Abstract

The aim of this mini-review is to synthesize and analyze information on how the process of granulation is affected by environmental and operational conditions in the reactor. The factors reviewed are temperature, pH, alkalinity, organic loading rate, upflow velocity, nature and strength of substrate, nutrients, multivalent cations and heavy metals, microbial ecology of seed sludge, exo-cellular polymer, and addition of natural and synthetic polymers. Careful temperature control and adequate alkalinity is required for generation and maintenance of granules. Nature and strength of substrate in conjunction with intra-granular diffusion to a large extent determines the microstructure of the granules. The divalent cations such as calcium and iron may enhance granulation by ionic bridging and linking exo-cellular polymers. However, their presence in excess may lead to cementation due to precipitation leading to increased ash content and mass transfer limitation. The addition of external additives such as ionic polymers may enhance granulation in the upflow anaerobic sludge blanket reactors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

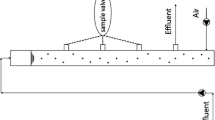

The upflow anaerobic sludge blanket (UASB) reactor introduced by Lettinga et al. (1980) has become a popular high-rate anaerobic treatment system throughout the world (Lettinga et al. 1993; Yu et al. 2001a). A high concentration of active anaerobic biomass is held in suspension in the reactor by hydraulic design and formation of granular biomass (Dolfing 1986; MacLeod et al. 1990). The anaerobic degradation in the sludge bed is a multi-step process consisting of hydrolysis of complex organic substrates such as proteins, fat, and carbohydrates into soluble amino acids, lipids, and sugars followed by the fermentation to acetate, formate, hydrogen, and carbon dioxide which are finally utilized by methenogenic bacteria to form methane (Gujer and Zehnder 1983). The upward motion of methane and carbon dioxide gas bubbles imparts mixing in the sludge bed. At the top of the reactor, the water phase is separated from sludge solids and gas in a three-phase separator known as the gas–liquid–solids separator.

The UASB process is attractive because of its compactness, low operational cost, low sludge production, and production of methane. More than 1,000 UASB units are currently being operated all over the world. The application of UASB reactors for the treatment of high-strength industrial wastewater containing easily hydrolyzed substrates such as sugar industry wastes, distillery wastes, and brewery wastes had been successful (Blonskaja et al. 2003; Fang et al. 1995; Guiot et al. 1991; Lettinga and Hulshoff Pol 1991). On the other hand, performances of UASB reactors treating difficult-to-hydrolyze and complex substrates such as phenols, effluents from food and milk processing plants, gelatine manufacturing plants, and animal slaughterhouses were less than satisfactory (Borja et al. 1996; Fang et al. 1996; Petruy and Lettinga 1997). UASB process for the treatment of domestic wastewater (low strength) also suffers from a number of shortcomings, such as long start-up time, poor gas production, susceptibility to shock loading, inability to form self-immobilized bacterial granules, and necessity for post-treatment of the effluent (Haandel and Lettinga 1994; Mergaert et al. 1992).

In the absence of a support medium in UASB reactors, different syntrophic groups closely associate to form roughly spherically shaped clusters known as granules (Dolfing 1986; Lettinga and Hulshoff Pol 1991). Granules may range from 0.1 to 5 mm in size and are differentiated from flocculated sludge by higher shear strength (Schmidt and Ahring 1996; Show et al. 2004). It is believed to be the most critical parameter affecting successful operation of a UASB reactor because granulated sludge has better settling property allowing higher hydraulic loading rate, granules reduce inter-species mass transfer limitation between syntrophic groups; granules can withstand high gas and liquid shear stress without disintegrating; and granules provide increased resistance to process shocks and toxins compared to dispersed microorganisms (Lettinga and Hulshoff Pol 1991; Schmidt and Ahring 1996; Show et al. 2004).

A granule can be functionally described as concentric layers of near-spherical biofilm possessing different bacterial trophic groups (Guiot et al. 1992; MacLeod et al. 1990). Each of the trophic groups of bacteria performs their respective role in the degradation of wastewater, producing biomass and exo-cellular polymers (ECPs) in their vicinity, which help other trophic groups to attach and derive nutrition. However, in reality, such layers may or may not exist within a granule although a few literatures have indicated existence of such segregated layers of microbial populations inside a granule (Guiot et al. 1992; Sekiguchi et al. 1999). The formation of layers will be discussed for specific cases in a later section.

The granulation process is commonly believed to be sensitive to the sudden change of environmental and operational conditions (Speece 1983). Factors governing granulation have been extensively studied on a variety of wastewaters. Some of these factors are operating conditions (Ahn et al. 2002; Kalyuzhnyi et al. 1996; Shayegan et al. 2005), pH and alkalinity (Gonzalez et al. 1998; Singh et al. 1999), temperature (Lau and Fang 1997; Singh and Viraraghavan 2003), strength and composition of wastewater (Erguder et al. 2003; Fang et al. 1994, 1996; MacLeod et al. 1990), reactor hydrodynamics (Kosaric et al. 1990; Singh and Viraraghavan 2003), presence of metal ions and trace metals (Lin and Chen 1999; Shen et al. 1993; Yu et al. 2000, 2001b), presence of polymers (Kalogo et al. 2001; Show et al. 2004; Tiwari et al. 2005), microbial ecology (El-Mamouni et al. 1997; Verrier et al. 1988), and production of exo-cellular polymeric substances by anaerobic bacteria (Jia et al. 1996; Morgan et al. 1990). A number of reviews are available on functioning of UASB reactor (Lin and Yang 1991; Mahmoud et al. 2003), its applicability to sewage treatment (Mergaert et al. 1992; Seghezzo et al. 1998), treatment of some of the toxic wastes (Veeresh et al. 2005), nutrient requirements for UASB process (Singh et al. 1999), and mechanism of granulation (Hulshoff Pol et al. 2004; Liu et al. 2003; Schmidt and Ahring 1996).

There has been constant effort for the last 20 years to enhance granulation in the UASB reactors. Optimization of granule size and density are crucial. As the size increases, diffusion becomes more rate limiting (Schmidt and Ahring 1996). Dense granules have better settling property but cause mass transfer limitations. Sparse granules, on the other hand, lose intermediates to convection and have a low settling velocity (Lettinga and Hulshoff Pol 1991). The primary purpose of this review is to synthesize and take a critical look at the effect of different environmental factors on enhancement of granulation.

Factors governing the granulation process

Temperature

Operational temperature apparently affects the methanogens more than the acidogens (Chou et al. 2004). The optimum temperature range for digestion in mesophilic reactors is 30–40 °C (Henze and Harremoes 1983). For thermophilic methanogens, the optimum growth temperatures are Methanosarcina sp. 55–58 °C, Methanosaeta sp. ∼70 °C, Methanobacterium sp. 65–70 °C, and acetate-utilizing mixed culture 60–65 °C (Zinder 1990; Zinder et al. 1984).

