Abstract

Rhodococcus sp. strain DTB (DSM 44534) grows aerobically on diethylether as sole source of carbon and energy. Dense cell suspension experiments showed that the induced ether-cleaving enzyme system attacks a broad range of ethers like tetrahydrofuran, phenetole and chlorinated alkylethers including Cα-substituted alkylethers. Identification of metabolites revealed that degradation of the ethers started by an initial attack of the ether bond. Diethylether-grown cells degraded bis(4-chloro-n-butyl) ether via an initial ether scission followed by the transient accumulation of γ-butyrolactone as intermediate at nearly stoichiometric concentrations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chlorinated alkylethers are a relevant source of xenobiotic environmental pollutants which are produced industrially for various purposes or are unwanted by-products as has been reported for epichlorohydrin synthesis (De Leer 1985; ARGE 2002). However, microorganisms are able to cleave a wide range of ether structures by expressing different enzyme systems. This subject has been reviewed by White et al. (1996). Among the group of gram-positive bacteria, rhodococci have received an increased attention in the last decade because of their broad catabolic versatility (Bell et al. 1998). As a consequence, genetic engineering of Rhodococcus to use the organism as a biocatalyst for biotransformation or biodegradation processes is rapidly advancing (van der Geize and Dijkhuizen 2004).

Several rhodococci have been described to degrade ether compounds whereby the formation of a labile hemiacetal seems to be the common initial reaction. Oxidation of the fuel compound ethyl tert-butyl ether (ETBE) by a P-450 monooxygenase system, for example, has been reported for Rhodococcus ruber IFP 2001. The enzymes involved are encoded by the ethRABCD gene cluster (Chauvaux et al. 2001). Rhodococcus erythropolis K2-3 cleaves the ether bond of the phenoxybutyrate herbicides 4-(2,4-dichlorophenoxy) butyrate and 4-(4-chloro-2-methylphenoxy) butyrate by a soluble cytochrome P-450 (Sträuber et al. 2003), whereas Rhodococcus rhodochrous strain 116 induces even two distinct cytochrome P-450 enzymes for the O-dealkylation of 4-methoxybenzoate or 2-ethoxyphenol (Karlson et al. 1993). A so far uncharacterized hydroxylase is postulated for the degradation of the cyclic ether tetrahydrofuran (THF) by R. ruber 219 (Bock et al. 1995), and a putative O-dealkylase was suggested to operate in Rhodococcus sp. DEE5151 which accepts ether substrates with at least one unsubstituted Cα-methylene moiety as the main structural prerequisite (Kim and Engesser 2004). Rhodococcus sp. strain DTB degrades the chlorinated bis Cα-substituted alkylether bis(1-chloro-2-propyl) ether (DDE) and uses it as a sole source of carbon and energy (Moreno-Horn et al. 2003). The ether-cleaving activity of this strain is strongly inhibited by methimazole, a competitive inhibitor of flavin containing monooxygenases (Tomasi et al. 1995). Here we report the aerobic growth of Rhodococcus sp. strain DTB on diethylether as sole source of carbon and energy. Under this condition, an ether-cleaving enzyme is induced that attacks ether bridges of chlorinated alkylethers including Cα-substituted alkylethers, the cyclic ether THF and the alkyl-arylether phenetole. Their conversion by dense cell suspensions and the identification of intermediates allow to suggest a pathway for the degradation of bis(4-chloro-n-butyl) ether (BCBE) resulting in the transient accumulation of γ-butyrolactone.

Materials and methods

Growth and culture conditions

Rhodococcus sp. strain DTB (DSM 44534) was cultivated with diethylether (5 mM) as sole source of carbon and energy omitting the vitamin solution used previously (Moreno-Horn et al. 2003). For growth experiments with volatile substrates, 130-ml serum flasks were used that were crimp sealed with Teflon-lined rubber septa and contained 20 ml of mineral medium (pH 7.2) with appropriate substrate concentrations. To prevent oxygen limitation during growth, the oxygen demand was calculated, and a volume ratio of air to liquid phase was chosen as 5:1 (v/v) for up to 2 mM substrates. The cultures were inoculated with diethylether-pregrown cells unless indicated otherwise. An inoculum of 2% (v/v) was used, resulting in an initial density (OD620) of 0.01. “No growth” was defined as no increase in OD620 after 60 days of incubation. With ethanol as substrate, cells were grown in 2-l Erlenmeyer flasks containing 800 ml of mineral medium with 20 mM ethanol as sole source of carbon and energy. All experiments were set up as triplicate cultures unless indicated otherwise. For the production of biomass, Rhodococcus sp. strain DTB was grown in 4 l of mineral medium with 10 mM diethylether under conditions described previously (Moreno-Horn et al. 2003). The flasks were sealed with butyl rubber stoppers. Cells were harvested at late exponential growth phase at an optical density of 0.8–1.0 and either used immediately or stored at −20°C.

