Abstract

To explore the potential of heterologous protein expression in Kluyveromyces cicerisporus, three expression plasmids, pUK1-PIT, pUKD-PIT and pUKD-S-PIT, based on the vector pUK1 or pUKD were constructed and transformed, respectively, into yeast strain K. cicerisporus Y179U. Human interferon α-2a, used as an example protein, was successfully expressed and secreted by transformant Y179U/pUKD-PIT and Y179U/pUKD-S-PIT. In the flask culture, strain Y179U/pUKD-S-PIT could express interferon at 60 mg/l. The stability of plasmid pUKD-S-PIT in the host was higher than that of pUKD-PIT. This was consistent with their expression levels of interferon. There were two interferon-related bands found by Western blotting analysis. The possible reason for this is discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Although varieties of hosts, ranging from bacteria to higher eukaryotes, have been examined and found to produce heterologous proteins, yeasts have been shown to have considerable advantages in their expression of these. Besides Saccharomyces cerevisiae which has been successfully developed as a protein-expression system, several other yeast protein-expression systems have been intensively studied (Swinkels et al. 1993). Among these, Kluyveromyces had drawn much attention as an alternative host for heterologous protein expression (Fleer et al. 1991).

In our laboratories, hundreds of different yeast stocks were screened for higher growth density and protein secretion ability. One yeast strain Kluyveromyces cicerisporus CBS4857 was found to be prominent, and could grow to a high density in YEPD medium. In particular, it was found to efficiently secrete a high-molecular weight protein, inulinase, representing >60% of total secreted protein. Subsequently, eight DNA fragments possessing promoter function were cloned from K. cicerisporus CBS4857 genomic DNA (Xu et al. 1998). Furthermore, the full-length inulinase gene, including its promoter and terminator, was cloned and analysed (Wen et al. 2003). It was of interest that although the inulinase gene coding region shared high similarity with K. marxianus CBS6556, K. marxianus ATCC12424 and Kluyveromyces lactis, the nucleotide sequence of the KcINU1 promoter was significantly different from that of other Kluyveromyces strains. Recently, the selection marker, KcURA3 was cloned and an ura3 mutant strain Y179U was obtained by counter selection on 5-fluoroorotic acid plates from K. cicerisporus CBS4857. Correspondingly, the vector pUK1 and pUKD were constructed and a transformation method was developed for K. cicerisporus (Zhang et al. 2003). All the findings indicated that K. cicerisporus CBS4857 was a prominent candidate for the development of an expression system.

The circular plasmid pKD1 of K. drosophilarum was found to replicate and maintain stability in several Kluyveromyces, which contribute to its application in expression system-construction in K. lactics and K. marxianus. As 2 μ in S. cerevisiae, all essential regions of the pKD1 had to be intact for its stability in the host cells. Usually, the extra DNA sequences necessary for the expression of the plasmid were inserted at the unique EcoRI site of pKD1, which was located in a cis-acting stability locus. Disruption of this region would affect segregational stability of the plasmid. Bianchi et al. (1991) found that the unique SphI site in the pKD1 was in its non-essential region. It would be better to use SphI as the insertion site for the construction of pKD1-derivative vectors.

In this article, we describe the construction of expression plasmids, the secretory expression of a heterologous protein and the identification of interferon α-2a expressed by K. cicerisporus.

Materials and methods

Strains and growth conditions

Yeast strain K. cicerisporus CBS4857 (stock of the Centraalbureau voor Schimmelcultures ; Yeast Division, Delft), and the corresponding ura3 mutant Y179U were developed previously (Zhang et al. 2003). Yeasts were grown in SD medium (0.67% yeast nitrogen base without amino acids, 2% glucose), supplemented with uracil when needed or YEPD medium (1% yeast extract, 2% peptone, 2% glucose) in a 250-ml flask at 30°C and on a 250-r.p.m. rotary shaker. Cell density was measured as optical density (OD) at 600 nm using a spectrophotometer.

Escherichia coli DH5α, used in construction of the expression vectors and for all other purposes in this research, was grown on Luria-Bertani medium (0.5% yeast extract, 1% polypeptone, 1% NaCl, pH 7.0), supplemented with ampicillin (100 μg/ml) when needed, at 37°C (Sambrook et al. 1989).

