (ATCC 51507), Desulfitobacterium chlororespirans strain Co23 (DSM 11544), and Desulfitobacterium sp. strain PCE1 (DSM 10344) were obtained from the Deutsche Sammlung von Mikroorganismen und Zelkulturen GmbH (DSMZ) or the American Type Culture Collection (ATCC) and maintained in a fresh water medium buffered to pH 6.8, DSMZ 720 as stated in the work of Milliken et al. (2004) with the following modifications. The medium contained 0.1% w/v yeast extract, 15 mM sodium formate, and 0.2 to 5 mM AQDS as potential carbon and energy sources. No other inorganic electron acceptors were added, and sodium thiosulfate, sodium sulfide, and resazurin were eliminated from the medium. All media prepared for tests in fuel cells were made without chemical reductants under strict anoxic conditions under N2:CO2 (80:20) that was passed over a palladium catalyst. Although Desulfitobacteria have not been reported to be grown in media lacking a chemical reductant, these bacteria were routinely grown in anaerobe tubes or in MFCs without the addition of a chemical reductant.

Construction of single- and dual-chamber fuel cells

Grade 10 graphite (Graphite Engineering and Sales, Greenville, MI, USA) was bathed consecutively for 24 h in 1 M HCl, distilled and deionized in H2O (ddH2O), 1 M NaOH, and once more with ddH2O to remove iron and other impurities (Bond and Lovley 2003). After multiple rinses with ddH2O, the graphite was dried and cut into 20×10×6 mm blocks. A conductive epoxy (Hosfelt Electronics, Steubenville, OH, USA) was used to fuse 18-gauge marine-grade wire (Anchor, Cotati, CA, USA) to the graphite, and finally the interface was sealed with Silicone II Sealant (GE Seals and Adhesives, Huntersville, NC, USA). The exposed surface area of the resulting block electrode was 6.7 cm2. The adhesives were allowed to cure for at least 48 h, and then the resistance of the electrode was confirmed to be less than 0.5 Ω. An 8-gauge needle (Big Daddy’s Tattoo and Supply, Oklahoma City, OK, USA) was used to make a temporary hole to feed the wire through a 20-mm diameter butyl stopper (Geo-Microbial Technologies, Ochelata, OK, USA).

Custom-built, 20-mm opening U-shaped tubes (Bellco, Vineland, NJ, USA) were used to make the two chambers of the fuel cell (Fig. 1). Two 18-ml anaerobe tubes (20 mm diameter, Bellco Glass) were cut, curled, and flanged so that they could be joined to make a U-shaped tube. The two chambers were separated with the PEM Nafion® 117 (The Fuel Cell Store, Boulder, CO, USA) and joined with a C-clamp, and the electrodes were positioned 1 cm from the PEM. A microspin bar (Fisher) was added to the anode chamber to circulate fuel and nutrients. A 21-gauge needle (B-D, Franklin Lake, NJ, USA) attached to Silastic® tubing (0.76 mm inner diameter; Dow, Midland, MI, USA) was used to deliver air to the cathode chamber, and a second needle covered with foil served as an exhaust vent. The completed assembly was wrapped in foil and autoclaved before placement for at least 12 h in an anaerobic Coy chamber (Grass Lake, MI, USA). The bacterial culture in 12 ml of medium (5.5 mg total cellular protein, 2.5×109 bacterial cells) and substrates were then added by syringe to the anode chamber of the fuel cell. All exchanges of the medium within the anode chamber were performed anaerobically under an atmosphere of N2:CO2 (80:20) by gently removing the medium by syringe and replacing it with new anoxic sterile medium. The cathode chamber was filled with the same medium as the anodic chamber without electron donor or acceptor. An aquarium pump (Aqua Culture, Bentonville, AR, USA) was used to supply air to the cathode chamber through an autoclaved, glass wool filter; the anode was connected to the cathode via 1 kΩ resistor, and the fuel cell was immediately connected to a multimeter.

A single-chamber MFC was constructed similarly but the block cathode and the liquid-containing cathode chamber were eliminated. The cathode was made of carbon cloth loaded with 0.5 mg Pt/cm2 using 10% Pt on Vulcan XC-72 (De Nora, Somerset, NJ, USA) and was clamped adjacent to the PEM with a 20-mm ID flange (Kimble-Kontes part 671750-0015) shortened to 1 cm. An alligator clip was used to connect the resistor to the cathode cloth (Fig. 1c).