It is generally believed that the degradation efficiency and the killing of pathogens become more effective at elevated temperature (Uemura and Harada 2000). The decision to operate the reactor in mesophilic or thermophilic condition depends upon the influent temperature. Thermophilic (55 °C) granules reportedly disintegrated due to increase in temperature (Lau and Fang 1997). Mesophilic granules, on the other hand, are sensitive to sudden temperature changes resulting in granule disintegration which may, in some cases, lead to reactor failure (Van Lier et al. 1990). Thus, careful temperature control is essential for the maintenance of granules in the reactors.

The composition of granules in a UASB reactor changes when the reactor is transformed from mesophilic to thermophilic condition, even though the integrity of granules remained intact (Macario et al. 1991). The layered structures of thermophilic granules were reported to be distinctively different from mesophilic granules (Syutsubo et al. 1997). Mesophilic granules as seed sludge surprisingly provided a faster and stable start-up compared to thermophilic digester sludge even for starting a thermophilic UASB reactor (Syutsubo et al. 1997). The exact mechanism for this microbial adaptation process from mesophilic granules to thermophilic granules is still unclear.

pH and alkalinity

It is generally agreed that a high partial pressure of hydrogen and a stable pH value close to neutrality are required to obtain good-quality granulated sludge (Gonzalez et al. 1998). The pH values inside a granule evidenced from the microprofile are lower than the bulk liquid (Lens et al. 1995). The proton translocation activity on the bacterial cell surface presumably pumps out protons into the immediate vicinity of the cell surface. This process may also create a proton conductance across the bacterial surface causing dehydration and consequently facilitate adherence to other bacterium or surface (Hulshoff Pol et al. 2004).

An acidogenic population is significantly less sensitive to pH fluctuations compared to methanogens, which has an optimum pH in the range of 6.3–7.8. Thus, in the extreme pH conditions, acid formation prevails over methanogenesis, resulting in accumulation of volatile fatty acid (VFA) in the reactor (Haandel and Lettinga 1994). The differential growth of fermentative bacteria and methanogens may cause pH to change if the un-ionized volatile fatty acid concentration exceeds the buffering capacity of the reactor content (Florencio et al. 1995). These conditions under most circumstances lead to disintegration of the granules because the methanogens die.

The buffering capacity in a UASB reactor is mostly provided by the alkalinity (Florencio et al. 1995). Alkalinity also helps in neutralizing fluctuations in the volatile acid concentration often arising from variation in organic loading (Isik and Sponza 2005). Thus, the ratio of alkalinity to chemical oxygen demand (COD) is one of the key parameters for granulation (Gonzalez et al. 1998). Optimum alkalinity in the influent reportedly ranges between 250 and 950 mg/l (Singh et al. 1999).

Organic loading rate

The pH, alkalinity, and organic loading rate (OLR) are closely linked parameters that affect granulation in a UASB reactor. The OLR variation can arise from either variation in influent COD or variation in flow rate with constant COD. An increase in OLR beyond its optimum range leads to decrease in pH due to increase in the concentrations of the VFAs (Dohanyos et al. 1985). Once the microbial biomass recovers and stabilizes, the extra VFAs are normally metabolized and the pH stabilizes (Myburg and Britz 1993). OLR of up to 104 kg COD m−3 day−1 has been reported for anaerobic digestion of sugar substrate (Wiegant and Lettinga 1985). Low OLR often causes acute mass transfer limitation leading to disintegration of the larger granules (Ahn et al. 2002). The granules loose their strength and stability because the decay starts at the center due to substrate limitation (Kosaric et al. 1990). In contrast to these studies, Teer et al. (2000) and Tiwari et al. (2005) have not experienced any granule disintegration while operating a UASB reactor under low OLR (<1.5 kg COD m−3 day−1).

Organic loading rate and hydraulic retention time (HRT) also have significant effect on the microbial ecology of granules (Torkian et al. 2003). An increase in OLR led to substantial shift of Methanothrix to Methanosarcina in the granules (Kalyuzhnyi et al. 1996).

Although Ghangrekar et al. (2005) recommended an OLR value in the range of 2.0–4.5 kg COD m−3 day−1 for developing good granular sludge, based on numerous studies reported so far for the variety of wastewater, it is safe to say that the optimum range of OLR and HRT can only be decided after considering the strength and composition of substrates, temperature, nutrient concentration, macro-metal concentrations, trace metals concentrations, and anions such as sulfate. These are discussed in the later sections.

Shear due to upflow and gas production

Granule formation and characteristics are strongly influenced by the upflow velocity of influent (Kosaric et al. 1990) and the superficial velocity of biogas (Haandel and Lettinga 1994). The upflow velocity applied in most of the laboratory and industrial scale reactors is about 1 m/h, although values up to 6 m/h in laboratory scale reactors have been also reported (Haandel and Lettinga 1994).

At high upflow velocities (above 1 m/h), the granules may disintegrate due to shearing, and the resulting fragments may wash out of the reactor (Kosaric et al. 1990). Vigorous gas evolution at high organic loading may similarly result in shear-off of bacteria cells from granule surface leading to granule erosion (Syutsubo et al. 1997).

For low-strength wastewaters with a COD-to-sulfate ratio of 2 or more, a higher upflow velocity of 1.5–2.5 m/h is helpful for reducing the toxicity due to sulfide as the sulfate-reducing bacteria are likely to wash out from the reactor because they lack the ability to form dense and firm granules (Shayegan et al. 2005).

An expanded granular sludge bed (EGSB), a variation of UASB reactors, can handle high upflow velocity of 4–10 m/h (Driessen and Yspeert 1999; Seghezzo et al. 1998; van der Last and Lettinga 1992). As a result, higher OLR of up to 40 kg COD m−3 day−1 can be accommodated in EGSB systems. The gas production is also consequently increased, imparting even more mixing inside the reactor (Seghezzo et al. 1998).

A two-stage internal circulation (IC) reactor with gas-driven effluent circulation in the lower section allows three to six times higher OLR and 8–20 times higher liquid upflow velocity compared to a UASB reactor (Pereboom and Vereijken 1994). For the same wastewater, IC granules are reported to be larger than UASB granules, but of lower strength (Pereboom 1994).

Substrate characteristics

Substrate characteristics, both composition and strength, dictate the microstructure in the form of spatial distribution of different microorganisms in a granule (Batstone and Keller 2001). For simple substrates such as acetate, only methanogens are needed to complete the degradation process and, hence, granules primarily consist of methanogens (Grotenhuis et al. 1991). Layered structures have been reported mostly for complex but easily hydrolyzable non-inhibitory substrates of higher concentration, i.e., glucose, proteins, sucrose, and brewery wastes (Fang et al. 1994; Guiot et al. 1992; MacLeod et al. 1990). As, the substrate flux is in a radial direction from the bulk towards the center, the population density of acetogens and acidogens is more near the outer surface (Guiot et al. 1992). Methanogens, on the other hand, are concentrated near the core of the granules (Guiot et al. 1992; MacLeod et al. 1990). There are some intermediate transition regions where both species are found. However, if the reactor feed contains acetate, methanogens may be present in the outer shell as well, as was observed by Sekiguchi et al. (1999), where the reactors were fed with mixtures of sucrose, acetate, propionate, and peptone. So, the presence of a certain species in a location within the granule is governed by the concentration of a specific substrate (e.g., acetate for methanogen and sucrose for acetogen) at that location. The concentration of a substrate in a location within the granule is in turn governed by the intra-granular diffusion and rate of formation (acetate by acetogen) or consumption (acetate by methanogen). Thus, it is safe to say that the layers in a granule may form due to the interplay of the rate of intra-granular diffusion of substrate and the reaction rates of different steps in the degradation.

