Abstract

Liposomes have been used as delivery vehicles for stabilizing drugs, overcoming barriers to cellular and tissue uptake, and for directing their contents toward specific sites in vivo. Chitosan is a biological macromolecule derived from crustacean shells and has several emerging applications in drug development, obesity control, and tissue engineering. In the present work, the interaction between chitosan and dipalmitoyl phosphatidylcholine (DPPC) liposomes was studied by transmission electron microscopy (TEM), zeta potential, solubilization using the nonionic detergent octylglucoside (OG), as well as Fourier transform infrared (FTIR) spectroscopy and viscosity measurements. The coating of DPPC liposomes by a chitosan layer was confirmed by electron microscope images and the zeta potential of liposomes. Coating of liposome by chitosan resulted in an increase in liposomal size by addition of a layer of 92 ± 27.1 nm. The liposomal zeta potential became increasingly positive as chitosan concentration increased from 0.1 to 0.3% w/v, then it held at a relatively constant value. The amount of detergent needed to completely solubilize the liposomal membrane was increased after coating of liposomes with chitosan, indicating an increased membrane resistance to the detergent and hence a change in the natural membrane permeation properties. In the analysis of FTIR spectra of DPPC, the symmetric and antisymmetric CH2 (at 2,800–3,000 cm−1) bands and the C=O (at 1,740 cm−1) stretching band were investigated in the absence and presence of the chitosan. It was concluded that appropriate combining of the liposomal and chitosan characteristics might be utilized for the improvement of the therapeutic efficacy of liposomes as a drug delivery system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Liposomes have represented a milestone in the field of innovative drug delivery systems for a number of years, having been investigated for delivery of chemotherapeutic agents for cancer (Harrington et al. 2002), vaccines for immunological protection (Zho and Neutra 2002), radiopharmaceuticals for diagnostic imaging (Matteucci and Thrall 2000), and nucleic acid-based medicines for gene therapy (Mady et al. 2004). However, liposomes also have some limitations. First, they generally show a short circulation half-life after intravenous administration (Bakker-Woudenberg et al. 1994). Second, they are prone to adhere to each other and fuse to form larger vesicles in suspension, which may result in inclusion leakage (Taylor et al. 2005; Zhang and Granick 2006). Therefore, stability is a general problem with lipid vesicles (Graff et al. 2001).

As an alternative, many attempts, such as the surface modification of liposomes (Oku and Namba 1994), have been performed to stabilize the liposomes for application in different environments and to avoid the rapid leakage of encapsulated or entrapped compounds. Different types of biocompatible polymers such as chitosan can be employed to improve the efficiency of conventional liposomal systems (Henriksen et al. 1994; Perugini et al. 2000).

Chitosan is a biocompatible, biodegradable, and nontoxic cationic polysaccharide (Hirano et al. 1988). Owing to its properties, chitosan can be used in medicine, pharmacy, biotechnology, agriculture, and the food industry (Nagai et al. 1984; Knapczyk et al. 1989).

Appropriate combining of the liposomal and chitosan characteristics may produce liposomes with specific, prolonged, and controlled release. Several authors have used chitosan as a liposome coating to increase the stability of drug release (Alamelu and Panduranga 1991; Dong and Rogers 1991; Henriksen et al. 1997) and for targeting purposes (Henriksen et al. 1994; Takeuchi et al. 1994, 2003; Guo et al. 2003).

In this study, chitosan-coated liposomes were prepared, and the interaction between chitosan and DPPC liposomes was studied using transmission electron microscopy (TEM), zeta potential, viscometry, liposome solubilization, and FTIR spectroscopy in an attempt to understand the overall behavior of the chitosan–liposome system.

Materials and methods

Materials

l-α-Dipalmitoyl phosphatidylcholine (DPPC) specified 99% pure, and nonionic detergent octylglucoside (OG) were purchased from Sigma (St. Louis, MO, USA). Chitosan (from crab shells) was purchased from Fluka with molecular weight of 150,000 and was used as received. Chloroform was of analytical grade and obtained from Merck. Double-distilled deionized water was used.