Monitoring formate and electron recovery

Formate measurements were made with a Dionex Ion Chromatograph DX120 (IC) equipped with an IonPak® AG11-HC guard column (4×50 mm), an IonPak® AS11-HC (4×250 mm) anion separation column, and a sensor with self-regenerating suppressor and a Regent Free™ RF-30 Ion Gradient Controller with EluGen™ producing eluent KOH concentration at 30 mM. Six consecutive shots were made on the IC, and the formate concentration was determined within the linear response range for sodium formate standards externally applied to the IC. The electron recovery (coulombic efficiency, Ec) was based on changes in formate consumption and current across 1 kΩ over time, where Ec = coulombs of current divided by coulombs available based on measured formate consumption. Conversions to coulombs were based on 1C=1A×1s, 1C=6.24×1018 electrons, 1 mol=6.02×1023 electrons and therefore 96,500 C/mol.

Monitoring electricity

Voltage measurements were made with MAS-344 digital multimeters manufactured by MASTECH (Multimeter Warehouse, Walnut, CA, USA), which were connected to Dell GX270 computers via a serial cable, and data were logged with DMM View Version 2.0 software. Continuous 30-min interval voltage measurements across a 1-kΩ resistor were taken throughout the experiments, unless noted otherwise, and Ohm’s law reveals that the readings in voltage are equivalent to milliampere (mA) across 1 kΩ. A decade box (Yokogawa Electric Works, Tokyo, Japan) was used to alter the resistance (100, 500, 1,000, 2,000, 4,000, 8,000, 16,000, 32,000, and 64,000 Ω) during discharge curve experiments to collect voltage–current and voltage–power data. Data were collected after 5 min of operation at each resistance. Current (I) was calculated as I(mA)=V(mV)/R(Ω), where V is the voltage and R is the external resistance. Power (P) in milliWatts (mW) was calculated as P(mW)=I 2(mA)R(Ω). Current and power densities were calculated by dividing by the surface area of the electrode.

For both dual- and single-chamber fuel-cell designs, current was not detected (limit of 0.001 mA) when the fuel cells were operated with uninoculated DSMZ 720 medium plus formate, or with E. coli in Luria-broth-glucose medium without an added mediator. A background current of 0.003 mA, which dissipated to 0.001 mA within 24 h, was observed with uninoculated DSMZ media plus 0.1% w/v yeast extract and 5 mM AQDS. All experiments with each strain were performed at least twice and demonstrated similar results, although only one set of data may be shown in this study.

Measurement of protein

To extract the protein from anode surfaces, the electrodes were gently submerged in sterile medium to remove protein from planktonic cells and were then placed in 1 ml of 1 M NaOH in a 10-ml serum vial, which was agitated for 1 h. Planktonic biomass (medium from the anode chambers) was mixed 1:1 (vol:vol) in 1 M NaOH. All samples were analyzed with the BioRad DC protein assay (BioRad, New York) to determine total protein; bovine serum albumin from BioRad was used as a standard.

Scanning electron microscopy

Anodes were removed from the dual-chamber MFCs, and the wires were cut from the graphite electrodes. The anodes (samples) were submerged in sterile anoxic medium and then immersed in sterile buffer containing 2% glutaraldehyde (with carbohydrazide copolymerization) for 30 min, followed by a postfix in 2% osmium tetraoxide for 30 min. The samples were then rinsed in ddH2O and dehydrated by a graded ethanol series to 100%. The ethanol was removed, and the sample was immersed in hexamethyldisilazane for 5 min. Hexamethyldisilazane was replaced, and the sample was then allowed to dry to completeness overnight. The samples were mounted with contact adhesive onto aluminum specimen studs and sputter-coated with gold–palladium (20 nm coating) using a Polaron SC7640 Sputter Coater. Observation was done with a JEOL JSM-5410 scanning electron microscope (SEM). The SEM was operated at 5 kV, and images were captured digitally.

