Abstract

Combining high-throughput growth physiology and global gene expression data analysis is of significant value for integrating metabolism and genomics. We compared global gene expression using 500 ng of total RNA from Escherichia coli cultures grown in rich or defined minimal media in a miniaturized 50-μl bioreactor. The microbioreactor was fabricated out of poly(dimethylsiloxane) (PDMS) and glass and equipped to provide on-line, optical measurements. cDNA labeling for microarray hybridizations was performed with the GeniconRLS system. From these experiments, we found that the expression of 232 genes increased significantly in cells grown in minimum medium, including genes involved in amino acid biosynthesis and central metabolism. The expression of 275 genes was significantly elevated in cells grown in rich medium, including genes involved in the translational and motility apparatuses. In general, these changes in gene expression levels were similar to those observed in 1,000-fold larger cultures. The increasing rate at which complete genomic sequences of microorganisms are becoming available offers an unprecedented opportunity for investigating these organisms. Our results from microscale cultures using just 500 ng of total RNA indicate that high-throughput integration of growth physiology and genomics will be possible with novel biochemical platforms and improved detection technologies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Global gene expression analysis using DNA microarrays is a technique widely applied in general biological research and in specialized fields such as drug screening, environmental testing, and clinical diagnosis (Debouck and Goodfellow 1999; Bodrossy and Sessitsch 2004). The ability to combine global gene expression analysis and high-throughput screening of microbial growth parameters allows the simultaneous rapid characterization of microbial strains at the physiological and molecular levels. The increasing availability of complete genomic sequences of microorganisms offers the unprecedented opportunity for detailed investigations of the functioning of these organisms. Genomic expression assays provide the ability to look at a single aspect of physiology and to see the interaction of those genes and operons with every other aspect of physiology.

To reach the goal of a rapid and informative high-throughput screening technology there remain two significant obstacles: first, as the techniques for DNA microarrays continue to be developed, an ongoing need persists for methods of performing microarrays on very small samples of bacterial cultures, and second, of the many metabolic and genetic experiments that can now be designed and performed in bacteria, only a small fraction can be tested using standard culture systems. The number of culture conditions that can be tested using tubes, flasks, and bench-scale bioreactors (with volumes of 0.5–10.0 l) is limited by the time required to obtain sufficient data, the effort required to obtain reproducible data, and the high costs of operation. In microbiological research, there clearly exists a need for a biochemical platform with integrated sensors yielding real-time data on process parameters. This allows high-throughput, parallel, and automated processing of a variety of microbial cultures under a variety of controlled conditions. Multidisciplinary efforts that link engineering and biology are generating novel miniaturized bioreactor platform devices that enable the production of multiple disposable bioreactor units for high-throughput data analysis (Kostov et al. 2001; Lamping et al. 2003; Maharbiz et al. 2004; Zanzotto et al. 2004). The 50-μl bioreactor platform, recently described by Zanzotto et al. (2004), is a step toward a system that can be economically scalable and can generate real-time data for optical density (OD), pH, and dissolved oxygen (DO), thereby offering the advantages of high-throughput processes in terms of labor, time, reproducibility, and cost.

We demonstrated (Zanzotto et al. 2004) that Escherichia coli cultures grown in the 50-μl microbioreactor platform exhibit reproducible growth characteristics in complex and minimal media, including OD, pH, and DO time-courses, as well as cell number and morphology, substrate uptake, and organic acid production. In these respects, growth of E. coli mimics that seen in conventional culture conditions (e.g. shake-flasks). They also demonstrated that serial harvest of microbioreactors was a feasible way to obtain samples for off-line analysis. The microbioreactor was fabricated out of poly(dimethylsiloxane) (PDMS) and glass, using soft lithography and was equipped with on-line measurements for OD, pH, and DO. Aeration of cultures was through a gas-permeable PDMS membrane.

In the present study, we sought to determine whether our microbioreactor format can be used to study global gene expression using DNA microarrays, as a step toward integrating high-throughput transcription profiling and bacterial fermentation analysis. To perform DNA microarray analysis for gene expression profiling, we used resonance light scattering (RLS) labeling technology. While microarray analysis is now well established, the technology continues to evolve, particularly toward an ongoing need for more sensitive methods and amplification techniques (Loge et al. 2002; Call et al. 2003). Current protocols for prokaryotic DNA microarrays require 5–10 μg of total RNA as starting material. Bao et al. (2002) reported the high-sensitivity detection of DNA hybridization on microarrays of human genes using RLS technology, by labeling the cDNA with colloidal metal particles (40–120 nm diam.), which scatter light. As detailed by Yguerabide and Yguerabide (2001), the light-emitting power of a single RLS particle label is an order of magnitude greater than fluorescent labels such as Cy3 and Cy5. More recently, Francois et al. (2003) were able to detect and identify bacterial pathogens with the RLS system from small culture volumes, starting with only 10–500 ng of total RNA. We performed global gene expression analysis using 500 ng of total RNA from E. coli cultures grown in LB medium and in defined minimal medium in the 50-μl bioreactor, using the GeniconRLS system (Invitrogen) for cDNA labeling. The data compare favorably with similar microarray studies conducted on bacterial cultures grown at larger scales. Our growth conditions were chosen based upon two earlier studies which compared gene expression in E. coli grown in 50-ml volumes of the same media (Tao et al. 1999; Wei et al. 2001), and their findings can be used to validate our experiments.

