Abstract

Major target of present paper is to investigate the drying kinetics of cornelian cherry fruits (Cornus mas L.) in a convective dryer, by varying the temperature and the velocity of drying air. Freshly harvested fruits are dried at drying air temperature of 35, 45 and 55 °C. The considered drying air velocities are V air = 1 and 1.5 m/s for each temperature. The required drying time is determined by taking into consideration the moisture ratio measurements. When the moisture ratio reaches up to 10 % at the selected drying air temperature, then the time is determined (t = 40–67 h). The moisture ratio, fruit temperature and energy requirement are presented as the functions of drying time. The lowest drying time (40 h) is obtained when the air temperature is 55 °C and air velocity is 1.5 m/s. The highest drying time (67 h) is found under the conditions of 35 °C temperature and 1 m/s velocity. Both the drying air temperature and the air velocity significantly affect the required energy for drying system. The minimum amount of required energy is found as 51.12 kWh, at 55 °C and 1 m/s, whilst the maximum energy requirement is 106.7 kWh, at 35 °C and 1.5 m/s. It is also found that, air temperature significantly influences the total drying time. Moreover, the energy consumption is decreasing with increasing air temperature. The effects of three parameters (air temperature, air velocity and drying time) on drying characteristics have also been analysed by means of analysis of variance method to show the effecting levels. The experimental results have a good agreement with the predicted ones.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Drying is generally used to remove moisture of liquid from a wet solid by bringing this moisture into a gaseous state. In most drying operations, water is the liquid evaporated and air is the normally employed purge gas. Drying of foodstuffs is an important method of preservation and it is applicable to a wide range of industrial and agricultural products. Natural open-air sun drying is practiced widely in hot climates and tropical countries. However, this technique is extremely weather, dependent and has the problems of contamination, infestation, microbial attack, etc. Recently, there have been many studies on the drying characteristic of various vegetables and fruits such as onion [1], chestnuts [2], banana [3], pumpkin [4] and peach [5]. Between recognized authors in literature, only a few numbers of works have been published related to drying characteristics of cornelian cherry fruits. Koyuncu et al. [6] explored the dehydration of these fruits in a parallel air flow type dryer at temperatures in the range 50–70 °C and low velocities of 0.3–0.9 m/s. Kaya and Aydin [7] also studied the drying kinetics of cornelian cherry fruits at the same air velocity range. Therefore, it becomes necessary to extend the study of Cornelian cherry drying under other conditions.

Cornelian cherry is a widely grown fruit species in different regions of Turkey. Although, it is naturally grown in orchards or mountains, there are some exclusive orchards of this fruit in some regions. Cornelian cherry growing area in North-East Anatolia is generally located around the river valleys. Currently, in Turkey there are 1,585,000 cornelian cherry trees in which yield is approximately 14,000 tons per year [8]. Cornelian cherry fruits which have sour and sweat tasting juice, contain a high amount of vitamin C. Furthermore, the fruits are not only consumed fresh, but also used to produce jam, stewed fruit, marmalade pestil, syrup and several types of soft drinks. They are also used for medical purposes. Fruit are rich in sugar, organic acid and tannin [9]. Cornelian cherry is the most important fruit from the 40 species of the family Cornaceae. Fresh cornelian cherry fruits contain twice as much ascorbic acid (vitamin C) as oranges. Cornelian cherry fruits has been used in Chinese herbal medicine and known for its tonic, analgesic and diuretic activities [10]. Cornelian cherry has only recently captured the attention of fruit breeders. Systematic collection, selection and breeding programs have recently been established in the Ukraine, Bulgaria, Slovakia, Austria, Yugoslavia, France, Germany, Poland and Turkey. Cornelian cherry is a valuable food, medicinal and ornamental plant. It is rarely attacked by pests and diseases and can be grown with minimal use of chemicals. It is therefore a very profitable crop. The fruits of the cornelian cherry can be dark red, cherry red, pink or yellow. They can be oval, pear-shaped or bottle-shaped [11]. In order to store cornelian cherry, different methods are used depending on the technical opportunities, food consumption and food processing ways. These are traditional method, cold storage and drying. In numerous papers cited in archival journals, it is possible to see more information about nutritional and physical properties of cornelian cherry [12–14].