Results

Humates as an electron-carrying mediator for electrode reduction by D. hafniense strain DCB2

An electric current from a dual-chamber fuel cell inoculated with D. hafniense strain DCB2 (1.5×109 cells) steadily increased over more than 2 days when the bacteria were supplied with humic acids and sodium formate (Fig. 2a). Electricity was also generated when using a lesser concentration of cells (1.5×108 cell total or approximately 1.0×107 cells/ml), but the lag preceding development of the current was extended by several days, and no significant current was observed when initial cell numbers were below 1.0×107 cells (data not shown). A second fuel cell inoculated with strain DCB2 and not supplied with humic acids generated current equal to that produced abiotically by the medium (0.001 mA), but the addition of 0.2 mM of the humate analog AQDS to this fuel cell resulted in a rapid increase in current (Fig. 2a). These results indicate that humates can serve as a mediator of electrode reduction by this Gram-positive bacterium.

Electric current from dual-chamber fuel cells inoculated with D. hafniense strain DCB2. a Humate required for significant electricity generation by D. hafniense strain DCB2. Three MFCs were initiated with cultures grown 4 days with 15 mM sodium formate and 15 mM sodium pyruvate. In one of the MFCs, the bacterial culture was supplied with 2 mg/ml of Aldrich humic acids (thin black line) 2 h after the initialization of the fuel cell. A 0.2-mM AQDS was amended to a similar fuel cell (thick black line), and another MFC was given no additive, labeled NA (thick gray line). b Sustainable and immediate electricity in an MFC inoculated with D. hafniense strain DCB2. Experiment was initiated with bacterial cultures first grown 4 days with 0.1% yeast extract, 15 mM sodium formate, and 0.2 mM AQDS, and exchanges (indicated by circles near x-axis) of medium include 0.2 mM AQDS, not yeast extract. Formate (F) was amended as the electron donor where specified by the black arrow. c The dependence on formate as the fuel. The experiment was initiated with bacterial cultures first grown 4 days with 0.1% yeast extract, 15 mM sodium formate, and 0.2 mM AQDS, and exchanges (indicated by circle near x-axis) of medium include 0.2 mM AQDS, not yeast extract. Formate (F) was amended as the electron donor where specified by the arrows. d Pasteurization of D. hafniense strain DCB2, a spore-forming Gram-positive bacterium. The experiment was initiated with bacterial cultures first grown 4 days with 0.1% yeast extract, 15 mM sodium formate, and 0.2 mM AQDS, and exchanges of medium (indicated by circles near x-axis) include AQDS, not yeast extract, unless specified. Formate (F) or 0.1% yeast extract (Y) was amended as the electron donor where specified by the arrows. The MFC was exposed to an extreme temperature event (90°C for 20 min)

Figure 2b presents data from a dual-chamber MFC inoculated with strain DCB2 pregrown with formate and AQDS. A current was immediately registered due to the reduced AQDS in the culture transferred to the MFC. This briefly dissipated until a stable current of more than 0.10 mA was generated. D. hafniense strain DCB2 did not grow in conventional anaerobe tubes, unless the medium initially included 0.1% yeast extract, nor could a robust sustained current be established in a fuel cell without yeast extract being added at the start, but a current was maintained after repeated exchanges of the media without yeast extract beginning on day 2 (Fig. 2b). The current rebounded to approximately 0.11 mA within a few minutes after each exchange of the medium. The regular exchange of the medium included 0.2 mM AQDS, and 20 mM sodium formate and current maintained this level for more than 2 weeks. Replicate experiments gave similar results. This confirmed that the biocatalyst was not lost with the replacement of the medium. These results also demonstrated that the yeast extract was not serving as the electron donor. The dependence on formate as the fuel is demonstrated in Fig. 2c, where after a current had been established in a fuel cell with strain DCB2, the medium was exchanged without formate and the current was allowed to dissipate to near zero. Current immediately was reestablished upon the readdition of formate. In this one example, an electron recovery of 67% was calculated from the time of formate addition until current had again dissipated to background and the formate had been depleted. This experiment was performed three times, and the average electron recovery was 67±4%. D. hafniense uses H2:CO2, lactate, pyruvate, and ethanol, but not acetate, proprionate, and butyrate, as carbon and energy sources for growth when grown with other electron acceptors in a conventional culture vessel (Niggemyer et al. 2001). In MFCs, the pattern of fuel (substrate) usage mirrored the reported substrate utilization during conventional growth of the organism. The ability of D. hafniense strain DCB2, a spore-forming bacterium, to recover and generate electricity after exposure to an extreme temperature event (90°C for 20 min) is demonstrated in Fig. 2d; replicate experiments gave similar results. Similar to initiating a new fuel cell or simply growing the bacterium under conventional conditions, yeast extract had to be added to recover electricity generation after exposure to heat.