Materials and methods

Organism and growth conditions

E. coli FB21591 (thiC∷Tn5-pKD46, Kan), obtained from the E. coli Genome Project at the University of Wisconsin (http://www.genome.wisc.edu), was used in all experiments. Cultures were grown in LB medium or defined minimal medium (DM), both supplemented with 10 g/l glucose. The composition of LB was: 10 g/l tryptone (Difco Laboratories, Sparks, Md.), 5 g/l yeast extract (Difco), 5 g/l NaCl. Following sterilization, the medium was supplemented with final concentrations of 10 g/l glucose (Mallinckrodt, Phillipsburg, N.J.), 100 mM MES buffer (pH 6.9; Sigma, St. Louis, Mo.), and 100 μg/ml kanamycin (Sigma). The 40% (w/v) glucose stock was autoclaved for 20 min at 120°C, 150 kPa; and the MES (2 M) and kanamycin (100 mg/ml) stocks were filter-sterilized. The composition of the DM was: 60 mM K2HPO4, 35 mM NaH2PO4, 15 mM (NH4)2SO4, 70 mM NH4Cl, 0.8 mM MgSO4·7H2O, 0.06 mM Ca(NO3)2·4H2O, 20 mM FeCl3, 0.003 μM (NH4)6Mo7O24·4H2O, 0.4 μM H3BO3, 0.01 μM CuSO4·5H2O, 0.08 μM MnCl2·4H2O, 0.01 μM ZnSO4·7H2O, 10 g/l glucose, 100 μM thiamine, 100 mM MES (pH 6.9), 100 μg/ml kanamycin. Glucose, MES, and kanamycin were added to DM as stock solutions, as described for the LB medium. Thiamine was also added as stock solution (100 mM, previously filter-sterilized).

For inoculum preparation, the strain was first adapted to LB or DM as follows: 5 ml of LB were inoculated with a single colony from an overnight LB-kanamycin agar plate and incubated at 37°C on a roller drum at 60 rpm. At an OD600 of 1.0±0.1, 1.6 ml were used to inoculate 30 ml of fresh LB or DM in 500 ml baffled shake-flasks and incubated at 37°C on a horizontal rotary shaker at 150–200 rpm until the OD600 reached about 1.0. At this point, the culture was diluted in fresh LB or DM to reach an OD600 of about 0.05 and used to inoculate the microbioreactors.

Microbioreactor fermentations

Microbioreactors (Fig. 1) fabricated from PDMS and glass (Zanzotto et al. 2004) were utilized for all fermentations. A separate microbioreactor was fabricated for each experiment. The bottom layer in which the sensors were embedded, the body of the fermentor, and the aeration membrane were made of PDMS. The base support of the bioreactor was made of glass, which provided the necessary rigidity and the optical access. The working volume of the microbioreactor was 50 μl. Optical sensing methods were selected to monitor OD, DO, and pH. The bottom layer of the microbioreactor contained two sensor foils (PreSens, Regensburg, Germany), one for DO and one for pH. The OD600 was used to monitor biomass. Light from an orange LED (L600-10 V, 600 nm; Epitex, Kyoto, Japan) was passed through the microbioreactor, collected by a collimating lens (F230 SMA-A; Thorlabs, Newton, N.J.), and sent to a photodetector (PDA55; Thorlabs). The OD600 was calculated using Eq. 1.

Schematic of the microfermentor and experimental set-up. After inoculation, a single microbioreactor is placed inside the chamber, which is kept at 100% humidity and 37°C. Three optical fibers carry three different wavelengths of light to the bottom of the microbioreactor for the three measurements: OD, DO, and pH. Photodetectors collect the transmitted or emitted light and send it to a lock-in amplifier, where the signal is detected and analyzed

In Eq. 1, I signal is the intensity of the signal and I reference is the intensity of the first measurement for a given experiment. The multiplication factor of 33.33 in Eq. 1 is used to normalize the data for the microbioreactor pathlength (300 μm), which enables direct comparisons with results from conventional cuvettes with pathlengths of 1 cm. This adjustment is only strictly valid if the absorption and light scattering by the cell culture are in a linear range. A calibration of OD measurements in the microbioreactor was performed using serial dilutions of an E. coli culture grown to an OD600 of about 7.0. The OD600 measurements of diluted cultures were made in the microbioreactor to a depth of 300 μm, using a Spectronic 20 Genesys spectrophotometer (Spectronic Instruments, Rochester, N.Y.). The calibration data (Fig. 2) produced a linear fit with a slope close to 1.0.

