Abstract

In a culture medium of Streptomyces caeruleus MTCC 6638 grown with p-coumaric acid (5 mM) as the sole source of carbon, co-production of caffeic acid and p-hydroxybenzoic acid was observed. Both caffeic acid and p-hydroxybenzoic acid are important phenolic compounds with pharmaceutical importance. These biotransformed products were identified by high-performance liquid chromatography and electrospray ionization mass spectrometry. Obtained data suggest that p-coumaric acid was possibly utilized by two different routes, resulting in the formation of a hydroxycinnamate and a hydroxybenzoate compound. However, higher concentration of p-coumaric acid (10 mM) favoured caffeic acid formation. Addition of 5 mM p-coumaric acid into S. caeruleus cultures pre-grown on minimal medium with 1.0 g/l glucose resulted in the production of 65 mg/l caffeic acid. Furthermore, S. caeruleus cells were able to produce the maximum amount of caffeic acid when pre-grown on nutrient broth for 16 h. Under this condition, the addition of 5 mM p-coumaric acid was sufficient for the S. caeruleus culture to produce 150 mg/l caffeic acid, with a molar yield of 16.6% after 96 h of incubation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phenylpropanoids, such as p-coumaric acid, caffeic acid and ferulic acid, are aromatic compounds containing a phenyl ring with a C3 side chain. These hydroxycinnamic acids are formed sequentially from cinnamic acid via the central phenylpropanoid pathway (Dixon and Paiva 1995). p-Coumaric acid is one of the most abundant constituents of plant cell wall found to be covalently linked to polysaccharides and lignins by ester bonds and/or ether bonds (Hartley and Harris 1981; MacAdam and Grabber 2002). These hydroxycinnamic acids appear to be relatively inert as far as degradative processes in the plant are concerned; however, in contrast, many species of microorganisms are able to transform or degrade plant aromatic compounds and to release vast amounts of carbon that otherwise would be locked away in plant secondary products such as lignin (Rosazza et al. 1995).

Because of the abundant availability of p-coumaric acid in nature, there is considerable interest in utilizing p-coumaric acid as a cheap source of natural substrate for microbial transformation aimed at producing value-added phenolic products such as caffeic acid (Nambudiri et al. 1969; Estrada Alvarado et al. 2003) and p-hydroxybenzoic acid (Sutherland et al. 1983; Estrada Alvarado et al. 2001). Hydroxylation at the meta position of p-coumaric acid resulted in the formation of caffeic acid (Douglas 1996), while hydroxybenzoic acid derivatives (C6–C1) were formed by cleavage of C2 fragment from phenylpropanoids (Hertweck et al. 2001).

Caffeic acid has antioxidant, antitumor and anti-inflammatory properties and is found to be especially useful in strengthening the resistance of human low-density lipoprotein to oxidative modification, thus preventing the pathogenesis of atherosclerosis (Nardini et al. 1995; Michaluart et al. 1999). p-Hydroxybenzoic acid and its derivatives find important applications as dietary antioxidants (Tomas-Barberan and Clifford 2000), natural flavours (Walton et al. 2003), preservatives and medicines and also in the production of liquid crystal polymers for varied purposes (McQualter et al. 2005).

Microorganisms, including fungi and actinomycetes, are known to be capable of producing either p-hydroxybenzoic acid (Sutherland et al. 1983; Sachan et al. 2005) or caffeic acid (Nambudiri et al. 1972; Estrada Alvarado et al. 2003) from p-coumaric acid upon biotransformation. Surprisingly, no report on the simultaneous bioconversation of p-coumaric acid into p-hydroxybenzoic acid and caffeic acid with any microorganism is available. In this paper, we report for the first time the co-production of caffeic acid and p-hydroxybenzoic acid from p-coumaric acid by newly isolated Streptomyces caeruleus MTCC 6638. Cultural conditions influencing the production processes of compounds (single or otherwise) were also investigated in static flask cultures.

Materials and methods

Microorganism

The microorganism used in this study (S. caeruleus) was isolated from the soil by a phenolic acid enrichment technique (Henderson 1961). This actinomycetes member was identified based on spore morphology, cell wall chemotype and other cultural and physiological characteristics, as described in the literature (Shirling and Gottlieb 1966; Wu and Chen 1995). Identification was later verified at the Microbial Type Culture Collection (MTCC) located at the Institute of Microbial Technology (Chandigarh, India). The strain has been deposited at MTCC (http://mtcc.imtech.res.in) as S. caeruleus MTCC 6638. Pure cultures were maintained in arginine glycerol salt (AGS) slants at 28°C.