In the literature, several investigators have attempted to develop new models for various fruits and vegetables, including the drying parameters as air velocity and air temperature. Togrul and Pehlivan [15] investigated the drying behavior of single apricots, hanging in the flow direction of hot air in a drying chamber. It was found that the new model could represent single apricot drying kinetics within 99.9 % accuracy. Akpinar et al. [16] studied experimentally the single layer drying behavior of potato slices in a convective cyclone dryer and also to perform mathematical modeling by using single layer drying models in the literature. Evin [17] analyzed for both the microwave and open sun drying conditions mathematical modeling of the thin layer drying kinetics of gundelia tournefortii. Zielinska and Markowski [18] investigated the effects of air temperature on drying kinetics of carrot cubes. Convective drying characteristics of carrot cubes in a spout-fluidized bed were evaluated through the effect of air temperature on drying kinetics. Sacilik and Elicin [19] tested the thin layer drying characteristics of organic apple slices. The effect of drying air temperature and slice thickness on the drying characteristics and quality parameter of the dried apple slices were also determined. Koyuncu et al. [20] reported drying characteristics and energy requirement for drying of chestnuts. The results showed that drying air temperature significantly influenced the total drying time and air velocity influenced the total energy requirement for drying.

Present study investigates the monolayer drying characteristics of cornelian cherry fruits in a cross-flow convective dryer at different drying conditions (temperatures of 35, 45 and 55 °C, air velocities of 1 and 1.5 m/s). For this aim, an experimental setup is conducted, and some measurements have been performed. The results are discussed comparing to the literature. In addition to this, Analysis of Variance has been done in order to verify the effect of the drying parameters on the experimental results.

2 Experimental setup and measurement procedure

A schematic diagram of the experimental apparatus is presented in Fig. 1. The experimental setup consists of a fan, heaters, power supply (variac with ±0.02 accuracy), drying chamber, air inlet and outlet channels and instruments for measurements. The airflow velocity is adjusted by a radial fan (max. power is 0.537 kW). The heating system consisted of an electric heater (2,000 W) placed inside the channel. A thermo-humidity is used to measure the humidity levels at various locations of the room with an accuracy of ±0.5 RH (air relative humidity). The drying chamber temperature is adjusted by the heater power control. Product surface temperatures and drying chamber inlet and outlet temperatures are measured by using T-type thermocouples (0.08 mm in diameter, accuracy 0.018 °C). The drying chamber length, width and height are arranged to be 60, 40 and 60 cm, respectively. The mass loss of the cornelian cherry fruits are measured at 60 min intervals by a digital balance in the measurement range of 0–6,100 g and an accuracy of ±0.1 g. The sample tray (27 cm in length and 21 cm in width) on which the cornelian cherry fruits are evenly put is attached to the electronic balance with the help of the sample holding wire. The electronic balance is placed outside the drying chamber.

Measurements are repeated 3 times to ensure that the results do not vary from test to test. In other words, accuracy is ensured by requiring that all measured items have equality (significant) at the end of the test.

The measured values in the experiments reported here are: drying chamber inlet temperature, drying chamber outlet temperature, ambient temperature, drying air velocity, mass loss of fruits and humidity. Measuring devices used in this study are given in Table 1. This table contains experimental photos and technical specifications.

Table 2 shows physical properties and nutritional properties of the cornelian cherry fruits [8, 9].

3 Thermal performance

The moisture content is the measure of the relative humidity in product. The moisture content is expressed as wet basis and dry basis. Moisture content according to wet basis and dry basis is determined using the following Eqs. (1) and (2):

where M w is the weight of water in the product, M T is the total weight of product, M k is the dry weight of product. The drying rate is the ratio of the initial moisture content of the moisture at time t. Drying rate is determined using the following equation:

where M t is the weight at time t of product, M e equilibrium moisture content of product, M 0 is the initial weight of un-dried product.

Drying air velocity changes per unit of time of the moisture content in product. Drying air velocity is determined using the following equation:

where M t+Δt is the weight at time t + Δt of product.

Three different temperatures such as 35, 45 and 55 °C and two air velocities such as 1 and 1.5 m/s are used for experimentation. During experiments, total drying time for different temperatures and velocities are found. In addition, total energy requirement for convective type dryer are determined (Eq. (5) and [6]).

