Abstract

This study aimed at determining the influence of temperature on drying, rehydration and consumed energy characteristics of common wormwood leaves during thin layer drying. The experiments were carried out at temperatures of 50, 60 and 70 °C and a constant air velocity of 0.7 m s−1. The dehydration duration decreased significantly with increasing drying air temperature. The usefulness of five different mathematical models to simulate the experimental drying kinetics was evaluated and the Midilli model was found to be the best model for explaining the curves. Effective moisture diffusivity values were obtained to be in the range of 7.099 × 10−8–3.191 × 10−7 m2 s−1. Rehydration capacity of the dried leaves increased with increasing rehydration water temperature and decreasing drying air temperature. The specific energy consumption decreased with any increment in drying air temperature and varied from 17.64 to 32.09 kWh kg−1.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Artemisia absinthium is an herbaceous-perennial plant, with fibrous roots and straight grooved, branched and silvery-green stems, growing to 80–120 cm tall. Its leaves are spirally arranged, greenish-grey above and white below, covered with silky silvery-white trichomes, and bearing minute oil-producing glands. The herb is an element in the spirit absinthe, and is used for flavouring in some other spirits and wines such as bitters and vermouth. In the middle ages, it was used to spice mead, and in Morocco it is used with tea, called sheeba [1].

Drying is one of the most important unit operation often used as a final production step in a variety of process industries. Dried products have some brilliant benefits in comparison with moist ones such as easy handling, safe storage, and diversity of usage [2]. Applying inappropriate drying method and conditions may lead to some disadvantages e.g., quality deterioration of product and unnecessary high energy utilization. Therefore, an accurate knowledge of mass transfer mechanism and also energy consumption is necessary to optimize the drying parameters, improve the exciting dryers and even ideal design for new drying systems [3].

Depending on the natural properties of fresh products and also specific attributes required for dried products, different methods are used. Thin layer drying is the widely used method for drying of fruits and vegetables. The mathematical modelling and determination of moisture diffusivity and activation energy are the most advantages of thin-layer drying technology [4]. Numerous studies have been reported on mathematical modelling of thin layer drying curves, moisture diffusivity and activation energy for various products in the literature such as fig [5], black grapes [6], rough rice [7], apples [8], sweet cherry [9], pomegranate arils [10], casuarina equisetifolia wood chips [11], hawthorn fruit [3], and lemon slice [12].

Most of the dehydrated products are generally rehydrated prior to or during usage. Therefore, a good knowledge of rehydration characteristics, as an important quality indicator influenced by drying conditions, could be practical and should be obtained [13]. Describing rehydration kinetics is important from a processing and engineering point of view. It is important to know how absorption of water can be accomplished, but also how it will be influenced by processing variables [14]. Fathima et al. [15] investigated the rehydration of various microwave-dried greens. Mujaffar and Loy [16] studied the effect of temperature on the rehydration behavior of microwave-dried amaranth (Amaranthus dubius) leaves. Ergün et al. [14] determined the rehydration behavior of freeze-dried kiwi slices by using distilled water at different solid–liquid ratios at room temperature.

The drying process not only leads to some changes in properties of the final products, but also needs a great amount of energy. Therefore, one of the important challenges of the drying industry is to ensure good quality of the final products with high energy efficiency. Energy analysis have been conducted and reported for drying process of different biological products using various drying systems [17–19].

The objectives of the present study were to (1) investigate the effects of air temperature on drying behavior of common wormwood leaves, (2) select the best mathematical model for describing the dynamic drying curves, (3) calculate the effective diffusivity and activation energy, (4) determine the rehydration capacity and behavior and (5) determine specific energy consumption of the process.