Preparation of liposomes

For DPPC liposomal preparation, the lipids must first be dissolved and mixed in chloroform to ensure a homogeneous mixture of lipids. The organic solvent should be removed by rotary evaporation to obtain a thin lipid film formed on the sides of a 50-ml round-bottom flask. The lipid film is thoroughly dried to remove residual organic solvent by placing the flask on a vacuum pump for nearly 90 min. Hydration of the dry lipid film is accomplished simply by adding an aqueous solution to the container of the dry lipid film and agitating at a temperature above the phase transition temperature of the lipid. The final lipid concentration was 4 mg/ml.

Chitosan-coated liposomes

Chitosan (0.5 g) was dissolved in 1% (w/v) acetic acid solution (100 ml) by using a magnetic stirrer at room temperature to obtain a chitosan solution of concentration 0.5%, which was used throughout the study. Chitosan solution was added drop-wise to 1 mg/ml of liposomal suspension under magnetic stirring at room temperature. After addition of the chitosan, the mixture was left under stirring for approximately 1 hour then incubated overnight at −4°C.

Transmission electron microscopy

DPPC liposomes and chitosan-coated liposomes were analyzed on negative stain electron microscopy using a JEM 1230 electron microscope (Jeol, Tokyo, Japan). A drop of each liposomal suspension was applied to copper coated with carbon grid, and the excess was drawn off with filter paper. An aqueous solution of ammonium molybdate (1% w/v) was used as a negative staining agent. Staining was followed by a 2-min wait at room temperature, removal of the excess solution with a filter paper, and then examination under the electron microscope. Thickness of the chitosan-coated layer was measured by the software provided with the transmission electron microscope.

Zeta potential measurements

Zeta potentials of DPPC liposomes and chitosan-coated liposomes with different chitosan concentrations (0.1–0.5% w/v) were determined by using the Malvern Zetasizer 2000 (Malvern Instruments, U.K.) after sample centrifugation at 13,000 rpm for 20 min. Pellets were then resuspended in double-distilled deionized water. The zeta potentials of chitosan-coated liposomes and DPPC–liposomes were measured after centrifugation to confirm that the liposomes were coated.

Viscosity measurements

Double samples of pure DPPC liposomes and chitosan-coated liposomes (0.2 and 0.4% chitosan solution) were analyzed at 25°C by using a Brookfield rheometer (Mod. DVIIICP, Boland) using CP 40 cone geometry (cone angle = 0.8 and diameter = 2.4 cm). The flow curves were plotted between shear stress (dyne/cm2) and shear rate (s−1) for each sample. Plastic viscosity and yield stress were investigated from the linear fitting of flow curves.

Liposome solubilization

The solubilization of liposomes and chitosan-coated liposomes samples were done by continuous addition of the nonionic detergent octylglucoside (OG) (initial concentration of 200 mM solution) and monitored by measuring their optical density (OD) at 400 nm using a UV/visible spectrophotometer (Jenway 6405, Barloworld Scientific, Essex, UK). The OG solution was continuously added to a cuvette containing 2 ml of the sample under study and stirred gently, then the OD was measured after addition of each volume of OG. The OD versus detergent volume was recorded until a steady-state level was reached. The detergent concentration was obtained from the following formula of Paternostre et al. (1997).

where D t is the total detergent concentration in the cuvette (in mM), D i is the initial detergent concentration before addition to the sample (in mM), V a is the added volume of the OG to the cuvette (in ml), and V t is the total volume of the sample in the cuvette (in ml).

FTIR spectroscopy

FTIR spectra of lyophilized samples of DPPC liposomes and chitosan-coated liposomes deposited in KBr disks were recorded on a Jasco FT/IR 460 plus (Japan) spectrometer. The scanning was done in the range 400–4,000 cm−1 with speed of 2 mm/s at a resolution of 4 cm−1 at room temperature. The band width was measured at 50% of height of the peaks.

Results and discussion

Transmission electron microscopy

Coating of liposome by chitosan resulted in an increase in liposomal size of 92 ± 27.1 nm owing to the coating layer. Surface morphological studies on the shape of prepared systems using transmission electron microscopy have indicated that the systems were almost spherical (Fig. 1). Also, the existence of chitosan surrounding the liposomes was well visualized on the surface of chitosan-coated liposomes. The hydrophilic polymer coating of liposomes would depend on the ability of the polymer to adhere to the lipid bilayers. The interaction between chitosan and liposomes is due to a combination of adsorption coagulation and bridging between them (Filipovic-Grcic et al. 2001).