Calibration curve for OD measurements in the microbioreactors. A dilution series of E. coli cells was used to compare direct measurements in a spectrometer with pathlength-adjusted measurements in the microbioreactor. The OD was measured at 600 nm in both systems; and the OD in the microbioreactor was adjusted to a pathlength of 1 cm (from 300 μm)

All instruments were PC-controlled under a LabVIEW software routine (National Instruments, Austin, Tex.), which allowed for automated and on-line measurements of OD600, pH, and DO every 10 min.

Each fermentation data set was obtained from an independent fermentation derived from a single colony inoculum and run in a single microbioreactor.

Experiments were carried out in an airtight, aluminum chamber (Fig. 1), which allowed control of humidity and the composition of the gas above the microbioreactor membrane; it also provided a large thermal mass, which stabilized the temperature at the desired set-point of 37°C. Temperature was controlled by circulating water at 37°C through the chamber base. In addition to controlling environmental parameters, the chamber provided optical isolation and optical access from directly above and below the microbioreactor.

The microbioreactor was inoculated from outside of the chamber by injection with a 1-ml syringe, equipped with a 23 gauge needle, through the microbioreactor side-channels (Fig. 1). The needle holes created in the channels were then sealed with epoxy and the microbioreactor secured to the base of the chamber. Open reservoirs of water were placed inside the chamber to provide humidity. Maintaining high humidity within the chamber minimized evaporation loss through the PDMS membrane. The chamber was then closed and real-time data collection initiated. Sterility was maintained through the addition of the antibiotic kanamycin to the growth medium. Additional details of the microbioreactor and its set-up are described by Zanzotto et al. (2004).

Total RNA isolation

Total RNA was isolated from three independent 50-μl fermentations in LB and three in DM. To isolate total RNA from 50-μl cultures, we developed the following procedure. Cells were harvested during exponential growth at OD600∼1.0, typically at a population density of 2–4×109 cells/ml; and thus ∼1–2×108 cells were recovered from 50 μl. To harvest cultures, the incubation chamber was opened and the entire culture withdrawn from the microbioreactor through the PDMS membrane, using a 200-μl Pipetman. The samples were transferred immediately to 1.5-ml Eppendorf tubes containing 2 vol. of RNAprotect Bacteria (Qiagen, Valencia, Calif.) for RNA stabilization. After 5 min of incubation at room temperature, cells were pelleted and resuspended in 200 μl of TE (10 mM Tris·HCl, 1 mM EDTA, pH 8.0) containing lysozyme (15 mg/ml) and incubated for 20 min at room temperature on a Nutator (Becton Dickinson, Parsippany, N.J.) for gentle mixing. The samples were then transferred to 2-ml tubes (Sarstedt, Newton, N.C.) containing 50 mg of acid-washed zirconia/silica beads (0.1 mm diam.; Biospec Products, Bartesville, Okla.) and lysed in a FastPrep FP120 beadbeater (Qbiogene, Carlsbad, Calif.) for 90 s at maximum speed. We found that we obtained consistently higher yields and better RNA quality when we performed a combination of enzymatic and mechanical cell disruption. Total RNA isolation was performed using an RNeasy kit (Qiagen) by loading the lysed sample, without the beads, directly onto RNeasy columns and then following the manufacturer’s protocol. The concentration and quality of the purified RNA was assessed by determination of the OD ratio at 260 nm/280 nm and analysis using an Agilent 2100 Bioanalyzer (Palo Alto, Calif.). RNA samples were stored at −80°C. The average yield of total RNA from 50 μl of E. coli culture grown in LB or DM to an OD600 of about 1.0 was approximately 3 μg and 1 μg, respectively.

Microarray hybridizations and analysis

DNA microarrays were printed at the MIT BioMicro Center (Cambridge, Mass.) with a BioRobotics MicroGrid Two printer (Genomic Solutions, Ann Arbor, Mich.) on Corning GAPS slides (Acton, Mass.) with a 50-mers oligo set (MWG-Biotech, High Point, N.C.) composed of 4,288 gene-specific oligonucleotide probes representing the complete E. coli (K12) genome.

