Abstract

Microorganisms aerobically degrading quinolinic acid, lutidinic acid or isocinchomeronic acid were isolated and the microbial regioselective hydroxylation of these pyridine dicarboxylic acids was studied. Alcaligenes sp. UK21 cells converted quinolinic acid into 6-hydroxypicolinic acid, suggesting the involvement of two enzyme reactions catalyzing hydroxylation at position C6 and decarboxylation at position C3 of quinolinic acid. Resting cells of Alcaligenes sp. UK21 accumulated 94.9 mM 6-hydroxypicolinic acid (13.2 g l−1), with a 96% molar conversion yield by 48 h incubation. Rhizobium sp. LA17 and Hydrogenophaga sp. IMA01 catalyzed the regioselective hydroxylation of lutidinic acid and isocinchomeronic acid into 6-hydroxylutidinic acid and 6-hydroxyisocinchomeronic acid, respectively. 6-Hydroxylutidinic acid accumulated up to 95.4 mM (17.5 g l−1) by 24 h incubation in the resting cells reaction, using Rhizobium sp. LA17, with a 99% molar conversion yield. Resting cells of Hydrogenophaga sp. IMA01 produced 88.7 mM 6-hydroxyisocinchomeronic acid (16.2 g l−1) by 24 h incubation, with a 81% molar conversion yield.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Regioselectivity and high efficiency are characteristics of microbial hydroxylation reactions of N-heterocyclic aromatic compounds; and N-heterocyclic compounds with hydroxyl groups can be utilized for the synthesis of various pharmaceuticals and agrochemicals. For example, 6-hydroxynicotinic acid and 3-cyano-6-hydroxypyridine are important materials in the synthesis of imidacloprid, a potential insecticide (Kagabu et al. 1992; Moriya et al. 1992, 1993). Microbial hydroxylation at the carbon atom adjacent to nitrogen of pyridine monocarboxylic acids, such as nicotinic acid, picolinic acid and isonicotinic acid, has been studied extensively (Gupta and Shukla 1979; Hurh et al. 1994b; Kiener et al. 1993; Kretzer and Andreesen 1991; Kretzer et al. 1993; Nagel and Andreesen 1989; Nakano et al. 1999; Shukla et al. 1977; Siegmund et al. 1990; Singh and Shukla 1986; Tate and Ensign 1974; Tinschert et al. 1997; Ueda and Sashida 1998; Yasuda et al. 1995). We previously established the efficient conversion process of nicotinic acid and 3-cyanopyridine into 6-hydroxynicotinic acid and 3-cyano-6-hydroxypyridine, respectively, by bacteria.

In contrast, studies on microbial conversion of pyridine dicarboxylic acids are limited solely to the degradation pathway of dipicolinic acid (pyridine-2,6-dicarboxylic acid), which is found in Bacillus spores (Slieman and Nicholson 2001). A possible degradation pathway via 3-hydroxydipicolinic acid is reported (Arima and Kobayashi 1962; Kobayashi and Arima 1962). However, there has been no comprehensive report on microbial degradation of pyridine dicarboxylic acids (Fetzner 1998; Schwarz and Lingens1994). In the present study, we found that some microorganisms degrade quinolinic acid (pyridine-2,3-dicarboxylic acid), lutidinic acid (pyridine-2,4-dicarboxylic acid) and isocinchomeronic acid (pyridine-2,5-dicarboxylic acid). We therefore applied these microbial cells to the synthesis of 6-hydroxypicolinic acid, 6-hydroxylutidinic acid and 6-hydroxyisocinchomeronic acid.

Materials and methods

Chemicals

Quinolinic acid, lutidinic acid and isocinchomeronic acid (see Fig. 1) were obtained from Wako Pure Chemical Industries (Japan). Yeast extract was purchased from the Oriental Yeast Co. (Japan). All other chemicals used in this work were of analytical grade and commercially available.