Analysis

Experiments with dense cell suspensions were performed as described previously at a cell concentration of about 1 mg dry wt ml−1 (Moreno-Horn et al. 2003). All degradation experiments were set up as triplicates if not noted otherwise, and heat-killed cells (100°C/15 min) were used as a control. To correct for evaporation of volatile compounds to the gas phase of the 5-ml vessels, non-inoculated samples were treated in the same way and analysed after appropriate time intervals. In addition, for detection and GC-MS confirmation of the metabolites, 4-chlorobutanol from BCBE degradation or γ-butyrolactone from THF degradation, dense cell incubations were performed in a larger scale as single experiments. Schott flasks (1-l) containing 100 ml of mineral medium and an increased cell concentration of 2 mg dry wt ml−1 were used. After incubation for an appropriate period of time, 50 ml of culture fluid was extracted with 5 ml of dichloromethane and concentrated by a continuous flash of N2 to a volume of 100 μl. The metabolites γ-butyrolactone and 4-chlorobutanol were identified by their gas chromatographic retention times and their electron-impact mass spectrometry (EI-MS) fragmentations that are identical with those of commercially available compounds, and EI-MS fragments were in accordance with the NIST data base. EI-MS of γ-butyrolactone resulted in the molecular ion at m/z (intensity in %)=86 ([M]+) (60) and major fragment ions at m/z=56 ([M–CH2]+) (50) and m/z=42 ([M–CO2]+) (100). EI-MS of 4-chlorobutanol resulted in major fragment ions at m/z=90 ([M–H2O]+) (15), m/z=55 ([M–H2O–Cl]+) (100) and m/z=49 ([CH2Cl]+) (30). The concentrations of all substrates and products were calculated using standard curves prepared with authentic compounds.

Enzyme activity

Etherolytic cleavage activity was determined at 28°C with dense cell suspensions measuring the disappearance of the ether compound by GC-FID analysis. Dry weight (dry wt) of cell suspensions was calculated from the optical density at 620 nm (OD620). An OD620 of 1 corresponds to a constant bacterial dry wt of 0.4 g l−1 at 105°C.

Chemicals

Bis(4-chloro-n-butyl) ether (BCBE), bis(2-chloroethyl) ether (BCEE), (+/−)-1,2-dichloroethyl-ethyl ether (DCEE), 2-chloroethyl-ethyl ether (CEE) and 4-hydroxybutyrate were purchased from Sigma-Aldrich. Bis(1-chloro-2-propyl) ether (DDE) was obtained from Suppelco. 4-Chlorobutanol and 1,4-butanediol were obtained from Fluka. 1,3-Dichloro-2-propyl-1′-chloro-2′-propyl ether (TClDE) with a purity of 85% was prepared as described previously (Garbe et al. 2004).

Results

Utilization of (chloroethyl) ethers

Rhodococcus sp. strain DTB grows on 10 mM diethylether as sole source of carbon and energy. When transferred to bis(1-chloro-2-propyl) ether (DDE), cells grown on diethylether started growth with a minimal lag phase and vice versa. Growth occurred also on ethanol at 20–30°C. No growth occurred at 37°C. At 25°C, the growth rates and growth yields were μ=0.027 h−1 (26 h doubling time) and Y x/c=0.95 g dry wt/g carbon for 10 mM diethylether, and μ=0.153 h−1 (4.5 h doubling time) and Y x/c=1.06 g dry wt/g carbon for 20 mM ethanol, respectively.

The organism failed to grow on 0.25–2.5 mM concentrations of ethoxyethanol, a possible hydroxylation product of diethylether, glycolic acid and the chlorinated ethylethers DCEE, CEE or BCEE. The halogenated ether cleavage intermediates 2-chloroethanol and 2-chloroacetaldehyde also did not serve as growth substrate.

Degradation of ether compounds

The substrate spectrum and activity of the ether-cleaving system induced during growth on diethylether were investigated by dense cell suspensions (Table 1).

