Abstract

During dye decoloration by Trametes versicolor ATCC 20869 in modified Kirk’s medium, manganese peroxidase (MnP) and laccase were produced, but not lignin peroxidase, cellobiose dehydrogenase or manganese-independent peroxidase. Purified MnP decolorized azo dyes [amaranth, reactive black 5 (RB5) and Cibacron brilliant yellow] in Mn2+-dependent reactions but did not decolorize an anthraquinone dye [Remazol brilliant blue R (RBBR)]. However, the purified laccase decolorized RBBR five to ten times faster than the azo dyes and the addition of a redox mediator, 2,2′-azino-bis(3-ethylbenzthiazoline-6-sulfonic acid), did not alter decoloration rates. Amaranth and RB5 were decolorized the most rapidly by MnP since they have a hydroxyl group in an ortho position and a sulfonate group in the meta position relative to the azo bond. During a typical batch decoloration with the fungal culture, the ratio of laccase:MnP was 10:1 to 20:1 (based on enzyme activity) and increased to greater than 30:1 after decoloration was complete. Since MnP decolorized amaranth about 30 times more rapidly than laccase per unit of enzyme activity, MnP should have contributed more to decoloration than laccase in batch cultures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Most synthetic dyes are resistant to microbial degradation (Clarke and Anliker 1980), with approximately 50% of all dyes being azo dyes (Waring and Hallas 1990). These compounds are used as colorants in the textile, food, plastic and biomedical industries. About 50,000 tonnes are discharged annually (Lewis 1999). The release of colored effluent into the environment is not aesthetically pleasing and some dyes are potential health hazards as they may be converted to toxic and/or carcinogenic products under anaerobic conditions (Maguire and Tracz 1991; Banat et al. 1996). Several countries are adopting stringent regulations for the release of colored industrial effluent. Because of the range of chemical structures and properties, all dyes cannot be efficiently removed by a single technology such as coagulation, ozonation or activated carbon (Dubrow et al. 1996; Matsui 1996).

White rot fungi have been evaluated for their potential to treat colored wastewaters (Blànquez et al. 2002; Kissi et al. 2001). These cultures produce lignin-modifying enzymes (LMEs)—lignin peroxidase (liP), Mn2+-dependent peroxidase (MnP), Mn2+-independent peroxidase (MnIP), laccase (phenol oxidase) and cellobiose dehydrogenase (CDH)—that are secreted during secondary metabolism (idiophase) when nitrogen, carbon or sulfur is limiting (Kirk and Farrell 1987; de Jong et al. 1994).

Many investigations emphasize the ability of a fungus to decolorize a variety of synthetic dyes. However, the mechanism(s) by which the culture decolorizes is(are) not completely determined and this knowledge could be helpful for process design and optimization. Trametes versicolor ATCC 20869 has been shown to secrete MnP and laccase during dye decoloration in batch culture on modified Kirk’s medium (Swamy and Ramsay 1999a,b). In the present study, neither liP, CDH nor MnIP were detected under these conditions. While cellobiose stimulates the production of CDH, the absence of manganese is required for the production of MnIP. However, since it is highly probable that manganese, but not cellobiose, would be present in modified Kirk’s medium, as well as textile and carpet dyeing process waters, production of neither MnIP nor CDH would be expected. Therefore, MnP and laccase are the major enzymes most likely to be involved in decoloration by this strain. In batch culture, enzyme concentrations are constantly changing so it is difficult to determine whether one or both enzymes play a role in decoloration in vivo. Furthermore, the combined effect of both enzymes on decoloration has never been reported. Consequently, this study examined the in vitro decoloration of an anthraquinone dye and four azo dyes by MnP and laccase purified from T. versicolor, both individually and in combination.

Materials and methods

Chemicals

All textile dyes, and the chemicals 2,2′-azino-bis(3-ethylbenzthiazoline-6-sulfonic acid) diammonium salt (ABTS), 2,6-dimethoxyphenol, methyl glucoside and meat peptone were purchased from Sigma-Aldrich (Mississauga, ON, Canada).