Medium and growth conditions

The cells of S. caeruleus were inoculated in minimal medium containing basal inorganic salts, NH4NO3 (3.0 g/l) as a nitrogen source, MgSO4·7H2O (0.2 g/l), NaCl (0.2 g/l), KH2PO4 (1.0 g/l), Na2HPO4 (4.0 g/l) and CaCl2 (0.05 g/l), as described by Muheim and Lerch (1999). The pH of the medium was adjusted to 7.0. All carbon substrates were filter-sterilized through a 0.2-μm nylon filter (Sigma, St. Louis, MO, USA) before their addition to the minimal medium. After growth on AGS broth for 7 days, 1 ml of cell suspension was transferred into 100-ml flasks, each containing 25 ml of minimal medium with p-coumaric acid as the sole carbon source. After a fixed period of incubation, culture media were processed to detect the biotransformed product of p-coumaric acid. Each experiment was carried out in triplicate and was repeated at least twice. Standard deviations of the analyses were less than 5%.

The growth of S. caeruleus was measured in terms of intracellular protein contents obtained via sonication, as described by Mitra et al. (1999). Measurement of biomass weight was not possible with this organism because of both its surfaced growth and its dispersed growth in the medium. Protein was assayed by the Coomassie dye-binding method (Bradford 1976).

Biotransformation by whole cells

Cells from AGS-grown cultures were inoculated in three different media: (1) minimal medium supplemented with p-coumaric acid; (2) minimal medium supplemented with 1 g/l glucose solution; and (3) nutrient broth. After 96 h of incubation at 28°C, cells were harvested from these batch cultures by centrifugation at 5,000 rpm for 20 min in room temperature. Pellets (whole-cell biomass) were used to carry out phenolic biotransformation experiments. The biomass was washed in Tris–HCl buffer (50 mM, pH 7.0) and resuspended. Reactions were performed in a 100-ml conical flask containing 25 ml of buffer supplemented with a sterile solution of each of the following phenolic acids (at 5 mM concentration), namely, p-coumaric acid, caffeic acid and p-hydroxybenzoic acid, as described by Barghini et al. (1998). Whole-cell suspension (1 ml volume) was added into the flask and incubated under static conditions at 28°C for 24 h. Reaction mixtures were analysed in the same way as described below for the processing of degradation products from the culture medium.

Extraction of degradation products released into the medium

In brief, a culture filtrate was acidified (pH 1–2) and extracted with an equal volume of ethyl acetate. The ethyl acetate was dried out using the vacuum rotary evaporator, the residue was redissolved in 50% methanol and biotransformed products were identified by thin-layer chromatography (TLC) followed by high-performance liquid chromatography (HPLC) (Ghosh et al. 2005).

Separation and identification of phenolic acid derivatives by TLC

Thin-layer chromatography was carried out on Avicel microcrystalline cellulose plates (E. Merck, Darmstadt, Germany), and TLC analysis was performed as described by Dey et al. (2003). The plates were developed in 2% aqueous formic acid. The phenolic acids were viewed under a dual-wavelength (254 nm/312 nm) UV lamp (UVItec, Cambridge, UK), and the bands corresponding to authentic standards were detected on the plates.

HPLC analysis

The separation of phenolic compounds from methanol extract was performed on a C18 column (3.5 μm, 75×4.6 mm, Symmetry; Waters, Milford, USA) using a BREEZE HPLC system (Waters) equipped with a Waters 2487 Dual-Absorbance Detector set at 254 and 310 nm, as described by Sachan et al. (2004). An isocratic linear solvent system of 1 mM aqueous trifluoroacetic acid (72%) and methanol (28%), with a flow rate of 1.0 ml/min for 15 min at room temperature, was used to elute the phenolic compounds. Samples were analyzed on a Windows XP platform with BREEZE software version 3.20 (Waters). Identification of each phenolic compound was confirmed by comparing retention time and UV spectra with external standards. For further confirmation, mass spectrometry was carried out. The separated phenolic compounds in HPLC were quantified by measurements of peak areas.