Medium and cultivation

For the isolation of quinolinic acid-, lutidinic acid- and isocinchomeronic acid-degrading microorganisms, conventional enrichment cultures were carried out aerobically at 28 °C in the following two media. Medium A contained 2.5 g pyridine dicarboxylic acid (either quinolinic acid, lutidinic acid or isocinchomeronic acid), 1 g KH2PO4, 3 g K2HPO4, 0.5 g MgSO4·7H2O and 10 ml metal solution in 1 l tap water (pH 7.0). Medium B comprised medium A with 1% (w/v) NH4Cl. Metal solution contained 400 mg CaCl2·2H2O, 300 mg H3BO3, 40 mg CuSO4·5H2O, 100 mg KI, 200 mg FeSO4·7H2O, 400 mg MnSO4·7H2O, 200 mg Na2MoO4·2H2O and 10 ml conc. HCl in 1 l distilled water. Soils were used as the source to isolate pyridine dicarboxylic acid-degrading microorganisms.

For the preparation of resting cells, the following cultivation was carried out. The subculture was done at 28 °C for 1 day with reciprocal shaking in a test-tube containing 2 ml nutrient medium, consisting of 5 g peptone, 0.5 g yeast extract, 5 g meat extract and 2 g NaCl in 1 l tap water (pH 7.0). The subculture was transferred into a 500-ml shaking-flask containing 40 ml medium C; and the cultivation was done at 28 °C for 3 days. Medium C consisted of 2.5 g pyridine dicarboxylic acid, 1 g KH2PO4, 3 g K2HPO4, 1 g yeast extract, 0.5 g MgSO4·7H2O and 10 ml metal solution in 1 l tap water (pH 7.0).

The cell growth of Alcaligenes sp. UK21 was estimated turbidimetrically at 610 nm; and 0.650 mg dry cell weight ml–1 was equivalent to 1.0 unit of optical density at 610 nm. As for Rhizobium sp. LA17 and Hydrogenophaga sp. IMA01, 0.424 mg and 0.576 mg dry cell weight ml–1 were equivalent to 1.0 unit of optical density at 610 nm, respectively.

Identification of microorganisms

The identification of pyridine dicarboxylic acid-degrading microorganisms was carried out by the Deutsche Sammelung von Mikroorganismen und Zellkulturen, Braunschweig, Germany.

Resting cells reaction

Cells harvested by centrifugation at 7,000 g at 4 °C for 20 min were suspended in 0.15 M NaCl and used as the resting cells. Cells from 30 ml culture broth were incubated with 50 µmol pyridine dicarboxylic acid and 250 µmol potassium phosphate buffer (pH 7.0) in a 2.0-ml reaction mixture. The reaction was carried out with reciprocal shaking (160 strokes min−1) at 30 °C for 30 min and stopped by the addition of 2 ml methanol. The reaction product and remaining substrate were determined by HPLC on a Shimadzu LC-10AS and SPD-10A system with a Wakosil-II RS column (4.6×150 mm) purchased from Wako Pure Chemical Industries. A 96:4 (v/v) mixture of 10 mM potassium phosphate buffer (pH 2.5) and acetonitrile was used for elution. The flow rate was maintained at 1.0 ml min−1; and the absorbance of eluates was monitored at 230 nm. Total activity was defined as the amount of hydroxylated product by resting cells per minute, derived from 1 ml culture broth.

Identification of reaction products

The reaction products from each pyridine dicarboxylic acid were isolated by a Dowex 1-X2 anion-exchange column and crystallized in distilled water. NMR spectrometries were analyzed with a Joel JNM-400 F17 NMR using DMSO-d 6. Mass spectrometry was analyzed with Quattoro-II (Micromass). 6-Hydroxypicolinic acid was a white needle crystalline solid [1H-NMR (400 MHz, DMSO-d 6) gave: δ 3.46 (1H, s, OH), 6.57 (1H, d, J=9 Hz), 6.90 (1H, d, J=6.8 Hz), 7.48 (1H, dd, J=6.8 Hz) and 12.3 (1H, s, COOH); 13C-NMR (100 MHz, DMSO-d 6) gave: δ 109.9, 123.4, 137.6, 140.0, 162.2 and 162.9; mass spectrometry gave m/z values of 139.9 (M+H+, 100%) and 121.9 (M–OH+, 5.7%)]. 6-Hydroxylutidinic acid was a white crystalline solid [1H-NMR (400 MHz, DMSO-d 6) gave: δ 4.19 (1H, s, OH), 7.07 (1H, s), 7.33 (1H, s) and 12.3 (1H, s, COOH); 13C-NMR (100 MHz, DMSO-d 6) gave: δ 109.0, 122.7, 139.8, 142.1, 162.8, 162.9 and 165.4; mass spectrometry gave m/z values of 181.8 (M–H–, 100%) and 137.8 (M–CO2–H–, 5.2%)]. 6-Hydroxyisocinchomeronic acid was a yellowish-white crystalline solid [1H-NMR (400 MHz, DMSO-d 6) gave: δ 3.48 (1H, s, OH), 7.19 (1H, s), 8.42 (1H, s) and 12.2 (1H, s, COOH); 13C-NMR (100 MHz, DMSO-d 6) gave: δ 110.2, 120.4, 141.4, 145.7, 161.3, 164.4 and 164.6; mass spectrometry gave m/z values of 181.7 (M–H–, 100%) and 137.7 (M–CO2–H–, 73.9%)].