Culture preparation and conditions for enzyme production

T. versicolor ATCC 20869 was maintained at 4°C on plates containing Kirk’s medium, 3% malt extract and 1.5% agar. Agar plugs of actively growing mycelium were used to inoculate 500-ml Erlenmeyer flasks containing 150 ml growth medium. For MnP production, the growth medium contained (per liter): 10 g glucose, 3.5 g malt extract, 2.5 g yeast extract, 5 g wheat bran, 2.0 g KH2PO4, 0.5 g MgSO4·7H2O, 10 μg thiamin, 1 ml trace minerals and 200 μmol MnSO4. After 4 days of growth, the inoculum was homogenized in a blender for 10 s and divided equally between four 1-l Erlenmeyer flasks containing MnP production medium comprising (per liter): 6.8 g KH2PO4, 20 g wheat bran, 10 μg thiamin and 200 μM MnSO4. The culture was harvested when MnP activity peaked on day 4. For laccase production, the inoculum was prepared with the growth medium of Fahraeus and Reinhammar (1967). A 5-day-old inoculum was distributed equally between four 1-l Erlenmeyer flasks containing 250 ml laccase production medium consisting of (per liter): 40 g glycerol, 15 g meat peptone and 1.0 g MgSO4 (Leitner et al. 2002). Laccase production was induced by adding a sterile stock solution of CuSO4·5H2O after day 10 to a final concentration of 0.5 mM and achieved a maximum of approximately 2,000 U l−1 at 22–26 days when the cultures were harvested. All cultures were incubated at room temperature (22°C) and 250 rpm.

MnP purification

MnP was purified according to Addleman et al. (1995). All steps were performed at room temperature unless otherwise stated. The supernatant, recovered after centrifugation at 6,000 g for 20 min using a Dupont Sorvall centrifuge, was filtered through cheesecloth, then applied to a 100-ml DEAE-Sephacel bed (Sigma). MnP was eluted by NaCl-step gradient with concentrations of 0.05, 0.1 and 0.3 M in 20 mM succinate buffer at pH 5.5. Fractions containing MnP were pooled and applied to a 15×30 mm Concanavalin-A Sepharose-4B column (Sigma) pre-equilibrated with 20 mM succinate-0.5 M NaCl buffer at pH 6.0. The enzyme was eluted with steps of 0.1, 0.2, 0.3, 0.4 and 0.5 M methyl glucoside dissolved in the same buffer. Fractions containing MnP were pooled and dialyzed against the buffer and stored at 4°C.

Laccase purification

Laccase was purified according to Fahraeus and Reinhammar (1967) and Leitner et al. (2002); all steps were carried out at 4°C unless otherwise stated. Culture flasks were pooled and the biomass removed by centrifugation at 10,000 g for 20 min using a Dupont Sorvall centrifuge. The supernatant was saturated to 30% ammonium sulfate and centrifuged for 20 min at 10,000 g. Further ammonium sulfate was added to 90% saturation and the protein allowed to precipitate overnight. The saturated supernatant was then centrifuged at 10,000 g for 1 h. The pellets were dissolved in 20 mM Na phosphate (heptahydrate) pH 7.0 and loaded on a 15×100 mm DEAE-Sephacel column (Sigma) and laccase was eluted with 0.2 M Na phosphate (heptahydrate) pH 7.0. The fractions containing laccase were pooled and, after concentrating, a 5-ml crude preparation was applied to a 900×26 mm Sephacryl HR S100 column (Amersham Biosciences, Baie-D’Urfée, QC, Canada) pre-equilibrated with 50 mM Na-phosphate (heptahydrate)–0.15 M NaCl at pH 7.0. The enzyme was eluted at a flow rate of 0.5 ml min−1 and the active fractions were pooled and dialyzed against 20 mM sodium succinate pH 5.0. These dialyzed fractions were applied onto a Q-Sepharose (Amersham Biosciences) and eluted using NaCl-step gradient of 0.15 and 0.2 M in 20 mM succinate buffer pH 5.0. The pooled fractions were re-dialyzed against 20 mM succinate pH 5.0 and stored at 4°C.