Mass spectrometry analysis

Samples purified by HPLC were subjected to electron spray ionization–mass spectrometry (ESI-MS) analysis. Samples were analysed with a Micromass LCT Mass Spectrometer (Waters) linked to MassLynx Software version 3.5 (Waters) for data processing. The samples were injected using a syringe attached to a Harvard Syringe Pump. The phenolic acids were analysed in negative ion mode. Operational details were as follows: electrospray capillary voltage and cone voltage in negative ion mode were 3.9 and 0.03 kV, respectively. Source temperature was set to 100°C, and desolvation temperature was set to 120°C. Mass spectra were scanned at unit mass resolution with a mass-to-charge ratio of 100–200 at a rate of 1 s/scan, with an interscan time of 0.1 s. Compounds were identified by comparison with their authentic standards.

Results

S. caeruleus was inoculated in minimal medium containing p-coumaric acid (5.0 mM) as the sole source of carbon and energy and then incubated at 28°C for 10 days. Culture filtrates were processed as usual at an interval of 24 h for the detection of biotransformed products. TLC and HPLC analyses revealed that metabolism of p-coumaric acid by S. caeruleus resulted in the formation of two products, namely, p-hydroxybenzoic acid and caffeic acid (Figs. 1 and 2). It was also observed that incubation at 37°C favoured caffeic acid formation, whereas growth of S. caeruleus at 28°C accumulated both caffeic acid and p-hydroxybenzoic acid in the medium. The chemical identities of p-hydroxybenzoic acid and caffeic acid were further confirmed by ESI-MS (Fig. 3). A trace amount of protocatechuic acid was also observed in the culture filtrate. In fact, accumulation of protocatechuic acid as a major degradation product was observed in the culture medium of S. caeruleus upon utilization of caffeic acid as the sole carbon source (Fig. 4).

TLC chromatogram showing the separation of phenolic acid standards and a processed culture supernatant of Streptomyces caeruleus. Lane 1: p-coumaric acid; lane 2: caffeic acid; lane 3: p-hydroxybenzoic acid; lane 4: p-hydroxybenzaldehyde; lanes 5 and 6: processed culture filtrate of S. caeruleus incubated for 24 and 72 h, respectively, with p-coumaric acid (5 mM) as the sole source of carbon. p-Hydroxybenzaldehyde was detected only after 24 h of incubation (lane 5), but not after 72 h of incubation (lane 6). This observation suggests that p-hydroxybenzaldehyde appears as an intermediate for p-hydroxybenzoic acid formation. Both caffeic acid and p-hydroxybenzoic acid were detected after 72 h of incubation with a substantial utilization of p-coumaric acid, as shown in lane 6

HPLC chromatograms of a processed culture supernatant of S. caeruleus grown on 5.0 mM p-coumaric acid for 48 h (top chromatogram) and for 144 h (bottom chromatogram), respectively. Detection wavelength was 254 nm. Peaks 1, 2 and 3 were identified as p-hydroxybenzoic acid, caffeic acid and p-coumaric acid, respectively

Mass spectral analysis of HPLC-purified caffeic acid (a) and p-hydroxybenzoic acid (b) formed from p-coumaric acid by S. caeruleus. ESI-MS analysis of caffeic acid and p-hydroxybenzoic acid was performed in negative ion mode showing one mass less than the original mass of p-hydroxybenzoic acid. The x-axis represents the increasing mass-to-charge (m/z) ratio, whereas the y-axis represents the relative abundance of each ion, which is related to the number of times that an ion of that m/z ratio strikes the detector. ESI-MS analysis performed in negative ion mode always shows one mass less than the original mass of both the authentic standard and the sample, as shown here in the case of p-hydroxybenzoic acid. In the case of caffeic acid, it appears that a substantial amount of caffeic acid has undergone fragmentation, resulting in detachment of phenylpropanoic side-chain -COOH from both the authentic standard and the sample

HPLC chromatograms of a processed culture supernatant of S. caeruleus grown on 5.0 mM caffeic acid and incubated for 120 h (5 days). Detection wavelength was 254 nm. Peaks 1 and 2 were identified as protocatechuic acid and caffeic acid, respectively. Separation was performed on a Phenomenex (Torrence, CA, USA) C18 column (RP-HYDRO, 4 μm, 250×4.6 mm) using a BREEZE HPLC system (Waters), as described by Sachan et al. (2004)