2 Materials and methods

2.1 Samples

The aerial parts of common wormwood were harvested by cutting the herb manually to a height of 5 cm above the ground before flowering in May/June 2016 from farms of Chaharmahal–Va–Bakhtiari province, central Iranian plateau (31°14′, 33°47′N and 49°49′, 51°34′E). Before the drying experiments, the leaves were separated from the stems accurately. To determine the initial moisture content of the samples, four 50 g of the leaves were placed in an oven at 105 °C for 24 h [20] and the following equation was used:

where M 0 is the initial moisture content (kg water kg−1 dry matter) of the fresh leaves, and W 0 and W d are the mass (kg) of fresh and dried samples, respectively.

The average value of the initial moisture content of the leaves was determined to be 2.67 ± 0.021 kg water kg−1 dry matter.

2.2 Drying experiments

A laboratory-scale convective hot air dryer (Fig. 1) was used to conduct the drying experiments. The drying air was blown by a centrifugal fan into an electrical heater (7000 W heating coils) to heat up desired temperature and then, passed to the drying chamber made of a plexiglas cylinder with 15 cm height, and internal and external diameters 14 and 15 cm, respectively. The drying air velocity was measured by a hot wire anemometer accurate to 0.1 m s−1 (Lutron, AM-4201 model, Taiwan) and controlled by using a frequency inverter (TECO, 7300 CV model, Taiwan). Temperature of the drying air was measured by a PT100 thermometer accurate to 0.1 °C in inlet of the drying chamber and controlled by using a microcontroller. Furthermore, the consumed energy of heating elements was measured using a digital power meter accurate to 1 J (Zigler Delta Power).

For each drying experiment, the leaves (60 g with a thickness of 5 cm) were placed on the drying chamber. The experiments were performed at constant air velocity of 0.7 m s−1 and temperatures of 50, 60, and 70 °C. In the experiments, relative humidity of drying air remained at the environment relative humidity (approximately 30%).

During the experiments, the samples were weighed with a digital balance accurate to 0.01 g (Shimadzu, model UW6200H, Japan) at regular time intervals of 5 min and the instantaneous moisture content was determined by using Eq. (2):

where M is the moisture content at any given time (kg water kg−1 dry matter) of the leaves. Also, W is the mass of samples at any given time (kg).

In each experiment, drying process of the leaves was continued until reaching to the final moisture content of about 0.20 kg water kg−1 dry matter. At each drying temperature, the experiments were replicated three times and the average values were used.

Drying rate was calculated by using Eq. (3):

where DR is the drying rate (kg water kg−1 dry matter min), M t and M t+dt are the moisture contents (kg water kg−1 dry matter) at t and t + dt respectively, and t is the time (min).

2.3 Mathematical modeling

To describe the drying curves of the samples, the five widely used mathematical models (listed in Table 1) were selected. In the models, MR represents the moisture ratio and defined as [21]:

where MR is the moisture content ratio (dimensionless); and M t and M e are the moisture content (kg water kg−1 dry matter) at any given time and the equilibrium moisture content (kg water kg−1 dry matter), respectively.

Curve fitting tool of MATLAB 7.10 (MathWorks, Inc., Natick, MA) and nonlinear regression technique were applied to fit the models to experimental moisture ratio data. To evaluate and compare the fit goodness of the applied models, the statistical factors including root mean square error (RMSE) and coefficient of determination (R 2) were used. Among the models, a model having the minimum RMSE and the maximum R 2 was selected as the best model to estimate the drying curves [20].

2.4 Determination of effective diffusivity (D) and activation energy (E a )

Liquid and/or vapour diffusion is the main mechanism that controls the moisture removing in fruits and vegetables during drying process. By considering the only diffusion-based moisture transfer in thin layer drying, one-dimensional diffusion and Fick’s diffusion equation can be used for a simple and accurate analysis of the process. To identify the moisture transfer, by assuming isotropic behavior of the samples with regards to the water diffusivity and negligible shrinkage of drying materials, Fick’s second law of transient diffusion can be used as follow:

Supposing uniform moisture distribution, negligible external resistance, and constant diffusivity through the drying process, Crank [22] has given an analytically solution for Eq. (5) for different solid geometries. For an infinite slab the solution is written as:

where D, L, and t are the effective diffusivity (m2 s−1), thickness of the slab (m), and the drying time (s), respectively.

