Abstract

Hot-air drying is a slow energy-extensive process. Use of intermittent microwave (IM) in hot-air (HA) drying of food products is characterized with advantages including reduced process time, energy saving, and improved final quality. In this study, the effect of IM-HA drying following an osmotic dehydration (OD) pretreatment was analyzed on qualitative and quantitative properties of the output (i.e. effective moisture diffusion coefficient (Deff), shrinkage, bulk density, rehydration and energy consumption). Temperature and airflow velocity were fixed at 40°C and 1 m/s, respectively. The process variables included sucrose solution concentration at five levels (0 or control, 10, 30, 50 and 70 w/w%), microwave output power at four levels (0 or control, 360, 600 and 900 W), and pulse ratio at four levels (1, 2, 3 and 4). Use of osmotic dehydration in combination with IM-HA drying reduced the drying time by up to about 54%. Increasing the osmotic solution concentration to 30% and using higher pulse ratios increased the Deff. The lowest shrinkage and bulk density as well as the highest rehydration belonged to the 900 W microwave power and pulse ratio of 4. The lowest energy consumption was observed when using the 900 W power level, showing 63.27% less consumption than the HA drying method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Potato (Solanum tuberosum) from the Soulanacea family is a healthy, commercial food with wide applications around the world. This food is one of the most important agricultural products besides wheat, corn and rice. With high mineral, dietary fiber and vitamin contents, potato is used as a composition of functional foods [1]. Increasing public reluctance to use food with chemical preservatives in their ingredients in addition to the considerable development of the fast food industry has resulted into a large demand for dried potatoes with suitable qualitative characteristics. Dried potato is used as an ingredient of ready-meal soups and different sauces in different shapes (e.g. granular, chips, and powder) [2]. It can be dried using different drying methods including convective, fluidized-bed, freeze-drying, vacuum, microwave or a combination of them. Freeze-drying is known as the method to achieve the highest quality in terms of shape, minimum color change, and reduced losses of heat-sensitive nutrients. Freeze-drying is an expensive method, and thus it is important to investigate more inexpensive drying methods that yield similar quality. The hybrid IM-HA drying can be one of these alternatives.

The drying process is a unit operation where moisture or other liquid volatile substances trapped inside the microscopic structure of the food are forced out by applying thermal energy. The drying process requires vast amounts of energy as 2700 kJ is required to vaporize 1 kg of water at 100 °C. It is much harder to remove moisture from inner parts of the food than from its surface due to the existence of continuous moisture [3]. Accordingly, the required energy for this operation is more than the latent heat of water vaporization. HA drying is the oldest, most conventional drying method; however, it has considerable disadvantages including reduced energy efficiency, longer process time (particularly at the falling rate drying phase), and intensive shrinkage. In addition, the long process time and use of high temperatures adversely affect qualitative properties of the food like nutrients, color and texture. Microwave drying can address these drawbacks to a large extent. Microwave drying significantly reduces the drying time and improves rehydration and shrinkage characteristics [4].

The effect of microwave energy on the inner part of a solid material depends on its dielectric properties, which can control heat distribution inside the substance. Dielectric properties are an electric characteristic of a substance measured by the interaction of the substance with an electromagnetic field. This property is dependent on the frequency of the electrical field, temperature and composition of the substance including its moisture content [5]. If microwave energy is not used properly during the drying process, it can adversely affect the product quality. For example, drying with high microwave powers leads to fast mass transfer, which in turn causes qualitative damages including unwanted texture changes. Moreover, non-uniform heating of samples and formation of hot points are results of non-uniform distribution of the electromagnetic field inside the microwave oven. These problems can be partly addressed using waveguides and a rotating tray.

The microwave energy is rarely used alone in the drying process, and it is usually coupled with other drying techniques. This is to avoid over-heating and to improve quality of the product. One of these hybrid techniques is to use microwave energy in combination with HA drying. Airflow inside a microwave system can continuously remove moisture from around the substances, expediting the drying process. At the same time, the substance temperature drops as a result of evaporative cooling during the process. Application of microwave energy as a supplement to the convective drying method can be done at three phases [6]:

-

a)

At the initial phase of drying: In this method, the microwave energy is applied for a known duration at the beginning of the process, and then the convective drying is used. In this technique, the microwave energy helps heating up the inner parts faster to reach the water evaporation temperature. At this stage, an outbound vapor stream is developed from the inner parts, which forms a porous texture that contributes to moisture removal. In the next step, application of hot air to the drying process drives away vapors around the products thus speeding up the process. This phase continues until reaching a given moisture content, where the process is terminated.

-

b)

At the middle phase of drying: Here, the microwave energy is applied to the HA- drying process when the drying rate starts to decline. At this phase, the moisture content near the product surface is reduced whereas the inner sections still has considerable amounts of water. Therefore, in this mode, microwave energy significantly increases the drying rate.

-

c)

At the final phase of drying: This technique is used to remove the water molecules bonded with the product structure, which cannot be easily removed by the convective method and large amounts of time and energy are required. Once reaching a certain moisture level, the convective flow is cut off and replaced by microwave energy.

Microwave-HA drying has been successfully applied to a number of agricultural products. However, in some cases, it has been shown that the product quality might decline by continuous application of microwave energy due to non-uniform temperature and moisture distribution throughout the product [7]. Particularly in smaller samples, the continuous method concentrates microwaves on a certain spot and over-heat the sample causing qualitative damages. This effect can be more destructive at longer process times. This can be addressed by intermittent application of microwaves during the process. In the intermittent application technique, microwave energy is applied as pulses for a given duration, then it is turned off for another given duration, and then turned back on [8]. Pulse Ratio (PR) is expressed using the following equation:

where ton is the “on” time and toff is the “off” time of the microwave (in seconds). PR values affect the drying rate, product quality, and also energy consumption.

Maskan [9] analyzed the qualitative characteristics of kiwi fruits dried using three different techniques: HA, Microwave (MC), and hybrid MC (210 W)-HA. The factors compared in the study were the drying time, shrinkage, and rehydration capacity of the dried kiwi samples. The drying curves showed that microwave drying is faster than the other two methods. Accordingly, the drying times of the microwave and hybrid MC-HA methods were 89% and 40%, respectively, faster than the convective method. Although kiwi fruit has high moisture content, its drying occurred within the falling rate stage of drying for all three methods. Shrinkage of dried products from MC, HA, and MC-HA drying methods was 85%, 81% and 76%, respectively. Therefore, samples dried with only MC method had the highest shrinkage. This can be due to high heat generation and fast moisture removal from sample texture when exposed to microwave energy. MC-dried kiwi fruits had a shorter process time, and thus their rehydration rate was higher than that of the other two methods. At the same time, samples dried with the hybrid MC-HA method had the highest rehydration.