In order to examine the effect of p-coumaric acid concentration on the production of caffeic acid and p-hydroxybenzoic acid, cells of S. caeruleus were inoculated on minimal medium containing different concentrations of p-coumaric acid (1.0, 2.5, 5.0, 7.5 and 10.0 mM) as the sole source of carbon and energy. The cultures were incubated at 28°C for 10 days, and analyses were carried out at an interval of 48 h for the detection of phenolic metabolites. It was found that p-hydroxybenzoic acid production was maximal at 5.0 mM concentration after 5 days of incubation and then decreased progressively (Fig. 5a). It was further observed that an increase in p-coumaric acid concentration resulted in decreased production of p-hydroxybenzoic acid. Caffeic acid production increased with higher concentrations of p-coumaric acid, and it was found to be maximal at 10.0 mM concentration after 7 days of incubation. A continuous consumption of p-coumaric acid was also monitored. It was completely consumed on day 10 of incubation at 28°C (Fig. 5b).

a Time course accumulation of caffeic acid and p-hydroxybenzoic acid by S. caeruleus grown on minimal medium with 5.0 mM p-coumaric acid as the sole source of carbon and energy. Growth of the microorganism was monitored in terms of protein concentration as described in “Materials and methods”. b Time course accumulation of caffeic acid and p-hydroxybenzoic acid by S. caeruleus grown on minimal medium with 10.0 mM p-coumaric acid as the sole source of carbon and energy. Growth of the microorganism was monitored in terms of protein concentration as described in “Materials and methods”

We also examined the effect of glucose on the production of p-hydroxybenzoic acid and caffeic acid. In order to study the effect of additional carbon source on the production of metabolites, S. caeruleus cells were grown in minimal medium containing filter-sterilized glucose solution (1 g/l). After 16 h of growth on glucose, p-coumaric acid was added into the medium. It was observed that only caffeic acid was produced as a major transformed product with little or no p-hydroxybenzoic acid formation. The maximum amount of 65 mg/l caffeic acid was found to have accumulated in the medium after 72 h of incubation. This observation was in sharp contrast to the results obtained earlier in minimal medium containing p-coumaric acid alone, where accumulation of both caffeic acid and p-hydroxybenzoic acid was observed (Fig. 5a).

The effect of nutrient broth supplementation on the production of co-products was also studied. The maximum amount of 150 mg/l caffeic acid (16.6% molar yield) accumulation was observed after 96 h of incubation with S. caeruleus pre-grown on nutrient broth for 16 h followed by p-coumaric acid (5 mM) supplementation.

Biotransformation studies were also carried out with whole cells of S. caeruleus pre-grown on various media, as described in “Materials and methods”. The results obtained are presented in Table 1. In whole-cell studies, cell suspension volume, incubation period (24 h) and substrate concentration (5 mM) were kept identical in all sets of experiments. Since the reaction mixtures did not contain any inorganic salts required for microbial growth and maintenance, as a consequence, growth inhibition of S.caeruleus was observed, leading to very low levels of product formation (quantitative data not shown).

Discussion

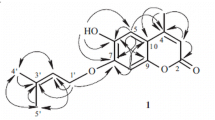

This work reports for the first time the capability of S. caeruleus MTCC 6638 to utilize p-coumaric acid and to co-produce two biotransformed phenolic compounds (caffeic acid and p-hydroxybenzoic acid) (Fig. 6). Streptomyces species were also explored earlier to test their ability to catabolize hydroxycinnamic acids, such as ferulic and p-coumaric acids. Formation of caffeic acid was reported with Streptomyces nigrifaciens on incubation with p-coumaric acid (Nambudiri et al. 1969, 1972). Another species of Streptomyces, namely, Streptomyces setonii, was shown to metabolize p-coumaric acid into p-hydroxybenzoic acid (Sutherland et al. 1983). More recently, Streptomyces halstedii was examined for its capability to biotransform cinnamic and ferulic acids; however, no mention of p-coumaric acid bioconversion was made in this report (Brunati et al. 2004). All these reports described either chain degradation products or hydroxylation products, but not both, as observed in our experiments with S. caeruleus.