No layer in the granules was reported to form with propionate, peptone, ethanol, and glutamate as substrates (Fang et al. 1994, 1995; Grotenhuis et al. 1991). The granules also do not show any layered structure in the presence of an inhibitory substrate such as phenol or lindane (Erguder et al. 2003; Fang et al. 1996). Methanogenesis is reported to be the rate-limiting step in the anaerobic degradation of the non-inhibitory substrate whereas with the inhibitory substrate, acetogenesis, is identified as the rate-limiting step (Chou and Huang 2005). Low substrate concentration in the feed may result in substrate limitation at the core of the larger granules as majority of the substrate is utilized near the surface (Ahn et al. 2002; Kosaric et al. 1990). This may result in flotation of large granules due to hollowing of the core (Schmidt and Ahring 1996). However, for low substrate concentrations, gas production is also low and the intra-granular pore network may not be filled with gas. As a result, these pores may be penetrated by substrates, resulting in additional transfer of substrates to the core region through these channels. No substrate limitation and flotation of the large granules (up to 3 mm) was observed for the granules grown with low strength sucrose-based wastewater (Tiwari et al. 2004, 2005).

Fats, oil, and grease are known to have low biodegradability and report on applicability of UASB reactor to treat such waste is divided. Typically reported problems include foaming, scum formation, and sludge washout in the presence of lipids (Lettinga and Hulshoff Pol 1991; Ozturk et al. 1993). A number of studies have reported low treatment efficiency and very little granulation with substrates rich in fats, oil, and grease (Boari et al. 1984; Petruy and Lettinga 1997). Some researchers have successfully used UASB reactor for treatment of wastewaters rich in fats, oil, and grease (Borja et al. 1996; Quarmby and Forster 1995; Tay and Yan 1996). The granules grown on such substrate were reported to be made up of a large number of close-packed but discrete colonies of multicellular filaments, typically Methanothrix, in a dense matrix (Borja et al. 1996; Quarmby and Forster 1995).

Oil and grease in the substrate tend to accumulate on the surface of sludge granules. This develops a superficial layer of scum and sludge with the consequent biomass washout (Rinzema et al. 1994). A hydrophobic environment produced by the adsorbed lipid layer may also result in reduction in diffusion of water-soluble substrate into the granules. Substrates containing fats, oil, and grease, especially long-chain fatty acids (LCFAs), were reported to inhibit several bacteria involved in the process (Koster and Cramer 1987; Sayed et al. 1988; Tay and Yan 1996). LCFAs affected obligate hydrogen-producing acetogenic bacteria as well as hydrogenotrophic and acetotrophic methanogenic archaea (Hanaki et al. 1981), resulting in impaired syntrophic interaction between microbial groups and, thus, difficulty in granulation (Tay and Yan 1996).

The rates of H2 consumption (by methanogens) as well as the H2 production (by acidogens and acetogens) are influenced by the partial pressure of H2 (Conrad et al. 1986; Mosey 1983). The different cell pathways metabolizing the substrate are regulated by the relative concentrations of NADH and NAD+. By assuming a constant internal cell pH, the ratio of the two concentrations could be related to hydrogen partial pressure (Costello et al. 1991a,b). For anaerobic fermentation where 1 mol of substrate releases two or three hydrogen molecules, small changes in the hydrogen partial pressure may largely affect the substrate conversion rates and, hence, the size and strength of granules in the reactor (Kleerebezem and Stams 2000). An elevated hydrogen partial pressure in the reactor leads to production of higher-order fatty acids instead of acetate which is believed to be the usual route due to largest energy yield (Mosey 1983). Thus, for favoring granulation, the partial pressure of hydrogen must be kept low to ensure efficient fermentation of the volatile fatty acids (Liu et al. 2003).

A parallel hypothesis put forward by Palns et al. (1987) states that high hydrogen partial pressure along with limited cysteine leads to over-secretion of amino acids (except cysteine) which can induce ECP formation and initiate anaerobic granulation. According to this, granulation is not likely to occur in reactors fed with acetate, propionate, or butyrate because of inadequate hydrogen partial pressure. However, there are experimental evidences of granulation in UASB systems fed with these substrates (Grotenhuis et al. 1991; Sekiguchi et al. 1999; Van Lier et al. 1995).

Nutrients

The requirements for nutrients such as nitrogen, phosphorus, and sulfur of various syntrophic groups in a heterogeneous culture are rather complex. During the formation of granules, an excess of nitrogen and phosphorus in the substrate is helpful and can be eliminated after the start of the granulation process without any deleterious effect on the granules’ development (Gonzalez et al. 1998). Singh et al. (1999) have reported that cell growth reduces drastically at a nitrogen concentration of less than 300 mg/l. In contrast, there are reports of inhibition of the process of granulation at higher concentrations of these nutrients (Jarrell and Kalmokoff 1988). Nitrogen, phosphorus, and potassium were indicated to retard the effect of shock loading and prevent the flotation of granule (Alphenaar et al. 1993; Blaszczyk et al. 1994).

Ammonia was reported to influence the methanogenesis in anaerobic reactors (Angelidaki and Ahring 1993; Hansen et al. 1998). All methanogens utilize ammonia as a source of nitrogen, which can also serve as electron donor and buffer (Gallert et al. 1998; Singh et al. 1999). The accumulation of ammonium ions can alter the intracellular pH and the activities of methane-synthesizing enzymes are inhibited by free ammonia (Kadam and Boone 1996). In most cases, acetate-utilizing methanogens were reportedly more sensitive to ammonia concentration than hydrogen-utilizing ones (Angelidaki and Ahring 1993; Lay et al. 1997) with one exception where hydrogen-utilizing methanogens were identified as the sensitive group (Wiegant and Zeeman 1986). In a recent study, propionate-degrading acetogenic bacteria were reported to be more sensitive to free ammonia compared to methanogenic archaea (Calli et al. 2005). Ammonia inhibition occurred above pH 7.4 in the range of 1,500–3,000 mg/l total ammonia nitrogen, whereas at concentrations in excess of 3,000 mg/l, ammonia was toxic irrespective of pH (Koster and Lettinga 1984; Van Velsen 1979).

Methanogens are capable of utilizing a broad spectrum of sulphur-containing compounds in various oxidation states for their maintenance and growth (Jarrell and Kalmokoff 1988). Several methanogens show requirements for magnesium for stimulating growth (Lettinga and Hulshoff Pol 1991). Amino acid transport, growth, methanogenesis, and internal pH regulation are all sodium dependent (Jarrell and Kalmokoff 1988).