Torringa et al. [10] applied MC-HA drying to mushroom samples pretreated with NaCl osmotic solution. The objective was to study the effect of NaCl solution on so dried samples. The salt concentrations were 10 and 15% (w/w) at 20 and 45 °C using 5 immersion times (10, 30, 50, 70 and 110 min). Specific microwave power was 4 W/g for samples during the experiments. The sample to osmotic solution weight ratio was 1 to 5. Increasing the solution temperature had the highest effect on moisture removal rate during osmotic dehydration. Use of osmotic solution improved dielectric properties and provided more uniform heating by introducing salt ions into the sample. These features were further improved by increasing the salt concentration. Results showed that 30% of the moisture content was removed from mushroom samples during immersion in the salt solution, which in turn reduced the drying time of the MC-HA method. Additionally, application of the salt solution reduced shrinkage and increased porosity of the final product compared to the control samples. It also enhanced rehydration of samples.

Sharma and Prasad [11] dried garlic cloves using the hybrid MC-HA technique to study effective moisture diffusion coefficient (Deff) variations during the drying process under different drying conditions. The process variables included four levels of microwave power (10, 20, 30 and 40 W), four levels of temperature (40, 50, 60 and 70 °C) and airflow velocity at two levels (1 and 2 m/s). Results showed that Deff increased by an increase in microwave power and air temperature at a constant velocity. In addition, increased airflow velocity reduced Deff provided that all other conditions were fixed. This was due to the decrease in garlic sample temperature when using faster airflow velocities.

Aghilinategh et al. [4] studied the drying of apple slices using convective and both continuous (CM) and intermittent microwave (IM) methods. They analyzed the kinetics of drying and qualitative characteristics (including color change, rehydration capacity, bulk density, and phenolic content). Experiment variables included microwave power at three levels (200, 400 and 600 W), PR at three levels (2, 3 and 6), temperature at five levels (40, 50, 60, 70 and 80 °C), and three airflow velocities (0.5, 1 and 2 m/s). Results showed that CM drying had the highest drying rate than the convective and intermittent methods. In addition, increasing microwave power and air temperature led to an increase in Deff, as its highest value was recorded for the CM and its lowest for convective drying methods, because temperature and a consequent increase in vapor pressure in CM drying are higher than those in the other two methods. This contributes to more moisture diffusion towards sample surface. In IM drying, the highest Deff was reported when using 600 W microwave power and at PR of 2. The bulk density decreased while increasing microwave power, temperature and airflow velocity. This can be due to more product porosity under such conditions. IM-dried samples had the lowest bulk density because re-distribution of temperature and moisture at microwave-off times releases internal stress and thus reduces shrinkage. Therefore, the highest rehydration was reported to be for IM-dried samples. The least color change and the highest phenolic content were achieved in CM-dried samples. This can be due to the shorter drying time of this method. It has been shown that ambient oxygen binds with the product ingredients at long drying times and develops damages such as reduction of phenolic contents.

According to the literature, there has been no focus on the effect of simultaneous application of intermittent microwave and forced convection of hot air on the drying of potato samples pretreated with a sucrose solution. The objective of this study was to investigate the combined effect of the osmotic process and then hybrid drying using intermittent microwave and hot-air forced convective drying on quantitative and qualitative characteristics of potato slices (e.g. drying kinetics, effective moisture diffusion coefficient, shrinkage, bulk density, rehydration, and specific energy consumption).

2 Materials and methods

2.1 Raw materials

Potato samples (Agria var.) with approximate moisture content of 4.82 g water / g dry solids) were purchased from a local market and were cold stored at 4–6 °C. To obtain uniform experimental conditions, all potato samples were bought from one location and one variety. Sucrose (Miandoab Sucrose Factory, Iran) was purchased for the preparation of the osmotic solution and was kept at room temperature (25 °C). Toluene was used to measure the volume of samples using the liquid displacement method.

2.2 Sample preparation

In each period, large, intact firm potatoes were selected and kept for about 60 min at room temperature to reach temperature equilibrium. They were then washed, peeled and chopped into 1.2 × 1.2 × 1.2 cm3 cubes using a hand cutter. For each experiment, 105 g of potato cubes were prepared and used. Prior to the blanching process, in order to prevent moisture reduction and color change, sliced samples were kept in a lid plate. For the next stage, samples were blanched in a water bath with a temperature control sensor (Fan Azma Gostar, model WM22, Iran). A 500-ml beaker containing water was placed in the water bath. Once it reached 100 °C, the samples were placed inside the beaker and were blanched for 5 min.

2.3 Osmotic pretreatment

Osmotic solutions of sucrose with distilled water were prepared at four concentrations (10, 30, 50 and 70% w/w). Before the drying process, potato slices were immersed in the osmotic solution for 120 min at room temperature. During osmotic dehydration, moisture is removed from samples and replaced by sucrose [12]. To avoid over-dilution of the osmotic solution over time [13], a weight ratio of 5 was selected between samples and the solution. Once a required period was over, the samples were removed from the osmotic solution, washed with distilled water, and then wiped clean of its surface water using absorption pads. In the next stage, moisture content and initial volume of treated samples were measured.

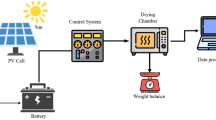

2.4 Drying experiments

In this study, a hybrid MC-HA dryer (LG SolarDOM, model SD-3855SCR, Korea, internal dimensions: 480 × 392 × 527 mm, 38 l) with adjustable microwave power (90, 180, 360, 600 and 900 W at 2450 MHz), equipped with temperature control (40–230 °C) and also a rotating tray (2.5 RPM) was used, which was designed for household uses. Microwave drying experiments were conducted at 360, 600 and 900 W each for 10, 4 and 3 min, respectively, with PRs of 1, 2, 3 and 4. After osmotic dehydration, potato samples were first exposed to microwaves, and the process was continued using the convective method at 40 °C and air velocity of 1 m/s. The moisture content of samples was measured at the end of the microwave phase and also at 45-min intervals during the HA drying phase. The drying process was terminated once the moisture content reached a minimum of 0.2 g water / g dry solids. Table 1 shows the microwave “on” and “off” times at different PRs and power levels.