The conversion of BCEE was accompanied by the formation of 2-chloroethanol. Within 30 min, 126 μM BCEE had vanished and a concentration of 100 μM 2-chloroethanol was found; BCEE was used up completely after 120 min. 2-Chloroacetaldehyde, the second metabolite that results from hemiacetal disproportionation, could not be analysed with the gas chromatographic system used.

DCEE was converted at a slower rate. After 90 min, 100 μM was used up and no further degradation was observed. TClDE (400 μmol) was converted within 240 min (1.8 mg dry wt ml−1), and the formation of chloroacetone and small amounts of 1-chloro-2-propanol were detected. From the compounds tested, BCBE showed the highest conversion rate and 4-chlorobutanol and γ-butyrolactone could be detected as products. Phenetole was also attacked, and its concentration decreased during incubation, but screening of the products phenol and acetaldehyde was not undertaken. The conversion of THF could be demonstrated by the formation of 20 μM γ-butyrolactone from a 2 mM solution after 3 h with 2 mg cell dry wt ml−1. The suspensions of Rhodococcus cells grown on diethylether also were able to convert all of the stereoisomers of DDE. As products, 1-chloro-2-propanol and chloroacetone were found like with DDE pregrown cells (Moreno-Horn et al. 2003). Methimazole inhibited the conversion of all the ethers investigated (data not shown).

Biotransformation of bis(4-chloro-n-butyl) ether

Dense cell suspensions of Rhodococcus sp. strain DTB pregrown on diethylether were used to study the BCBE degradation pathway. Disappearance of BCBE was accompanied by the delayed formation and transient accumulation of γ-butyrolactone. Within 60 min, 205 μM of the initial concentration of 225 μM BCBE was converted and about 290 μM γ-butyrolactone was formed. After additional 120 min, another 10 μM from the remaining 20 μM BCBE disappeared, whereas the concentration of γ-butyrolactone increased by 56 μM resulting in a total of about 350 μM γ-butyrolactone. Analysis of non-inoculated samples revealed an evaporation loss of BCBE from the liquid phase of about 33 μM after 180 min. Considering the loss of the ether, about 90% of BCBE had been converted to γ-butyrolactone, which is an almost stoichiometric formation of the product. The difference of 10% might be also caused by a slow degradation of the lactone. After 24 h, the accumulated γ-butyrolactone had been used up completely (data not shown).

Significant concentrations of 4-chlorobutanol were not detected during degradation of BCBE that can be interpreted as a result of the rapid conversion of this metabolite. The intermediate formation of 4-chlorobutanol as metabolite was verified by a separate experiment under large-scale conditions (see Materials and methods).

Incubation of the intermediate 4-chlorobutanol and the hypothetical intermediate 1,4-butanediol (each 250 μM) with dense cell suspensions (1.1 mg dry wt ml−1) resulted also in the formation of γ-butyrolactone suggesting the catabolic pathway. Both compounds were converted to γ-butyrolactone, although the yield observed (after 180 min) decreased in the order BCBE (90%)>4-chlorobutanol (51%)>1,4-butanediol (18%).

Even though Rhodococcus sp. strain DTB converted BCBE, it did not serve as growth substrate under standard conditions with 0.25–1 mM substrate concentration. Inoculation was performed with suspensions of cells pregrown on diethylether or γ-butyrolactone resulting in an initial OD620 of 0.01 or 0.2. When BCBE (0.5 mM) was supplemented as co-substrate to a 5 mM diethylether medium, the cells grew until the diethylether was depleted. Conversion of BCBE, which started within the beginning of the growth phase, and the transient formation of γ-butyrolactone could also be observed. However, 4-hydroxybutyrate or γ-butyrolactone at concentrations of 2 mM was used for growth by Rhodococcus cells, pregrown on diethylether after an extended lag phase of 14 days. 4-Chlorobutanol or 1,4-butanediol also supported growth, yet an even longer lag phase of 21 days was observed. Parallel cultures with 2 mM diethylether or 1 mM DDE as carbon source showed completion of growth after 3 days. After transfer of cells grown on 4-hydroxybutyrate into fresh medium with 4-hydroxybutyrate, immediate growth occurred without a lag phase. Also, Rhodococcus sp. strain DTB grown on γ-butyrolactone, 4-chlorobutanol or 1,4-butanediol resumed growth immediately after being transferred to fresh medium with the same carbon source. No growth occurred with 1–10 mM THF by diethylether or γ-butyrolactone pregrown cells inoculated at an initial OD620 of 0.01 or 0.2.