Enzyme assays

MnP activity was determined by monitoring either the formation of Mn3+-malonate complex at 270 nm (ɛ 270=8,500 M−1 cm−1) (Kuan et al. 1993) or the oxidation of 2,6-dimethoxyphenol at 468 nm (ɛ 468=49,600 M−1 cm−1) (Wariishi et al. 1992). Assay mixtures contained 0.2 mM MnSO4, 50 mM sodium malonate (pH 4.5), 0.1 mM H2O2 and 100-μl aliquots of appropriately diluted enzyme preparation. One unit of MnP activity was defined as 1 μmol product formed per minute. Laccase activity was determined by measuring the oxidation of ABTS at 420 nm (ɛ 420=36,000 M−1 cm−1) (Wolfenden and Willson 1982). The assay mixture contained 0.2 mM ABTS, 50 mM sodium acetate buffer (pH 5.0) and 100-μl aliquots of diluted enzyme sample. One unit of laccase activity was defined as 1 μmol ABTS+ formed per minute. MnIP was determined by monitoring the oxidation of indigo trisulfonate at 603 nm (ɛ 603=47,600 M−1 cm−1) (F. Archibald, personal communication). The assay mixture contained 10 mM sodium succinate (pH 3.2), 10 mM sodium lactate (pH 3.2), 40 μM indigo trisulfonate, and a 100-μl aliquot of appropriately diluted enzyme sample; the reaction was initiated by adding 0.1 mM H2O2. CDH was determined by monitoring oxidation of 2,6-dichlorophenol-indolphenol at 520 nm (ɛ 520=6,800 M−1 cm−1) (Baminger et al. 1999). The assay mixture contained 100 mM sodium acetate (pH 4.0), 30 mM lactose, 0.3 μM 2,6-dichlorophenol-indolphenol, 100 mM NaF and 100-μl aliquots of appropriately diluted enzyme sample. All assays were conducted using a Unicam UV1 spectrophotometer (Spectronic Unicam, Cambridge, UK) or a Spectramax 250 spectrophotometer (Molecular Devices, Sunnyvale, Calif.) at room temperature.

Electrophoretic analysis

Denaturing sodium dodecylsulfate polyacrylamide gel electrophoresis (SDS-PAGE) was carried out using Bio-Rad casting (Bio-Rad, Hercules, Calif.). The protein sample was treated with 2% SDS and 200 mM dithiothreitol, and 20 μl was applied to a 12–15% polyacrylamide gel in a Tris/glycerin buffer pH 8.8 for 45–60 min at 115–150 V. The proteins were stained with Coomassie blue overnight. The gel was washed three times with acetate buffer for 20 min each time and visualized with a Phosphorimager (Molecular Dynamics; http://www.mdyn.com).

Decoloration assay

Assays were conducted in 96-well microtiter plates at room temperature. The total assay volume was 180 μl in 300-μl wells. For decoloration with MnP, assay mixtures contained 50 mM malonate as a buffer (pH 4.5), 0.2 mM MnSO4, 20 μM dye and aliquots of the enzyme preparation with the reaction initiated by adding 0.1 mM of H2O2. For in vitro decoloration using the laccase preparation, assay mixtures contained 50 mM malonate (pH 4.5), 20 μM textile dye and an aliquot of the enzyme preparation. Where appropriate, 0.2 mM MnSO4 and/or 0.1 mM H2O2 were added or omitted. MnP and laccase concentrations were 0.215 and 0.888 U ml−1, respectively. Degradation rates were monitored with a Spectramax 250 plate multi-reader at the maximum wavelength of each dye (Fig. 1).

Effect of organic acids on in vitro amaranth decoloration by MnP or laccase

For MnP decoloration, four different organic acids were tested: malonate, lactate, oxalate, and tartrate. For laccase, only malonate and oxalate were used. Stock solutions of the sodium salts of the organic acids were prepared and diluted to 50 mM in 180 μl. The buffers were adjusted to pH 4.5. The experiment was repeated twice with at least five replicates.

Effect of MnP and laccase activity on the rate of dye decoloration

Analyses were conducted with MnP concentrations of 0, 0.072, 0.152, 0.176, 0.215 and 0.238 U ml−1. The initial concentration of amaranth was 20 μM. Effects of laccase activity on Remazol brilliant blue R (RBBR) were analyzed. The initial RBBR concentration was 19.2 μM and enzyme concentrations were 0, 0.22, 0.44, 0.88 and 1.39 U ml−1 in malonate buffer (pH 3.8).

Decoloration of amaranth in presence of both MnP and laccase

Decoloration assays contained 20 μM amaranth, 0.1 mM H2O2 and 0.2 mM MnSO4 in 50 mM malonate pH 3.8. The experiment was performed at three different combinations of MnP and laccase activities.

Results

Purification of MnP and laccase

After purification, a total of 50 U MnP and 1,200 U laccase were typically obtained, representing yields of approximately 10% and 57%, respectively. The molecular weights (MWs) for MnP and laccase from T. versicolor 52J are 42 and 68 kDa, respectively (Addleman et al. 1995; Bourbonnais et al. 1995). The MnP preparation had a single band on SDS-PAGE at 44–45 kDa with no band visible at 68 kDa (Fig. 2). However, the laccase preparation had an intense band at 55 kDa, which may have been deglycosylated laccase, and those at 50 and 17 kDa may have been laccase fragments from the ammonium sulfate precipitation as the MWs total 67 kDa. Although the faint band at 40–43 kDa may indicate trace amounts of MnP, MnP activity was not detected. No liP, CDH or MnIP activity was detected in the culture broth or in any of the enzyme preparations.