2.5 Moisture content measurement

The moisture content of potato slices was determined by drying them in an oven (Fan Azma Gostar, model BM120, Iran) at 105 °C for 24 h [14]. Moisture content (d.b) was determined using Eq. 2:

where Mw is mass of water (g) and Ms is the mass of sample dry solids (g). Mean initial moisture content of potatos for control and treated samples with 10, 30, 50 and 70% sucrose solutions was 4.82, 4.59, 3.30, 2.15 and 2.06 g water / g dry solids, respectively.

2.6 Water loss and solid gain measurement during osmotic pretreatment

Samples were immersed in known-concentration solutions (10, 30, 50 and 70%) for 120 min to determine variations in solids and water contents of potato samples during osmotic dehydration. At 30-min intervals, samples were removed from the solutions to calculate their water loss and solid gain using Eqs. 3 and 4 [15]:

In these relations, w is the sample weight (g), M is the sample moisture content (w.b), i denotes a untreated fresh sample, and f shows a sample treated with an osmotic solution.

2.7 Effective moisture diffusion coefficient (Deff)

Since diffusion is the dominant phenomenon for transferring moisture to surface during the drying process, moisture content variations are expressed by the Fick’s diffusion equation. With the assumptions of uniform distribution of the initial moisture content, moisture transfer by diffusion, constant diffusion coefficient, and insignificant shrinkage and resistance against mass transfer, Crank [16] solved this equation as follows:

where MR is moisture ratio, Mt is moisture at the tth moment (d.b), M0 and Me are initial and equilibrium moisture contents (d.b), respectively, Deff is effective moisture diffusion coefficient (m2/s), L is a half of sample thickness (m), and t is the drying time (s). For long drying times, only the first term of the series is considered. This is due to the negligible value of other terms of series on moisture ratio. Since Me is negligible compared to Mt and M0, Eq. 5 can be expressed as follows:

By taking logarithm from both sides of Eq. 6, the following equation is obtained:

Effective moisture diffusion coefficient can be obtained by plotting the ln (MR) curve against time and then calculating its slope from Eq. 7.

2.8 Shrinkage measurement

Shrinkage represents the volume changes of the samples based on the following Eq. [17]:

where S is shrinkage percent, Vt is the apparent volume of the dried sample after time t (cm3) and V0 is the apparent volume of the raw sample (cm3). Apparent volume was measured using the toluene displacement technique with a 50-ml glass pycnometer. In this method, the weighed sample is placed inside a pycnometer half-filled with toluene. The remaining volume of the pycnometer is then filled to the top with more toluene, and it is weighed. The apparent volume of the sample was calculated as follows [17]:

where Vf is pycnometer volume (cm3), Msf is the weight of toluene added to fill up the pycnometer (g), Mt + s shows the weight of pycnometer plus toluene and sample (g), Mf is pycnometer weight (g), M is sample volume (g), and ρ s is toluene density (0.87 g/cm3 @20 °C).

2.9 Bulk density measurement

The bulk density of fresh and dried potatoes was determined using the ration of sample weight (mt) (g) to its volume (cm3), as follows [3]:

2.10 Rehydration measurement

To measure rehydration ratio, the dried potato samples were immersed in 500 ml of boiling water for 20 min. The samples were then taken from water and were wiped with absorbent pads to remove the excess water. The mass of dried samples before and after rehydration was determined by a digital balance. The rehydration percent of dried samples was calculated by the following Eq. [18]:

where M0 and Mt were dried sample weight (g) before and after rehydration.

2.11 Specific energy consumption (SEC)

SEC of the IM-HA drying method was defined as the sum of SECs of intermittent microwave and convective hot air drying, as follows [4, 19, 20]:

where E1 is energy consumption in microwave drying (kJ), E2 is energy consumption in convective drying (kJ), P is microwave power (W), tm is microwave drying time (s), PR is microwave pulse ratio, A is the area of the sample container (m2), Va denotes air velocity (1 m/s), ρa is air density (kg/m3), ΔH is air enthalpy (kJ/kg of dry air), tc is the convective hot air drying time (s), Cp,a stands for air specific energy (kJ/kg °C), Cp,v is specific energy of water vapor (kJ/kg °C), W is absolute air humidity (kg water/kg dry air), Tin is the dryer temperature (40 °C), Tamb shows the ambient temperature (25 °C), λ is the latent heat of water evaporation (kJ/kg water), and finally mvm and mvc show masses of removed water during microwave and convective hot air drying (kg), respectively.

2.12 Statistical analysis

In this study, SAS 9.4 was used for statistical analysis as a 5 × 4 × 4 factorial experiment (osmotic solution concentration × microwave power × pulse ratio) with a completely randomized design and three replications. The experiments were conducted to analyze the effect of the study variables on moisture content, effective moisture diffusion coefficient, shrinkage, bulk density, rehydration, and specific energy consumption in the drying process of potato slices. The variables included osmotic solution concentration at five levels (0 or control, 10, 30, 50 and 70% w/w), microwave power at four levels (0 or control, 360, 600 and 900 W), and pulse ratio at four levels (1, 2, 3 and 4). Duncan’s multiple range test (p < 0.05) was used for mean comparison.

3 Results and discussion

3.1 Water loss and solid gain during osmotic dehydration

Osmotic dehydration is a mild drying process where the drying occurs due to the direct contact of the plant/animal texture with a hypertonic solution (osmotic solution), which triggers water to move out through the semipermeable membrane and let osmotic solution solids to migrate into the food material. The chemical potential gradient of water between the food material and the osmotic environment supplies the required power for dehydration in this process [12]. Osmotic dehydration is widely used as pretreatment in food drying processes for quality improvement purposes. The advantages of osmotic dehydration are better color and flavor preservation as well as less energy requirement in supplementary drying processes due to reduced moisture content by osmotic dehydration [15, 21].

The water diffusion rate from sample to solution and also the movement rate of solids from solution to sample depend on temperature and concentration of the osmotic solution [22], as any increase in their values would speed up the mass transfer rate. Solid gain from solution by samples can improve their dielectric properties, besides improving their flavor. In microwave drying, a portion of the energy is reflected from the surface of the sample exposed to electromagnetic waves, while the rest of the energy passes through. The passed energy is also partly absorbed by the substance. The energy level and characteristics of each of the three categories are determined by material dielectric properties. These properties are defined by parameters such as dielectric constant, loss tangent and loss factor [20]. Since microwave heating involves ionic polarization and dipole rotation, the higher the number of ions, the faster the heating rate. In osmotic pretreatment, dielectric constant, loss factor and loss tangent largely increase due to water loss and solid gain phenomena. Therefore, the drying time can be reduced in the IM-HA drying phase by reducing the initial moisture content and improving dielectric properties [23]. In osmotic dehydration, higher solid gain develops more resistance against mass transfer, which in turn reduces moisture removal rate at the terminal stages of the drying [12]. It is this imperative to optimize process variables to achieve suitable properties in the final product.