Plasmids and expression plasmid construction

The T-vector pMD-18 was purchased from Takara (China). The vectors of K. cicerisporus pUK1 and pUKD were constructed previously (Zhang et al. 2003). pHC11-IFNα-A is an expression plasmid in S. cerevisiae for human interferon α-2a production (Huo et al. 1993). For construction of expression plasmids, 1.2 kb KcINU1 promoter Pinu and 0.8 kb KcINU1 terminator Tinu were amplified by PCR with the primer pairs, Pinu-F: 5′CGCCGCGGATCCGAAAGG3′/Pinu-R: 5′AAGAATTCATCTAACAAAAAAAAAATTAAATGTGTCAC3′, and Tinu-F: 5′ ACCCAATTTAAGCTTTGATCTGAT3′/Tinu-R5′AGTCGACGGATCCTAGAATGTTG GTCAGATGTAGA 3′, respectively. A 1.1-kb DNA fragment encoding α factor signal peptide and human interferon α-2a was cleaved from pHC11-INFαA by EcoRI and HindIII. Above three fragments were then ligated with BamHI linearized pUK1 to form expression plasmid pUK1-PIT. To construct expression plasmid pUKD-PIT, the 3.0-kb BamHI fragment, including the cassette for human interferon expression, PIT from pUKI-PIT and SalI linearized pUKD, were blunted by Klenow reaction and ligated. The construction of expression plasmid pUKD-S-PIT was divided into two steps. The first step was to insert pUC19 and KcURA3 sequences into the SphI site of pKD1 to form the plasmid pUKD-S. This plasmid was then linearized with restriction enzyme Sse8387I and ligated with blunted expression cassette PIT.

Yeast transformation

The yeast transformation was carried out by the modified LiAc method (Zhang et al. 2003).

Plasmid stability of transformants

Yeast plasmid stability was assayed according to the procedure described by Jayaram et al. (1983). After 20-generations growth, about 100 randomly selected colonies were tested for growth on SD-ura and YEPD plates. Plasmid stability was defined as the percentage of Ura+ colonies.

Western blotting analysis

Proteins from culture broth were separated using sodium dodecyl sulphate polyacrylamide gel electrophoresis (SDS-PAGE) and transferred to PVDF membrane (Bio-Rad). The Western blot procedure was carried out as described (Sambrook et al. 1989). After blocking for 1 h, the PVDF membrane was then incubated with mouse monoclonal antibody against hIFN α-2a in PBS and 5% skim milk powder at room temperature on an orbital shaker for 1 h; the goat anti-mouse secondary antibody was conjugated for 1 h. Visualization was performed by enhanced chemiluminescence (Amersham).

Bio-activity assay

The antiviral activity of expressed IFN-alpha 2a was quantified by inhibition of the cytopathic effect of vesicular stomatitis virus in the human WISH cell line.

Results

Construction of the expression plasmids

The structure of expression plasmids, pUK1-PIT, pUKD-PIT and pUKD-S-PIT are illustrated in Fig. 1. All plasmids contained the interferon expression cassette PIT. pUK1-PIT and pUKD-PIT were derived from vectors pUK1 and pUKD, respectively. Unlike pUKD-PIT, the disruption site of plasmid pKD1 in the pUKD-S-PIT was SphI instead of EcoRI. The structure of the constructed expression plasmids was verified by restriction mapping analysis (data not shown).

Transformant confirmation and expression of interferon

Three expression plasmids, pUK1-PIT, pUKD-PIT and pUKD-S-PIT, were used to transform Y179U using a modified LiAc method. Unlike pUKD-PIT and pUKD-S-PIT, which both give transformants forming average-size colonies, pUK1-PIT gives two kinds of transformants forming colonies of different size, about 5% of which were big colonies and the rest small colonies. Six colonies from each kind of transformant were selected randomly for plasmid recovery. Except for big colonies of pUK1-PIT transformants, the plasmids were recovered from all other transformants and gave the same pattern of restriction maps as original plasmids (data not shown). Southern blot analysis further confirmed that the big colony, without plasmid recovery, integrated plasmid into the chromosome (data not shown).

Each kind of transformant was cultured in SD medium overnight as seed culture, then inoculated at 1 OD per flask containing 25 ml YEPD. After growing at 30°C, 250 r.p.m. for 3 days, culture broth was collected and subjected to SDS-PAGE detection. As shown in Fig. 2, Y179U/pUKD-S-PIT transformants were found to be prominent in the expression of interferon; Y179U/pUKD-PIT transformants secreted quite a high amount of interferon too, although much less than those of Y179U/pUKD-S-PIT. Both kinds of Y179U/pUK1-PIT transformants, forming a big or small colony, showed almost no interferon expression; however, samples forming a big colony showed a weak band on the Western blot membrane (data not shown).

Expression of interferon by Y179U/pUKD-S-PIT shown by sodium dodecyl sulphate polyacrylamide gel electrophoresis (SDS-PAGE)

30 µL of each sample was subjected to electrophoresis after growing for 72 h. 1, Y179U (negative control); 2, Y179U/pUKD-S-PIT; 3, Y179U/pUKD-PIT; 4, Y179U/pUK1-PIT (small); 5, Y179U/pUK1-PIT (big); Sm, protein marker of standard molecular weight. The band pointed by arrowhead was the interferon alpha-2a

Plasmid stability in different kinds of transformants

As shown in Table 1, the expression plasmid in Y179U/pUKD-S-PIT was much more stable than those in Y179U/pUKD-PIT. Expression plasmids in Y179U/pUK1-PIT transformants forming a small colony possess very low stability, while the plasmid in Y179U/pUK1-PIT transformants forming a big colony was completely stable. This was consistent with the result of the Southern blot analysis.