Examination of the graphite anodes by SEM revealed a heavily colonized biofilm of strain DCB2 on the surface of current-generating anodes across a 1-kΩ resistor, whereas bacterial cells were difficult to find on the surface of noncurrent-generating (open circuit) anodes (Fig. 3). The graphite blocks had a very rough surface with many crevices, and strain DCB2 tended to colonize such areas. The examination of the electrodes was made after several exchanges of the medium without yeast extract which avoided fermentative growth of the bacterial cells on or away from the electrodes and selected for cells that would grow by respiration with the reduction of AQDS and the electrode. Visual observation of the anode chamber medium clearly indicated that the amount of planktonic cells (turbidity) decreased once yeast extract was eliminated from the medium and protein concentration decreased from 1.27 to 0.01 mg/ml. The total protein extracted from a current-generating anode was 0.29 vs 0.003 mg from an uninoculated graphite block electrode.

Scanning electron micrographs of D. hafniense strain DCB2. Images were taken from the surface of the graphite anode from a two-chamber microbial fuel cell (MFC) that was current-generating (a, b) and unconnected (c, d). The two graphite electrodes were connected via a 1-kΩ resistor in dual-chamber MFC. The MFCs were periodically exchanged and fueled with formate for 15 days before preparing the anode for SEM viewing; replicate experiments gave similar results

Generation of electricity in a single-chamber fuel cell with an air-fed, Pt–carbon cloth cathode

A single-chamber fuel cell was prepared as described in the “Materials and methods” (Fig. 1c). The intent of this design was to optimize current generation by increasing the available oxygen to the cathode and by enhancing the catalysis of oxygen reduction with platinum. The concentration of AQDS added to the fuel cell was tested in several single-chamber MFCs with D. hafniense strain DCB2, and current was sustained with 0.2 to 10 mM AQDS with 1 mM or more supporting the highest levels of current and no apparent inhibition at the highest concentrations (data not shown). After the initial oxidation of reduced AQDS from the culture medium transferred to the MFC, the current slowly increased to more than 0.25 mA over 3 days when strain DCB2 was incubated in the single-chamber fuel cell with 0.1% yeast extract, 15 mM sodium formate, and 0.45 mM AQDS (Fig. 4a). After 3 days, the medium was exchanged, and 15 mM sodium formate plus 5 mM AQDS were added (no yeast extract). Furthermore, the medium was exchanged in the same manner twice more. A current over 0.3 mA was maintained and was quickly recovered after the exchanges of the medium similar to what was observed with the dual-chamber system.

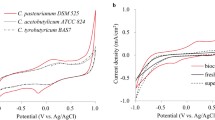

a Electricity in a single-chamber MFC inoculated with D. hafniense strain DCB2. The experiment was initiated with bacterial cultures first grown 4 days with 0.1% yeast extract, 15 mM sodium formate, and 0.45 mM AQDS, and exchanges (indicated by circles near x-axis) of medium include 5 mM AQDS, not yeast extract. Formate (F) was amended as the electron donor where specified by the black arrow. b Voltage (squares) and power density (circles) vs current density produced by D. hafniense strain DCB2 with formate in single-chamber MFC with an air-fed carbon cloth cathode (white) or two-chamber MFC with graphite block electrodes (black). Resistance was set at 100, 500, 1,000, 2,000, 4,000, 8,000, 16,000, 32,000, or 64,000 Ω for 5 min before a voltage reading was taken