Table 2 presents water loss and solid gain data of potato samples during the immersion in the osmotic solutions with different concentrations and immersion times. For a constant osmotic solution concentration, increased immersion time led to significant and non-significant increases in some treatments in terms of water loss and solid gain (Table 3). The increase was larger at the beginning of the process boosted by higher osmotic drive at this phase. Other authors have also reported high water loss and solid gain rates at the early phases of osmotic dehydration [12]. Increasing the concentration of the osmotic solution also increased water loss and solid gain (Table 3). This increase was significant (P < 0.05) for the 10% treatment when compared to other treatments. High concentrations of osmotic solution developed a concentration difference, and thus increased the osmotic pressure. This in turn supplied the drive to further increase solid gain and water loss of samples [24]. Mass transfer during osmotic dehydration depends on different process variables. For further water loss of the sample textures during this process, it can be effective to use higher temperatures and shorter periods; however, solid gain is also inevitable in this phase. If the objective of the osmotic dehydration process is to minimize solid gain, it is more suitable to apply lower temperatures and concentrations; however, longer time periods should be spent for water loss in this mode.

3.2 Drying kinetics

Decline in the quality of hot-air-dried samples at higher temperatures corresponds to long drying times. Literature results show that certain chemicals in food materials are sensitive to temperature and decompose at high temperatures. In addition to destruction of heat-sensitive compounds, other downsides of using high-temperature airflow for convective drying include reduced sensory profiles like texture and color of the final product. High temperature airflow leads to faster moisture loss at the beginning of the process and reduction in surface moisture content. This causes hardening [25]. In contrast, lower drying rate, longer drying time, and more shrinkage are the main limitations of using low-temperature airflow for drying. Using auxiliary energy sources such as microwave, ultrasonic and infrared waves in combination with low-temperature drying can resolve these limitations [26].

Figure 1a shows the drying kinetics of control and pretreated potato samples at different concentrations of the osmotic solution for the HA drying method. The initial moisture content of the samples treated with osmotic solution was lower than the control samples, and it significantly increased moisture loss by increasing the osmotic solution concentration (Table 6). According to Fig. 1a, moisture content consistently decreased in all treatments as the drying time advanced. The drying process was continued for all samples until reaching the final moisture content of 0.2 g water/ g dry solids) (Table 4). Over time, the moisture removal rate (slope) decreased in all samples. This can be concluded by reduced difference between two consecutive moisture contents by reaching to the end of the drying process. At the same time, drying curve slopes for samples pretreated with the osmotic solutions were lower than the control treatment. Increasing the concentration of the osmotic solution gave rise to a wider difference between the slopes of pretreated and control samples. This can be due to a difference in initial moisture content of pretreated and control samples. In other words, osmotically-treated samples had slower drying rate (slope) due to lower initial moisture content. Increase in solid content of potato samples during immersion in the sucrose solution acted as the bonding agent of moisture, which in turn made moisture removal to be much more difficult during drying. Note that the control sample needed longer drying time to reach the final moisture content (0.2 g water / g dry solids) due to its higher moisture content. However, the drying time of pretreated samples was lower. In general, the drying time further decreased by increasing the osmotic solution concentration (Table 4). Similar results have been reported by Tan et al. [27] in drying of osmotaically-treated potatoes.

a Drying Kinetics of control potato samples (without microwave drying) pretreated with osmotic solutions at concentrations of 0 (control), 10, 30, 50 and 70% during convective hot-air drying. b Drying Kinetics of potato samples pretreated with osmotic solutions at concentrations of 0 (control), 10, 30, 50 and 70% during both microwave and convective hot-air drying at 360 W (a,b,c,d), 600 W (e,f,g,h) and 900 W (i,j,k,l) with different pulse ratios (PR)

Figure 1b (a,b,c,d) shows the drying kinetics of control and pretreated samples for the IM-HA drying method using 360 W and different PRs. The sharp drying slope at the beginning of the process shows the considerable effect of microwave energy on moisture content reduction of potato samples. During the early stages of drying, the samples had high moisture content. The high moisture content is the main reason for internal heating during microwave application, which leads to increased product temperature and fast moisture diffusion. As a result, moisture content considerably decreases in a short time period [28]. In other words, compared to HA-drying (Fig. 1a), the IM-HA drying technique cuts the drying time in all samples (control and pretreated). The effect of osmotic pretreatment on drying kinetics was similar to that in the HA method.

Results showed that sample moisture contents after the microwave phase further decreased at higher PRs (Table 6). Accordingly, for all three power levels, the highest moisture removal of control and pretreated samples occurred while using PR = 4. Longer off times at higher PRs facilitated moisture migration from inner sections to the surface, and, in the next step, by application of the microwave energy, moisture removal increases at the beginning of each drying period [29]. Pan et al. [29] showed that drying of squash using 100 °C airflow and longer off times leads to shorter drying time than that in continuous microwave drying.

Figure 1b also shows the IM-HA drying process of control and pretreated potato samples at 600 (e,f,g,h) and 900 W (i,j,k,l), respectively, under different PRs. In this configuration, the effect of osmotic pretreatment and PR on drying kinetics was similar to that in the 360 W setting. Results showed that increasing the microwave power from 360 to 900 W significantly decreased moisture content (Table 6) and, consequently, reduced the time to reach a similar moisture content (Table 4). Higher microwave powers led to higher internal heating in samples, faster mass transfer and thus shorter time to reach the required moisture content [30].

3.3 Effective moisture diffusion coefficient (Deff)

Effective moisture diffusion coefficient is probably the most important characteristic in physical food handling, which is central to engineering analyses of different food processes like drying. It describes all possible moisture transfer mechanisms inside foods. These include moisture diffusion, vapor diffusion, surface diffusion, capillary flow and viscous flow. Its value in the IM-HA drying method depends on factors such as microwave power, temperature and airflow velocity (that are highly effective in the drying rate). Any increase in any of these would increase the Deff [11]. The food moisture content also affects Deff, and the latter is higher at the early stages of drying due to high moisture content. Additionally, when applying microwave energy to foods with low moisture content, Deff is lower due to lower energy absorption at low moisture contents.