Multivalent cations and heavy metals

Granulation is initiated by bacterial adsorption and adhesion to inert matters, to organic precipitates, and/or to each other through physico–chemical interactions and syntrophic associations (Dolfing 1986; Schmidt and Ahring 1996). The cations may accelerate this process through bridging between negatively charged groups on cell surfaces and linking exo-cellular polymers (Hulshoff Pol et al. 2004; Morgan et al. 1991; Schmidt and Ahring 1996). In addition, multivalent cations condense the diffused double layers and facilitate flocculation due to Van der Waals forces (Liu et al. 2003; Schmidt and Ahring 1996). The predominant binding groups for metals on the surface of bacteria are carboxyl and amino groups in proteins (Artola et al. 1997). Prolonged exposure to low pH also affects the metal retention dynamics within the granular sludge (Singh et al. 1999).

Heavy metals compete with other ions in the solution for these binding sites on the cell surface. The relative toxicities of some metals depend on pH, VFA concentration, HRT, type and form of metal ions, and strength and affinity of the binding groups present on the surfaces of prevalent microorganisms (Gould and Genetelli 1984; Lin and Chen 1999). The presence of inert solids in the granules offers some abiotic surfaces to interact with the metal ions and, in turn, increases the toxicity resistances of biogranules (Oleszkiewicz and Sharma 1990).

Extensive literature is available on the role of a few specific multivalent cations on granulation. These are discussed below.

Calcium

Calcium enhances the initial adhesion of the cells through exo-cellular polymers, which preferentially bind to divalent metals (Rudd et al. 1984). Calcium presumably gets embedded into extracellular polysaccharides and/or proteins, which are used as linking material (Morgan et al. 1991). Calcium also has the ability to bridge between the electronegative carboxyl and phosphate groups associated with bacterial surfaces (Shen et al. 1993). Calcium ion may also contribute to the conformational stability of the polymer networks in the granules by interacting with the secondary functional groups in the polysaccharides like OH− and, thereby, influencing the folding of the polymers (Turakhia and Characklis 1988).

While calcium concentrations in the range of 80–150 mg/l stimulated the formation of granules during the start-up of a UASB reactor, it did not induce granulation and was not a key element in granules (Alibhai and Forster 1986). In another study, the optimum concentration of Ca2+ for granulation was reported to be 150–300 mg/l (Yu et al. 2001a). As very different optimum ranges were reported in various literatures, it is imperative to understand the actual effect of calcium on granule formation.

At high calcium concentration, formation of CaCO3 precipitate may block the intragranular pores, leading to severe mass transfer limitation and higher ash content in granules (Langerak van et al. 2000; Yu et al. 2001a). This may lead to strong agglomerates or cementation of sludge bed with low specific methanogenic activity (SMA). If CaCO3 precipitation takes place in the bulk solution instead of intragranular pores, they provide inert supports for bacteria and facilitating new biofilm to develop on the crystal surface (Iza et al. 1992). This may lead to sludge with high ash content accompanied by a relatively high SMA (Kettunen and Rintala 1998). The precipitation of CaCO3 rarely takes place at the surface of well-formed granules because they are rapidly dissolved or covered with a layer of fast-growing, acid-forming biomass (Langerak van et al. 2000).

The location of precipitation is influenced by existing granule size, the crystallization rate constants, and the composition of the feed solution (Langerak van et al. 2000). Phosphate is an important inhibitor of CaCO3 crystal growth (House 1987). Bulk precipitation can be promoted by not inhibiting the crystal growth, which can be accomplished by providing a low phosphate concentration in the reactor, applying a low Ca/Na ratio, and using smaller-sized granules in the seed sludge (Langerak van et al. 2000).

Iron

The conversion of COD to biomass or yield is a function of iron concentration (Oleszkiewicz and Sharma 1990). The presence of Fe+2 at a concentration higher than 300 mg/l promoted granule formation by allowing aggregates to form earlier and to achieve a larger size presumably due to double-layer compression (Yu et al. 2000). The average granule size reportedly increased with increasing Fe+2 concentrations. However, very high influent Fe+2 concentration led to higher ash content and severe mass transfer limitations in granules (Yu et al. 2000). The increased mineral content was very likely the result of more FeS and the compounds formed by iron and exo-polysaccharides in the granules.

Aluminum

Like the divalent metal ions, Al3+ was also reported to have a positive effect on sludge granulation. In the only available study on effects of aluminum additive on granulation, Yu et al. (2001b) have found that aluminum prompts granule formation by allowing aggregates to form earlier and to achieve a larger size.

Trace elements and heavy metals

The trace element requirement of anaerobic microorganisms is specific because of many cobalt-, nickel-, and iron-containing enzymes involved in the biochemistry of fermentation and methane production (Shen et al. 1993). Therefore, the lack of some key trace metal can severely limit the overall anaerobic conversion process and granulation. The toxicity of heavy metal towards anaerobic digestion is independent of total metal concentration in the digester but depends on the concentration of free metal species in the sludge (Lawrence and McCarty 1965; Mueller and Steiner 1992). Active, inactive, and dead biomass is capable of binding and accumulating high quantities of heavy metals (Kuyucak and Volesky 1988). Some trophic group(s) or organisms within the anaerobic consortia in the digesters may be more severely inhibited by a pulse addition of toxic heavy metals than the methanogenic populations (Hickey et al. 1989). A significant decrease in gas production and simultaneous accumulation of VFA in the UASB reactor was reported in the presence of heavy metals (Lawrence and McCarty 1965), and methane production decreased as the metal concentrations increased (Lin and Chen 1999). Although acidogens are generally considered to be less sensitive to toxins compared to methanogens (Lin and Yang 1991), they are reportedly more sensitive to chromium, nickel, zinc, and copper (Hickey et al. 1989; Lin 1993). Mixed acid seed sludge was more sensitive to metal ions (except Pb) than acetic acid seed sludge (Lin 1992).

Heavy metals affect the production of acetic acid and n-butyric acid to different degrees (Lin 1993; Lin and Chen 1999). Lin (1993) reported that the relative toxicities of heavy metals to production of acetic acid and n-butyric acid were Cu > Zn > Cr > Cd > Pb > Ni and Cu > Zn > Cr > Cd > Ni > Pb, respectively. The toxicity of mixed metals was antagonistic to acetic acid production but synergistic to n-butyric acid production (Lin 1993).

The presence of sulfide leads to formation of insoluble metal sulfide precipitates in the reactor with most heavy metals (Lawrence and McCarty 1965; Mueller and Steiner 1992) and reduces the effect of toxic heavy metals. During anaerobic digestion, sulfide can be produced by sulfate reduction or protein degradation. HgS, PbS, CuS, and CdS have very low solubility and precipitate even at pH values as low as pH 1, whereas NiS, CoS, MnS, and ZnS precipitate at pH value above pH 7 (Mueller and Steiner 1992). In addition, many metals precipitate as hydroxide at neutral pH. Metal precipitates are generally pH sensitive and their solubility increases with lower pH values.