Microarray hybridizations were performed with the GeniconRLS two-color array detection system (Invitrogen, Carlsbad, Calif.), based on RLS technology. From each fermentation, 500 ng of total RNA were used to generate cDNA labeled with biotin-16-dUTP (Enzo Life Sciences, Framingdale, N.Y.) for LB samples and fluorescein-12-dUTP (Roche, Indianapolis, Ind.) for DM samples. Direct labeling was performed with the LabelStar kit (Qiagen), using a modified protocol as follows. For each of the biotin-labeled reactions, the labeling mix contained the following components: 5 μl of 10× buffer, 5 μl dNTP-Mix H, 1 μl of biotin-labeled dUTP, 1 μl of random DNA hexamers (Roche Diagnostic, Indianapolis, Ind.), 0.5 μl of RNase inhibitor, 2.5 μl of LabelStar reverse transcriptase, 15 μl of RNase-free water, and 20 μl of denatured RNA template. The fluorescein-labeled mixes were prepared as described for the biotin-labeled mixes, except that 2 μl of fluorescein-labeled dUTP and 14 μl of RNase-free water were used. dNTP mixes contained dATP, dCTP, dGTP (0.5 mM each), and 0.04 mM dTTP. RNA templates were denatured before cDNA labeling by adding 2 μl of denaturation solution to 18 μl of RNA sample, followed by incubation for 5 min at 65°C in a water bath and subsequent cooling on ice.

Labeling mixes were incubated for 2 h at 37°C in a thermocycler with a hot lid. Then, 1 μl of dTTP (20 mM) was added to each labeling mix and incubation at 37°C was continued for 1 h. Reactions were then stopped with the addition of 2 μl of stop solution LS (Invitrogen). Purification of labeled cDNA was performed immediately, using the LabelStar kit (Qiagen) as directed, except that each of the six samples was purified independently. Also, in the final step of the purification, each column was eluted twice with 50 μl of EB (Qiagen). Each labeled cDNA sample (100 μl) was then diluted with 400 μl of RNase-free water. One labeled cDNA sample generated from a LB culture and one labeled cDNA sample generated from a DM culture were pooled and concentrated to 12 μl with a Microcon Y-30 0.5-ml column (Millipore, Bedford, Mass.) as directed by the manufacturer.

Before hybridization, microarray slides were baked in an oven at 80°C for 2 h. After cooling, the slides were cross-linked with UV light in a Stratalinker 2400 (Stratagene, La Jolla, Calif.) at 300 mJ. Slide prehybridization was performed as recommended by the manufacturer: incubated for 30 min at 42°C in a polypropylene slide mailer filled with 25 ml of pre-hybridization solution, washed twice in deionized water at room temperature, and dried with a stream of filtered nitrogen gas.

We performed three co-hybridizations, in each case comparing LB and DM fermentations on a single array (Fig. 4). The hybridization mixes (25 μl) contained 12.5 μl of hybridization solution (pre-heated to 42°C), 0.5 μl of hybridization blocker (salmon sperm DNA, 10 mg/ml), and 12 μl of labeled target cDNA (biotin-, fluorescein-labeled cDNA). We used a smaller volume than the one recommended in the protocol, since we used lifter slips (Erie Scientific, Portsmouth, N.H.) of smaller dimensions (24×24 mm). Hybridization mixes were incubated at 95°C for 5 min. Before hybridization, the lifterslips were washed first with deionized water, then with 70% ethanol, and finally dried with a stream of filtered nitrogen gas. The lifterslips were then placed over the arrays and the hot (95°C) hybridization mix was added to one of the free edges of the lifterslip, to flood the array area by capillary action. The slides were placed in ArrayIt hybridization cassettes (TeleChem International, Sunnyvale, Calif.), together with 250 μl of water for humidity control, and placed in a 42°C incubator overnight. Post-hybridization washes were performed as directed. Microarray slides were then blocked in 25 ml of blocking solution (Invitrogen) for 2 min at room temperature. The slides were then placed on a wet paper towel and placed in a Tupperware container, which functioned as a hydration chamber. Each array was covered with 45 μl of the RLS particle mix, composed of 15 μl of AntiBiotin RLS particle Au (gold), 15 μl of AntiFluorescein particle Ag (silver), and 15 μl RLS particle diluent. Lifterslips were washed and dried as described above and carefully lowered over the array area. Microarray slides were then incubated in the hydration chamber for 1 h. The RLS particle wash was performed as directed with wash solutions, using a squirt bottle and a slide mailer. Following final washes in a glass tank with deionized water, the slides were dried with a stream of filtered nitrogen gas and archived in 25 ml of archiving solution (Invitrogen) and dried for about 2 h in a laminar flow hood.

To determine spot intensities, microarray slides were scanned in a GSD-501 RLS detection and imaging instrument (Invitrogen) and image data were calculated using MolecularWare software (Cambridge, Mass.).