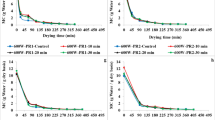

Figure 2a shows ln (MR) over time for HA-dried samples. Deff was calculated from slope of this curves during drying under different experimental drying conditions using Eq. (7). This equation shows that Deff has a direct relationship with the curve slope. Similarly, Fig. 2b (from a to l) also presents ln (MR) values against the drying time of potato samples for the IM-HA drying technique under different power and PR levels. Table 5 shows Deff values for potato drying using HA and IM-HA techniques with different osmotic solution concentration, microwave power and PR levels. The higher Deff of IM-HA-dried samples compared to HA-dried samples (Table 5) indicates the effect of microwave energy on faster moisture removal.

a Ln (MR) versus drying time of control potato samples (without microwave drying) pretreated with osmotic solutions at concentrations of 0 (control), 10, 30, 50 and 70% during convective hot-air drying. b Ln (MR) versus drying time of potato samples pretreated with osmotic solutions at concentrations of 0 (control), 10, 30, 50 and 70% during both microwave and convective hot-air drying at 360 W (a,b,c,d), 600 W (e,f,g,h) and 900 W (i,j,k,l) with different pulse ratios (PR)

Analysis of the effect of osmotic pretreatment on Deff values showed that increasing the osmotic solution concentration up to 30% increased Deff; however, at higher concentrations, the trend was inversed as Deff decreased with increasing osmotic solution concentration. These variations were significant (P < 0.05) for all treatments except for 50 and 70% treatments (in comparison with each other) (Table 6). It seems that osmotic pretreatment with lower concentrations (10 and 30%) facilitated moisture removal and thus increased Deff by preventing further shrinkage of samples than the control samples. Increased texture resistance against shrinkage as a result of sucrose gain can be a reason for higher Deff for concentrations up to 30% (Table 6). Reduction of Deff in the samples pretreated with higher sucrose concentrations (50 and 70%) is a result of higher sucrose gain of the cellular texture of potatoes from the osmotic solution, which in turn leads to higher resistance against moisture removal (Table 3). In addition, high osmotic solution concentrations might degrade the fruit texture and disrupt moisture diffusion during drying [13]. Rahman and Lamb [31] and Simal et al. [32] found similar behaviors in Deff values of pineapple and apple samples, respectively. Moreover, an increase in PR at different power levels raised Deff values. This increase was non-significant (P < 0.05) only in PR values of 1 and 2 (Table 6). Longer off times facilitated moisture transfer from center to surface, and, at the next stage, microwave energy application increased moisture removal and thus Deff at the beginning of every drying cycle [29].

Additionally, for all microwave energy levels, Deff values were significantly (P < 0.05) higher than Deff of control samples (Table 6). Analysis of the effect of different power levels showed that the 900 W power level had the highest Deff and the zero power level (no microwave application) had the lowest value. Higher power levels caused faster heating followed by increased vapor pressure inside samples, which facilitated moisture diffusion to the surface [11]. Deff values at 360 W was also higher than 600 W. This is likely due to longer exposure to microwave energy when using 360 W (10 min) than 600 W (4 min).

3.4 Shrinkage

Shrinkage and texture quality of dried samples are their other qualitative characteristics. During the drying of high moisture content foods such as fruits and vegetables, variations occur in their shape, density and porosity. Variations in shape and size of products affect their physical properties and change the final texture and (mass and heat) transfer characteristics of the dried products. Shrinkage disrupts moisture and heat transfer phenomena. Shrinkage in fruits and vegetables occurs when the viscoelastic matrix moves towards the space once occupied by water, which is now removed from the texture as a result of drying. Shrinkage from different drying techniques can be measured using direct measurement or through variations in shrinkage-dependent parameters like porosity [33].

Figure 3a shows the shrinkage kinetics of control and pretreated potato samples at different concentrations of the sucrose solution for the HA drying method. Shrinkage increased significantly in all samples during the drying time as a result of moisture loss and volume reduction [14]. The initial shrinkage (following the osmotic process and at the start of the drying process) increased for samples pretreated with the osmotic solution as the osmotic solution concentration increased. Accordingly, the samples pretreated with the 70% sucrose solution had the highest amount of initial shrinkage. This can be due to the higher difference in osmotic pressure in osmotic solutions with higher concentrations, and thus higher moisture loss of samples and further contraction of the viscoelastic matrix towards water-free spaces [33]. As the drying draws closer to its end, the difference between two consecutive shrinkage (slope) decreased. This is indicative of faster shrinkage at the beginning of the process and also its reduction as moisture content is reduced. This can be due to high Deff and surface hardening of samples at the beginning of the drying process [17].

a Shrinkage variations of control potato samples (without microwave drying) pretreated with osmotic solutions at concentrations of 0 (control), 10, 30, 50 and 70% during convective hot-air drying b Shrinkage variations of potato samples pretreated with osmotic solutions at concentrations of 0 (control), 10, 30, 50 and 70% during both microwave and convective hot-air drying at 360 W (a,b,c,d), 600 W (e,f,g,h) and 900 W (i,j,k,l) with different pulse ratios (PR)

In general, the final shrinkage of the pretreated samples was significantly (P < 0.05) lower than the control samples. As the osmotic solution concentration increased, shrinkage showed further decrease (Table 6); as, for the osmotic solution concentration of 70%, shrinkage was lower by 12.65% than the control treatment. In agreement with the study results, Dehghannya et al. [17] reported that osmotic dehydration reduced shrinkage in the final product, and that shrinkage decreased with increasing the osmotic solution concentration. This is due to formation of a dense layer on the sample surface made of soluble solids inside the osmotic solutions with high concentration. At the same time, given the low initial moisture content and thus shorter drying time of osmotically-pretreated samples (Table 4), their shrinkage was also smaller during drying.

Figure 3b (a,b,c,d) shows shrinkage curves for control and pretreated potato samples for IM-HA drying at 360 W and different PRs. According to this figure, the initial shrinkage (as a result of osmotic dehydration) of osmotically-pretreated sample with high concentrations was higher, which gave rise to higher shrinkage after the microwave phase. However, as the drying process continued with the HA method, the shrinkage difference between pretreated and control samples narrowed, as the shrinkage at the end of the process was even lower in the pretreated samples. Generally, sample shrinkage decreased significantly (P < 0.05) by 14.22% as PR reached 4 from 0 (Table 6). Continuous microwave application (PR = 1) created larger shrinkage due to large heat generation and accelerated moisture removal. Higher PR (longer off time) balanced heat generation, increased moisture removal, and reduced the drying time (Table 4), which in turn reduced shrinkage.