Characterization of the expressed interferon

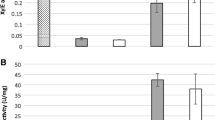

For characterization of the expressed interferon, further study was focused on transformant Y179U/pUKD-S-PIT. It can be seen from Fig. 2 that the expressed interferon possesses a higher molecular weight than that of normal interferon α-2a. To estimate whether the quantity and quality of expressed interferon could be optimized, the growth conditions, including the duration of culture, concentration of glucose in the YEPD and the addition of detergent (Tween-20), were investigated. In contrast to the 72-h culture, both the 48-h and 60-h culture contained two components of interferon (Fig. 3). The molecular weight of the lower band was about the size of normal interferon α-2a. The Western blot analysis shown that both bands could react with monoclonal antibody against interferon α-2a (Fig. 4). Correspondingly, the antivirus activities of culture supernatants were preliminary assayed, and found to be about 1.3×106 IU/ml. It was found that if the glucose concentration in the YEPD was increased to 4%, the expression level of interferon could be greatly elevated (Fig. 5). Interestingly, adding a final concentration 0.2% of Tween-20 in YEPD could also elevate the expression level. In addition, the interferon band of higher molecular weight almost completely disappeared (Fig. 5).

Western blot analysis showing reaction of two components of interferon with monoclonal antibody against interferon α-2a

A: the expressed human interferon was analyzed by staining with Coomassie Blue; B: the expressed interferon was detected by immunoblotting with monoclonal antibody against human interferon. 1, protein marker with standard molecular weight; 2, sample from 72 h culture in YEPD medium; 3, sample from 60 h culture in YEPD medium; 3, sample of negative control (transformant Y179U/pUKD-S)

To more clearly evaluate the expression level, the culture supernatant of K. cicerisporus Y179U/pUKD-S-PIT, interferon α-2a expressed by S. cerevisiae and purified standard interferon α-2a, were loaded on the same gel (Fig. 6). After scanning the density of interferon bands, the data were then treated with Smart View. Interferon with the correct molecular weight expressed by K. cicerisporus was estimated to be >60 mg/l.

Expression level of interferon from a culture supernatant of K. cicerisporus Y179U/pUKD-S-PIT, interferon α-2a expressed by S. cerevisiae and purified standard interferon α-2a

1-2, human interferon alpha-2a expressed by S. cerevisiae; 3-4, human interferon alpha-2a expressed by K. cicerisporus Y179U/pUKD-S-PIT; 5, 0.5 ug standard sample; 6, 1.0 ug standard sample; 7, 2.0 ug standard sample; Sm, protein marker with standard molecular weight

Discussion

The aim of this study was to evaluate the possibility of developing a vector/host system using K. cicerisporus in the expression and secretion of heterologous proteins. Since the 1980s, recombinant human interferon α-2a has been expressed in E. coli cells, yeast, baculovirus-infected cells and mammalian cells (Rossmann et al. 1996; Platis and Foster 2003). In our laboratories, human interferon α-2a was also successfully expressed in S. cerevisiae by using expression plasmid pHC11-IFNα-A (Huo et al. 1993). Based on the vectors pUK1 and pUKD, three expression plasmids, pUK1-PIT, pUKD-PIT and pUKD-S-PIT were constructed. All three expression plasmids contained an expression cassette allowing expression of the interferon gene where the promoter, and terminator were from K. cicerisporus INU1 gene and signal sequence from MFα. The results showed that the human interferon α-2a could be successfully expressed and secreted by K. cicerisporus. The secretory expression level could reach 60 mg/l, even when the fermentation was carried out at the flask-culture scale. In our study, the promoter and terminator of INU1 could control the transcription of the foreign gene, but they were not as efficient as for the native gene. To further understand their structure and function, or to clone them and use other kinds of transcription elements, may help us to further increase the expression level of foreign genes.

Compared with the Y179U/pUKD-PIT transformant, the interferon expression level of the Y179U/pUKD-S-PIT transformant was almost doubled. It may be partly explained by plasmid stability, because the plasmid stability of Y179U/pUKD-S-PIT is much higher than that of Y179U/pUKD-PIT. Correspondingly, the poor stability of the Y179U/pUK1-PIT transformant which formed a small colony led to its lack of interferon expression. The Y179U/pUK1-PIT transformant forming a big colony also exhibited poor expression ability, although its plasmid stability reached up to 100%. Its low copy number of integrated plasmid should be considered as an important factor.