Effect of Mn2+ and H2O2 on amaranth decoloration by MnP

With the MnP preparation, the highest initial amaranth decoloration rate of 14.96±1.83 μM min−1 U−1 and apparent first order rate constant (k) of 31.3 min−1 were achieved when both MnSO4 and H2O2 were present (Table 1). When either H2O2 or MnSO4 was omitted, the rate decreased by at least 80%. However, complete decoloration still occurred in less than 24 h with MnSO4 alone (data not shown) but not with H2O2 alone.

Effect of Mn2+, H2O2 and ABTS on amaranth decoloration by laccase

Laccase decolorized amaranth less efficiently than MnP, with an initial rate of 0.85±0.03 μM min−1 U−1 and a k value of 0.85×10−3 min−1 (Table 1). Adding 0.2 mM MnSO4 and/or H2O2 slightly enhanced the initial decoloration rate, and the addition of 10 μM ABTS had no significant effect (P≤0.821 for α=0.05). With 80 mU laccase (0.444 U ml−1), amaranth was decolorized in the absence and presence of ABTS at a rate of 0.038±0.001 and 0.045±0.006 μM min−1, respectively.

Effect of organic acids on decoloration of amaranth and RB5

The initial rate of amaranth decoloration by MnP depended on the organic acid added to the assay (Table 2). Decoloration was fastest in malonate and lactate, with initial rates of 0.94±0.10 and 0.73±0.09 μM min−1, respectively, and was significantly slower with oxalate and tartrate. In similar experiments with laccase, the initial decoloration rate and extent of decoloration of amaranth or RB5 in malonate was faster than in oxalate (Table 2).

Decoloration of azo and anthraquinone dyes by MnP and/or laccase

MnP decolorized amaranth (mono-azo dye) and RB5 (di-azo dye) more rapidly and to a greater extent than laccase (Table 3), with 25.03±0.35% amaranth and 11.7±0.1% RB5 decolorized after 8 min. However, little decoloration was achieved for CBY and there was an increase in absorbance for Congo Red and RBBR. In contrast, laccase decolorized RBBR (anthraquinone dye) much more rapidly than amaranth, RB5 and CBY.

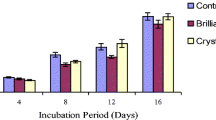

The initial rate of amaranth or RBBR decoloration increased with increasing laccase concentration (Fig. 3a). However, laccase had a much higher specific rate of RBBR decoloration (0.61 μM min−1 U−1) than amaranth decoloration (0.13 μM min−1 U−1). Increasing the MnP concentration led to a higher specific rate of amaranth decoloration (3.59 μM min−1 U−1) than laccase but MnP did not decolorize RBBR (Fig. 3b). The amaranth decoloration rate when both enzymes were present was approximately equal to the sum of the rates of each enzyme alone (Table 4). Thus the combined effect of the two enzymes is additive rather than synergistic.

Effect of a laccase and b MnP concentration on decoloration of amaranth and Remazol brilliant blue R (RBBR). Laccase was added to 50 mM malonate (pH 4.5) and MnP was added to 50 mM malonate (pH 4.5), 0.2 mM MnSO4, and 0.1 mM H2O2 with 19.1 μM RBBR or 18.2 μM amaranth. Each experiment was performed at least twice with five replicates for each data point

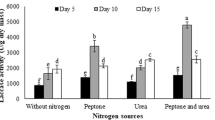

Amaranth decoloration by T. versicolor

In typical batch decolorations of amaranth by T. versicolor ATCC 20869 in modified Kirk’s medium, decoloration occurred early (within 2–8 h) when the laccase:MnP ratio (based on enzyme activity) was usually less than 30:1 (Fig. 4). This ratio was frequently lower (about 10:1 to 20:1). After more than 90% of the amaranth had disappeared, it was not uncommon for laccase production to increase significantly, and for MnP production to decrease such that the laccase:MnP ratio was greater than 30:1.

Discussion

Enzyme purity

Purification resulted in low recovery (25 and 57% of the initial MnP and laccase activity, respectively) with negligible amounts of contaminating enzymes. The addition of MnSO4 and/or H2O2 slightly enhanced the initial decoloration rate by laccase. The slight enhancement by Mn2+ may reflect the ability of laccase to catalyze the production of manganic chelates (Archibald and Roy 1992; Hofer and Schlosser 1999). Any contribution from trace levels of laccase (<0.014 U ml−1) was minimal in the MnP preparation, since high laccase activities resulted in low rates of amaranth decoloration (e.g., 1.39 U laccase ml−1 decolorized amaranth at a rate of 0.18 μM min−1).