In our study, when S. caeruleus cells were grown at 28°C on minimal medium containing p-coumaric acid (5.0 mM) as the sole carbon source, formation of both phenolic products occurred concurrently. This indicates that two different routes possibly utilized p-coumaric acid simultaneously, forming two different products, namely, caffeic acid and p-hydroxybenzoic acid, at optimal conditions. A higher concentration of p-coumaric acid as the sole carbon source favoured caffeic acid formation. Use of a high-density cell mass (as obtained with glucose feeding prior to p-coumaric acid addition) also favours caffeic acid accumulation. This could be explained by the fact that caffeic acid formation from p-coumaric acid requires only a single-step reaction leading to hydroxylation at the meta position, as evidenced ubiquitously in higher plants (Sato 1966; Dixon and Paiva 1995) and microbes (Nambudiri et al. 1972). On the contrary, p-hydroxybenzoic acid formation requires either a three-step biochemical reaction [activation of coenzyme A thioester, side-chain cleavage (C2-chain cleavage) leading to the formation of p-hydroxybenzaldehyde and, finally, oxidation of aldehyde to p-hydroxybenzoic acid] (Löscher and Heide 1994; Abd El-Mawla and Beerhues 2002; Mitra et al. 1999) or a two-step reaction via a non-β-oxidative route (Schnitzler et al. 1992; Podstolski et al. 2002). Thus, the fact that caffeic acid accumulation was favoured in S. caeruleus under a higher substrate concentration encourages the idea that microorganisms may channelize the biotransformation capability of p-coumaric acid towards caffeic acid formation, which could be achieved with less metabolic costs compared to p-hydroxybenzoic acid formation.

When S. caeruleus was pre-grown in minimal medium containing glucose as carbon source, the addition of p-coumaric acid immediately favoured caffeic acid (instead of p-hydroxybenzoic acid) formation. Similar results were obtained with Pycnoporus cinnabarinus, where it was found that glucose appears to be a more efficient carbon source when used alone. Feeding of p-coumaric acid into Pycnoporus cultures grown on 20 g/l glucose medium resulted in the production of 257 mg/l caffeic acid (Estrada Alvarado et al. 2003). Supplementation of p-coumaric acid in nutrient broth also resulted in caffeic acid formation as the major biotransformed product.

Biotransformation experiments with resting cells also indicated similar identical routes to p-coumaric acid degradation, as observed with the culture medium supplemented with p-coumaric acid. Growth-associated catabolic products (caffeic acid and p-hydroxybenzoic acid) were formed as a result of the degradation of the substrate (p-coumaric acid), which served as the sole carbon source for the growth of S. caeruleus. Incubation of the substrate with whole cells in the buffer did not allow the bacteria to grow because of the absence of inorganic nutrients. This resulted in less substrate utilization, leading to much less amounts of product formation.

The ability to form diverse natural products due to secondary metabolism is considered as a typical feature of plants and microorganisms. Actinomycetes members, such as Streptomyces species having a complex life cycle and a large genome, seem to be particularly rich in natural plant products, indicating that some “typical plant pathways” may originate from microorganisms (Bode and Müller 2003). Alternatively, microorganisms might have taken up biosynthetic pathway genes from plant materials via horizontal gene transfer (Nielsen et al. 1998). Another facet concerns a convergent evolution of pathways in phylogenetically unrelated organisms, such as cinnamic acid formation by the phenylalanine ammonia lyase (PAL) enzyme in plants and actinomycetes (Hartmann et al. 2005). Although the presence of PAL activity has recently been established in Streptomyces maritimus and although its functional expression has been demonstrated in Streptomyces coelicolor, nevertheless, the enzyme awaits detailed characterization for a comparison with PALs from eukaryotic and prokaryotic sources (Xiang and Moore 2002). More recently, a plant-like benzoate pathway has been characterized in marine actinomycetes S. maritimus (Hertweck and Moore 2000).

The existence of typical plant pathways in Streptomyces might be due to their saprophytic lifestyle and their proximity to plants in the soil environment (Bode and Müller 2003). The capability of Streptomyces species to utilize hydroxycinnamic acids that are available in the soil as a result of lignin degradation by soil microbes is well-known (Sutherland et al. 1983). It therefore seems likely, that under stress conditions, such as when nutrient availability is limited, Streptomyces might well utilize these hydroxycinnamic acids for its own maintenance. Thus, formation of caffeic acid and p-hydroxybenzoic acid from p-coumaric acid by S. caeruleus appears to be a unique degradation mechanism for carbon source utilization and its own maintenance mechanism under stress conditions.

Due to the appearance of caffeic acid and p-hydroxybenzoic acid as two major phenolic co-products on p-coumaric acid utilization, we regard S. caeruleus as an excellent model that fully elucidates p-hydroxybenzoic acid and caffeic acid biosynthesis at the enzymatic and genetic levels. Work is being continued to characterize these pathways in this microorganism.