Voltage and current data over a range of resistance settings were collected with the single-chamber fuel cell inoculated with strain DCB2 (Fig. 4b). The current density at the lowest resistance tested (100 Ω) in the single-chamber fuel cell exceeded 1,100 mA/m2 of anode surface, and the power density was greater than 180 mW/m2 when resistance was set between 0.5 and 1 kΩ. These values for current and power were four- to sixfold greater, respectively, than that achieved with the dual-chamber cell lacking platinum. The single-chamber cell contained a graphite block anode with 6.7 cm2 surface area and a platinum-coated graphite cloth cathode with a surface area of 1.8 cm2. Repeating the experiment with a smaller block graphite anode with a surface area equal to that of the cathode (1.8 cm2) resulted in a power density of 400 mW/m2 (14 mW/m3 of culture volume) with a resistance of 1 kΩ, which was more than tenfold greater than the value obtained with the dual-chamber fuel cell equipped with electrodes of equal surface area. The single-chamber fuel cells were routinely operated with 12 ml of culture volume (bacterial media and electrode), but the same current level was achieved when the culture volume was reduced to 3 ml (enough to submerge the anode). The power density to this culture volume was 56 W/m3. Electron recovery from formate oxidation by strain DCB2 in the single-chamber MFC averaged 85±4% (n=3).

Generation of electricity by other Desulfitobacterium spp.

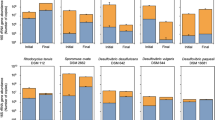

Six Desulfitobacterium spp., including strain DCB2, were initially grown by sequential transfer in media with 1 mM AQDS, 0.1% yeast extract, and 15 mM formate. Each strain reduced AQDS (based on the development of bright orange color in the culture tube) and grew to similar levels under such conditions. After three sequential transfers in such media, the cultures were placed in single-chamber fuel cells with air-fed cathodes (surface area of electrodes: graphite block anode, 6.7 cm2; and Pt–carbon cloth cathode, 1.8 cm2). A current was immediately observed with each strain due to the oxidation of the reduced AQDS on the anode, but thereafter, the current from each strain steadily dropped over the course of several hours (Fig. 5). Four of the strains managed to partially and temporarily regenerate a current; D. hafniense strain DP7 was the only strain not to continue to reduce AQDS and generate current in the MFC, and D. hafniense strain DCB2 was the only strain to fully recover and sustain a current for more than a day. Chemically reducible AQDS (through the addition of dithionite) was recoverable from the medium from each fuel cell at the end of the experiment, indicating that degradation or adsorption (to the graphite) of AQDS was not responsible for the loss of current with any of the strains. Formate analysis in this experiment revealed that none of the strains had consumed all of the fuel (>10 mM remained in each), confirming the mechanism for electrode reduction was not present in the other strains. Transfer of bacteria from the fuel cells to new AQDS-supplemented medium in anaerobe tubes showed that each strain, except strain DP7, would still reduce AQDS and grow. Microscopic analysis of the bacterial cells from the MFCs showed robust-looking vegetative cells of each strain except for DP7.

Electric current from a single-chamber fuel cell inoculated with different Desulfitobacterial strains grown with 1 mM AQDS. MFCs were initiated with cultures grown 4 days with 15 mM sodium formate as electron donor and 1 mM AQDS as the electron acceptor. Desulfitobacterium hafniense strain PCP1 (x-shape symbols), D. hafniense strain PCE1 (diamonds), D. hafniense strain DP7 (thin line, no symbol), Desulfitobacterium dehalogenans strain JW/DU1 (squares), D. chlororespirans strain Co23 (dashed line, no symbol), and D. hafniense strain DCB2 (thick black line, no symbol) were grown in culture tubes with 1 mM AQDS as the electron acceptor

Discussions

Electricity generation by MFCs depends on the fuel-cell design and materials, the microorganisms, the fuels, and the mechanism of electron transfer, which make direct comparisons of results from different systems difficult. However, to date, the highest power densities generated with MFCs operated with oxygen as the final electron acceptor are 51 W/m3 fuel-cell volume (1,540 mW/m2 cathode surface) by an undefined bacterial community from wastewater while consuming glucose (15.5 W/m3 and 464 mW/m2 with wastewater alone) (Cheng et al. 2006) and 60 W/m3 (355 mW/m2) by the Gram-negative G. sulfurreducens while consuming acetate with no added electron-carrying mediator (Lovley 2006). These studies were done with continuous flow fuel cells. No Gram-positive bacterium in pure culture in a fuel cell with oxygen as the cathode oxidant has been shown to generate electricity at these levels. The Gram-positive, spore-forming, D. hafniense strain DCB2 generated power densities up to 56 W/m3 (400 mW/m2) when formate was supplied as a fuel in a batch-fed fuel cell, indicating that such an organism can be used to achieve electrical power similar to that generated by Gram-negative bacteria or mixed microbial communities. However, a quinone or humate, anthropogenic or naturally available, must be supplied to the organism for this to occur, making it clear that the mechanism of electrode reduction by these Gram-positive bacteria requires a soluble exogenous mediator.