Optimization of culture medium

To optimize the culture medium, the following carbon sources were added to medium C: glucose, lactose, sucrose, galactose, fructose, glycerol, sodium l-glutamate, sodium citrate and sodium fumarate. In order to optimize nitrogen sources in the culture medium, the following compounds were tested: yeast extract, corn steep liquor, casamino acids, NZ amine, malt extract, NH4Cl, (NH4)2HPO4, (NH4)2SO4 and NaNO3. Enzyme induction by the following compounds was examined: quinolinic acid, lutidinic acid, isocinchomeronic acid, nicotinic acid, 3-pyridinesulfonic acid, picolinic acid, 6-hydroxynicotinic acid, 2-hydroxynicotinic acid, 6-hydroxypicolinic acid, 3-hydroxypicolinic acid, isonicotinic acid, benzoic acid, salicylic acid, m-hydroxybenzoic acid, p-hydroxybenzoic acid, o-phthalic acid, m-phthalic acid and p-phthalic acid. Cultivation was carried out at 28 °C for 3 days.

Results

Isolation of pyridine dicarboxylic acid-degrading microorganisms

Through enrichment culture using quinolinic acid, seven microorganisms degrading quinolinic acid were isolated. Among them, strain UK21 exhibited the highest activity and was identified as Alcaligenes sp. As for lutidinic acid-degrading microorganisms, six strains were isolated. Strain LA17 was selected as the most promising one to degrade lutidinic acid and was identified as Rhizobium sp. The degradation of isocinchomeronic acid was found in only one isolated strain, Hydrogenophaga sp. IMA01.

Conversion of pyridine dicarboxylic acids by resting cells reaction

Resting cells reactions were carried out using quinolinic acid, lutidinic acid or isocinchomeronic acid as substrate; and the reaction products were identified as described in Materials and methods. The cells of Alcaligenes sp. UK21 converted quinolinic acid into 6-hydroxypicolinic acid. Therefore, Alcaligenes sp. UK21 catalyzed hydroxylation at position C6 and decarboxylation at position C3, resulting in the formation of 6-hydroxypicolinic acid (Fig. 1). The reaction product from lutidinic acid by the resting cells of Rhizobium sp. LA17 was 6-hydroxylutidinic acid. Isocinchomeronic acid was converted into 6-hydroxyisocinchomeronic acid by the cells of Hydrogenophaga sp. IMA01. Whereas quinolinic acid was hydroxylated and decarboxylated, lutidinic acid and isocinchomeronic acid were only hydroxylated at position C6. It might be plausible to conclude that the degradation of these pyridine dicarboxylic acids was initiated by the hydroxylation reaction at position C6.

Optimization of culture conditions

To increase the hydroxylation activity of pyridine dicarboxylic acid-degrading microorganisms, the culture media were optimized. The hydroxylation activities of quinolinic acid, lutidinic acid or isocinchomeronic acid were measured by resting cells reaction. The addition of 1% (w/v) galactose and 1% (w/v) yeast extract was effective on the growth of Alcaligenes sp. UK21, resulting in an enhancement of the formation of 6-hydroxypicolinic acid from quinolinic acid. The 6-hydroxypicolinic acid-producing activity of the bacterium was induced by quinolinic acid and 6-hydroxypicolinic acid. The reaction product, 6-hydroxypicolinic acid, was a more effective inducer (41.2 nmol min–1 mg–1 dry cell weight) than quinolinic acid (24.0 nmol min–1 mg–1 dry cell weight). The highest activity was observed after 60 h cultivation.