For long drying periods, Eq. (6) can be simplified to only the first term of the series as:

To determine the effective diffusion, the graph of ln(MR) against drying time (s) was plotted and Eq. (8) was used:

To calculate the activation energy, the effective moisture diffusivity was related with absolute temperature of drying air as follow:

Equation (9) was rewritten in logarithmic form as follow:

where D 0 is Arrhenius constant or the constant equivalent to the diffusivity at infinitely high temperature (m2 s−1), R is the universal gas constant (8.314 × 10−3 kJ mol−1 k−1), T abs is the absolute temperature (k), and E a is the activation energy (kJ mol−1).

The graph of ln(D) against 1/T abs was plotted and activation energy determined as [23]:

2.5 Rehydration

To determine the rehydration characteristics of the dried leaves, dried common wormwood leaves were immersed in distilled water maintained at 25, 50 and 80 °C. Five g of the dried leaves was weighed accurately and placed into a 250 ml beaker containing 150 ml distilled water, agitated and allowed to rehydrate for 5 h. At every 30 min intervals, the samples were removed from water, drained and weighed. The rehydration was expressed by moisture content of the leaves during rehydration process [24]. Rehydration of the leaves continued until the water absorption was insignificant and equilibrium moisture content of the rehydrated leaves was determined. Rehydration capacity of the leaves was calculated as follow [3]:

The experiments were replicated three times and the average values were calculated.

2.6 Energy analysis

The obtained data about energy consumption using the digital power meter was used to calculate the specific energy consumption (SEC) index by using the following equation [17]:

where E is the consumed energy (kW h) and m w is the mass of removed water (kg) from the leaves during the drying process.

2.7 Statistical analysis

For statistical analysis a complete randomized design was used with three replications. The data was statistically analyzed using one–way ANOVA by SPSS (19.0), and means were compared using the least significant difference (LSD) test (P < 0.05).

3 Results and discussion

3.1 Drying characteristics and mathematical modeling

Variation in moisture content (kg water kg−1 dry matter) of the common wormwood leaves during drying process at air temperatures of 50, 60 and 70 °C are illustrated in Fig. 2. Also, Fig. 3 shows the changes of drying rate (kg water kg−1 dry matter min) versus moisture content (kg water kg−1 dry matter) during the process for the leaves. As shown, drying duration of the samples was affected by air temperature significantly (P < 0.05) where average drying time for temperatures of 50, 60 and 70 °C was obtained to 140, 80 and 40 min, respectively. This observation agrees well with the reported results in the literature e.g., for hot air drying of red chillies [25], hot air and vacuum drying of kiwi slices [26], convective drying of green bell peppers [27] and microwave-vacuum drying of pomegranate arils [10]. In fact, at higher drying temperature, heat transfer rate between thermal source and the material is increased which accelerates moisture evaporation and consequently results in lower drying duration [12].

From Fig. 3, it is clear that drying process of the leaves at the applied temperatures occurred in the falling rate entirely and constant rate period was not observed. This observation is in agreement with the reported results for hot air drying of some biological products in the literature [28, 29]. Falling-rate drying period points to control the moisture movement in the samples mainly by diffusion. In fact, in falling-rate period, diffusion is the dominant physical mechanism and water migration from the interior to the surface of product is controlled by molecular diffusion [23].

Statistical analyses results obtained through fitting experimental moisture ratio data with the mathematical models for the temperatures of 50, 60 and 70 °C are presented in Table 2. As shown, the Midilli model had the best performance in describing drying curves of the common wormwood leaves. Some researchers have reported similar results on the applicability of the Midilli model to simulate the drying curves of agricultural materials e.g., oyster mushroom [30], white mulberry [31], and pomegranate arils [32].