Pili of G. sulfurreducens, a Gram-negative electrode-reducing bacterium, have been shown to be electrically conductive (Reguera et al. 2005), and the outer membrane proteins of this organism may be required for the reduction of electrodes (Lovley 2006). The potential for the pili from Gram-positive spore-forming bacteria to be conductive has not been investigated, and all Gram-positive bacteria lack an outer membrane. A deficiency of outer membrane proteins in Gram-positive bacteria suggests that they would not reduce an electrode in the absence of a soluble electron-carrying mediator, and indeed the Desulfitobacteria tested do not. However, C. butyricum strain EG3, a Gram-positive spore-forming bacterium capable of reducing soluble Fe(III), has been reported to be electrically active without the addition of a soluble mediator (Park et al. 2001). Apparently, this activity in a Gram-positive microorganism is rare since, in addition to the results presented in this study on Desulfitobacterium spp., Park et al. reported that four other strains of C. butyricum and a strain of Clostridium acetobutylicum were not electrically active. The mechanism of electron-mediated or mediatorless electrode reduction by Gram-positive spore formers remains unexplained.

Humic acids support the generation of electricity by D. hafniense strain DCB2, but the specific mediator in this complex mixture of organic aromatic polymers and inorganic minerals was not identified. AQDS is used in experiments as an analog of quinone compounds commonly found in humic acids. It is soluble in water, is readily reduced by humate-reducing bacteria, and is generally not toxic to such bacteria. The highest current and power densities were observed with strain DCB2 when AQDS was added to the fuel-cell medium. Therefore, a nontoxic quinone, potentially available from humates, can serve as an electron-carrying mediator for electrode reduction by these bacteria. However, the ability to reduce the mediator is not enough to sustain a current in a fuel cell. When several strains of Desulfitobacterium were tested, only D. hafniense strain DCB2 sustained the generation of electricity at all concentrations of AQDS tested (0.2 to 5 mM). This is not due to an inability to reduce or grow with AQDS because all six strains tested could be sequentially transferred (5×) in media with AQDS added as the sole electron acceptor. The presence of reduced AQDS was apparent due to the development of a bright orange color and the immediate generation of current when the strains were transferred to the fuel cells. Although bacterial cell numbers in addition to AQDS concentration may enable some strains to generate electricity for a longer period of time, the inability of several of the strains to maintain the reduction of AQDS, and thereby the generation of current, suggests that they lack a critical factor possessed by D. hafniense strain DCB2.

Yeast extract is reported as a component of the medium used to grow Desulfitobacteria (Cervantes et al. 2002; Niggemyer et al. 2001), and none of the strains tested would grow without the addition of 0.1% w/v yeast extract to the medium. Generation of electricity with D. hafniense strain DCB2 and AQDS in a fuel cell could not be established unless yeast extract at 0.1% w/v was added at the time of fuel-cell inoculation, but once biomass was established on the electrode and a current was sustained, the medium could be repeatedly exchanged (5× and more) without the addition of yeast extract and current would be maintained. Hence, yeast extract did not serve as the fuel source. The addition of yeast extract to an MFC did not enable any Desulfitobacterium strain other than DCB2 to sustain the reduction of AQDS and the electrode for more than a day. Additional supply of yeast extract to fuel cells with the nonelectricity-producing Desulfitobacterium strains did result in a temporary reduction of AQDS and a low current, but this current always returned to zero shortly thereafter. If the yeast extract is supplying a needed factor for the maintenance of a particular physiological state required for AQDS and electrode reduction, then it must be consumed, transformed, or abiotically lost in the case of all the strains, except DCB2 or strain DCB2 uses it differently. Whatever this factor(s) may be, it would likely influence the selection of a Gram-positive humate-reducing bacterium when fuel-cell electrodes are employed in situ, e.g., in anoxic sediments.