Microbial ecology of seed sludge

Acetogenic bacteria and Methanosaeta sp. have been reported to be key populations which significantly accelerate granule development (El-Mamouni et al. 1997). The study by El-Mamouni et al. (1997) on granulation rates reported that granulation was rapid on nuclei enriched with Methanosaeta and syntrophic organisms, slightly poorer on nuclei enriched with Methanosarcina and very slow on acidogenic nuclei. Methanosarcina apparently plays no part in initial biofilm formation as it does not attach to either hydrophobic or hydrophilic synthetic support structure (Verrier et al. 1988).

Exo-cellular polymer

The exo-cellular polymers produced by the bacteria are believed to play a critical role in maintaining structural integrity of granules (Schmidt and Ahring 1996; Shen et al. 1993). Several studies (Jia et al. 1996; Ross 1984) indicate that the ECP influences the formation of granules in UASB reactors. As ECPs are biopolymers accumulated on the surfaces of microbes, presumably some of the charges or the functional groups on the surface are associated to the ECP. The functional groups associated with the ECP of one microbial cell may increase ionic interactions between oppositely charged functional groups in the ECP of other microbial cells, leading to formation of a bond between the two cells. In addition, ions in the media help in bridging between two like-charged functional groups of the cell ECPs (Hulshoff Pol et al. 1983; Schmidt and Ahring 1994). However, a high amount of ECP seems unnecessary for active granules and may cause deterioration in floc formation (Schmidt and Ahring 1996). ECP isolated from cells cultivated separately and added externally at the start-up appears to have no effect on granulation in the UASB reactors (Morgan et al. 1990). The addition of excess external ECP has been reported to show inhibitory effects on the granulation (Morgan et al. 1990).

Natural and synthetic polymers

In anaerobic reactors, polymers are mainly used either to immobilize the anaerobic sludge or to reinforce the strength of the already existing granules by coating the granule surface with a thin layer of polymer (Ahn 2000; Liu et al. 2003). Adsorption of polymers on the surface of the dispersed bacteria and neutralization of their surface charges is one of the principal mechanisms to promote anaerobic granulation (Kalogo et al. 2001). It appears that both synthetic and natural polymers can assist anaerobic bacteria to aggregate together and form granules (Liu et al. 2003).

Several studies have been reported with natural and synthetic polymers to study the effect of polymer addition on the granulation process. Kalogo et al. (2001) reported that the extract of Moringa oleifera seeds (a natural polymer) in the feed favored aggregation of coccoid bacteria and growth of microbial nuclei. A few cationic polymers reported to enhance granulation are natural cationic polymers Chitosan (El-Mamouni et al. 1998; Tiwari et al. 2005) and cationic fraction of Reetha (Sapindus trifoliata) extract (Tiwari et al. 2005), synthetic polymers AA 184 H (Show et al. 2004) and Percol 763 (El-Mamouni et al. 1998). The efficiency of Chitosan was found to be better than the synthetic polymer Percol 763 (El-Mamouni et al. 1998) and natural polymer Reetha extract (Tiwari et al. 2005). This was attributed to the polysaccharide structure of the Chitosan, similar to exo-cellular polymer found in aggregating anaerobic sludge (Hughes et al. 1990) and the water-absorbing nature of the polymer. Imai et al. (1997) have demonstrated the effectiveness of some water-absorbing polymers in the enhancement of granulation. Some anionic polymers such as anionic fraction of Reetha extract and Sulphonated-Lignin also reportedly increased biomass aggregation (Guiot et al. 1991; Tiwari et al. 2005). Jeong et al. (2005) reported the effectiveness of the organic–inorganic hybrid polymers in quick formations (within 5 min) of granules with sewage digester sludge.

Concluding remarks

The granule composition strongly depends on the operational temperature as different species have optimum growth rate at different temperature. Sudden temperature changes could result in granule disintegration in the reactor. Optimum alkalinity is essential to maintain the reactor pH and buffer significant fluctuations in the VFA concentrations. The preferred conditions for granulation are a high partial pressure of hydrogen and neutral pH. The fluctuation in VFA may arise due to fluctuation in OLR, either in the form of HRT or influent COD. The optimum range of OLR and HRT can only be decided after considering the influent characteristics and other operating conditions. Layer formation in granules is due to interaction of intragranular diffusion and degradation kinetics of the substrate. Thus, the granule microstructure is governed by the substrate type and strength. The presence of adequate nutrients and metals is essential for granulation. Calcium and iron may enhance granulation but are also capable of causing mass transfer limitation when present in large quantities. The effect of calcium is influenced by phosphate. Iron forms sulfide deposits when sulfate reduction activity is present in the reactor, which is influenced by HRT. The presence of toxic heavy metals in the influent can cause granule degeneration. Although exo-cellular polymers provide strength to the granules, external addition of ECP does not enhance granulation. External addition of ionic natural and synthetic polymers can be used to enhance granulation. They help in the initial stages of formation of granules.

Although studies on applicability of UASB and granulation process in reactor are aplenty, it is still an active area of research. The UASB reactor is presently successfully applied for wastewater containing non-inhibitory substrate at high concentration, e.g., distillery waste, brewery waste, and sugar industry waste. A suitable modification for the treatment of complex industrial wastewaters in the presence of some inhibitory compounds is a challenge. Development in this direction will lead to successful application of UASB for milk and food processing waste, gelatine manufacturing plant waste, slaughterhouse waste, etc. A successful way of formation and maintenance of granules with very low strength domestic wastewater and mixed wastewater (sewage and industrial wastewater) will go a long way to solve problems faced by many developing countries. In this connection, microbial adoption process inside the sludge bed with change in substrate type needs to be understood. Many studies are reported for optimum level of the nutrients and trace elements favoring granulation for many different substrate types, but they are unlikely to yield a unique answer. The requirements of nutrients and trace metals depend on the type of species present and their relative abundance (microbial ecology) in the granules, which are functions of wastewater type and strength.

Another challenge is to shorten the start-up time of the reactor by enhancing granule formation. Various external additives have shown promising results in this direction; however, most of these studies are limited to laboratory-scale reactor. The effect of these additives should be investigated in pilot-scale reactors along with the economics of the additives.