Figure 4 shows the experimental ln(MR) versus drying time (min). By using Eq. (8) the effective moisture diffusivity of the common wormwood leaves was calculated and the average values for drying temperatures of 50, 60 and 70 °C were determined to be 7.099 × 10−8, 1.635 × 10−7 and 3.191 × 10−7 m2 s−1, respectively. The obtained moisture diffusivity values are generally within the range of 10−11–10−6 m2 s−1 which is given for food materials [23]. The statistical analyses indicated that drying temperature in the applied range had significant effect on moisture diffusivity of the leaves (P < 0.05) where any increment in drying temperature led to an increment in the diffusivity. In fact, resistance of fluid outflow is decreased at higher temperatures resulting in facilitated diffusion of water molecules in the product capillaries and higher moisture diffusivity [12]. Furthermore, the diffusivity values obtained for the common wormwood leaves in this study are comparable with those reported in the literature for hot air drying of olive leaves (1.05–4.97 × 10−9 m2 s−1) [33], peppermint leaves (1.809–4.649 × 10−9 m2 s−1) [20] and bertoni leaves (4.67–14.9 × 10−9 m2 s−1) [34].

The ln(D) values were plotted against 1/T abs (Fig. 5) and, by using Eq. (11), the activation energy (E a ) was determined to be 69.33 kJ mol−1. The obtained activation energy is within the general range reported for food materials (1.27–110 kJ mol−1) [17].

3.2 Rehydration characteristics

Generally, rehydration is a complex phenomenon which is affected by the process conditions and product characteristics. Rehydration of dried products with cellular structures is more complex where drying treatments can affect the process due to changes in the physical and chemical properties of the material during removal of water [35]. Table 3 shows the average values of rehydration capacity for the common wormwood leaves dried at the different drying and rehydration temperatures. As shown, any increment in rehydration water temperature significantly (P < 0.05) led to an increment in rehydration capacity. This case can be associated to the effect of water temperature on cell wall and tissue [3]. Similar results have been reported in the literature for different products e.g., betel leaves [24], green bell peppers [27] and hawthorn fruit [3]. The results obtained in this study showed that rehydration capacity of leaves dried at lower temperatures was more than leaves dried at higher temperatures. Lower drying temperatures may cause more porous structure which lead to higher water penetration. Similar results have been reported by Seremet et al. [35] in term of drying temperature effects on rehydration capacity for pumpkin slices (Table 3).

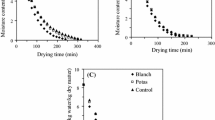

Figure 6 illustrates the variations in moisture content (kg water kg−1 dry matter) of the leaves dried at 60 °C during rehydration process at different water temperatures. For the two other drying temperatures the same trends were also obtained. As shown, rehydration curves can be divided into two regions including fast water absorption and slight water absorption periods. The quick initial water uptake is expected due to filling of capillaries and cavities near the surface of the leaves. Proceeding water absorption, the free capillaries and intercellular spaces are filled up with water which leads to a decline of the soaking rate. Some researchers have reported a similar observation during rehydration of different biological products e.g., kiwi slices [14], pumpkin slices [35], and betel leaves [24].

3.3 Energy consumption

Specific energy consumption (SEC) for drying of the leaves was calculated using experimental data for energy consumption and applying Eq. (13). The SEC value for drying temperatures of 50, 60 and 70 °C was obtained to be 32.09, 26.11 and 17.64 kW h kg−1, respectively. The SEC values obtained in this study are comparable with those reported in the literature for different products. Torki-Harchegani et al. [20] dried peppermint leaves in a convective oven at temperatures of 50, 60 and 70 °C and reported the SEC values to be 64.71, 55.37 and 42.72 MJ kg−1 for the applied temperatures, respectively. Aghbashlo et al. [17] investigated energy consumption during thin layer drying of berberis fruit at drying temperatures of 50–70 °C and air velocities of 0.5–2 m s−1, and found the specific energy consumption to be in the range of 20.94–1110.07 kW h kg−1. Furthermore, the results show that any increment in drying air temperature caused a decrement in specific energy consumed during dying of common wormwood leaves. This observation agrees well with reported consequences in the literature by researchers during drying of different products e.g., nettle leaves [36], apple slices [37], chamomile [38] and paddy kernels [39].