The culture conditions for Rhizobium sp. LA17 and Hydrogenophaga sp. IMA01 were also examined. The optimized medium for Rhizobium sp. LA17 comprised 4 g lutidinic acid, 1 g KH2PO4, 3 g K2HPO4, 15 g yeast extract, 0.5 g MgSO4·7H2O and 10 ml metal solution in 1 l tap water, pH 7.0. The lutidinic acid-producing activity of Rhizobium sp. LA17 reached a maximum after 60 h cultivation. The 6-hydroxyisocinchomeronic acid-producing activity of Hydrogenophaga sp. IMA01 was highest after 18 h cultivation in the following medium: 2 g isocinchomeronic acid, 1 g KH2PO4, 3 g K2HPO4, 5 g yeast extract, 5.0 g malt extract, 0.5 g MgSO4·7H2O and 10 ml metal solution in 1 l tap water, pH 7.0. The hydroxylation activities for lutidinic acid and isocinchomeronic acid were induced only in the presence of lutidinic acid and isocinchomeronic acid, respectively. Other pyridine-related compounds tested were inert as the inducer.

Synthesis of 6-hydroxypicolinic acid, 6-hydroxylutidinic acid and 6-hydroxyisocinchomeronic acid

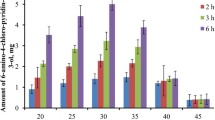

For the synthesis of 6-hydroxypicolinic acid, 6-hydroxylutidinic acid and 6-hydroxyisocinchomeronic acid by the cells of pyridine dicarboxylic acid-degrading microorganisms, the resting cells reactions were optimized. The effects of pH, temperature and aeration were examined. With the resting cells of Alcaligenes sp. UK21, the highest amount of 6-hydroxypicolinic acid accumulated from quinolinic acid when the reaction was carried out in 75 mM Tris-HCl buffer (pH 7.5) at 35 °C with reciprocal shaking at 160 strokes min–1. As shown in Fig. 2a, 94.9 mM 6-hydroxypicolinic acid (13.2 g l–1) was produced from 105 mM quinolinic acid after 48 h, with a 91% molar conversion yield. Optimum conditions for the synthesis of 6-hydroxylutidinic acid and 6-hydroxyisocinchomeronic acid were also examined using Rhizobium sp. LA17 and Hydrogenophaga sp. IMA01, respectively. The cells of both strains showed their highest activity at 35 °C in 75 mM Tris-HCl buffer (pH 8.5) with reciprocal shaking at 160 strokes min–1. Under optimized conditions, the resting cells of Rhizobium sp. LA17 accumulated up to 95.4 mM 6-hydroxylutidinic acid (17.5 g l–1), with a 99% molar conversion yield (Fig. 2b). The resting cells of Hydrogenophaga sp. IMA01 accumulated 88.7 mM 6-hydroxyisocinchomeronic acid (16.2 g l−1), with a 81% molar conversion yield (Fig. 2c).

Accumulation of 6-hydroxypicolinic acid (a), 6-hydroxylutidinic acid (b) and 6-hydroxyisocinchomeronic acid (c). The reaction mixture contained resting cells, 250 μmol each pyridine dicarboxylic acid and 1,250 μmol Tris-HCl (optimized pH) in 10 ml with shaking at 30 °C. Then, 100 mg (a), 254 mg (b) and 300 mg (c) resting cells (as dry weight) were added to the reaction mixture, respectively. White circles Quinolinic acid, black circles 6-hydroxypicolinic acid, white triangles lutidinic acid, black triangles 6-hydroxylutidinic acid, white squares isocinchomeronic acid, black squares 6-hydroxyisocinchomeronic acid

Substrate specificity

The substrate specificities of three pyridine dicarboxylic acid-degrading bacteria were examined by the resting cells reaction (Table 1). The following heterocyclic and aromatic compounds were inert as the substrate: nicotinic acid, 3-pyridinesulfonic acid, picolinic acid, 6-hydroxynicotinic acid, 2-hydroxynicotinic acid, 6-hydroxypicolinic acid, 3-hydroxypicolinic acid, isonicotinic acid, benzoic acid, salicylic acid, pyridine-3,4-dicarboxylic acid, pyridine-3,5-dicarboxylic acid, m-hydroxybenzoic acid, p-hydroxybenzoic acid, o-phthalic acid, m-phthalic acid and p-phthalic acid.