References

Ahn YH (2000) Physicochemical and microbial aspects of anaerobic granular pallets. J Environ Sci Health A 35:1617–1635

Ahn YH, Song YJ, Lee YJ, Park S (2002) Physicochemical characterization of UASB sludge with different size distributions. Environ Technol 23:889–897

Alibhai KRK, Forster CF (1986) An examination of granulation process in UASB reactors. Environ Technol Lett 7:193–200

Alphenaar PA, Sleyster R, de Reuver P (1993) Phosphorus requirement in high-rate anaerobic wastewater treatment. Water Res 27:749–756

Angelidaki I, Ahring BK (1993) Thermophilic anaerobic digestion of livestock waste: effect of ammonia. Appl Microbiol Biotechnol 38:560–564

Artola A, Balaguer MD, Rigola M (1997) Heavy metal binding to anaerobic sludge. Water Res 31:997–1003

Batstone DJ, Keller J (2001) Variation of bulk properties of anaerobic granules with wastewater type. Water Res 35:1723–1729

Blaszczyk R, Gardner D, Kosaric N (1994) Response and recovery of anaerobic granules from shock loading. Water Res 28:675–680

Blonskaja V, Menert A, Vilu R (2003) Use of two-stage anaerobic treatment for distillery waste. Adv Environ Res 7:671–678

Boari G, Brunetti A, Passino R, Rozzi A (1984) Anaerobic digestion of olive oil mill wastewaters. Agric Wastes 10:161–175

Borja R, Banks CJ, Sanchez E (1996) Anaerobic treatment of palm oil mill effluent in a two-stage up-flow anaerobic sludge blanket (UASB) system. J Biotechnol 45:125–135

Calli B, Mertoglu B, Inanc B, Yenigun O (2005) Effects of high free ammonia concentrations on the performances of anaerobic bioreactors. Process Biochem 40:1285–1292

Chou HH, Huang JS (2005) Comparative granule characteristics and biokinetics of sucrose-fed and phenol-fed UASB reactors. Chemosphere 59:107–116

Chou HH, Huang JS, Hong WF (2004) Temperature dependency of granule characteristics and kinetic behavior in UASB reactors. J Chem Technol Biotechnol 79:797–808

Conrad R, Schink B, Phelps TJ (1986) Thermodynamics of H2-consuming and H2-producing metabolic reactions in diverse methanogenic environments under in situ conditions. FEMS Microbiol Ecol 38:353–360

Costello DJ, Greenfield PF, Lee PL (1991a) Dynamic modelling of a single-stage high-rate anaerobic reactor—I. Model derivation. Water Res 25:847–858

Costello DJ, Greenfield PF, Lee PL (1991b) Dynamic modelling of a single-stage high-rate anaerobic reactor—II. Model verification. Water Res 25:859–871

Dohanyos M, Kosova B, Zabranska J, Grau P (1985) Production and utilization of volatile fatty acids in various types of anaerobic reactors. Water Sci Technol 17:191–205

Dolfing J (1986) Granulation in UASB reactors. Water Sci Technol 18:15–25

Driessen W, Yspeert P (1999) Anaerobic treatment of low, medium and high strength effluent in the agro-industry. Water Sci Technol 40:221–228

El-Mamouni R, Leduc R, Guiot SR (1997) Influence of the starting microbial nucleus type on the anaerobic granulation dynamics. Appl Microbiol Biotechnol 47:189–194

El-Mamouni R, Leduc R, Guiot SR (1998) Influence of synthetic and natural polymers on the anaerobic granulation process. Water Sci Technol 38:341–347

Erguder TH, Guven E, Demirer GN (2003) The inhibitory effects of lindane in batch and upflow anaerobic sludge blanket reactors. Chemosphere 50:165–169

Fang HHP, Chui HK, Li YY, Chen T (1994) Performance and granule characteristics of UASB process treating wastewater with hydrolyzed proteins. Water Sci Technol 30:55–63

Fang HHP, Chui HK, Li YY (1995) Microstructural analysis of UASB granules treating brewery wastewater. Water Sci Technol 31:129–135

Fang HHP, Chen T, Li YY, Chui HK (1996) Degradation of phenol in wastewater in an upflow anaerobic sludge blanket reactor. Water Res 30:1353–1360

Florencio L, Field JA, Lettinga G (1995) Substrate competition between methanogens and acetogens during the degradation of methanol in UASB reactors. Water Res 29:915–922

Gallert C, Bauer S, Winter J (1998) Effect of ammonia on the anaerobic degradation of protein by a mesophilic and thermophilic biowaste population. Appl Microbiol Biotechnol 50:495–501

Ghangrekar MM, Asolekar SR, Joshi SG (2005) Characteristics of sludge developed under different loading conditions during UASB reactor start-up and granulation. Water Res 39:1123–1133

Gonzalez JS, Rivera A, Borja R, Sanchez E (1998) Influence of organic volumetric loading rate, nutrient balance and alkalinity: COD ratio on the anaerobic sludge granulation of an UASB reactor treating sugar cane molasses. Int Biodeterior Biodegrad 41:127–131

Gould MS, Genetelli EJ (1984) Effects on complexation on heavy metal binding by anaerobically digested sludges. Water Res 18:123–126

Grotenhuis JT, Smit M, Plugge CM, Xu YS, van Lammeren AA, Stams AJ, Zehnder AJ (1991) Bacterial composition and structure of granular sludge adapted to different substrates. Appl Environ Microbiol 57:1942–1949

Guiot SR, Lavole L, Hawari JA, Samson R (1991) Effect of NSSC spent liquor on granule formation and specific microbial activities in upflow anaerobic reactors. Water Sci Technol 24:139–148

Guiot SR, Pauss A, Costerton JW (1992) A structured model of the anaerobic granule consortium. Water Sci Technol 25:1–10

Gujer W, Zehnder AJB (1983) Conversion processes in anaerobic digestion. Water Sci Technol 15:127–167

Haandel AC, van Lettinga G (1994) Anaerobic sewage treatment: a practical guide for regions with a hot climate. Wiley, Chichester England

Hanaki K, Matsuo T, Nagase M (1981) Mechanism of inhibition caused by long-chain fatty acids in the anaerobic digestion process. Biotechnol Bioeng 23:1591–1610

Hansen KH, Angelidaki I, Ahring BK (1998) Anaerobic digestion of swine manure: inhibition by ammonia. Water Res 32:5–12

Henze M, Harremoes P (1983) Anaerobic treatment of wastewater in fixed film reactors—a literature review. Water Sci Technol 15:1–101

Hickey RF, Vanderwielen J, Switzenbaum MS (1989) The effect of heavy metals on methane production and hydrogen and carbon monoxide level during batch anaerobic sludge digestion. Water Res 23:207–218

House WA (1987) Inhibition of calcite crystal growth by inorganic phosphate. J Colloid Interface Sci 119:505–511

Hughes J, Ramsden DK, Symes KC (1990) The flocculation of bacteria using cationic synthetic flocculants and Chitosan. Biotechnol Tech 4:55–60

Hulshoff Pol LW, de Zeeuw WJ, Velzeboer CTM, Lettinga G (1983) Granulation in UASB reactor. Water Sci Technol 15:291–304

Hulshoff Pol LW, de Castro Lopes SI, Lettinga G, Lens PNL (2004) Anaerobic sludge granulation. Water Res 38:1376–1389

Imai T, Ukita M, Liu J, Sekine M, Nakanishi H, Fukagawa M (1997) Advance start up of UASB reactors by adding of water absorbing polymer. Water Sci Technol 15:399–406

Isik M, Sponza DT (2005) Effects of alkalinity and co-substrate on the performance of an upflow anaerobic sludge blanket (UASB) reactor through decolorization of Congo red azo dye. Bioresour Technol 96:633–643

Iza J, Keenan PJ, Switzenbaum MS (1992) Anaerobic treatment of municipal solid waste landfill leachate: operation of a pilot scale hybrid UASB/AF reactor. Water Sci Technol 25:255–264