References

Abd El-Mawla AMA, Beerhues L (2002) Benzoic acid biosynthesis in cell cultures of Hypericum androsaemum. Planta 214:727–733

Barghini P, Montebove F, Ruzzi M, Schiesser A (1998) Optimal conditions for bioconversion of ferulic acid into vanillic acid by Pseudomonas fluorescens BF13 cells. Appl Microbiol Biotechnol 49:309–314

Bode HB, Müller R (2003) Possibility of bacterial recruitment of plant genes associated with the biosynthesis of secondary metabolites. Plant Physiol 132:1153–1161

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein–dye binding. Anal Biochem 72:248–254

Brunati M, Marinelli F, Bertolini C, Gandolfi R, Daffonchio D, Molinari F (2004) Biotransformation of cinnamic and ferulic acid with actinomycetes. Enzyme Microb Technol 34:3–9

Dey G, Sachan A, Ghosh S, Mitra A (2003) Detection of major phenolic acids from dried mesocarpic husk of mature coconut by thin layer chromatography. Ind Crops Prod 18:171–176

Dixon RA, Paiva NL (1995) Stress-induced phenylpropanoid metabolism. Plant Cell 7:1085–1097

Douglas CJ (1996) Phenylpropanoid metabolism and lignin biosynthesis: from weeds to trees. Trends Plant Sci 1:171–178

Estrada Alvarado I, Lomascolo A, Navarro D, Delattre M, Asther M, Lesage-Meessen L (2001) Evidence of a new biotransformation pathway of p-coumaric acid into p-hydroxybenzaldehyde in Pycnoporus cinnabarinus. Appl Microbiol Biotechnol 57:725–730

Estrada Alvarado I, Navarro D, Record E, Asther M, Asther M, Lesage-Meessen L (2003) Fungal biotransformation of p-coumaric acid into caffeic acid by Pycnoporus cinnabarinus: an alternative for producing a strong natural antioxidant. World J Microbiol Biotechnol 19:157–160

Ghosh S, Sachan A, Mitra A (2005) Degradation of ferulic acid by a white-rot fungus Schizophyllum commune. World J Microbiol Biotechnol 21:385–388

Hartley RD, Harris PJ (1981) Phenolic constituents of the cell walls of dicotyledons. Biochem Syst Ecol 9:189–203

Hartmann T, Kutchan TM, Strack D (2005) Evolution of metabolic diversity. Phytochemistry 66:1198–1199

Henderson MEK (1961) The metabolism of aromatic compounds related to lignin by some hyphomycetes and yeast-like fungi of soil. J Gen Microbiol 26:155–165

Hertweck C, Moore BS (2000) A plant-like biosynthesis of benzoyl CoA in the marine bacterium ‘Streptomyces maritimus’. Tetrahedron 56:9115–9120

Hertweck C, Jarvis AP, Xiang L, Moore BS, Oldham NJ (2001) A mechanism of benzoic acid biosynthesis in plants and bacteria that mirrors fatty acid β-oxidation. Chembiochem 10:784–786

Löscher R, Heide L (1994) Biosynthesis of p-hydroxybenzoate from p-coumaric acid and p-coumaryl-coenzyme a in cell-free extracts of Lithospermum erythrorhizon cell cultures. Plant Physiol 106:271–279

MacAdam JW, Grabber JH (2002) Relationship of growth cessation with the formation of diferulic acid cross-links and p-coumaroylated lignins in tall fescue leaf blades. Planta 215:783–793

McQualter RB, Chong BF, Meyer K, Van Dyk DE, O’Shea MG, Walton NJ, Viitanen PV, Brumbley SM (2005) Initial evaluation of sugarcane as a production platform for p-hydroxybenzoic acid. Plant Biotechnol J 3:29–41

Michaluart P, Masferrer JL, Carothers AM, Subbaramaiah K, Zweifel BS, Koboldt C, Mestre JR, Grunberger D, Sacks PG, Tanabe T, Dannenberg AJ (1999) Inhibitory effect of caffeic acid phenethyl ester on the activity and expression of cyclooxygenase-2 in human oral epithelial cell and in rat model of inflammation. Cancer Res 59:2347–2352