Decoloration by MnP

Few studies on dye decoloration by purified MnP have been reported. Some have shown that MnP required H2O2 (Ollika et al. 1993; Mielgo et al. 2003) as well as MnSO4 to achieve maximal decoloration rates. However, MnP from Bjerkandera adusta DSM 11310 and Pleurotus eryngii ATCC 90787 decolorized four azo and two phthalocyanine dyes in Mn2+-independent reactions in which the enzyme interacted directly with the dye (Heinfling et al. 1998). MnP from Phanerochaete chrysosporium ATCC 24725 decolorized a polymeric dye, Poly R-478, in a Mn2+-dependent reaction (Moreira et al. 2001), poorly oxidized a phthalocyanine dye, and did not decolorize azo dyes in either Mn2+-dependent (Heinfling et al. 1998; Young and Yu 1997) or Mn2+-independent reactions (Heinfling et al. 1998). In contrast, we found that T. versicolor MnP decolorized three azo dyes, including amaranth, in Mn2+-dependent reactions. Complete (100%) amaranth decoloration required the presence of MnSO4 but not H2O2 (Table 1). In the latter case, the rate of decoloration was slower but total decoloration was achieved within 24 h, indicating that MnP from T. versicolor, via Mn3+, was the decolorizing mediator, and other peroxidases (such as Mn2+-independent peroxidase) were not involved. Furthermore, MnP would not have interacted directly with amaranth, probably because of its lack of affinity for the dye molecule.

MnP needs an alpha-hydroxy acid such as malonic acid to stabilize the Mn3+ generated (Wariishi et al. 1992; Kuan et al. 1993). Although malonate has been shown to be suitable for MnP from Phanerochaete chrysosporium (Wariishi et al. 1992), it decreased the extent of decoloration of Orange II (an azo dye) by MnP from Bjerkandera sp. BOSS55 (Mielgo et al. 2003). As a result of these conflicting reports, the impact of malonate and other organic acids on amaranth decoloration by MnP from T. versicolor was evaluated. Amaranth decolorized fastest when malonate or lactate was used as the chelator (Table 2). Based on these results and those of Wariishi et al. (1992), the Mn3+-organic acid complex is likely the decolorizing agent.

Pasti-Grigsby et al. (1992) found that peroxidases from Streptomycete sp. readily degraded sulfonated azo dyes with a para or ortho hydroxyl group and at least one or two ortho electron-releasing substituents relative to the azo bond (–N=N–) on an aromatic ring. However, Phanerochaete chrysosporium and its purified liP and MnP degraded azo dyes that did not have these molecular features. This may be due to differences between the enzymes of the two cultures and their affinity for the dye molecules. Spadaro and Renganathan (1994) proposed that the initial attack on sulfonated azo dyes occurs at the hydroxyl group, since 1,2-naphtoquinone was detected when disperse yellow 3 was decolorized by liP, MnP and Mn3+-malonate complexes. In our study, Amaranth and RB5 were the only dyes with a hydroxyl group in an ortho position relative to the azo bond and a sulfonic acid group in the meta position (Fig. 1). This may have contributed to their more rapid decoloration compared to the other dyes (Table 3). RB5 decolorized more slowly than amaranth, probably due to the presence of two azo bonds in RB5 (compared to one for amaranth), and steric hindrance due to [(sulfoxy)ethylsulfonyl]phenyl azo chains surrounding the hydroxyl group (Fig. 1).

Decoloration by laccase

Laccase has been shown to decolorize anthraquinone dyes more efficiently than azo (Rodriguez et al. 1999; Claus and Konig 2002; Nyanhongo et al. 2002) and triarylmethane dyes (Claus and Konig 2002; Nyanhongo et al. 2002). However, a redox mediator was needed for a commercial formulation of recombinant laccase expressed in Aspergillus niger to decolorize RBBR (an anthraquinone dye) (Soares et al. 2001), and for laccase from a strain of T. versicolor to decolorize a mixture of eight dyes, including azo dyes, quickly and to a greater extent (Claus and Konig 2002). In our studies, although purified laccase from T. versicolor decolorized an anthraquinone dye more rapidly than the azo dyes (Table 3), a redox mediator was not required to achieve comparable or better decoloration rates since the addition of ABTS had no significant effect. This is consistent with the recent findings of Selvam et al. (2003) who showed that laccase from Thelephora sp. degraded three azo dyes (orange G, amido black and congo red) without a redox mediator.