In this equation; A is drying air flow surface area, v is drying air speed, ρ is air density, c is specific heat of air, ΔT is the temperature difference between inlet and outlet of the dryer and D t is total drying time. Before introducing the experimental results, a simple notification is done for reading facility. The cases, which are tested, are coded and the codes are presented in Table 3.

4 ANOVA (Analysis of variance)

The experimentally found results have been analyzed by a statistical method. The magnitude of the effects of the experimental parameters on mass loss is aimed to be determined by means of analysis of variance method, ANOVA [21, 22]. The ANOVA evaluates the experimental errors and test of significance to understand the effect of various factors. The method and equation of the ANOVA is presented in “Appendix”.

5 Results and discussions

The dryer is adjusted at a specified drying air temperature and velocity for about one an hour prior to the start of experiment to achieve the steady-state conditions. Fresh cornelian cherry fruits used in the experiment are collected from a garden located in Elazig. Then, 304 g of wet cornelian cherry fruits are put on the sample tray. During drying time, the mass of the cornelian cherry fruit samples are measured for each hour by using a balance. The dryer is installed in the conditions that have a relative humidity between 22 and 40 % and a temperature between 20 and 25 °C. The drying is carried out to final moisture content of 10 % from initial moisture content of about 68.8 % (w.b.).

Stages of the drying process are supported by the following photographs. Fresh cornelian cherry fruits used in experiment are shown in Fig. 2a, the view of the cornelian cherry fruits in the drying chamber is given in Fig. 2b, 30 h after the view of the cornelian cherry fruits is in Fig. 2c, and the view of the dried cornelian cherry fruits is in Fig. 2d.

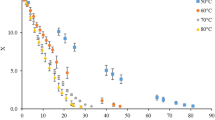

The moisture content of the products as a function of drying time is presented in Fig. 3 for C1 to C6. The moisture content rapidly reduces and then slowly decreases with increase in drying time. As expected for these drying curves, the drying air temperature affects the moisture content of cornelian cherry fruit. In other words, the increase in drying air temperature resulted with a decrease of drying time. In addition, it is obvious from the figures that drying air velocities did not significantly influence the drying time. On the contrary, the drying temperature has an important effect on the total drying time. The lowest drying time (40 h) is obtained at C6. The highest drying time (67 h) is found at C1. This value is followed by 64 h (C4), 57 h (C2), 53 h (C5) and 46 h (C3), respectively.

Figure 4 shows the changings in drying rate as a function of drying time for the various cases (C1 to C6). The drying rate decreases continuously with increasing drying time. It is observed that the main factor influencing drying rate is the drying air temperature. Therefore, a higher drying air temperature produced a higher drying rate and consequently the drying time decreased. It is observed that the main factor influencing drying rate is the drying air temperature, as reported in earlier researches [23, 24]. Therefore, a higher drying air temperature produced a higher drying rate and consequently the drying time decreased.

Figure 5 shows the temperature inside the product. The surface temperature of the cornelian cherry fruit is recorded continuously during drying. The surface temperature rapidly increases and then slowly constant with increase in drying time.

The dried product had reached up to temperature 32.3 °C for C1. This is the lowest temperature ever obtained. The highest product temperature is obtained as 52.8 °C, when the case is C6. It is observed that the drying air temperature have influence on the surface temperature of product, as reported in earlier researches [25, 26].

The parameters generated depending on the data obtained from the experiments are presented in Table 4. As seen in Table 4, the independent parameters that affect the dependent target parameter are air velocity, air temperature and drying time. These three parameters are called control factors in the analysis [22]. Two of the control factors (drying time and air temperature) have three levels, while the third parameter (air velocity) has two levels. For the aim of setting the experiment plan, an experimental design method consisting of orthogonal arrays has been used. With this purpose in mind, the most suitable orthogonal array is considered to be L18 as shown in Table 5.

The F test is used to make a decision about the magnitude of the effects in other words. The calculated F values are compared to appropriated standard confidence table. In the case of any F value turns out as a result of the mentioned comparison to be higher than such F value on the table, it is concluded that the analysis has the assumed confidence level [27–29].

In Table 6 the influences of the parameters on the result are presented. Accordingly, it has been determined that the drying time is the most effective parameter is mass loss with 82.12 % [21].