Discussion

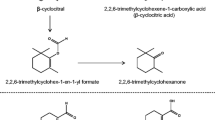

The present study describes the capability of diethylether-induced Rhodococcus sp. strain DTB to break down several ether pollutants of environmental relevance such as chlorinated alkylethers. A pathway for the conversion of bis(4-chloro-n-butyl) ether (BCBE) by ether scission, hydrolytic dehalogenation and the transient formation of γ-butyrolactone is suggested (Fig. 1).

Proposed transformation route of bis(4-chloro-n-butyl) ether (BCBE) into γ-butyrolactone by Rhodococcus sp. strain DTB. a1,4-Butanediol was not found as a metabolite during degradation but was converted to γ-butyrolactone by dense cell suspensions. bCompounds not found and commercially not available

Rhodococcus sp. strain DTB grows aerobically on diethylether as sole source of carbon and energy. Diethylether is cleaved into ethanol and acetaldehyde, for example, by the binuclear-iron toluene 2-monooxygenase (TMO) of Burkholderia cepacia G4/PR1 (Hur et al. 1997) and by the ammonia monooxygenase (AMO) of Nitrosomonas europaea (Hyman et al. 1994). The ability of Rhodococcus strains to grow on diethylether has been reported (Bock et al. 1995), and the degradation mechanism, e.g. O-dealkylation (Kim and Engesser 2004), was postulated, but the enzymes involved have not been characterized.

We suggest an analogous ether cleavage mechanism for Rhodococcus sp. strain DTB since the organism after growth on diethylether continued to grow after transfer onto ethanol but failed to do so when transferred to ethoxyethanol. Ethoxyethanol would result from hydroxylation of diethylether at a terminal methyl group (Hardison et al. 1997). In addition, BCEE cleavage by dense cell suspensions results in a significant formation of 2-chloroethanol; however, Rhodococcus sp. strain DTB failed to grow on BCEE and also on the degradation intermediate 2-chloroethanol. 2-Chloroacetaldehyde and a following dehalogenated metabolite, glycolic acid, were also not used as growth substrate. The strain also failed to grow on DCEE or CEE, although ethanol supports growth. The same phenomenon was observed with a toluene 2-monooxygenase constitutive derivate B. cepacia G4/PR1 that, after growth on diethylether, cleaved CEE into the four products acetaldehyde, ethanol, 2-chloroacetaldehyde and 2-chloroethanol but failed to grow on CEE. This was attributed to the toxicity of 2-chloroacetaldehyde since ethanol and acetaldehyde could serve as substrates (Hur et al. 1997). Rhodococcus sp. strain DDE5151 utilized CEE as sole source of carbon and energy but failed to grow with 2-chloroethanol or 2-chloroacetaldehyde (Kim and Engesser 2004). The authors concluded that the strain could use the non-halogenated ethyl moiety for growth. Nevertheless, there are several bacteria reported which can grow on 2-chloroethanol via 2-chloroacetaldehyde and glycolic acid (Dijk et al. 2003).

The failure of Rhodococcus sp. strain DTB to grow on BCBE presents a different situation. Unspecific AMO from N. europaea cleaves dimethylether and diethylether involving an O-dealkylation reaction into the corresponding alcohol and aldehyde products, but n-dipropyl and n-dibutylether were oxidized to hydroxyl compounds leaving the ether uncleaved (Hyman 1999). In contrast, we found that BCBE is converted by Rhodococcus sp. strain DTB into nearly stoichiometric amounts to γ-butyrolactone which indicates a specific hydroxylation at the carbon adjacent to the ether bridge. Dense cell experiments revealed that 4-chlorobutanol, which was also found as intermediate of BCBE scission, was converted into γ-butyrolactone albeit to a lesser extend. Also, 1,4-butanediol, which can result from hydrolytic dehalogenation, was transformed into γ-butyrolactone. Therefore, we suggest a pathway of BCBE degradation via ether scission and dehalogenation followed by oxidation and lactonisation (Fig. 1).