To obtain normalized ratios from the two fluorescence intensity channels, we performed rank-invariant intensity-dependent non-linear normalization LOWESS (Tseng et al. 2001) on the intensity data of each array, using the lcDNA ver. 0.03 program (Hyduke et al. 2003). Normalized intensity ratios were calculated, using DM as numerator and LB as denominator. The two growth conditions were compared by determining mean log2 intensity ratios across the three replicates. Genes were considered upregulated if the log2 ratio of DM intensity (positive numbers) over LB intensity (negative numbers) for each ORF was greater than +1 or less than −1. The complete set of gene expression data can be viewed on the NCBI gene expression omnibus web site (http://www.ncbi.nlm.nih.gov/geo/, accession number GSE1981). Pearson’s correlation coefficients were calculated using the three normalized log ratios to determine the concordance among the microarrays (Table 1).

For gene annotation, E. coli sequences were compared to proteins in the cluster of orthologous group (COG) database (Tatusov et al. 1997) using the BlastP sequence similarity search program (Altschul et al. 1997). Assignment to a particular COG group was made by transferring the COG function of the top alignment to the E. coli protein. This allowed a high-throughput annotation of gene functions.

Results

Triplicate fermentations of E. coli grown in LB and DM in 50-μl microbioreactors with on-line measurements for OD600, pH, and DO are shown in Fig. 3. All fermentations were independent (inoculum derived from a single colony) and run in single microbioreactors on different days. As expected (Cooper 1991), in the microbioreactors E. coli grew faster in rich than in minimal medium, with average generation times of 28.8±3.2 min and 45.3 ±2.1 min in LB and DM, respectively. Also as expected, oxygen depletion and acidification of the medium occurred earlier in LB cultures than in DM cultures, since growth was more rapid in rich medium. Growth patterns across the three fermentations in each medium were reproducible. To investigate global gene expression in cells grown in our miniaturized 50-μl bioreactors, we carried out triplicate fermentations in DM and LB. Cells for RNA isolation were harvested when the cultures reached an OD600 of about 1.0. At this population density, the average pH of both media was about pH 6.6 and the DO concentrations were on average 60–80% in DM and 40–60% in LB, where 100% was the oxygen concentration of saturated medium in equilibrium with air.

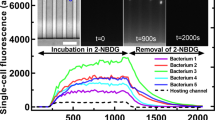

To assess gene expression profiles under the two growth conditions, we identified upregulated genes by taking the log2 ratio of the spot mean intensities of DM over LB (Fig. 4). The Pearson’s correlation coefficient among the three microarrays replicates was about 0.82 for all three arrays (Table 1). Table 2 summarizes the numbers of upregulated genes under the two growth conditions, annotated by functional group and class. The total number of upregulated genes in the two media was 507, of which 232 were upregulated in DM and 275 in LB (Table 2). When E. coli was grown in DM, a larger number of “Metabolism” genes was upregulated, while in LB more “Cellular processes” and “Information storage and processing” genes were upregulated.

E. coli microarrays (left) hybridized with cDNA obtained from 500 ng of total RNA from cultures grown in 50-μl microbioreactors in DM (green) and LB (red). Normalized mean spot intensities averaged from three replicates from each of the two growth conditions were plotted against each other (right); and the log2 ratios of DM (green) over LB (red) intensities were binned to identify genes upregulated more than two-fold

These results were expected, since E. coli growing on glucose (DM) as sole carbon and energy source must generate de novo building blocks (i.e. amino acids, vitamins, nucleosides, etc.) for macromolecular synthesis. But E. coli grows more rapidly in LB, since the building blocks for macromolecular synthesis are provided by yeast extract and tryptone, and both transcrption and translation are expected to be upregulated (Gaal et al. 1997).

The total number of upregulated genes in the “Metabolism” functional group, in E. coli grown in DM versus LB was 96 and 49 respectively (Table 3). The major differences arose in the two functional classes “Amino acid transport and metabolism” and “Energy production and conversion”. Specifically, in DM, 48 “Amino acid transport and metabolism” genes were upregulated, including genes involved in the synthesis of all 20 amino acids found in proteins (Table 3). For example, three genes for proline biosynthesis (proVWX) were strongly upregulated, with proX showing the most significant increase in this functional class. Other genes highly upregulated in DM were leuB (responsible, with leuACD, for leucine biosynthesis), the three genes of the thrABC operon for threonine biosynthesis, four genes (aroCFGL) for the synthesis of chorismate (a central intermediate in aromatic amino acids biosynthesis), and seven genes (cysACDHJMP) for the synthesis and metabolism of cysteine.

In LB medium, only ten genes in the functional class “Amino acid transport and metabolism” were upregulated, none of which are involved in amino acid biosynthesis but four of which are involved in amino acid degradation: sdaB and yhaP (glycine), tnaA (tryptophan) and tdcB (threonine).