Mitra A, Kitamura YJ, Gasson MJ, Narbad A, Parr A, Payne J, Rhodes MJC, Sewter C, Walton NJ (1999) 4-Hydroxycinnamoyl-CoA-hydratase/lyase (HCHL)—an enzyme of phenylpropanoid chain cleavage from Pseudomonas. Arch Biochem Biophys 365:10–16

Muheim A, Lerch K (1999) Towards a high-yield bioconversion of ferulic acid to vanillin. Appl Microbiol Biotechnol 51:456–461

Nambudiri AMD, Subba Rao PV, Bhat JV (1969) Metabolism of p-coumaric acid by Streptomyces—formation of caffeic acid as intermediate. Curr Sci 38:402

Nambudiri AMD, Bhat JV, Subba Rao PV (1972) Conversion of p-coumaric acid into caffeic acid by Streptomyces nigrifaciens: purification and properties of the hydroxylating enzyme. Biochem J 130:425–433

Nardini M, D’Aquino M, Tomassi G, Gentili V, Felice MD, Scaccini C (1995) Inhibition of human low-density lipoprotein oxidation by caffeic acid and other hydroxycinnamic acid derivatives. Free Radic Biol Med 19:541–552

Nielsen KM, Bones AM, Smalla K, van Elsas JD (1998) Horizontal gene transfer from transgenic plants to terrestrial bacteria—a rare event. FEMS Microbiol Rev 22:79–103

Podstolski A, Havkin-Frenkel D, Malinowski J, Blount JW, Kourteva G, Dixon RA (2002) Unusual 4-hydroxybenzaldehyde synthase activity from tissue cultures of the vanilla orchid Vanilla planifolia. Phytochemistry 61:611–620

Rosazza JPN, Huang Z, Dostal L, Volm T, Rousseau B (1995) Biocatalytic transformations of ferulic acid: an abundant aromatic natural product. J Ind Microbiol 15:457–471

Sachan A, Ghosh S, Mitra A (2004) An efficient isocratic separation of hydroxycinnamic acids and their corresponding benzoates from microbial and plant sources by HPLC. Biotechnol Appl Biochem 40:197–200

Sachan A, Ghosh S, Mitra A (2005) Biotransformation of p-coumaric acid by Paecilomyces variotii. Lett Appl Microbiol (in press)

Sato M (1966) Metabolism of phenolic substances by the chloroplasts II. conversion by the isolated chloroplasts of p-coumaric acid to caffeic acid. Phytochemistry 5:385–389

Schnitzler J, Madlung J, Rose A, Seitz HU (1992) Biosynthesis of p-hydroxybenzoic acid in elicitor-treated carrot cell cultures. Planta 188:594–600

Shirling EB, Gottlieb D (1966) Methods of characterization of Streptomyces. Int J Syst Bacteriol 61:313–340

Sutherland JB, Crawford DJ, Pometto AL III (1983) Metabolism of cinnamic, p-coumaric and ferulic acids by Streptomyces setonii. Can J Microbiol 29:1253–1257

Tomas-Barberan FA, Clifford MN (2000) Dietary hydroxybenzoic acid derivatives—nature, occurrence and dietary burden. J Sci Food Agric 80:1024–1032

Walton NJ, Mayer MJ, Narbad A (2003) Vanillin. Phytochemistry 63:505–515

Wu R-Y, Chen M-H (1995) Identification of Streptomyces strain KS3-5. Bot Bull Acad Sin 36:201–205

Xiang LK, Moore BS (2002) Inactivation, complementation and heterologous expression of encP, a novel bacterial phenyalanine ammonia-lyase gene. J Biol Chem 277:32505–32509

Acknowledgements

This work was supported by a ‘Career Award for Young Teachers’ (no. 1-51/FD/CA/(001)/2003–2004; to A. Mitra) from the All India Council for Technical Education, India, and in part by a multi-institutional research grant (no. BT/PR/2516/PID/24/120/2001; to A. Mitra and S.K. Sen) from the Department of Biotechnology (DBT), Ministry of Science and Technology, India. A. Sachan acknowledges the Indian Institute of Technology Kharagpur for an institute research scholarship award. S. Ghosh was funded by DBT in the form of a senior research fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sachan, A., Ghosh, S., Sen, S.K. et al. Co-production of caffeic acid and p-hydroxybenzoic acid from p-coumaric acid by Streptomyces caeruleus MTCC 6638. Appl Microbiol Biotechnol 71, 720–727 (2006). https://doi.org/10.1007/s00253-005-0197-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-005-0197-1