Heterogeneity of expressed proteins has been a drawback of yeast expression systems (Wang et al. 1995; Hitzeman et al. 1983). In our study, although there was no obvious degradation as observed in S. cerevisiae, there were two components of interferon with different molecular weights expressed by K. cicerisporus. During the 72-h culture process, the component with the higher molecular weight increased, while the component with normal molecular weight increased during the first 60 h and quickly reduced after that time. Hashimoto et al. (1998) also found that the lysozyme expression directed by a MFα signal sequence exhibits the same trend: the amounts of misprocessed sub-products increased as the cultivation time lengthened. Although we still do not know the exact reason for this phenomenon, cell autolysis maybe the most possible reason for this. Furthermore, glycosylation status should be another important point to be considered. The culture conditions including composition of the medium and culture technology is crucial not only for heterologous protein production and but also for correct processing (Jahic et al. 2002). In this study, the production of interferon was doubled just by increasing the glucose concentration to 4% in the medium. However, high amounts of contaminating proteins in the culture broth were seen, which would be a great obstacle to further purification of targeted proteins. To reduce such contaminating proteins, production methods should be the focus to perfect this novel expression system. It seems that the quality of expressed product could be improved just by adding detergent in YEPD. Further optimization of culture conditions combined with host/vector improvement would be an attractive way to develop this novel heterologous protein-expression system.

References

Bianchi MM, Santarelli R, Frontali L (1991) Plasmid functions involved in the stable propagation of the pKD1 circular plasmid in Kluyveromyces lactis. Curr Genet 19:155–161

Fleer R, Chen XJ, Amellal N, Yeh P, Fournier A, Guinet F, Gault N, Faucher D, Folliard F, Fukuhara H (1991) High-level secretion of correctly processed recombinant human interleukin-1 beta in Kluyveromyces lactis. Gene 107:285–295

Hashimoto Y, Koyabu N, Imoto T (1998) Effects of signal sequences on the secretion of hen lysozyme by yeast: construction of four secretion cassette vectors. Protein Eng 11:75–77

Hitzeman RA, Leung DW, Perry LJ, Kohr WJ, Levine HL, Goeddel DV (1983) Secretion of human interferons by yeast. Science 219:620–625

Huo KK, Yu LL, Chen XJ, Li YY (1993) A stable vector for high-level expression and secretion of human interferon alpha A in yeast. Sci China B 36:557–567

Jahic M, Rotticci-Mulder JC, Martinelle M, Hult K, Enfors SO (2002) Modeling of growth and energy metabolism of Pichia pastoris producing a fusion protein. Bioprocess Biosystem Eng 24:385–393

Jayaram M, Li YY, Broach JR (1983) The yeast plasmid 2mu circle encodes components required for its high copy propagation. Cell 34:95–104

Platis D, Foster GR (2003) High yield expression, refolding, and characterization of recombinant interferon alpha2/alpha8 hybrids in Escherichia coli. Protein Expr Purif 31:222–230

Rossmann C, Sharp N, Allen G, Gewert D (1996) Expression and purification of recombinant, glycosylated human interferon alpha 2b in murine myeloma NSO cells. Protein Expr Purif 7:335–342

Sambrook J, Fritsch EF, Maniatis T (1989) Molecular cloning: a laboratory manual. Cold Spring Harbor Laboratory Press, New York

Swinkels BW, van Ooyen AJ, Bonekamp FJ (1993) The yeast Kluyveromyces lactis as an efficient host for heterologous gene expression. Antonie Van Leeuwenhoek J Serol Microbiol 64:187–201

Wang H, Gao B, Chen P, Dong L, Li Y (1995) Analysis of heterogeneity of gene products (interferon) expressed in yeast. Sci China B 38:954–962

Wen TQ, Liu F, Huo KK, Li YY (2003) Cloning and analysis of the inulinase gene from Kluyeromyces cicerisporus CBS4857. World J Microbiol Biotechnol 19:426

Xu GZ, Pan F, Huo KK, Li YY (1998) Cloning of DNA Fragments Possessing Promoter Function from Kluyveromyces cicerisporus. Sheng Wu Hua Xue Yu Sheng Wu Wu Li Xue Bao (Shanghai) 30:35–40

Zhang J, Yuan H, Wen T, Xu F, Di Y, Huo K, Li YY (2003) Cloning of the KcURA3 gene and development of a transformation system for Kluyveromyces cicerisporus. Appl Microbiol Biotechnol 62:387–391

Acknowledgement

This project was granted financial support from the China Postdoctoral Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, X.P., Zhang, J., Yuan, HY. et al. Secretory expression of heterologous protein in Kluyveromyces cicerisporus. Appl Microbiol Biotechnol 67, 364–369 (2005). https://doi.org/10.1007/s00253-004-1834-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-004-1834-9