In the functional classes “Carbohydrate transport and metabolism” and “Energy production and conversion”, again a larger number of genes was upregulated in DM than in LB (Table 3). In DM cultures, genes involved in acetate utilization and the glyoxylate shunt (aceA, aceB, gltA), those in the tricarboxylic acid cycle, [e.g. citrate synthetase (sdhAD), succinyl-CoA synthetase (sucCD), and the NADH dehydrogenase genes (nuoBEGHI) involved in oxidative phosphorylation and ubiquinone biosynthesis were upregulated. Also upregulated were genes and operons involved in galacitol and tagatose transport and metabolism (gatACDYZ) and in glycolysis, such as glyceraldehyde 3-phosphate dehydrogenase (gapC 1) and pyruvate kinase (pykF).

During growth in LB, the most strongly upregulated genes belonging to the two functional classes “Carbohydrate transport and metabolism” and “Energy production and conversion” were those involved in the expression of the phosphotransferase system (PTS) protein N-acetyl glucosamine (agaCDW) and another PTS protein that is glucose-specific (ptsG).

In contrast, compared with growth in DM, the E. coli cells grown in LB had a larger number of genes categorized as “Cellular processes” that were upregulated (Table 2). The marked differences within this functional group were in the functional class “Cell motility and secretion”, where E. coli grown in LB exhibited 17 upregulated genes (Table 4), with eight of these involved in flagellum assembly (fliACNS, flgACEK) and five involved in chemotaxis (cheAYZ, tar, motB), indicating that the strain grown in rich medium at an OD of 1.0, was actively motile.

As expected, higher expression of genes from the group “Information storage and processing” was observed in LB than in DM (35 vs 21; Table 2). Indeed, E. coli divides more rapidly in LB than in DM and faster-growing cultures synthesize protein at a higher rate than the slower-growing ones (Grunberg-Manago 1996; Keener and Nomura 1996; Gaal et al. 1997). Of the 35 “Information” genes upregulated in LB medium, most (22) belonged to the “Transcription” functional class (Table 2). Among the more strongly expressed were hcaR (Table 5), a transcriptional regulator of the LysR family that controls the hca cluster for propionate catabolism (Diaz et al. 1998), and iclR, a repressor of the aceBA operon that mediates acetate utilization. Accordingly, the aceBA genes were strongly upregulated in E. coli grown in DM (Table 3).

In DM, rpoS, which encodes the RNA polymerase sigma subunit regulating many cellular responses to environmental stress (Hengge-Aronis 1993; Loewen and Hengge-Aronis 1994), was strongly expressed (Table 5), in agreement with the reports of Tao et al. (1999) and Wei et al. (2001), and suggests that RpoS regulation may be important not only during the transition between the exponential and stationary phases, but also in the early and late logarithmic phases. Other genes that exhibited upregulation in DM were narP, a nitrate/nitrite response regulator belonging to the LuxR/UhpA family of the two-component regulatory system controlling the expression of several genes involved in anaerobic fermentation and respiration (Rabin and Stewart 1993), and uhpA of the two-component regulatory system UhpB/UhpA, involved in the uptake of hexose phosphates (Dahl et al. 1997).

Discussion

Rapid screening for microorganisms exhibiting specific patterns of gene expression and protein production is critical for progress in microbiology, biotechnology, and the pharmaceutical industry. We used a novel microbioreactor platform that is scalable and has the advantage of providing real-time data on bacterial growth parameters for OD600, pH, and DO. E. coli cultures grown in this microbioreactor platform exhibited growth patterns that are comparable with those from bench-scale 500-ml bioreactors (Zanzotto et al. 2004). Microbioreactors have the potential to provide much of the data and functionality that a large bioreactor system does, while offering the advantages of scale for high-throughput processes. Also, the use of microbioreactors is of increasing value, since recent advances in molecular biology make it possible to create large numbers of evolved biocatalysts, new pathway designs, and to discover a variety of unique biological organisms from diverse sources. It is likely that microbioreactors with integrated sensors and actuators will be the driving force behind research in high-throughput screening for general biological research.

Our aim was to demonstrate that the microbioreactor platform we had previously described (Zanzotto et al. 2004) can be used not only to grow potentially large numbers of microbial strains to study their physiology, but also to link this real-time information to global gene expression analysis. To this end, we performed a microarray analysis on 500 ng of total RNA from E. coli cultures grown in LB medium and in minimal medium (DM) in an instrumented 50-μl bioreactor, using the RLS system for cDNA labeling. Two previous studies (Tao et al. 1999; Wei et al. 2001) reported microarray analysis on E. coli MG1655 grown in rich and minimal media in 50-ml batch culture in 250-ml Erlenmeyer flasks. The two studies then used different methods for microarray analysis. Tao et al. (1999) used 1 μg of total RNA (with 32P-dCTP to label cDNA) and Nylon DNA arrays; and Wei et al. (2001) used 6 μg of total RNA, Cy3 and Cy5 fluorophores to label cDNA, and printed microarrays with PCR-amplified ORFs.