Zeta potential measurements

Zeta potential has often been used for characterizing colloidal drug delivery systems. It is a measure of the surface electrical charge of the particles. The magnitude of the zeta potential gives an indication of the potential stability of the colloidal system. As the zeta potential increases, the repulsion phenomenon between particles will be greater, thus leading to a more stable colloidal dispersion. If all the particles in suspension have a large negative or positive zeta potential then they will tend to repel each other, and there will be no tendency for the particles to come together (Paolino et al. 2006).

The surface potential is an important parameter influencing liposomal behavior. In vivo, the surface charge density has been found to influence the distribution of liposomes, and in vitro, a high potential might contribute to the physical stability of liposomes by reducing the rate of aggregation and fusion (Crommelin 1984). So, the information on the overall charge of chitosan-coated liposomes by zeta-potential measurements can speed up the development of liposomes with specific, prolonged, and controlled release. DPPC liposomes showed a slight negative zeta potential, in agreement with the observation of others (Plank et al. 1985; Klein et al. 1987; Law et al. 1988; Makino et al. 1991; Henriksen et al. 1994).

It is clear from Fig. 2 that coating of liposomes by chitosan shifted the zeta potential, from slightly negative value to positive values. The results show that DPPC liposomes had positive zeta values after being coated with 0.1–0.5% w/v chitosan solutions. The liposome zeta potential was increasingly positive as chitosan concentration was increased from 0.1 to 0.3%, then it came to a relatively constant value. The increase in zeta potential was attributed to the more cationic polymers adsorbed to the liposomal surface. Since chitosan carried a high positive charge, the adsorption of chitosan increased the density of the positive charge and made the zeta potential positive. DPPC liposomes were nearly neutral and the mechanism of coating neutral DPPC liposomes by chitosan involved hydrogen bonding between the polysaccharide and the phospholipid head groups (Perugini et al. 2000; Guo et al. 2003).

Liposomal solubilization

Nonionic detergents are widely used as molecular tools in membranology. In particular, they are essential in the solubilization and reconstitution of integral membrane proteins (Morandat and El Kirat 2007). According to the well-known three-stage model of Helenius and Simons (1975), detergent monomers insert into the membrane bilayer (stage I), then the bilayer becomes saturated with detergent, and lipid–detergent-mixed micelles start to form (stage II), finally the mixed micelles become further enriched in detergent (stage III). Figure 3 shows the changes in the absorbance of two different liposomal lipid concentrations (0.2 and 0.5 mM) as a function of detergent concentration before and after coating with chitosan.

Changes in absorbance at 400 nm as a function of OG detergent concentration for a pure DPPC liposomes of concentrations 0.2 and 0.5 mM and b 0.2 mM DPPC/chitosan and 0.5 mM DPPC/chitosan. A and B indicate how transition points in Table 1 were calculated

As can be noted from Fig. 3a, detergent molecules started to solubilize lipids during stage I until point A. As detergent concentration increased, the detergent molecules began to be incorporated within the membrane bilayer. The increase in detergent concentration caused a corresponding increase in detergent molecules incorporated within the bilayer leading to the complete solubilization of the membrane (stage II until point B) and formation of mixed micelles. Stage III started after point B.

Coating of liposomes with chitosan resulted in changes in profiles of stage I as shown in Fig. 3b. Solubilization may occur slowly and the absorbance may first increase—due to size growth of part of the liposomes because of the incorporation of detergent molecules in the chitosan coating layer—before reaching the lipid bilayer, and subsequently the absorbance decreased sharply at point A to a minimum value that reflects the absorbance of mixed micelles. The coexistence phase, that is, the vesicular/mixed micellar phase of chitosan-coated liposomes, shifted towards higher detergent concentrations after coating with chitosan (Table 1), indicating increasing membrane resistance to the detergent. The shift in detergent concentration was found to be a dose-dependent factor. The data indicate that the chitosan–lipid interaction makes the liposomal membrane more stable and less soluble in the detergent than the same formulation without chitosan coating.