Furthermore, Wong and Yu (1999) demonstrated that Acid Green 27 (an anthraquinone dye) was not only a substrate for laccase purified from T. versicolor ATCC 48424 but also a mediator for the decoloration of two non-substrate dyes: acid violet (azo dye) 7 and indigo carmine (indigoid dye). This indicates that the range of dyes that may be decolorized by laccase could be expanded in the presence of anthraquinone dyes.

Although the effect of organic acids on dye decoloration by MnP has been documented, there are no reports for laccase. Oxalate accumulates in cultures of T. versicolor (Dutton et al. 1993; Galkin et al. 1998) and, like malonate, is commonly used as a buffer for MnP assays (Wariishi et al. 1992; Kuan et al. 1993). We found that laccase decolorized amaranth and RB5 faster and to a greater extent with malonate than with oxalate (Table 2), indicating that oxalate may have inhibited laccase, or the activated dye molecules generated by laccase.

Decoloration in the presence of both enzymes

Although there are no reports of in vitro decoloration studies in the presence of two or more LMEs, it is possible that laccase may cooperate with MnP in dye decoloration. Schlosser and Hofer (2002) demonstrated interactions between MnP and laccase from Stropharia rugosoannulata, where laccase indirectly produced H2O2 by oxidizing Mn2+. This type of cooperation may enhance reaction rates when both enzymes are present. However, our results show that the rate of amaranth decoloration in the presence of both enzymes is additive, suggesting that the enzymes do not interact with each other during decoloration.

MnP decolorizes amaranth more rapidly (3.59 μM min−1 U−1) than laccase (0.13 μM min−1 U−1) (Fig. 3). About 30 times more activity units of laccase are needed to achieve a similar level of decoloration as 1 activity unit of MnP. In batch decolorations of amaranth by T. versicolor, more than 90% of the color loss occurred when the laccase:MnP ratio was less than 30:1 (Fig. 4). This indicates that the lower MnP activity contributed more to decoloration than laccase. Toward the end of decoloration, there may be an increase in laccase activity such that the laccase:MnP ratio becomes greater than 30:1. Under these conditions, laccase would play a more important role in amaranth decoloration.

Based on our data and on published literature, a mechanism for amaranth decoloration by T. versicolor is proposed in Fig. 5. The solid and dashed lines represent the dominant reactions when the laccase:MnP ratio is less than and greater than 30:1, respectively. In batch culture when MnP is the main decolorizing enzyme (solid lines in Fig. 5), decoloration is initiated by the Mn3+-organic acid complex that is regenerated by MnP. A minimum of 0.34 g glucose/l is required for maximal decoloration rates (Swamy and Ramsay 1999a). It is likely that H2O2 is generated from glucose via glucose oxidase (Zhao and Janse 1996) and by the non-enzymatic degradation of oxalate (or another organic acid) (not shown in Fig. 5). This would increase the extent of decoloration without the addition of H2O2. When laccase plays the primary role in decoloration (dashed lines in Fig. 5), O2 but not a redox mediator is required for decoloration to occur. Laccase can regenerate the Mn3+-organic acid complex (not shown in Fig. 5) and oxidize the dye molecule.

For other azo dyes, such as CBY and RB5, a similar relationship between MnP and laccase is expected except that the ratio at which one enzyme would dominate the decoloration activity may be different e.g., for RB5, the optimum laccase:MnP ratio is probably around 15:1 (Table 3). For the anthraquinone dye, RBBR, it would appear that only laccase contributed to decoloration as the presence of MnP alone resulted in an increase in absorbance. These two enzymes may be antagonistic to each other for RBBR. Although laccase or the Mn3+-organic acid complex initiates decoloration by oxidizing the dye, the oxidized dye will undergo several subsequent reactions, some of which may be spontaneous or be promoted by the same enzyme to eventually destroy the chromophore group(s), resulting in color loss. Due to the complex nature of the reactions involved, it is difficult to predict the structures of the decolorized intermediates and/or products without further analytical studies.