Figure 3b also shows the shrinkage kinetics of control and pretreated potato samples dried by the IM-HA method at 600 (e,f,g,h) and 900 W (i, j,k,l), respectively, and different PRs. Results from these power levels in relation to the effect of osmotic solution concentration and PR were similar to the results obtained for 360 W. The effect of different power levels on shrinkage of potato samples is compared in Table 6. Shrinkage of potato samples decreased significantly (P < 0.05) with increasing microwave power. Accordingly, IM-HA drying at 900 W reduced shrinkage by 13.3% compared to HA drying. This can be due to shorter microwave exposure as a result of higher microwave power (Table 1).

3.5 Bulk density

Bulk density is a structural property of foods. Structural properties are important for describing qualitative indices of dried products. Bulk density is mainly considered for powder products and porous foods. As porosity increases, bulk density decreases and rehydration increases. The low bulk density of dried samples is thus a desirable characteristic. Long drying times lead to larger bulk densities due to increased shrinkage.

Figure 4a shows the bulk density of control and pretreated potato samples during HA drying. The initial bulk density (after osmotic dehydration and at the beginning of drying process) increased for higher osmotic solution concentrations. This can be due to the increased sucrose gain and shrinkage of samples (Fig. 3a) and thus their smaller volumes following the osmotic dehydration. In general, at the early stages of the drying process, bulk density first followed a gradual rising trend and then a falling one as the sample moisture content decreased. The bulk density increased at the early stages of HA drying due to shrinkage and a large decrease in sample volumes (Fig. 3a). As the end of the process approached, bulk density decreased as the samples reached a fixed volume, and the rates of shrinkage (Fig. 3a, b) and moisture removal decreased. Final bulk density values of osmotically-treated samples were lower than those of control samples. As the osmotic solution concentration reached 70%, bulk density dropped by 10.3%, which was statistically significant in some treatments while non-significant in others (Table 6). This finding can be caused by less shrinkage in osmotically-pretreated samples (Table 6) and, consequently, their smaller volume during HA-drying.

a Bulk density variations of control potato samples (without microwave drying) pretreated with osmotic solutions at concentrations of 0 (control), 10, 30, 50 and 70% during convective hot-air drying b Bulk density variations of potato samples pretreated with osmotic solutions at concentrations of 0 (control), 10, 30, 50 and 70% during both microwave and convective hot-air drying at 360 W (a,b,c,d), 600 W (e,f,g,h) and 900 W (i,j,k,l) with different pulse ratios (PR)

Figure 4b (a,b,c,d) shows the bulk density of control and pretreated samples for the IM-HA drying method using 360 W and different PRs. At the end of the microwave drying phase, bulk density was lower in all treatments (Fig. 4b). This is due to the positive effect of microwave application on increasing moisture removal, internal pressure and thus volume expansion of samples (Aghilinategh et al. [4]). For the rest of the process (HA drying), density variations were similar to those reported for HA-dried control and pretreated samples. Bulk density decreased as PR increased (longer off time). This increase was not significant between PR = 2 and PR =3 (Table 6). By increasing PR from 0 to 4, bulk density showed a 33.84% decrease. This improvement in dried product quality can be a result of temperature and moisture redistribution during the off-time periods. Accordingly, temperature and moisture gradients at different sample points became smaller, which resulted into less internal stress [4].

Figure 4b also shows variation curves of bulk density during IM-HA drying at 600 (e,f,g,h) and 900 W (i,j,k,l), respectively, using different PRs. The effect of osmotic pretreatment and pulse ratio on bulk density variations for these two power levels were also similar to those in drying at 360 W. A comparison between the effect of different microwave power levels on bulk density showed that use of lower microwave power and higher exposure time (Table 1) increased bulk density. In comparison of different power levels, the increase was significant in some and non-significant in others (Table 6). Aghilinategh et al. [4] also reported similar results for drying of apple. Long microwave exposure times can negatively affect density, structure and porosity of the dried product. Therefore, given the longer duration of HA drying and the subsequent larger shrinkage (Fig. 3a) and bulk density of HA-dried samples, the hybrid IM-HA technique considerably reduced bulk density by cutting the drying time. In comparison to HA-drying, the IM-HA technique at 900 W reduced bulk density by 33.84% (Table 6).

3.6 Rehydration

Rehydration of dried products is another qualitative characteristic. It is the most important stage in using dried fruits and vegetables. The higher the rehydration in the final product, the higher their quality and attractiveness. Rehydration is a complicated process that presents the physicochemical changes of the sample during the drying process. Rehydration level of dried products is affected by factors such as drying conditions, different pretreatements, and sample composition. Other parameters including shrinkage also affect this qualitative factor as rehydration decreases when the product shrinks and its density changes [34].

Figure 5a shows rehydration of control and osmotically-pretreated potato samples during the drying process. Rehydration increased by increasing osmotic solution concentration after the osmotic dehydration (starting point of IM-HA drying: 0 min) (Fig. 5a). This can be due to further reduction in moisture content of samples pretreated with higher osmotic solution concentrations (Table 6), which in turn increased their capacity to absorb more water in the rehydration phase. Results showed that rehydration improved by 4.37% when increasing the osmotic solution concentration to 10%. However, further increase in osmotic solution concentration reduced rehydration. Accordingly, samples treated with 70% sucrose solution had 30.89% lower rehydration than control samples. Rehydration variations were significant at the 5% level (Table 6). Consistent with the results of this study, Rastogi et al. [35] observed that dried carrot samples pretreated with the 5 and 10% sucrose solution had the highest rehydration compared to control samples and samples pretreated at higher concentrations. Higher osmotic solution concentrations lead to cellular failure and damage, which in turn prevent cells from absorbing more water during rehydration. At the same time, at lower concentrations, sucrose can maintain protein function and support its 3D structure, prevent the cellular membrane from damages, and improve rehydration of the samples pretreated with the low-concentration sucrose solutions [35]. In addition, Noshad et al. [36] also reported reduced rehydration of osmotically-pretreated samples. This finding can be due to high sucrose gain during its immersion in osmotic solution. The gained sucrose narrows texture pores, which develop more resistance against water diffusion during rehydration. Furthermore, stress induced by osmotic dehydration changes the cellular permeability, which renders cells incapable of absorbing water as much as untreated samples [36].

a Rehydration ratio variations of control potato samples (without microwave drying) pretreated with osmotic solutions at concentrations of 0 (control), 10, 30, 50 and 70% during convective hot-air drying b Rehydration ratio variations of potato samples pretreated with osmotic solutions at concentrations of 0 (control), 10, 30, 50 and 70% during both microwave and convective hot-air drying at 360 W (a,b,c,d), 600 W (e,f,g,h) and 900 W (i,j,k,l) with different pulse ratios (PR)

Figure 5b (a,b,c,d) shows rehydration curves for control and pretreated potato samples for IM-HA drying at 360 W and different PRs (1, 2, 3 and 4). Following the microwave drying phase, the rehydration level of osmotically-pretreated samples was higher than that of control samples. Accordingly, samples pretreated with 50 and 70% sucrose solution had the highest rehydration (Fig. 5b). In other words, samples pretreated with higher osmotic solution concentration had a higher capacity to absorb water due to their low moisture content (following the osmotic dehydration and at the beginning of the drying process: time 0 min). The trend was reversed for the rest of the HA process, and the final rehydration of samples pretreated with higher osmotic solution concentration was lower. Additionally, sample rehydration increased significantly (P < 0.05) by 38.05% as PR reached 4 from 0 (Table 6). In agreement with these results, Aghilinategh et al. [4] reported increased rehydration of apple samples for higher PRs. This can be due to longer off time, balanced heat distribution and thus improved structure of foods.