The lipid molecules interact with chitosan in two steps. In the first step, the molecules get anchored to chitosan chains through interactions between their head groups and the specific functional groups of chitosan, i.e., between the carboxylic groups of fatty acids and −NH3 + groups of chitosan by electrostatic interactions, and between the hydroxyl groups of lipid and of chitosan by hydrogen bonding, which makes lipid molecules localized. In the second step, hydrophobic interactions between the lipid tails and chitosan take place, allowing chitosan to incorporate within the bilayer membrane. In addition to lipid–chitosan electrostatic interactions and hydrogen bonding, the process includes hydrophobic lipid–chitosan interactions (Wydro et al. 2007).

FTIR spectroscopy

FTIR spectroscopy is inherently well-suited to studying conformational order in phospholipid acyl chains (Mendelsohn and Moore 1998; Los and Murata 2004). With this technique, it is possible to monitor subtle changes in the structure of the lipid assemblies by analyzing the frequency and the bandwidth changes of the vibrational modes. These changes can be used to extract information about various physicochemical processes taking place in the systems (Severcan et al. 2005).

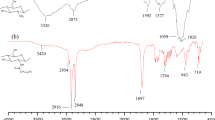

FTIR was used, as a nonperturbing technique, to analyze possible changes in the structure of DPPC by analyzing the frequency of different functional groups and by investigating the acyl chains and head-group region of the lipid molecule in the presence or absence of chitosan.

The position of the symmetric and antisymmetric CH2 (at 2,800–3,000 cm−1) bands is hardly changed in the presence of chitosan (Fig. 4). Moreover the band widths of the CH2 stretching bands give dynamic information about the system (Severcan et al. 2005).

The band width of antisymmetric CH2 stretching band, for example, at 2,919.7 cm−1, decreased from 60 to 26 cm−1 for chitosan-coated liposomes, which implies a decrease in the membrane fluidity and thereby stabilization of the system in the gel phase (Biruss et al. 2007).

In order to analyze the interaction of chitosan with the glycerol backbone near the head group of the phospholipids, the C=O stretching band at 1,739.48 cm−1 was analyzed. The characteristic lipid peak C=O slightly shifted in the presence of chitosan to lower frequency values, and the signal intensity became more intensive in the gel phase. The decrease in the frequency indicates a strengthening of the hydrogen bonds or even a formation of new hydrogen bonds between the components (Korkmaz and Severcan 2005). Also, the degree of hydrogen-bond formation was monitored in the glycerol backbone region of the DPPC molecule by changes in the contours of the ester C=O stretching bands (Blume et al. 1988).

Viscosity measurements

The rheological properties of liposomes were measured to evaluate the interaction between chitosan and DPPC liposomal membranes. Figure 5 shows the flow curves of different liposomal samples.

The rheological properties of liposomal formulations can be described by the power law model (Steffe 1996):

where τ is the shear stress, k is the consistency index, γ is the shear rate, and n is the flow behavior index. In order to obtain the flow behavior index (n) and consistency index (k) values, Eq. 2 was used to fit the experimental data of different samples, and the rheological parameters are shown in Table 2.

The yield stress (the minimum stress needed to cause a Bingham plastic to flow) increases from 0.28 dyne/cm2 for DPPC liposomes to 0.83 dyne/cm2 after addition of 0.4% chitosan to DPPC liposomes (Steffe 1996).

The n and k values ranged from 0.87 to 0.9 and from 1.22 to 3.32, respectively. Liposome suspension exhibited a pseudoplastic behavior because the values of the flow behavior index (n), a measure of departure from Newtonian flow, were less than 1. The consistency index (k), an indication of the viscous nature of liposomes, can be used to describe the variation in plastic viscosity (a measure of the internal resistance to fluid flow of a Bingham plastic, expressed as the tangential shear stress in excess of the yield stress divided by the resulting rate of shear) with different concentrations of chitosan (Steffe 1996).