Proposed mechanism of amaranth decoloration by T. versicolor. Thick and dashed lines represent major and minor reactions when the laccase:MnP ratio (based on units of activity) is less than and greater than 30:1, respectively. At laccase:MnP ratios less than 30:1, MnP would be the main enzyme decolorizing amaranth

In conclusion, MnP and laccase were purified and their ability to degrade four azo and an anthraquinone dyes was investigated. MnP was most efficient at decolorizing amaranth, and laccase readily decolorized RBBR without the addition of a mediator. Our results provide strong evidence that while both laccase and MnP are capable of decolorizing amaranth, it is MnP, via the Mn3+-organic acid chelates, and not laccase that is the key enzyme during batch decoloration of amaranth in cultures of T. versicolor. Furthermore, decoloration in the presence of both enzymes showed that the contribution of each enzyme to decoloration was additive. Since each enzyme attacks different chemical structures, it would be advantageous to use whole fungal cultures or an enzymatic reactor containing more than one LME to target a wider range of chemical structures in waste effluents. The advantage of using a culture instead of an enzymatic reactor would be lower cost. However, the fungus must secrete several LMEs and associated isoenzymes. To achieve this, the induction of enzyme production during the decoloration process must be further investigated to optimize treatment of wastewaters that contain a mixture of dyes. Finally, knowledge of the influence of dye structure on dye decoloration must be further deepened to help design efficient treatment processes.

References

Addleman K, Dumonceaux T, Paice MG, Bourbonnais R, Archibald F (1995) Production and characterization of Trametes versicolor mutants unable to bleach hardwood kraft pulp. Appl Environ Microbiol 61:3687–3694

Archibald F, Roy B (1992) Production of manganic chelates by laccase from the lignin-degrading fungus Trametes versicolor. Appl Environ Microbiol 58:1496–1499

Baminger U, Nidetzky B, Kulbe KD, Schlosser D (1999) A simple assay for measuring cellobiose dehydrogenase activity in the presence of laccase. J Microbiol Methods 35:253–259

Banat IM, Nigam P, Singh D, Marchant R (1996) Microbial decolorization of textile-dye-containing effluents: a review. Bioresour Technol 58:217–227

Blànquez C, Caminal G, Sarra M, Vincent M, Gabarell X (2002) Olive oil mill waste water decoloration and detoxification in a bioreactor by the white rot fungus Phanerochaete flavido-alba. Biotechnol Prog 18:660–662

Bourbonnais R, Paice M, Reid I, Lanthier P, Yaguchi M (1995) Lignin oxidation by laccase isozymes from Trametes versicolor and role of the mediator 2,2-azino-bis(3-ethylbenzthiazoline-6-sulfonate) in kraft lignin depolymerization. Appl Environ Microbiol 61:1876–1880

Clarke E, Anliker R (1980) Organic dyes and pigments. In: Handbook of environmental chemistry, anthropogenic compounds, vol 3, 2nd edn. Springer, Berlin Heidelberg New York, pp 181–215

Claus H, Faber G, Konig H (2002) Redox-mediated decolorization of synthetic dyes by fungal laccases. Appl Microbiol Biotechnol 59:672–678

Dubrow SF, Boardman GD, Michelsen DJ (1996) Chemical pretreatment and aerobic–anaerobic degradation of textile dye wastewater. In: Reife A, Freeman HS (eds) Environmental chemistry of dyes and pigments. Wiley, New York, pp 75–102

Dutton MV, Evans CS, Atkey PT, Wood DA (1993) Oxalate production by basidiomycetes, including the white-rot Coriolus versicolor and Phanerochaete chrysosporium. Appl Microbiol Biotechnol 39:5–10

Fahraeus G, Reinhammar B (1967) Large-scale production and purification of laccase from cultures of the fungus Polyporus versicolor and some properties of laccase A. Acta Chem Scand 21:2367–2378

Galkin S, Vares T, Kalsi M, Hatakka A (1998) Production of organic acids by different white-rot fungi as deleted using capillary zone electrophoresis. Biotechnol Tech 12:267–271

Heinfling A, Martinez M, Martinez A, Bergbauer M, Szewyk U (1998) Transformation of industrial dyes by manganese peroxidases from Bjerkandera adusta and Pleurotus eryngii in a manganese-independent reaction. Appl Environ Microbiol 64:2788–2793

Hofer C, Schlosser D (1999) Novel enzymatic oxidation of Mn2+ to Mn3+ catalysed by a fungal laccase. FEBS Lett 451:186–190

Jong E de, Field J, de Bont J (1994) Aryl alcohols in the physiology of ligninolytic fungi. FEMS Microbiol Rev 13:153–188

Kirk T, Farrell R (1987) Enzymatic “combustion”: the microbial degradation of lignin. Annu Rev Microbiol 41:465–505

Kissi M, Mountadar M, Assobhri O, Gargiulo E, Palmieri G, Giardina P, Sannia G (2001) Roles of two white-rot basidiomycete fungi in decolorisation and detoxification of olive waste water. Appl Microbiol Biotechnol 57:221–226

Kuan C, Johnson J, Tien M (1993) Kinetic analysis of manganese peroxidase. The reaction with manganese complexes. J Biol Chem 268:20064–20070