Discussion

We isolated the bacteria assimilating pyridine dicarboxylic acids, and characterized the initial reactions in each case. Pyridine dicarboxylic acid-degrading bacteria were applied to produce 6-hydroxypicolinic acid, 6-hydroxylutidinic acid and 6-hydroxyisocinchomeronic acid, which might be used for the synthesis of biologically active compounds. The resting cells of Alcaligenes sp. UK21, Rhizobium sp. LA17 and Hydrogenophaga sp. IMA01 accumulated 6-hydroxypicolinic acid, 6-hydroxylutidinic acid and 6-hydroxyisocinchomeronic acid, respectively, with high molar conversion yields. Further conversion of these reaction products was barely observed in the resting cells reaction. In our previous studies on the conversion of nicotinic acid into 6-hydroxynicotinic acid by Pseudomonas fluorescens and Serratia marcescens, nicotinic acid strongly inhibited the activity of 6-hydroxynicotinic acid 3-monooxygenase (Hurh et al. 1994a; Nagasawa et al. 1994). Therefore, the producing system of 6-hydroxynicotinic acid with a high conversion yield was established. The accumulation of the hydroxylated compounds in our present study suggests that enzymes degrading the accumulated compounds might be inhibited by quinolinic acid, lutidinic acid and isocinchomeronic acid, as in the case of nicotinic acid.

In the resting cells reaction, Alcaligenes sp. UK21 catalyzed decarboxylation at position C3 together with hydroxylation at position C6. We suspect that the hydroxylation and decarboxylation do not proceed at the same time. Probably, the intermediate of 6-hydroxypicolinic acid production from quinolinic acid is 6-hydroxyquinolinic acid, but not picolinic acid. When picolinic acid was incubated with the resting cells of Alcaligenes sp. UK21 cultivated in medium containing quinolinic acid as the inducer, the formation of 6-hydroxypicolinic acid was not observed at all. Thus, the first step of 6-hydroxypicolinic acid production from quinolinic acid is assumed to be the hydroxylation of quinolinic acid; and the resulting 6-hydroxyquinolinic acid is decarboxylated in a second step.

References

Arima K, Kobayashi Y (1962) Bacterial oxidation of dipicolinic acid. I. Isolation of microorganisms, their culture conditions, and end products. J Bacteriol 84:759–764

Fetzner S (1998) Bacterial degradation of pyridine, indole, quinoline and their derivatives under different redox conditions. Appl Microbiol Biotechnol 49:237–250

Gupta RC, Shukla OP (1979) Isonicotinic and 2-hydroxyisonicotinic acid hydroxylases of Sarcina sp. Indian J Biochem Biophys 16:72–75

Hurh B, Ohshima M, Yamane T, Nagasawa T (1994a) Microbial production of 6-hydroxynicotinic acid, an important building block for the synthesis of modern insecticides. J Ferment Bioeng 77:382–385

Hurh B, Yamane T, Nagasawa T (1994b) Purification and characterization of nicotinic acid dehydrogenase from Pseudomonas fluorescens TN5. J Ferment Bioeng 78:19–26

Kagabu S, Moriya K, Shibuya K, Hattori Y, Tsuboi S, Shiokawa K (1992) 1-(6-Halonicotinyl)-2-nitromethylene-imidazolidines as potential new insecticides. Biosci Biotechnol Biochem 56:362–363

Kiener A, Glöckler R, Heinzmann K (1993) Preparation of 6-oxo-1,6-dihydropyridine-2-carboxylic acid by microbial hydroxylation of pyridine-2-carboxylic acid. J Chem Soc Perkin Trans 1:1201–1202