4 Conclusion

In the present, common wormwood leaves were dried in a convective dryer at air temperatures of 50, 60 and 70 °C and water removal, rehydration and consumed energy characteristics of the leaves during thin layer drying were investigated. Drying process of leaves occurred in the falling rate period entirely. The dehydration duration was affected by air temperature significantly where average required time for water removal from the samples was 140, 80 and 40 min for temperatures of 50, 60 and 70 °C, respectively. The experimental data was fitted to five thin layer models and Midilli best explained the drying curves. Effective moisture diffusivity was increased with any increment in air temperature and obtained to be in the range of 7.099 × 10−8–3.191 × 10−7 m2 s−1. Rehydration capacity of the dried common wormwood leaves increased with any increment in rehydration water temperature and any decrement in drying air temperature. Rehydration curves included an initially fast water absorption period continued by a slightly water absorption period. The maximum and minimum specific energy consumption values were obtained at drying air temperatures of 50 and 70 °C, respectively.

References

Hartley D (1985) Food in England, Futura Publications

Šumic Z, Vakula A, Tepic A, Cakarevic J, Vitas J, Pavlic B (2016) Modeling and optimization of red currants vacuum drying process by response surface methodology (RSM). Food Chem 203:465–475

Aral S, Bese AV (2016) Convective drying of hawthorn fruit (Crataegus spp.): effect of experimental parameters in drying kinetics, color, shrinkage, and rehydration capacity. Food Chem 210:577–584

Onwude DI, Hashin N, Janius RB, Nawi NM, Abdan K (2016) Modeling the thin-layer drying of fruits and vegetables: a review. Compr Rev Food Sci Food Saf 15(3):559–618

Babalis SJ, Belessiotis VG (2004) Influence of drying conditions on the drying constants and moisture diffusivity during the thin- layer drying of figs. J Food Eng 65(3):449–458

Doymaz I (2006) Drying kinetics of black grapes treated with different solutions. J Food Eng 76(2):212–217

Cihan A, Kahveci K, Hacihafizoglu O (2007) Modelling of intermittent drying of thin layer rough rice. J Food Eng 79(1):293–298

Aktas M, Ceylan I, Yilmaz S (2009) Determination of drying characteristics of apples in a heat pump and solar dryer. Desalination 239(1–3):266–275

Doymaz I, Ismail O (2011) Drying characteristics of sweet cherry. Food Bioprod Process 89(1):31–38

Dak M, Pareek NK (2014) Effective moisture diffusivity of pomegranate arils undergoing microwave-vacuum drying. J Food Eng 122:117–121

Sirdhar D, Madhu GM (2015) Drying kinetics and mathematical modelling of Casuarina equisetifolia wood chips at various temperatures. Period Polytech Chem Eng 59(4):288–295

Torki-Harchegani M, Ghasemi-Varnamkhasti M, Ghanbarian D, Sadeghi M, Tohidi M (2016) Dehydration characteristics and mathematical modelling of lemon slices drying undergoing oven treatment. Heat Mass Transf 52(2):281–289

Planinic´ M, Velic´ D, Tomas S, Bilic M, Bucic´ A (2005) Modelling of drying and rehydration of carrots using Peleg’s model. Eur Food Res Technol 221(3):446–451

Ergün K, Çaliskan G, Dirim SN (2016) Determination of the drying and rehydration kinetics of freeze dried kiwi (Actinidia deliciosa) slices. Heat Mass Transf 52(12):2697–2705

Fathima A, Begum K, Rajalakshmi D (2001) Microwave drying of selected greens and their sensory characteristics. Plant Food Hum Nutr 56(4):303–311

Mujaffar S, Loy AL (2016) The rehydration behavior of microwave-dried amaranth (Amaranthus dubius) leaves. Food Sci Nutr. doi:10.1002/fsn3.406

Aghbashlo M, Kianmehr MH, Samimi-Akhijahani H (2008) Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energy Convers Manage 49(10):2865–2871