The ability to establish a biofilm on the surface of a graphite electrode is a commonly reported feature of direct electrode-reducing bacteria (Bond and Lovley 2003; Chaudhuri and Lovley 2003), but if a microorganism can grow by the reduction of an exogenous mediator and that mediator is reoxidized by the electrode, then growth on the anode would be enhanced. Once yeast extract was eliminated from the fuel-cell medium, the amount of planktonic cells of strain DCB2 decreased dramatically while the amount of biomass on the surface of the anode increased in relation to that on an unconnected (noncurrent-generating) anode. The microscopic visualization of heavy growth on the anode confirmed that strain DCB2 colonizes the electrode surface, and the increase of biomass on the electrode with current generation indicates a coupling of growth through reduction of the soluble mediator and electrode. The selection for growth on the electrode vs planktonic growth may be expected because the concentration of oxidized electron acceptor, AQDS, would be highest at the surface of the electrode where it is regenerated. Similarly, planktonic growth of strain DCB2 decreased when H2, ethanol, and lactate were used as fuels, but planktonic growth increased when pyruvate was the fuel even though electricity was generated. D. hafniense strain DCB2 can grow fermentatively with pyruvate (Niggemyer et al. 2001), thus, the selection for growth at the electrode was probably diminished when pyruvate was the supplied fuel. These findings suggest that in a natural environment such as sediment, the growth of strain DCB2 or a similar Gram-positive bacterium on an anode would be influenced by the presence of a naturally available mediator (abiotic or biotic) and the type of electron donor.

Our data demonstrate that electricity can be generated with the freshwater, spore-forming, Gram-positive D. hafniense strain DCB2, and it is clear that the bacterium requires an exogenous electron-carrying mediator to establish a current-generating biofilm on a graphite anode. AQDS or humates can be used as the mediator, indicating that such an organism could use a natural and abundant supply of quinones commonly found in soils and sediment to mediate electrode reduction. Alternatively, AQDS can be added directly to a graphite anode to enhance power generation, as demonstrated recently by Lowy et al. (2006) who observed a fivefold increase in power when AQDS-doped graphite anodes were used in sediment fuel cells. The data in this study indicate that not all Gram-positive spore-forming bacteria that are capable of reducing AQDS or humates will be able to support sustained generation of electricity. Other properties of humate-reducing bacteria must first be identified and understood in relation to electrode reduction before this type of bacterium and metabolism is most efficiently and effectively used in a fuel cell. Additionally, other Gram-positive bacteria may be capable of using other naturally abundant mediators, artificially and biologically produced, to effectively generate electricity. Many exciting advances in the understanding of electrode-reducing bacteria have been made, but the physiological, biochemical, and genetic diversity of the microbes that can be applied to MFC technology remains vast and largely untapped. D. hafniense strain DCB2, and perhaps similar Gram-positive spore-forming bacteria, represent one important fraction of the microbial world that can catalyze the generation of electricity through the reduction of natural electron-carrying mediators.

References

Bond DR, Lovley DR (2003) Electricity production by Geobacter sulfurreducens attached to electrodes. Appl Environ Microbiol 69:1548–1555

Bond DR, Lovley DR (2005) Evidence for involvement of an electron shuttle in electricity generation by Geothrix fermentans. Appl Environ Microbiol 71:2186–2189

Bond DR et al (2002) Electrode-reducing microorganisms that harvest energy from marine sediments. Science 295:483–485

Cervantes FJ et al (2002) Reduction of humic substances by halorespiring, sulphate-reducing and methanogenic microorganisms. Environ Microbiol 4:51–57

Chaudhuri SK, Lovley DR (2003) Electricity generation by direct oxidation of glucose in mediatorless microbial fuel cells. Nat Biotechnol 21:1229–1232

Cheng S et al (2006) Power densities using different cathode catalysts (Pt and CoTMPP) and polymer binders (Nafion and PTFE) in single chamber microbial fuel cells. Environ Sci Technol 40:364–369