Kobayashi Y, Arima K (1962) Bacterial oxidation of dipicolinic acid. II. Identification of α-ketoglutaric acid and 3-hydroxypicolinic acid and some properties of cell-free extracts. J Bacteriol 84:765–771

Kretzer A, Andreesen JR (1991) A new pathway for isonicotinate degradation by Mycobacterium sp. INA1. J Gen Microbiol 137:1073–1080

Kretzer A, Frunzke K, Andreesen JR (1993) Catabolism of isonicotinate by Mycobacterium sp. INA1: extended description of the pathway and purification of the molybdoenzyme isonicotinate dehydogenase. J Gen Microbiol 139:2763–2772

Moriya K, Shibuya K, Hattori Y, Tsuboi S, Shiokawa K, Kagabu S (1992) 1-(6-Chloronicotinyl)-2-nitroimino-imidazolidines and related compounds as potential new insecticides. Biosci Biotechnol Biochem 56:364–365

Moriya K, Shibuya K, Hattori Y, Tsuboi S, Shiokawa K, Kagabu S (1993) Structural modification of the 6-chloropyridyl moiety in the imidacloprid skeleton: introduction of a five-membered heteroaromatic ring and the resulting insecticidal activity. Biosci Biotechnol Biochem 57:127–128

Nagasawa T, Hurh B, Yamane T (1994) Production of 6-hydroxynicotinic acid from nicotinic acid by resting cells of Pseudomonas fluorescens TN5. Biosci Biotechnol Biochem 58:665–668

Nagel M, Andreesen JR (1989) Molybdenum-dependent degradation of nicotinic acid by Bacillus sp. DSM 2923. FEMS Microbiol Lett 59:147–152

Nakano H, Wieser M, Hurh B, Kawai T, Yoshida T, Yamane T, Nagasawa T (1999) Purification, characterization and gene cloning of 6-hydroxynicotinate 3-monooxygenase from Pseudomonas fluorescens TN5. Eur J Biochem 260:120–126

Schwarz G, Lingens F (1994) Bacterial degradation of N-heterocyclic compounds. In: Retledge C (ed) Biochemistry of microbial degradation. Kluwer, London, pp 459–486

Shukla OP, Kaul SM, Khanna M (1977) Microbial transformation of pyridine derivatives: α-picolinate metabolism by a gram-negative coccus. Indian J Biochem Biophys 14:292–295

Siegmund I, Koenig K, Andreesen JR (1990) Molybdenum involvement in aerobic degradation of picolinic acid by Arthrobacter picolinophilus. FEMS Microbiol Lett 67:281–284

Singh RP, Shukla OP (1986) Isolation, characterization and metabolic activities of Bacillus brevis degrading isonicotinic acid. J Ferment Technol 64:109–117

Slieman TA, Nicholson W (2001) Role of dipicolinic acid in survival of Bacillus subtilis spores exposed to artificial and solar UV radiation. Appl Environ Microbiol 67:1274–279

Tate RL, Ensign JC (1974) Picolinic acid hydroxylase of Arthrobacter picolinophilus. Can J Microbiol 20:695–702

Tinschert A, Kiener A, Heinzmann K, Tschech A (1997) Isolation of new 6-methylnicotinic acid-degrading bacteria, one of which catalyzes the regioselective hydroxylation of nicotinic acid at position C2. Arch Microbiol 168:355–361

Ueda M, Sashida R (1998) Microbial production of 2-hydroxynicotinic acid from nicotinic acid by intact cells of MCI3289. J Mol Catal B 4:199–204

Yasuda M, Sakamoto T, Sashida R, Ueda M, Morimoto Y, Nagasawa T (1995) Microbial hydroxylation of 3-cyanopyridine to 3-cyano-6-hydroxypyridine. Biosci Biotechnol Biochem 59:572–575

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uchida, A., Yoshida, T., Ogawa, M. et al. Regioselective hydroxylation of quinolinic acid, lutidinic acid and isocinchomeronic acid by resting cells of pyridine dicarboxylic acid-degrading microorganisms. Appl Microbiol Biotechnol 62, 337–341 (2003). https://doi.org/10.1007/s00253-003-1248-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-003-1248-0