Martynenko A, Zheng W (2016) Electrohydrodynamic drying of apple slices: energy and quality aspects. J Food Eng 168:215–222

Motevali A, Minaei S, Khoshtaghaza MH (2011) Evaluation of energy consumption in different drying methods. Energy Convers Manage 52(2):1192–1199

Torki-Harchegani M, Ghanbarian D, Ghasemi Pirbalouti A, Sadeghi M (2016) Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew Sust Energy Rev 58:407–418

Beigi M (2016) Influence of drying air parameters on mass transfer characteristics of apple slices. Heat Mass Transf 52(10):2213–2221

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, London

Beigi M (2016) Hot air drying of apple slices: dehydration characteristics and quality assessment. Heat Mass Transf 52(8):1435–1442

Balasubramanian S, Sharma R, Gupta RK, Patil RT (2011) Validation of drying models and rehydration characteristics of betel (Piper betel L.) leaves. J Food Sci Technol 48(6):685–691

Kaleemullah S, Kailappan R (2006) Modelling of thin-layer drying kinetics of red chillies. J Food Eng 76(4):531–537

Orikasa T, Koide S, Okamoto S, Imaizumi T, Muramatsu Y, Takeda J, Shiina T, Tagawa A (2014) Impacts of hot air and vacuum drying on the quality attributes of kiwifruit slices. J Food Eng 125:51–58

Doymaz I, Ismail O (2010) Drying and rehydration behaviours of green bell peppers. Food Sci Biotechnol 19(6):1449–1455

Sacilik K, Elicin AK (2006) The thin layer drying characteristics of organic apple slices. J Food Eng 73(3):281–289

Ghanbarian D, Baraani Dastjerdi M, Torki-Harchegani M (2016) Mass transfer characteristics of bisporus mushroom (Agaricus bisporus) slices during convective hot air drying. Heat Mass Transf 52:1081–1088

Tulek Y (2011) Drying kinetics of oyster mushroom (Pleurotus ostreatus) in a convective hot air dryer. J Agric Sci Technol 13(5):655–664

Evin D (2011) Microwave drying and moisture diffusivity of white mulberry: experimental and mathematical modelling. J Mech Sci Technol 25:2711–2718

Minaei S, Motevali A, Ahmadi E, Azizi MH (2012) Mathematical models of drying pomegranate arils in vacuum and microwave dryers. J Agric Sci Technol 14(2):311–325

Erbay Z, Icier F (2010) Thin-layer drying behaviors of olive leaves (Olea europaea L.). J Food Process Eng 33:287–308

Lemus-Mondaca R, Vega-Gálvez A, Moraga NO, Astudillo S (2015) Dehydration of stevia rebaudiana bertoni leaves: kinetics, modeling and energy features. J Food Proces Preserv 39(5):508–520

Seremet L, Botez E, Nistor OV, Andronoiu DG, Mocanu GD (2016) Effect of different drying methods on moisture ratio and rehydration of pumpkin slices. Food Chem 195:104–109

Alibas I (2007) Energy consumption and colour characteristics of nettle leaves during microwave, vacuum and convective drying. Biosyst Eng 96(4):495–502

Beigi M (2016) Energy efficiency and moisture diffusivity of apple slices during convective drying. Food Sci Technol 36(1):145–150

Motevali A, Minaei S, Banakar A, Ghobadian B, Khoshtaghaza MH (2014) Comparison of energy parameters in various dryers. Energy Convers Manage 87:711–725

Tohidi M, Sadeghi M, Torki-Harchegani M (2017) Energy and quality aspects for fixed deep bed drying of paddy. Renew Sust Energy Rev 70:519–528

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beigi, M. Thin layer drying of wormwood (Artemisia absinthium L.) leaves: dehydration characteristics, rehydration capacity and energy consumption. Heat Mass Transfer 53, 2711–2718 (2017). https://doi.org/10.1007/s00231-017-2018-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-2018-3