The drying temperature has an important role on the total drying time (see Fig. 6). The lowest drying time (40 h) is obtained for C6. The highest drying time (67 h) is found for the case, C1. This value is followed by 64 h (C4), 57 h (C2), 53 h (C5) and 46 h (C3).

The total energy requirement for a convective type dryer can be seen from Fig. 7. As it is understood from this figure, the minimum heat energy is 51.12 kWh for C3. The maximum energy requirement is 106.7 kWh for C4. The energy consumption is decreasing with increasing drying temperature. According to the results, it can be said that C3 must be selected for drying freshly harvested cornelian cherry fruits.

6 Conclusions

The drying characteristics of the cornelian cherry fruits are studied in a convective hot air dryer at the drying air temperatures of 35, 45, 55 °C and drying air velocity of 1 and 1.5 m/s. Some important results can be drawn from this study as;

-

The moisture content and drying rate are affected by the drying air temperature. Increasing in the drying air temperature causes a decrease in the drying time.

-

Drying of cornelian cherry fruits starts with initial moisture content around 68.8 % (w.b.) and continued to the final moisture content of about 10 % (w.b.).

-

The time for reaching up to 10 % moisture content from the initial moisture content at the various drying air temperatures are found to be between 40 and 67 h.

-

It is found from the results of the experimental investigation that the drying air temperature has an important role on the total drying time. The least drying time (40 h) is obtained at 55 °C and 1.5 m/s. The highest drying time (67 h) is also found at 35 °C and 1 m/s.

-

It is also seen from the results that both the drying air temperature and the air velocity significantly affect the energy required for drying of cornelian cherry fruits. The required energy for the case 35 °C, 1 m/s is nearly 2 times greater (~52 %) than the case 55 °C, 1.5 m/s.

-

ANOVA analysis shows that the drying time contributes to the drying process of about 82.12 %, the temperature at 13.82 % and velocity at 1.29 %.

Abbreviations

- A :

-

Drying air flow surface area, m2

- c :

-

Specific heat of air under adiabatic conditions, J/kg K

- df :

-

Number of degrees of freedom

- D t :

-

Total drying time, h

- E t :

-

Total energy requirement of dryer, kWh

- F factor :

-

F test value of the factor

- k :

-

Number of factor’s level

- M w :

-

Weight of water in the product, g

- M T :

-

Total weight of product, g

- M k :

-

Dry weight of product, g

- M wb :

-

Moisture content according to wet basis, g/g

- M db :

-

Moisture content according to dry basis, g/g

- M t :

-

Weight at time t of product, g

- M t+Δt :

-

Weight at time t + Δt of product, g

- M 0 :

-

Initial weight of undried product, g

- M e :

-

Equilibrium moisture content of product, g water/g dry matter

- N :

-

Repeating number of each levels of factors

- n :

-

Number of experiments

- SS e :

-

Sum of square due to error

- SS factor :

-

Sum of square due to factor

- SS m :

-

Mean sum of square

- SS T :

-

Total sum of square

- S/N :

-

Signal to noise ratio, η

- ρ :

-

Air density, kg/m3

- ν :

-

Drying air speed, m/s

- V factor :

-

Variance of the factor

- W :

-

Drying air velocity, m/s

- W s :

-

Drying rate, g water/g dry matter h

- ΔT :

-

Temperature differences, K

- η factor−i :

-

Sum of ith level of factor

References

Sarsavadia PN (2007) Development of a solar-assisted dryer and evaluation of energy requirement for the drying of onion. Renew Energy 32:2529–2547

Moreira R, Chenlo F, Chaguri L, Vazquez G (2011) Air drying and colour characteristics of chestnuts pre-submitted to osmotic dehydration with sodium chloride. Food Bioprod Process 89:109–115

Thuwapanichayanan R, Prachayawarakorn S, Kunwisawa J, Soponronnarit S (2011) Determination of effective moisture diffusivity and assessment of quality attributes of banana slices during drying. LWT Food Sci Technol 44:1502–1510

Alibas I (2007) Microwave, air and combined microwave-air-drying parameters of pumpkin slices. LWT 40:1445–1451

Wang J, Sheng K (2006) Far-infrared and microwave drying of peach. LWT 39:247–255