Figure 6 shows that the plastic viscosity of DPPC liposomes is increased after coating them with different concentrations of chitosan solution. The plastic viscosities were 0.59 cP for DPPC liposomes and 0.76 and 1.34 cP for chitosan-coated liposomes with 0.2 and 0.4% chitosan solutions, respectively. Based on the present results of liposomal rheological properties, it can be concluded that coating of liposomes with chitosan would cause an increase in the DPPC liposomes plastic viscosity.

Conclusion

The coating of DPPC liposomes by a chitosan layer was confirmed by electron microscope images and the zeta potential of liposomes. The results of solubilization, FTIR spectroscopy, and viscosity measurements indicate that chitosan interacts with the phospholipid surface and the lipophilic core of the bilayers. The coating of DPPC liposomes with chitosan led to an improvement in the stability of lipid vesicles. These results shed light on the mechanism by which chitosan will interact with lipids either in natural tissues or in artificial drug delivery systems. Appropriate combinations of the liposomal and chitosan characteristics may produce liposomes with specific, prolonged, and controlled release. The results indicate that a lipid–chitosan complex might be used either in cosmetology or in pharmacology as an effective drug delivery system.

References

Alamelu S, Panduranga K (1991) Studies on the carboxymethyl chitosan containing liposomes for their stability and controlled release of dapsone. J Microencapsul 8:505–519

Bakker-Woudenberg IA, Storm G, Woodle MC (1994) Liposomes in the treatment of infections. J Drug Target 2:363–371

Biruss B, Dietl R, Valenta C (2007) The influence of selected steroid hormones on the physicochemical behaviour of DPPC liposomes. Chem Phys Lipids 148:84–90

Blume A, Hübner W, Messner G (1988) Fourier transform infrared spectroscopy of 13CO-labeled phospholipids. Hydrogen bonding to carbonyl groups. Biochemistry 27:8239–8249

Crommelin DJ (1984) Influence of lipid composition and ionic strength on the physical stability of liposomes. J Pharm Sci 73:1559–1563

Dong C, Rogers JA (1991) Polymer-coated liposomes: stability and release of ASA from carboxymethyl chitin-coated liposomes. J Control Release 17:217–224

Filipovic-Grcic J, Skalko-Basnet N, Jalsenjal I (2001) Mucoadhesive chitosan-coated liposomes: characteristics and stability. J Microencapsul 18:3–12

Graff A, Winterhalter M, Meier W (2001) Nanoreactors from polymer-stabilized liposomes. Langmuir 17:919–923

Guo J, Ping Q, Jiang G, Huang L, Tong Y (2003) Chitosan-coated liposomes: characterization and interaction with leuprolide. Int J Pharm 260:167–173

Harrington KJ, Syrigos KN, Vile RG (2002) Liposomally-targeted cytotoxic drugs in the treatment of cancer. J Pharm Pharmacol 54:1573–1600

Helenius A, Simons K (1975) Solubilization of membranes by detergents. Biochim Biophys Acta 415:29–79

Henriksen I, Smistad G, Karlsen J (1994) Interaction between liposomes and chitosan. Int J Pharm 101:227–236

Henriksen I, Vagen SR, Sande SA, Smitad G, Karlsen J (1997) Interactions between liposomes and chitosan II: effect of selected parameters on aggregation and leakage. Int J Pharm 146:193–204

Hirano S, Seino H, Akiyama Y, Nonaka I (1988) Biocompatibility of chitosan by oral and intravenous administration. Polym Eng Sci 59:897–901

Klein JW, Ware BR, Barclay G, Petty HR (1987) Phospholipid dependence of calcium ion effects on electrophoretic mobilities of liposomes. Chem Phys Lipids 43:13–23

Knapczyk J, Krowczynski L, Krzck J, Brzeski M, Nirnberg E, Schenk D, Struszcyk H (1989) Requirements of chitosan for pharmaceutical and biomedical applications. In: Skak-Braek G, Anthonsen T, Sandford P (eds) Chitin and chitosan: sources, chemistry, biochemistry, physical properties and applications. Elsevier, London, pp 657–663

Korkmaz F, Severcan F (2005) Effect of progesterone on DPPC membrane: evidence for lateral phase separation and inverse action in lipid dynamics. Arch Biochem Biophys 440:141–147