Jarrell KF, Kalmokoff ML (1988) Nutritional requirements of the methanogenic archaebacteria. Can J Microbiol 34:557–576

Jeong HS, Kim YH, Yeom SH, Song BK, Lee SI (2005) Facilitated UASB granule formation using organic–inorganic hybrid polymers. Process Biochem 40:89–94

Jia XS, Fang HHP, Furumai H (1996) Surface charge and extracellular polymer of sludge in the anaerobic degradation process. Water Sci Technol 34:309–316

Kadam PC, Boone DR (1996) Influence of pH on ammonia accumulation and toxicity in halophilic, methylotrophic methanogens. Appl Environ Microbiol 62:4486–4492

Kalogo Y, Seka AM, Verstraete W (2001) Enhancing the startup of a UASB reactor treating domestic wastewater by adding a water extract of Moringa oleifera seeds. Appl Microbiol Biotechnol 55:644–651

Kalyuzhnyi SV, Sklyar VI, Davlyatshina MA, Parshina SN, Simankova MV, Kostrikina NA, Nozhevnikova AN (1996) Organic removal and microbiological features of UASB-reactor under various organic loading rates. Bioresour Technol 55:47–54

Kettunen RH, Rintala JA (1998) Performance of an on-site UASB reactor treating leachate at a low temperature. Water Res 32:537–546

Kleerebezem R, Stams AJM (2000) Kinetics of syntrophic cultures: a theoretical treatise on butyrate fermentation. Biotechnol Bioeng 67:529–543

Kosaric N, Blaszczyk R, Orphan L (1990) Factors influencing formation and maintenance of granules in upflow anaerobic sludge blanket reactors (UASBR). Water Sci Technol 22:275–282

Koster IW, Cramer A (1987) Inhibition of methanogenesis from acetate in granular sludge by long-chain fatty acids. Appl Environ Microbiol 53:403–409

Koster IW, Lettinga G (1984) The influence of ammonium-nitrogen on the specific activity of palletized methanogenic sludge. Agric Wastes 9:205–216

Kuyucak N, Volesky B (1988) Biosorbents for recovery of metals from industrial solutions. Biotechnol Lett 10:137–142

Langerak van EPA, Ramaekers H, Wiechers J, Veeken AHM, Hamelers HVM, Lettinga G (2000) Impact of location of CaCO3 precipitation on the development of intact anaerobic sludge. Water Res 34:437–446

Lau IWC, Fang HHP (1997) Effect of temperature shock to thermophilic granules. Water Res 31:2626–2632

Lawrence AW, McCarty PL (1965) The role of sulfide in preventing heavy metal toxicity on anaerobic treatment. J Water Pollut Control Fed 37:392–406

Lay JJ, Li YY, Noike T (1997) Influences of pH and moisture content on the methane production in high-solids sludge digestion. Water Res 31:1518–1524

Lens P, de Beer D, Cronenberg C, Ottengraf S, Verstraete W (1995) The use of microsensors to determine population distributions in UASB aggregates. Water Sci Technol 31:273–280

Lettinga G, Hulshoff Pol LW (1991) UASB—process design for various types of wastewaters. Water Sci Technol 24:87–107

Lettinga G, Van Velsen AFM, Hobma SW, de Zeeuw W, Klapwijk A (1980) Use of the upflow sludge blanket (USB) reactor concept for biological wastewater treatment especially, for anaerobic treatment. Biotechnol Bioeng 22:699–734

Lettinga G, De Man A, Van der Last ARM, Wiegant W, Van Knippenberg K, Frijns J, Van Buuren JCL (1993) Anaerobic treatment of domestic sewage and wastewater. Water Sci Technol 27:67–73

Lin CY (1992) Effect of heavy metals on volatile fatty acid degradation in anaerobic digestion. Water Res 26:177–183

Lin CY (1993) Effect of heavy metal on acidogenesis in anaerobic digestion. Water Res 27:147–152

Lin CY, Chen CC (1999) Effect of heavy metals on the methanogenic UASB granule. Water Res 33:409–416

Lin KC, Yang Z (1991) Technical review on the UASB process. Int J Environ Stud 39:203–222

Liu Y, Xu HL, Yang SF, Tay JH (2003) Mechanisms and models for anaerobic granulation in upflow anaerobic sludge blanket reactor. Water Res 37:661–673

Macario AJL, Visser FA, Van Lier JB, De Macario EC (1991) Topography of methanogenic subpopulations in a microbial consortium adapting to thermophilic conditions. J Gen Microbiol 137:2179–2189

MacLeod FA, Guiot SR, Costerton JW (1990) Layered structure of bacterial aggregates produced in an upflow anaerobic sludge bed and filter reactor. Appl Environ Microbiol 56:1598–1607

Mahmoud N, Zeeman G, Gijzen H, Lettinga G (2003) Solids removal in upflow anaerobic reactors, a review. Bioresour Technol 90:1–9

Mergaert K, Vanderhaegen B, Verstraete W (1992) Applicability and trends of anaerobic pre-treatment of municipal wastewater. Water Res 26:1025–1033

Morgan JW, Forster CF, Evison LM (1990) A comparative study of the nature of biopolymers extracted from anaerobic and activated sludge. Water Res 24:743–750

Morgan JW, Evison LM, Forster CF (1991) Changes to the microbiological ecology in anaerobic digesters treating ice cream wastewater during start-up. Water Res 25:639–653

Mosey FE (1983) Mathematical modelling of the anaerobic digestion process: regulatory mechanisms for the formation of short-chain volatile acids from glucose. Water Sci Technol 15:209–232

Mueller RF, Steiner A (1992) Inhibition of anaerobic digestion caused by heavy metals. Water Sci Technol 26:835–846

Myburg C, Britz TJ (1993) Influence of higher organic loading rates on the efficiency of an anaerobic hybrid digester while treating landfill leachate. Water SA 19:319–324

Oleszkiewicz JA, Sharma VK (1990) Stimulation and inhibition of anaerobic processes by heavy metals— a review. Biol Wastes 31:45–67

Ozturk I, Eroglu V, Ubay G, Demir I (1993) Hybrid upflow anaerobic sludge blanket reactor (HUASB) treatment of dairy effluents. Water Sci Technol 28:77–85

Palns SS, Loewenthal RE, Dold PL, Marais GR (1987) Hypothesis for pelletisation in upflow anaerobic sludge blanket reactor. Water SA 13:69–80

Pereboom JHF (1994) Size distribution model for methanogenic granules from full scale UASB and IC reactors. Water Sci Technol 30:211–221

Pereboom JHF, Vereijken TLFM (1994) Methanogenic granule development in full scale internal circulation reactors. Water Sci Technol 30:9–21

Petruy R, Lettinga G (1997) Digestion of a milk-fat emulsion. Bioresour Technol 61:144–149

Quarmby J, Forster CF (1995) An examination of the structure of UASB granules. Water Res 29:2449–2454