Koyuncu T, Tosun I, Pinar Y (2007) Drying characteristics and heat energy requirement of cornelian cherry fruits (Cornus mas L.). J Food Eng 78:735–739

Kaya A, Aydin O (2010) Drying kinetics and sorption isotherms of cornelian cherry fruits. Desalin Water Treat 22:30–39

Güleryüz M, Bolat İ, Pırlak L (1998) Selection of table cornelian cherry (Cornus mas L.) types in Çoruh valley. Tr J Agric For 22:357–364

Demir F, Kalyoncu İH (2003) Some nutritional, pomological and physical properties of cornelian cherry (Cornus mass L.). J Food Eng 60:335–341

Hamid H, Yousef H, Jafar H, Mohammad A (2011) Antioxidant capacity and phytochemical properties of cornelian cherry (Cornus mas L.) genotypes in Iran. Sci Hortic 129:459–463

Klimenko S (2004) The cornelian cherry collection, preservation and utilization of genetic resources. J Fruit Ornam Plant Res 12:93–98

Ersoy N, Bagci Y, Gok V (2011) Antioxidant properties of 12 cornelian cherry fruit types (Cornus mas L.) selected from Turkey. Sci Res and Essay 6(1):98–102

Mamedov N, Craker LE (2004) Cornelian cherry: a prospective source for phytomedicine. In: Proceedings of the XXVI IHC-Future for medicinal and aromatic plants, Acta Hort 629. ISHS, Amherst, USA

Olszanska AN, Biesiada A, Letowska AS, Kucharska AZ (2011) Content of bioactive compounds and antioxidant capacity of pumpkin puree enriched with Japanese quince, cornelian cherry, strawberry and apples. Acta Scientiarum Polonorum Aliment 10(1):51–60

Togrul IT, Pehlivan D (2003) Modelling of drying kinetics of single apricot. J Food Eng 58:23–32

Akpinar E, Midilli A, Bicer Y (2003) Single layer drying behaviour of potato slices in a convective cyclone dryer and mathematical modelling. Energy Convers Manag 44:1689–1705

Evin D (2012) Thin layer drying kinetics of Gundelia tournefortii L. Food Bioprod Process 90:323–332

Zielinska M, Markowski M (2010) Air drying characteristics and moisture diffusivity of carrots. Chem Eng Process Process 49:212–218

Sacilik K, Elicin AK (2006) The thin layer drying characteristics of organic apple slices. J Food Eng 73:281–289

Koyuncu T, Serdar U, Tosun I (2004) Drying characteristics and energy requirement for dehydration of chestnuts (Castanea sativa mill.). J Food Eng 62:165–168

Tasirin SM, Kamarudin SK, Ghani JA, Lee KF (2007) Optimization of drying parameters of bird’s eye chilli in a fluidized bed dryer. J Food Eng 80:695–700

Celik N, Turgut E (2012) Design analysis of an experimental jet impingement study by using Taguchi method. Heat Mass Transf 48:1407–1413

Doymaz I (2007) Air drying characteristics of tomatoes. J Food Eng 78:1291–1297

Wang J, Xi YS (2005) Drying characteristics and drying quality of carrot using a two-stage microwave process. J Food Eng 68:505–511

Karim MA, Hawlader MNA (2005) Drying characteristics of banana: theoretical modelling and experimental validation. J Food Eng 70:35–45

Erdem M (2013) Experimental investigation of drying characteristics of fish in tray dryer. Master Thesis, 67 p (in Turkish)

Oztop MH, Sahin S, Sumnu G (2007) Optimization of microwave frying of potato slices by using Taguchi technique. J Food Eng 79:83–91

Moreno R, Antolin G, Reyes A (2006) Quality of fluidisation for the drying of forestry biomass particles in a fluidised bed. Biosyst Eng 94:47–56

Chen HH, Chung CC, Wang HY, Huang TC (2011) Application of Taguchi method to optimize extracted ginger oil in different drying conditions. Int Conf Food Eng Biotechnol 9:310–316

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Ozgen, F. Experimental investigation of drying characteristics of cornelian cherry fruits (Cornus mas L.). Heat Mass Transfer 51, 343–352 (2015). https://doi.org/10.1007/s00231-014-1397-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-014-1397-y