The organism does not grow on BCBE but has the ability to cleave the ether after growth on diethylether, and the organism grows with the identified intermediates 4-chlorobutanol or γ-butyrolactone and the likely intermediate 1,4-butanediol. A toxic effect of BCBE can be excluded because growth with diethylether is not inhibited in the presence of at least 0.5 mM BCBE. An explanation for the inability of the strain to use BCBE as sole carbon source is that the ether itself does not induce the ether-cleaving enzyme. Another reason could be that the ether cleavage products 4-chlorobutanol, 1,4-butanediol and γ-butyrolactone are favoured substrates which repress formation of the ether-cleaving system. The catabolic repression of less favourable substrates by other carbon sources has been described for gram-positive bacteria (Saier et al. 1996). In this case, the organism is caught and cannot escape from this impasse so that growth under standard conditions does not occur. Rhodococcus sp. strain DTB, however, is able to biodegrade the pollutant BCBE under co-metabolic conditions in the presence of diethylether as substrate.

Curragh et al. (1994) found that R. rhodochrous growing on 1-chlorobutane degrades the compound via butanol and butyric acid. The authors also found traces of γ-butyrolactone, which they contributed to chemical lactonisation of 4-chlorobutyrate into γ-butyrolactone. Further degradation of γ-butyrolactone was delayed and due to a slow induction of γ-butyrolactone catabolizing enzymes. This phenomenon is similar to our findings. Recently, we described that DDE-pregrown Rhodococcus sp. strain DTB shows diauxic growth (Moreno-Horn et al. 2003) when transferred to 0.8 mM DDE plus 0.6 mM 1-chloro-2-propanol, a product of DDE degradation. The cells stopped degrading DDE, and as soon as 1-chloro-2-propanol was spent, cells started again after a lag phase to degrade DDE. Rhodococcus sp. strain DTB does not grow on THF, but we detected small amounts of γ-butyrolactone as intermediate using dense cell suspensions of diethylether-grown cells after incubation with THF. With other bacteria, the formation of γ-butyrolactone from THF has been proposed to be the result of a hydroxylation to 2-hydroxytetrahydrofuran and subsequent oxidation (Bernhardt and Diekmann 1991; Kohlweyer et al. 2000). Hyman (1999) identified γ-butyrolactone after incubation of THF with alkane monooxygenase-induced Mycobacterium vaccae JOB-5. Conversion experiments with Rhodococcus sp. strain DTB revealed that among the alkylethers, the degradation rate decreased in the order BCBE>BCEE>DCEE indicating that chlorine substituents close to the functional ether group were lowering the activity of the ether-attacking enzyme system.

The results of this study demonstrated that the diethylether-induced enzyme of Rhodococcus sp. strain DTB catalyses the scission of a broad range of ether compounds including the bis Cα-substituted DDE, TClDE and the cyclic alkyl ether THF.

Rhodococcus sp. strain DTB might serve as an effective biocatalyst for the treatment of ether-contaminated sites.

References

ARGE Arbeitsgemeinschaft für die Reinhaltung der Elbe (2002) Chlorierte Ether in Wasser-und Fischgewebeproben der Elbe und ihrer Nebenflüsse 1992–2000. http://www.arge-elbe.de

Bell KS, Philp JC, Aw DWJ, Christofi N (1998) The genus Rhodococcus. J Appl Microbiol 85:195–210

Bernhardt D, Diekmann H (1991) Degradation of dioxane, tetrahydrofuran and other cyclic ethers by an environmental Rhodococcus strain. Appl Microbiol Biotechnol 36:120–123, DOI: https://doi.org/10.1007/BF00164711

Bock C, Kroppenstedt RM, Diekmann H (1995) Degradation and bioconversion of aliphatic and aromatic hydrocarbons by Rhodococcus ruber 219. Appl Microbiol Biotechnol 45:408–410, DOI: https://doi.org/10.1007/s002530050704

Chauvaux S, Chevalier F, Le Dantec C, Fayolle F, Miras I, Kunst F, Beguin P (2001) Cloning of a genetically unstable cytochrome p-450 gene cluster involved in degradation of the pollutant ethyl tert-butyl ether by Rhodococcus rubber. J Bacteriol 183:6551–6557, DOI: https://doi.org/10.1128/JB.183.22.6551-6557.2001

Curragh H, Flynn O, Larkin MJ, Stafford TM, Hamilton JT, Harper DB (1994) Haloalkane degradation and assimilation by Rhodococcus rhodochrous NCIMB 13064. Microbiology 140:1433–1442

De Leer EWB (1985) The identification of highly chlorinated ethers and diethers in river sediment near an epichlorohydrin plant. Water Res 19:1411–1419

Dijk JA, Stams AJ, Schraa G, Ballerstedt H, de Bont JA, Gerritse J (2003) Anaerobic oxidation of 2-chloroethanol under denitrifying conditions by Pseudomonas stutzeri strain JJ. Appl Microbiol Biotechnol 63:68–74, DOI: https://doi.org/10.1007/s00253-003-1346-z