Rinzema A, Boone M, van Knippenberg K, Lettinga G (1994) Bactericidal effect of long chain fatty acids in anaerobic digestion. Water Environ Res 66:40–49

Ross WR (1984) The phenomenon of sludge pelletisation in anaerobic treatment of a maize processing waste. Water SA 10:197–204

Rudd T, Sterritt RM, Lester JN (1984) Complexation of heavy metals by extracellular polymers in the activated sludge process. J Water Pollut Control Fed 56:1260–1268

Sayed S, Van der Zanden J, Wijffels R, Lettinga G (1988) Anaerobic degradation of various fractions of slaughterhouse wastewater. Biol Wastes 23:117–142

Schmidt JE, Ahring BK (1994) Extracellular polymers in granular sludge from different upflow anaerobic sludge blanket (UASB) reactors. Appl Microbiol Biotechnol 42:457–462

Schmidt JE, Ahring BK (1996) Granular sludge formation in upflow anaerobic sludge blanket (UASB) reactors. Biotechnol Bioeng 49:229–246

Seghezzo L, Zeeman G, van Lier JB, Hamelers HVM, Lettinga G (1998) A review: the anaerobic treatment of sewage in UASB and EGSB reactors. Bioresour Technol 65:175–190

Sekiguchi Y, Kamagata Y, Nakamura K, Ohashi A, Harada H (1999) Fluorescence in situ hybridization using 16S rRNA-targeted oligonucleotides reveals localization of methanogens and selected uncultured bacteria in mesophilic and thermopilic sludge granules. Appl Environ Microbiol 65:1280–1288

Shayegan J, Ghavipanjeh F, Mirjafari P (2005) The effect of influent COD and upward flow velocity on the behavior of sulphate-reducing bacteria. Process Biochem 40:2305–2310

Shen CF, Kosaric N, Blaszczyk R (1993) The effect of selected heavy metals (Ni, Co and Fe) on anaerobic granules and their exracellular polymeric substances (EPS). Water Res 27:25–33

Show KY, Wang Y, Foong SF, Tay JHJ (2004) Accelerated start-up and enhanced granulation in upflow anaerobic sludge blanket reactors. Water Res 38:2293–2304

Singh KS, Viraraghavan T (2003) Impact of temperature on performance, microbiological, and hydrodynamic aspects of UASB reactors treating municipal wastewater. Water Sci Technol 48:211–217

Singh RP, Kumar S, Ojha CSP (1999) Nutrient requirement for UASB process: a review. Biochem Eng J 3:35–54

Speece RE (1983) Anaerobic biotechnology for industrial wastewater treatment. Environ Sci Technol 17:416A–427A

Syutsubo K, Harada H, Ohashi A, Suzuki H (1997) An effective start-up of thermophilic UASB reactor by seeding mesophilically-grown granular sludge. Water Sci Technol 24:35–59

Tay JH, Yan YG (1996) Influence of substrate concentration on microbial selection and granulation during start-up of upflow anaerobic sludge blanket reactors. Water Environ Res 68:1140–1150

Teer JE, Leak DJ, Dudeney AWL, Nayaranan A, Stuckey DC (2000) Changes in pre-formed granule composition and structure in sulphidogenic UASB treating a synthetic ferric oxalate wastewater. Environ Technol 21:1325–1335

Tiwari MK, Guha S, Harendranath CS (2004) Enhanced granulation in UASB reactor treating low-strength wastewater by natural polymers. Water Sci Technol 50:235–240

Tiwari MK, Guha S, Harendranath CS, Tripathi S (2005) Enhanced granulation by natural ionic polymer additives in UASB reactor treating low-strength wastewater. Water Res 39:3801–3810

Torkian A, Eqbali A, Hashemian SJ (2003) The effect of organic loading rate on the performance of UASB reactor treating slaughterhouse effluent. Resour Conserv Recycl 40:1–11

Turakhia MH, Characklis WG (1988) Activity of Pseudomonas aeruginosa in biofilm: effect of calcium. Biotechnol Bioeng 33:406–414

Uemura S, Harada H (2000) Treatment of sewage by a UASB reactor under moderate to low temperature conditions. Bioresour Technol 72:275–282

Van der Last ARM, Lettinga G (1992) Anaerobic treatment of domestic sewage under moderate climatic (Dutch) conditions using upflow reactors at increased superficial velocities. Wat Sci Technol 25:167–178

Van Lier JB, Rintala J, Sanz Martin JL, Lettinga G (1990) Effect of short-term temperature increase on the performance of a mesophilic UASB reactor. Water Sci Technol 22:183–190

Van Lier JB, Sanz Martin JL, Lettinga G (1995) Effect of temperature on the anaerobic thermophilic conversion of volatile fatty acids by dispersed and granular sludge. Water Res 30:199–207

Van Velsen AFM (1979) Adaptation of methanogenic sludge to high ammonia-nitrogen concentrations. Water Res 13:995–999

Veeresh GS, Kumar P, Mehrotra I (2005) Treatment of phenol and cresols in upflow anaerobic sludge blanket (UASB) process: a review. Water Res 39:154–170

Verrier D, Mortier B, Dubourguier HC, Albagnac G (1988) Adhesion of anaerobic bacteria to inert supports and development of methanogenic biofilms. In: Hall ER, Hobson PN (eds) Anaerobic digestion. Pergamon, Oxford, pp 61–70

Wiegant WM, Lettinga G (1985) Thermophilic anaerobic digestion of sugars in upflow anaerobic sludge blanket reactors. Biotechnol Bioeng 27:1603–1607

Wiegant WM, Zeeman G (1986) The mechanism of ammonia inhibition in the thermophilic digestion of livestock wastes. Agric Wastes 16:243–253

Yu HQ, Fang HHP, Tay JH (2000) Effect of Fe2+ on sludge granulation in upflow anaerobic sludge blanket reactor. Water Sci Technol 41:199–205

Yu HQ, Tay JH, Fang HHP (2001a) The roles of calcium in sludge granulation during UASB reactor start-up. Water Res 35:1052–1060

Yu HQ, Fang HHP, Tay JH (2001b) Enhanced sludge granulation in upflow anaerobic sludge blanket (UASB) reactors by aluminum chloride. Chemosphere 44:31–36

Zinder SH (1990) Conversion of acetic acid to methane by thermophiles. FEMS Microbiol Rev 75:125–138

Zinder SH, Anguish T, Cardwell SC (1984) Effects of temperature on methanogenesis in a thermophilic (58 °C) anaerobic digester. Appl Environ Microbiol 47:808–813

Acknowledgements

The authors gratefully acknowledge the sponsorship of this research provided by Swedish International Development Co-operation Agency (SIDA) through Asian Regional Research Program on Environmental Technology (ARRPET) coordinated by Asian Institute of Technology (AIT), Bangkok.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tiwari, M.K., Guha, S., Harendranath, C.S. et al. Influence of extrinsic factors on granulation in UASB reactor. Appl Microbiol Biotechnol 71, 145–154 (2006). https://doi.org/10.1007/s00253-006-0397-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0397-3