Leitner C, Hess J, Galhaup C, Ludwig R, Nidetzky B, Kulbe KD, Haltrich D (2002) Purification and characterization of a laccase from the white-rot fungus Trametes multicolor. Appl Biochem Biotechnol 99:497–508

Lewis DM (1999) Coloration in the next century. Rev Prog Coloration 29:23–28

Maguire R, Tracz R (1991) Occurrence and persistence of dyes in a Canadian river. Water Pollut Res J Can 26:145–146

Matsui M (1996) Ozonation. In: Reife A, Freeman (eds) Environmental chemistry of dyes and pigments. Wiley, New York, pp 43–59

Mielgo I, Lopez C, Moreira M, Feijoo G, Lema JM (2003) Oxidative degradation of azo dyes by manganese peroxidase under optimized conditions. Biotechnol Prog 19:325–331

Moreira M, Palma C, Mielgo I, Feijoo G, Lema J (2001) In vitro degradation of a polymeric dyes (poly R-478) by manganese peroxidase. Biotechnol Bioeng 75:362–368

Nyanhongo G, Gomes J, Gubitz G, Zvauya R, Read J, Steiner W (2002) Decolorization of textile dyes by laccases from a newly isolated strain from Trametes modesta. Water Res 36:1449–1456

Ollika P, Alhonmaki K, Leppananen V-M, Glumoff T, Raijola T, Suominen I (1993) Decolorization of azo, triphenyl methane, heterocyclic, and polymeric dyes lignin peroxidase isoenzymes from Phanerochaete chrysosporium. Appl Environ Microbiol 59:4010–4016

Pasti-Grigsby M, Paszcynski A, Goszczynski S, Crawford R, Crawford D (1992) Influence of aromatic substitution pattern on azo dyes by Streptomyces spp. and Phanerochaete chrysosporium. Appl Environ Microbiol 58:3605–3613

Rodriguez E, Pickard M, Vazquez-Duhalt R (1999) Industrial dye decoloration by laccases from ligninolytic fungi. Curr Microbiol 38:27–32

Schlosser D, Hofer C (2002) Laccase-catalyzed oxidation of Mn2+ in the presence of natural Mn3+ chelators as a novel source of extracellular H2O2 production and its impact on manganese peroxidase. Appl Environ Microbiol 68:3514–3521

Selvam K, Swaminathan K, Chae K (2003) Decolourization of azo dyes and a dye industry effluent by a white rot fungus Thelephora sp. Bioresour Technol 88:115–119

Soares GM, de Amorim MP, Costa-Ferreira M (2001) Use of laccase together with redox mediators to decolorize remazol brilliant blue R. J Biotechnol 89:123–129

Spadaro J, Renganathan V (1994) Peroxidase-catalyzed oxidation of azo dyes: mechanism of disperse yellow 3 degradation. Arch Biochem Biophys 312:301–307

Swamy J, Ramsay JA (1999a) Effect of glucose and NH4 + concentrations on sequential dye decoloration by Trametes versicolor. Enzyme Microb Technol 25:278–284

Swamy J, Ramsay JA (1999b) Effect of Mn2+ and NH4 + concentrations on laccase and manganese peroxidase production and amaranth decoloration by Trametes versicolor. Appl Microbiol Biotechnol 51:391–396

Wariishi H, Valli K, Gold M (1992) Manganese (II) oxidation by manganese peroxidase from the basidiomycete Phanerochaete chrysosporium. J Biol Chem 267:23688–23695

Waring D, Hallas G (1990) The chemistry and application of dyes. Plenum, New York

Wolfenden B, Willson R (1982) Radical-cations as reference chromogens in kinetic studies of one-electron transfer reactions. J Chem Soc Perkin Trans II:805–812

Wong Y, Yu J (1999) Laccase-catalyzed decolorization of synthetic dyes. Water Res 33:3512–3520

Young L, Yu J (1997) Ligninase catalysed decolorization of synthetic dyes. Water Res 31:1187–1193

Zhao J, Janse BJ (1996) Comparison of H2O2-producing enzyme in selected white rot fungi. FEMS Microbiol Lett 139:215–221

Acknowledgements

This research is financially supported by the Natural Science and Engineering Research Council of Canada, the Premier’s Research Excellence Award, Government of Ontario, and the Chancellor’s Award of Queen’s University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Champagne, PP., Ramsay, J.A. Contribution of manganese peroxidase and laccase to dye decoloration by Trametes versicolor . Appl Microbiol Biotechnol 69, 276–285 (2005). https://doi.org/10.1007/s00253-005-1964-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-005-1964-8