Figure 5b also shows rehydration curves of control and pretreated potato samples dried by the IM-HA method at 600 (e,f,g,h) and 900 W (i,j,k,l) and different PRs. The effect of osmotic pretreatment and pulse ratio on rehydration kinetics of these curves were similar to those in drying at 360 W. In IM-HA drying, rehydration increased by increasing power, which was significant (P < 0.05) for all power levels compared to the control sample (Table 6). This can be due to shorter microwave exposure time (Table 1). Shorter microwave exposure reduced shrinkage of samples (Table 6). A low-shrinkage texture has higher rehydration capacity. The results supports literature findings [4]. Microwave application in drying increases internal pressure of samples creating a puffy structure, which develops a higher rehydration capacity and better reconstruction of the dried structure. The hybrid IM-HA method at 900 W improved rehydration by 35.07% compared to the HA technique (Table 6).

3.7 Specific energy consumption (SEC)

Today, the most important objective of different industries is to increase profitability and reduce production costs, besides developing quality products for end users. Use of different process methods that contribute to less energy consumption is an important solution for this objective. Energy consumption of different drying processes is either expressed as the total energy consumption of the process (in Joules) or based on specific energy consumption (SEC) (in Joules / kg of the evaporated water). Generally the latter in more important. Use of microwave energy during the drying process is an effective way of reducing energy consumption. In this method, as the microwave energy infiltrates into food materials, it is directly converted to kinetic energy of water molecules generated throughout the sample. Therefore, the drying rate increases, and energy is effectively saved [37]. Intermittent application of microwave can improve this energy saving because, in intermittent microwave application, heat is distributed throughout the sample at certain microwave off times. As a result, the direct exposure time is much less than the continuous microwave method. Energy consumption in the microwave drying phase depends on its power and also moisture content, and energy requirement differs by changing the moisture content [38].

Specific energy consumption (SEC) in drying of control and pretreated potato samples in the IM-HA method at different power levels and PRs is given in Table 7. Generally, SEC increased when raising the osmotic solution concentration from 10 to 70% (Table 6). Increasing osmotic solution concentration to 70% increased SEC by 39.51% compared to the control samples. In comparison with the control samples, this increase was significant only in the 50 and 70% treatments (Table 6). According to Table 3, higher solid gain of potato samples during immersion in the sucrose solution can act as a moisture bonding agent, which makes moisture removal more difficult and increases SEC. Moreover, SEC was lower for higher PRs, and the results were significant (P < 0.05) compared to the control sample (Table 6). By increasing PR from 0 (control) to 4, SEC showed a 60.86% decrease. According to Table 6, moisture removal generally increased during the microwave phase. Therefore, higher PRs led to shorter HA-drying process (Table 4) and thus less energy consumption.

A comparison between energy consumption at zero power level (HA drying) with other power levels in Table 6 shows the significant effect of integrating microwave energy in HA drying on reduced energy consumption. Energy consumption significantly decreased for all power levels compared to the zero power level (HA drying). The lowest energy consumption was observed for the 900 W power level with 63.27% reduction compared to HA drying. According to Table 6, it seems that high Deff at 900 W led to faster moisture removal and less drying time (Table 4) and thus decreased energy consumption.

3.8 Sample images

Images of the potato samples dried using the IM-HA technique at 900 W and PR = 4 with different osmotic solution concentrations are given in Fig. 6, as an example. The figure shows improved appearance and reduced shrinkage as osmotic solution concentration increased.

4 Conclusion

The effect of simultaneous application of intermittent microwave (IM) and forced convection of hot air (HA) on the drying of potato samples pretreated with a sucrose solution was investigated. Results showed that the highest drying time (495 min) belonged to the HA-dried control treatment. The lowest drying time (228 min) belonged to the samples pretreated with 50 and 70% osmotic solutions at 900 W microwave power with pulse ratio (PR) of 4. Use of higher microwave power and PR led to increased Deff. Increasing the osmotic solution concentration to 70% decreased shrinkage by 12.65%. Besides, shrinkage was 13.3% lower than the HA drying when using the hybrid IM-HA method at 900 W. Moreover, increasing the concentration of the sucrose solution to 70% reduced the bulk density by 10.30%. Use of IM-HA drying at 900 W reduced bulk density by 33.84% compared to the HA-dried samples. On the other hand, in IM-HA drying, rehydration of dried samples was higher than the HA method, and increasing the microwave power and PR in the former led to 35.07 and 38.05% effects, respectively. Finally, specific energy consumption increased by 39.51% (compared to the control treatment) when increasing osmotic solution concentration to 70%, whereas increased power level and PR reduced this parameter by maximum 63.27 and 60.86%, respectively.

References

Wang R, Zhang M, Mujumdar AS (2010) Effect of osmotic dehydration on microwave freeze-drying characteristics and quality of potato chips. Dry Technol 28:798–806

Markowski M, Bondaruk J, Błaszczak W (2009) Rehydration behavior of vacuum-microwave-dried potato cubes. Dry Technol 27:296–305

Dehghannya J, Gorbani R, Ghanbarzadeh B (2016b) Determination of bulk density of Mirabelle plum during hot air drying as influenced by ultrasound-osmotic pretreatment. J Food Measure Character 10:738–745

Aghilinategh N, Rafiee S, Gholikhani A, Hosseinpur S, Omid M, Mohtasebi SS, Maleki N (2015) A comparative study of dried apple using hot air, intermittent and continuous microwave: evaluation of kinetic parameters and physicochemical quality attributes. Food Sci Nutr 3:519–526

Yadav DN, Anand T, Sharma M, Gupta RK (2014) Microwave technology for disinfestation of cereals and pulses: an overview. J Food Sci Technol 51:3568–3576