Law SL, Lo WY, Pai SH, Teh GW (1988) The electrokinetic behavior of liposomes adsorbed with bovine serum albumin. Int J Pharm 43:257–260

Los DA, Murata N (2004) Membrane fluidity and its roles in the perception of environmental signals. Biochim Biophys Acta 1666:142–157

Mady MM, Ghannam MM, Khalil WA, Repp R, Markus M, Rascher W, Müller R, Fahr A (2004) Efficient gene delivery with serum into human cancer cells using targeted anionic liposomes. J Drug Target 12:11–18

Makino K, Yamada T, Kimura M, Oka T, Ohshima H, Kondo T (1991) Temperature- and ionic strength-induced conformational changes in the lipid head group region of liposomes as suggested by zeta potential data. Biophys Chem 41:175–183

Matteucci ML, Thrall DE (2000) The role of liposomes in drug delivery and diagnostic imaging: a review. Vet Radiol Ultrasound 41:100–107

Mendelsohn R, Moore D (1998) Vibrational spectroscopic studies of lipid domains in biomembranes and model systems. Chem Phys Lipids 96:141–157

Morandat S, El Kirat K (2007) Solubilization of supported lipid membranes by octyl glucoside observed by time-lapse atomic force microscopy. Colloids Surf B 55:179–184

Nagai T, Sawayanagi Y, Nambu N (1984) Application of chitin and chitosan to pharmaceutical preparations. In: Zikakis JP (ed) Chitin, chitosan and related enzymes. Academic, New York, pp 21–39

Oku N, Namba Y (1994) Long-circulating liposomes. Crit Rev Ther Drug Carr Syst 11:231–270

Paolino D, Fresta M, Sinha P, Ferrari M (2006) Drug delivery systems. In: Webster JG (ed) Encyclopedia of medical devices and instrumentation, 2nd edn. Wiley, New York, pp 437–495

Paternostre M, Virad M, Meyer O, Ghannam M, Ollivon M, Blumenthal R (1997) Solubilization and reconstitution of vesicular stomatitis virus envelope using octylglucoside. Biophys J 72:1683–1694

Perugini P, Genta I, Pavanetto F, Conti B, Scalia S, Baruffini A (2000) Study on glycolic acid delivery by liposomes and microspheres. Int J Pharm 196:51–61

Plank L, Dahl CE, Ware BR (1985) Effect of sterol incorporation on head group separation in liposomes. Chem Phys Lipids 36:319–328

Severcan F, Sahin I, Kazanci N (2005) Melatonin strongly interacts with zwitterionic model membranes—evidence from Fourier transform infrared spectroscopy and differential scanning calorimetry. Biochim Biophys Acta 1668:215–222

Steffe J (1996) Rheological methods in food process engineering, 2nd edn. Freeman Press, East Lansing

Takeuchi H, Yamamoto H, Niwa T, Hino T, Kawashima Y (1994) Mucoadhesion of polymer-coated liposomes to rat intestine in vitro. Chem Pharm Bull 42:1954–1956

Takeuchi H, Matsui Y, Yamamoto H, Kawashima Y (2003) Mucoadhesive properties of carbopol or chitosan-coated liposomes and their effectiveness in the oral administration of calcitonin to rats. J Control Release 86:235–242

Taylor TM, Davidson PM, Bruce DB, Weiss J (2005) Liposomal nanocapsules in food science and agriculture. Crit Rev Food Sci Nutr 45:1–19

Wydro P, Krajweska B, Hac-Wydro K (2007) Chitosan as a lipid binder: a langmuir monolayer study of chitosan-lipid interactions. Biomacromolecules 8:2611–2617

Zhang LF, Granick S (2006) How to stabilize phospholipid liposomes (using nanoparticles). Nano Lett 6:694–698

Zho F, Neutra MR (2002) Antigen delivery to mucosa-associated lymphoid tissues using liposomes as a carrier. Biosci Rep 22:355–369

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mady, M.M., Darwish, M.M., Khalil, S. et al. Biophysical studies on chitosan-coated liposomes. Eur Biophys J 38, 1127–1133 (2009). https://doi.org/10.1007/s00249-009-0524-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00249-009-0524-z