Garbe L-A, Moreno-Horn M, Tressl R, Rewicki D, Görisch H (2004) Microbial desaturation of bis(1-chloro-2-propyl) ether into a dichloro vinyl ether. ChemBioChem 5:876–878, DOI: https://doi.org/10.1002/cbic.200300904

Hardison LK, Curry SS, Ciuffetti LM, Hyman MR (1997) Metabolism of diethyl ether and cometabolism of methyl tert-butyl ether by a filamentous fungus, a Graphium sp. Appl Environ Microbiol 63:3059–3067

Hur HG, Newman LM, Wackett LP, Sadowsky MJ (1997) Toluene 2-monooxygenase-dependent growth of Burkholderia cepacia G4/PR1 on diethyl ether. Appl Environ Microbiol 63:1606–1609

Hyman MR (1999) Final report: aerobic cometabolism of ether-bonded compounds, National Center for Environmental Research. EPA Grant Number: R823426, http://es.epa.gov/ncer/final/grants/95/envbio/hyman.html

Hyman MR, Page CL, Arp DJ (1994) Oxidation of methyl fluoride and dimethyl ether by ammonia monooxygenase in Nitrosomonas europaea. Appl Environ Microbiol 60:3033–3035

Karlson U, Dwyer DF, Hooper SW, Moore ER, Timmis KN, Eltis LD (1993) Two independently regulated cytochromes P-450 in a Rhodococcus rhodochrous strain that degrades 2-ethoxyphenol and 4-methoxybenzoate. J Bacteriol 175:1467–1474

Kim Y-H, Engesser K-H (2004) Degradation of alkyl ethers, aralkyl ethers, and dibenzyl ether by Rhodococcus sp. strain DEE5151, isolated from diethyl ether-containing enrichment cultures. Appl Environ Microbiol 70:4398–4401, DOI: https://doi.org/10.1128/AEM.70.7.4398-4401.2004

Kohlweyer U, Thiemer B, Schrader T, Andreesen JR (2000) Tetrahydrofuran degradation by a newly isolated culture of Pseudonocardia sp. strain K1. FEMS Microbiol Lett 186:301–306, DOI: https://doi.org/10.1016/S0378-1097(00)00161-0

Moreno-Horn M, Garbe L-A, Tressl R, Adrian L, Görisch H (2003) Biodegradation of bis (1-chloro-2-propyl) ether via initial ether scission and subsequent dehalogenation by Rhodococcus sp. strain DTB. Arch Microbiol 179:234–241, DOI: https://doi.org/10.1007/s00203-003-0522-y

Saier MH Jr, Chauvaux S, Cook GM, Deutscher J, Paulsen IT, Reizer J, Ye JJ (1996) Catabolite repression and inducer control in gram-positive bacteria. Microbiology 142:217–230

Sträuber H, Muller RH, Babel W (2003) Evidence of cytochrome P450-catalyzed cleavage of the ether bond of phenoxybutyrate herbicides in Rhodococcus erythropolis K2-3. Biodegradation 14:41–50, DOI: https://doi.org/10.1023/A:1023550209155

Tomasi I, Artaud I, Bertheau Y, Mansuy D (1995) Metabolism of polychlorinated phenols by Pseudomonas cepacia AC1100: determination of the first two steps and inhibitory effect of methimazole. J Bacteriol 177:307–311

van der Geize R, Dijkhuizen L (2004) Harnessing the catabolic diversity of rhodococci for environmental and biotechnological applications. Curr Opin Microbiol 7:255–261, DOI https://doi.org/10.1016/j.mib.2004.04.001

White GF, Russell NJ, Tidswell EC (1996) Bacterial scission of etherbonds. Microbiol Rev 60:216–232

Acknowledgements

This work was supported by funds from the “Bundesministerium für Wirtschaft und Arbeit” in the course of the research project no. 13556 of the “Arbeitsgemeinschaft industrieller Forschungsvereinigungen—Otto von Guericke e.V. (AiF).”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moreno-Horn, M., Garbe, LA., Tressl, R. et al. Transient accumulation of γ-butyrolactone during degradation of bis(4-chloro-n-butyl) ether by diethylether-grown Rhodococcus sp. strain DTB. Appl Microbiol Biotechnol 69, 335–340 (2005). https://doi.org/10.1007/s00253-005-1984-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-005-1984-4