Finneran KT et al (2002) Desulfitobacterium metallireducens sp. nov., an anaerobic bacterium that couples growth to the reduction of metals and humic acids as well as chlorinated compounds. Int J Syst Evol Microbiol 52:1929–1935

Holmes DE et al (2004a) Electron transfer by Desulfobulbus propionicus to Fe(III) and graphite electrodes. Appl Environ Microbiol 70:1234–1237

Holmes DE et al (2004b) Microbial communities associated with electrodes harvesting electricity from a variety of aquatic sediments. Microb Ecol 48:178–190

Holmes DE et al (2004c) Potential role of a novel psychrotolerant member of the family Geobacteraceae, Geopsychrobacter electrodiphilus gen. nov., sp. nov., in electricity production by a marine sediment fuel cell. Appl Environ Microbiol 70:6023–6030

Kim HJ, Park HS, Hyun MS, Chang IS, Kim M, Kim BH (2002) A mediator-less microbial fuel cell using a metal reducing bacterium Shewanella putrefaciens. Enzyme Microb Technol 30:145–152

Liu H, Logan BE (2004) Electricity generation using an air-cathode single chamber microbial fuel cell in the presence and absence of a proton exchange membrane. Environ Sci Technol 38:4040–4046

Lovley DR (2006) Bug juice: harvesting electricity with microorganisms. Nat Rev Microbiol 4:497–508

Lowy DA et al (2006) Harvesting energy from the marine sediment-water interface II. Biosens Bioelectron 21:2058–2063

Milliken CE, Meier GP, Watts JEM, Sowers KR, May HD (2004) Microbial anaerobic demethylation and dechlorination of chlorinated hydroquinone metabolites synthesized by basidiomycete fungi. Appl Environ Microbiol 70:385–392

Niggemyer A et al (2001) Isolation and characterization of a novel As(V)-reducing bacterium: implications for arsenic mobilization and the genus Desulfitobacterium. Appl Environ Microbiol 67:5568–5580

Park DH, Zeikus JG (2000) Electricity generation in microbial fuel cells using neutral red as an electronophore. Appl Environ Microbiol 66:1292–1297

Park DH, Zeikus JG (2003) Improved fuel cell and electrode designs for producing electricity from microbial degradation. Biotechnol Bioeng 81:348–355

Park HS, Kim BH, Kim HS, Kim HJ, Kim GT, Kim M, Chang IS, Park YK, Chang HI (2001) A novel electrochemically active and Fe(III)-reducing bacterium phylogenetically related to Clostridium butyricum isolated from a microbial fuel cell. Anaerobe 7:297–306

Rabaey K, Boon N, Siciliano SD, Verhaege M, Verstraete W (2004) Biofuel cells select for microbial consortia that self-mediate electron transfer. Appl Environ Microbiol 70:5372–5382

Rabaey K, Boon N, Höfte M, Verstraete W (2005) Microbial phenazine production enhances electron transfer in biofuel cells. Environ Sci Technol 39:3401–3408

Reguera G et al (2005) Extracellular electron transfer via microbial nanowires. Nature 435:1098–1101

Reimers CE et al (2001) Harvesting energy from the marine sediment-water interface. Environ Sci Technol 35:192–195

Tender LM et al (2002) Harnessing microbially generated power on the seafloor. Nat Biotechnol 20:821–825

Zhao F et al (2005) Application of pyrolysed iron(II) phthalocyanine and CoTMPP based oxygen reduction catalysts as cathode materials in microbial fuel cells. Electrochem Commun 7:1405–1410

Acknowledgments

This research was supported with funds from the National Institutes of Environmental Health Sciences (grant ES012815-01) and National Aeronautics and Space Administration (grant 897-7557-223-2094553/01-0). The authors would like to thank Tom Shaak (United States Air Force) for the assistance in the monitoring of the fuel cells, Carol Moskos (MUSC) for the assistance and instruction on the operation of the SEM, and Steve Creager (Clemson University) for the technical advice on fuel cells.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Milliken, C.E., May, H.D. Sustained generation of electricity by the spore-forming, Gram-positive, Desulfitobacterium hafniense strain DCB2. Appl Microbiol Biotechnol 73, 1180–1189 (2007). https://doi.org/10.1007/s00253-006-0564-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0564-6