The two studies reached similar general conclusions indicating that, in E. coli grown in minimal medium, metabolic genes for processes such as amino acid biosynthesis and energy production and conversion are upregulated, while in cultures grown in rich medium, genes involved in translation and ribosome structure and biogenesis are stimulated. These results confirm general predictions that bacteria grown in minimal media must generate the monomers needed to build macromolecules de novo, whereas in conditions that support rapid growth they increase the assemblage of ribosomes and translation factors de novo.

In our miniaturized system, we found that E. coli grown in minimal medium, with glucose as sole carbon and energy source, upregulated a large number of genes involved in amino acid biosynthesis, energy production, and energy conversion. This parallels the two large-scale studies described above, in which threonine, phenylalanine, leucine, serine, tryptophan, isoleucine/valine, and histidine biosynthesis genes were over-expressed. Other similarities included the overexpression of aceAB, involved in acetate metabolism, and rpoS, a global gene expression regulator. Several additional genes that were upregulated in minimal medium in our microbioreactors were also upregulated in minimal medium in at least one of the two studies mentioned.

However, we found some differences with reported results (Tao et al. 1999; Wei et al. 2001) in the gene expression profiles of E. coli cultures grown in LB. One was the clear upregulation of genes for chemotaxis and motility in our system. Our result was, however, expected since E. coli is motile in LB but not in minimal medium due to catabolite repression by glucose (sole carbon source) in the medium (Silverman and Simon 1974). Also in our study, we did not observe large differences between cells grown in LB versus DM in their expression of the genes for translational apparatus, ribosomal structure, and biogenesis. This dissimilarity with previous reports may be attributable to differences in growth and analytical conditions, such as medium composition, phase of physiological growth at which cells were harvested, type of microarray platform used, etc. It could also be due to the cDNA labeling system that we used. At the time of our investigations, the RLS system had proven to be sufficiently sensitive to obtain gene expression profiles of human genes (Bao et al. 2002) and we were among the first to apply it to bacterial cultures. In a more recent study, the RLS system was used to efficiently detect bacterial cultures down to 105 cells (Francois et al. 2003). In our experiments with RLS, we found some variability between replicates. Also, we were not able to confirm all of our results in dye-swap experiments (data not shown) and excluded these data from the analysis. We believe that these difficulties may be due to the facts that: (1) we were using much more complex arrays than Francois et al. (2003), who tested a limited number of ORFs and used a single RLS label (gold), and (2) the RLS system may require optimization to perform a global gene expression analysis. Nevertheless, it was useful in our proof of concept study of cDNA arrays from small volume bacterial cultures.

In summary, we have shown that microbioreactors can be used to reproducibly grow bacterial cultures, we have developed protocols to isolate high-quality total RNA from small volumes of cultures grown in microbioreactors, and we have performed differential gene expression analysis in E. coli grown under two different conditions in microbioreactors equipped with real-time monitoring of growth parameters. In general, E. coli exhibited gene expression profiles that were predicted for growth under the conditions tested, essentially in agreement with data from 1,000-fold larger culture volumes.

The ability to obtain reliable data from 50-μl cultures demonstrates that, in the future, rapid screening of metabolic and genomic data will be possible with the use of scalable microbioreactor platforms and improvements in technology that increase the sensitivity of microarrays.

References

Altschul SF, Madden TL, Schaffer AA, Zhang J, Zhang Z, Miller W, Lipman DJ (1997) Gapped BLAST and PSI-BLAST: a new generation of protein database search programs. Nucleic Acids Res 25:3389–3402

Bao P, Frutos AG, Greef C, Lahiri J, Muller U, Peterson TC, Warden L, Xie XY (2002) High-sensitivity detection of DNA hybridization on microarrays using resonance light scattering. Anal Chem 74:1792–1797

Bodrossy L, Sessitsch A (2004) Oligonucleotide microarrays in microbial diagnostics. Curr Opin Microbiol 7:245–254

Call DR, Borucki MK, Loge FJ (2003) Detection of bacterial pathogens in environmental samples using DNA microarrays. J Microbiol Methods 53:235–243

Cooper S (1991) Synthesis of the cell surface during the division cycle of rod-shaped, gram-negative bacteria. Microbiol Rev 55:649–674

Dahl JL, Wei BY, Kadner RJ (1997) Protein phosphorylation affects binding of the Escherichia coli transcription activator UhpA to the uhpT promoter. J Biol Chem 272:1910–1919

Debouck C, Goodfellow PN (1999) DNA microarrays in drug discovery and development. Nat Genet 21:48–50