Wray D, Ramaswamy HS (2015) Microwave-osmotic/microwave-vacuum drying of whole cranberries: comparison with other methods. J Food Sci 80:E2792–E2802

Soysal Y, Ayhan Z, Eştürk O, Arıkan MF (2009b) Intermittent microwave–convective drying of red pepper: drying kinetics, physical (colour and texture) and sensory quality. Biosyst Eng 103:455–463

Kumar C, Karim MA, Joardder MUH (2014) Intermittent drying of food products: a critical review. J Food Eng 121:48–57

Maskan M (2000) Microwave/air and microwave finish drying of banana. J Food Eng 44:71–78

Torringa E, Esveld E, Scheewe I, van den Berg R, Bartels P (2001) Osmotic dehydration as a pre-treatment before combined microwave-hot-air drying of mushrooms. J Food Eng 49:185–191

Sharma GP, Prasad S (2004) Effective moisture diffusivity of garlic cloves undergoing microwave-convective drying. J Food Eng 65:609–617

Dehghannya J, Emam-Djomeh Z, Sotudeh-Gharebagh R, Ngadi M (2006) Osmotic dehydration of apple slices with carboxy-methyl cellulose coating. Dry Technol 24:45–50

Dehghannya J, Gorbani R, Ghanbarzadeh B (2015) Effect of ultrasound-assisted osmotic dehydration pretreatment on drying kinetics and effective moisture diffusivity of Mirabelle plum. J Food Process Pres 39:2710–2717

Dehghannya J, Naghavi E-A, Ghanbarzadeh B (2016c) Frying of potato strips pretreated by ultrasound-assisted air-drying. J Food Process Pres 40:583–592

Dehghannya J, Gorbani R, Ghanbarzadeh B (2017) Influence of combined pretreatments on color parameters during convective drying of Mirabelle plum (Prunus domestica subsp. syriaca). Heat Mass Transf. https://doi.org/10.1007/s00231-00017-01995-00236

Crank J (1975) The Mathematic of Diffusion, 2nd edn Claredon Press, Oxford

Dehghannya J, Gorbani R, Ghanbarzadeh B (2016a) Shrinkage of Mirabelle plum during hot air drying as influenced by ultrasound-assisted osmotic dehydration. Int J Food Prop 19:1093–1103

Antonio GC, Alves DG, Azoubel PM, Murr FEX, Park KJ (2008) Influence of osmotic dehydration and high temperature short time processes on dried sweet potato (Ipomoea batatas Lam). J Food Eng 84:375–382

Chayjan RA, Kaveh M, Khayati S (2015) Modeling drying characteristics of hawthorn fruit under microwave-convective conditions. J Food Process Pres 39:239–253

Singh RP, Heldman DR (2014) Introduction to Food Engineering, 5th edition Academic Press (Elsevier Inc.), San Diego

Emam-Djomeh Z, Dehghannya J, Gharabagh RS (2006) Assessment of osmotic process in combination with coating on effective diffusivities during drying of apple slices. Dry Technol 24:1159–1164

Akbarian M, Ghanbarzadeh B, Sowti M, Dehghannya J (2015) Effects of pectin-CMC-based coating and osmotic dehydration pretreatments on microstructure and texture of the hot-air dried quince slices. J Food Process Pres 39:260–269

Therdthai N, Visalrakkij T (2012) Effect of osmotic dehydration on dielectric properties, microwave vacuum drying kinetics and quality of mangosteen. Int J Food Sci Technol 47:2606–2612

Azoubel PM, da Rocha Amorim M, Oliveira SSB, Maciel MIS, Rodrigues JD (2015) Improvement of water transport and carotenoid retention during drying of papaya by applying ultrasonic osmotic pretreatment. Food Eng Rev 7:185–192

Bai Y, Rahman MS, Perera CO, Smith B, Melton LD (2002) Structural changes in apple rings during convection air-drying with controlled temperature and humidity. J Agr Food Chem 50:3179–3185

Gamboa-Santos J, Montilla A, Cárcel JA, Villamiel M, Garcia-Perez JV (2014) Air-borne ultrasound application in the convective drying of strawberry. J Food Eng 128:132–139

Tan M, Chua K, Mujumdar A, Chou S (2001) Effect of osmotic pre-treatment and infrared radiation on drying rate and color changes during drying of potato and pineapple. Dry Technol 19:2193–2207

Bilbao-Sáinz C, Andrés A, Chiralt A, Fito P (2006) Microwaves phenomena during drying of apple cylinders. J Food Eng 74:160–167

Pan YK, Zhao LJ, WB H (1998) The effect of tempering-intermittent drying on quality and energy of plant materials. Dry Technol 17:1795–1812

Wang J, Xiong Y-S, Yu Y (2004) Microwave drying characteristics of potato and the effect of different microwave powers on the dried quality of potato. Eur Food Res Technol 219:500–506

Rahman MS, Lamb J (1991) Air drying behavior of fresh and osmotically dehydrated pineapple. J Food Process Eng 14:163–171

Simal S, Deya E, Frau M, Rosello C (1997) Simple modelling of air drying curves of fresh and osmotically predehydrated apple cubes. J Food Eng 33:139–150

Yadollahinia A, Jahangiri M (2009) Shrinkage of potato slice during drying. J Food Eng 94:52–58

Reyes A, Ceron S, Zuniga R, Moyano P (2007) A comparative study of microwave-assisted air drying of potato slices. Biosyst Eng 98:310–318

Rastogi NK, Nayak CA, Raghavarao KSMS (2004) Influence of osmotic pre-treatments on rehydration characteristics of carrots. J Food Eng 65:287–292

Noshad M, Mohebbi M, Shahidi F, Mortazavi SA (2012) Kinetic modeling of rehydration in air-dried quinces pretreated with osmotic dehydration and ultrasonic. J Food Process Pres 36:383–392

Jindarat W, Sungsoontorn S, Rattanadecho P (2015) Analysis of energy consumption in a combined microwave–hot air spouted bed drying of biomaterial: coffee beans. Exp Heat Transfer 28:107–124

Soysal Y, Arslan M, Keskin M (2009a) Intermittent microwave-convective air drying of oregano. Food Sci Technol Int 15:397–406

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Dehghannya, J., Bozorghi, S. & Heshmati, M.K. Low temperature hot air drying of potato cubes subjected to osmotic dehydration and intermittent microwave: drying kinetics, energy consumption and product quality indexes. Heat Mass Transfer 54, 929–954 (2018). https://doi.org/10.1007/s00231-017-2202-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-2202-5