Diaz E, Ferrandez A, Garcia JL (1998) Characterization of the hca cluster encoding the dioxygenolytic pathway for initial catabolism of 3-phenylpropionic acid in Escherichia coli K-12. J Bacteriol 180:2915–2923

Francois P, Bento M, Vaudaux P, Schrenzel J (2003) Comparison of fluorescence and resonance light scattering for highly sensitive microarray detection of bacterial pathogens. J Microbiol Methods 55:755–762

Gaal T, Bartlett MS, Ross W, Turnbough CL Jr, Gourse RL (1997) Transcription regulation by initiating NTP concentration: rRNA synthesis in bacteria. Science 278:2092–2097

Grunberg-Manago M (1996) Regulation of the expression of aminoacyl-tRNA synthetases and translation factors. In: Neidhardt FC , Curtis III R, Ingraham JL, Lin ECC , Low KB, Magasanik B, Reznikoff WS , Riley M , Schaechter M , Umbarger HE (eds) Escherichia coli and Salmonella typhimurium: cellular and molecular biology. ASM, Washington, D.C., pp 1432–1457

Hengge-Aronis R (1993) Survival of hunger and stress: the role of rpoS in early stationary phase gene regulation in E. coli. Cell 72:165–168

Hyduke DR, Rohlin L, Kao KC, Liao JC (2003) A software package for cDNA microarray data normalization and assessing confidence intervals. Omics 7:227–234

Keener J, Nomura M (1996) Regulation of ribosome biosynthesis. In: Neidhardt FC III, Ingraham JL, Lin ECC, Low KB, Magasanik B, Reznikoff WS, Riley M, Schaechter M, Umbarger HE (eds) Escherichia coli and Salmonella typhimurium: cellular and molecular biology. ASM, Washington, D.C., pp 1417–1431

Kostov Y, Harms P, Randers-Eichhorn L, Rao G (2001) Low-cost microbioreactor for high-throughput bioprocessing. Biotechnol Bioeng 72:346–352

Lamping SR, Zhang H, Allen B, Shamlou PA (2003) Design of a prototype miniature bioreactor for high throughput automated bioprocessing. Chem Eng Sci 58:747–758

Loewen PC, Hengge-Aronis R (1994) The role of the sigma factor sigma S (KatF) in bacterial global regulation. Annu Rev Microbiol 48:53–80

Loge FJ, Thompson DE, Call DR (2002) PCR detection of specific pathogens in water: a risk-based analysis. Environ Sci Technol 36:2754–2759

Maharbiz MM, Holtz WJ, Howe RT, Keasling JD (2004) Microbioreactor arrays with parametric control for high-throughput experimentation. Biotechnol Bioeng 85:376–381

Rabin RS, Stewart V (1993) Dual response regulators (NarL and NarP) interact with dual sensors (NarX and NarQ) to control nitrate- and nitrite-regulated gene expression in Escherichia coli K-12. J Bacteriol 175:3259–3268

Silverman M, Simon M (1974) Flagellar rotation and the mechanism of bacterial motility. Nature 249:73–74

Tao H, Bausch C, Richmond C, Blattner FR, Conway T (1999) Functional genomics: expression analysis of Escherichia coli growing on minimal and rich media. J Bacteriol 181:6425–6440

Tatusov RL, Koonin EV, Lipman DJ (1997) A genomic perspective on protein families. Science 278:631–637

Tseng GC, Oh M-K, Rohlin L, Liao JC, Wong WH (2001) Issues in cDNA microarray analysis: quality filtering, channel normalization, models of variations and assessment of gene effects. Nucleic Acids Res 29:2549–2557

Wei Y, Lee JM, Richmond C, Blattner FR, Rafalski JA, LaRossa RA (2001) High-density microarray-mediated gene expression profiling of Escherichia coli. J Bacteriol 183:545–556

Yguerabide J, Yguerabide EE (2001) Resonance light scattering particles as ultrasensitive labels for detection of analytes in a wide range of applications. J Cell Biochem S37:71–81

Zanzotto A, Szita N, Boccazzi P, Lessard P, Sinskey AJ, Jensen KF (2004) Membrane-aerated microbioreactor for high-throughput bioprocessing. Biotechnol Bioeng 87:243–254

Acknowledgements

We gratefully acknowledge the DuPont-MIT Alliance (DMA) for funding. The authors are also grateful to Dr. Jefferson Parker for his help with gene annotation, Dr. Phil Lessard for continuous, stimulating discussions and for reviewing the manuscript, and Prof. Jacqueline Piret for critically reviewing the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boccazzi, P., Zanzotto, A., Szita, N. et al. Gene expression analysis of Escherichia coli grown in miniaturized bioreactor platforms for high-throughput analysis of growth and genomic data. Appl Microbiol Biotechnol 68, 518–532 (2005). https://doi.org/10.1007/s00253-005-1966-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-005-1966-6