Abstract

An experimental investigation on steady state convection heat transfer from vertical helical coiled tubes in water was performed for laminar flow regime. Three coils with curvature ratios as 0.0757, 0.064, 0.055 and range of Prandtl number from 3.81 to 4.8, Reynolds number from 3,166 to 9,658 were considered in this work. The heat transfer data were generated from 30 experiments conducted at constant water bath temperature (60 °C) for different cold water flow rates in helical coils. For the first time, an innovative approach of correlating Nusselt number with ‘M’ number is proposed which is not available in the literature and the developed correlations are found to be in good agreement with the work of earlier researchers. Thus, dimensionless number ‘M’ was found to be significant to characterize the hydrodynamics of fluid flow and heat transfer correlations in helical coils. Several other correlations based on experimental data are developed. To cover wide range of industrial applications, suitable generalized correlations based on extended parameters beyond the range of present experimental work are also developed. All these correlations are developed by using least-squares power law fit and multiple-regression analysis of MATLAB software. Correlations so developed were compared with published correlations and were found to be in good agreement. Comparison of heat transfer coefficients, friction factor and Nusselt number for different geometrical conditions is presented in this paper.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the compact size and high heat transfer coefficient as compared to straight tube, helical coil heat exchangers are frequently used in power generation, nuclear industries, refrigeration and air-conditioning systems, heat recovery systems, food and dairy processes and other thermal processing plants. A secondary flow induced by centrifugal force has significant ability to enhance heat transfer rate in helical coils. In spite of their widespread use, there is limited experimental information and correlations available in literature on convective heat transfer in helical coils in laminar flow regime. The difference between the heat transfer coefficient in coiled tubes and straight tubes is significant which was first demonstrated by Jeschke [1] who proposed the use of a factor based on curvature ratio as:

Further studies carried out by Seban and McLaughlin [2] showed that this factor i.e. (1 + 3.5 (a/R)) was not accurate and even greater enhancement in the heat transfer coefficient was achieved.

An experimental investigation of heat transfer in tube coils having ratios of coil to tube diameter of 17 and 104 (two coils) was carried out by Seban and McLaughlin [2], both for laminar and turbulent flow regimes for flow of water. The fluid was heated by electrical dissipation through the tube wall. They developed a correlation to determine inner Nusselt number based on thermo physical properties of fluid at mean film temperature as:

applicable for the range; Re (a/R) > 6, 6,000 ≤ Re ≤ 65,000, 2.9 ≤ Pr ≤ 5.7. Rogers and Mayhew [3] developed a correlation to determine inner Nusselt number based on fluid properties at mean film temperature as:

A second correlation was also developed by same authors for heat transfer to fluid flowing inside a helical tubes heated by steam but this was based on fluid properties estimated at mean bulk temperature as:

This correlation is valid for the range, 10,000 ≤ Re ≤ 100,000 and 0.05 < δ < 0.0926.

Mori and Nakayama [4, 5] investigated forced convective heat transfer in turbulent regime for both, wall heat flux and constant wall temperature boundary conditions and they found that the increase in heat transfer rate is not as significant as that under laminar flow conditions. The turbulent effects become a dominant factor over secondary flow at higher Reynolds and Prandtl numbers which makes the heat transfer coefficient comparable to those in straight tubes. Authors developed a correlation and stated that it is applicable to both the boundary conditions, Mori and Nakayama [5] as:

applicable for; Pr > 1 and Re (a/R)2.5 > 0.4. Xin and Ebadian [6] carried out an experimental work with three different fluids- air, water and ethylene glycol on five uniformly heated helical pipes. They proposed correlation for laminar flow in coil as:

This equation is valid for the range 20 < De < 2,000, 0.5 < Pr < 175 and 0.0267 < a/R < 0.0884.

Prabhanjan et al. [7] performed experiments to determine the relative advantage of helical coil versus straight tube heat exchangers for heating liquids. The experimental setup for helical coil heat exchanger was having parameters as number of turns = 10, inner diameter of tube = 15.7 mm, wall thickness = 1.2 mm and no pitch, coil stretched length = 6.38 m with helix diameter = 203 mm. The helical coil was housed in a cylindrical mild steel container of size 450 mm diameter and 600 mm length. For each case, they used two levels of temperatures as 40 and 50 °C and three levels of water flow rates as 5, 15 and 25 l/min. The range of Reynolds number used was from 8,300 to 41,400 and 7,700 to 38,300 for flows in the coil and the straight pipe respectively. They developed experimental model and the developed model was used to determine the significance for temperature rise and heat transfer coefficients. They found that on an average, the helical coil had a heat transfer coefficient 1.16 and 1.43 times larger than for the straight tube heat exchanger for 40 and 50 °C respectively. Sahoo et al. [8] developed an iterative technique for accurate estimation of heat transfer coefficients in a triple tube helical heat exchanger and the same innovative method was validated with their experimental results. Three flow rates of milk considered were 135, 153 and 176 (l/h) which corresponds Reynolds number as 5,159, 5,791 and 6,587. The results obtained by this method were found to be closer to the experimental results. This iterative technique is easily applicable to any concentric heat exchanger involving two heat transfer surfaces. Devanahalli et al. [9] experimentally investigated the natural convection heat transfer from helical coiled tubes in water for turbulent flow. Investigators used four coil sets of coil curvature ratios as 0.0518 and 0.0665 (two coils of same ratio) with different pitches as 47.4, 15.8, 13.5 and 40.5 mm, and number of each coil turns as 9.5. Range of Reynolds number was kept as 12,000 to 27,000. Outside Nusselt number was correlated to the Rayleigh number using different characteristic lengths (the overall length of the coil, the diameter of the tube, the diameter of the coil, the height of the coil as a normalized length). They developed a prediction model (flowchart) to predict the outlet temperature of a fluid flowing through a helically coiled heat exchanger when inlet temperature, bath temperature, coil dimensions and flow rates are known. They found that the results of the developed prediction model of outlet temperatures are close to the experimental values.

Rennie et al. [10] performed experiments on a double pipe helical heat exchanger for parallel flow and counter flow configurations. They used outer tube do = 15.9 mm, inner tube with outer tube do = 9.5 or 6.4 mm, wall thickness = 0.8 mm. Hot water was circulated in inner tube and cold water in annular space. Total 300 trials were taken. Overall heat transfer coefficients, heat transfer coefficients in the inner tube and the annulus were calculated by using Wilson plots. They found that the heat transfer rates in the counter flow configuration were much higher than parallel flow due to the higher average temperature difference. Naphon [11] studied experimentally the thermal performance and pressure drop of a helical coil heat exchanger with and without helically crimped fins. The heat exchanger consisting of a shell and helically coiled tube unit with two different coil curvature ratios as 0.048 and 0.0748 with 13 turns were considered. The cold water and hot water were used as test fluids. They noticed that the effectiveness tends to decrease with increasing hot water mass flow rate. Coronel and Sandeep [12] conducted experiments in helical coil heat exchangers with two concentric coils of different coil curvature ratios as 0.114 and 0.078. The experiments in straight tubular heat exchangers at various flow rates (1.89 × 10−4 to 6.31 × 10−4 m3/s) and for different end point temperatures (92–149 °C) were conducted. The experiments were performed under turbulent flow conditions, and non-isothermal, non-constant heat flux conditions. They presented a new method to determine the overall heat transfer coefficient of an industrial helical heat exchanger. The results obtained by this method were found to be similar to those obtained by published correlations. They also developed a correlation to compute the inside convective heat transfer coefficient (hi) as a function of Re, Pr and a/R. They found that the overall heat transfer coefficient was larger for coil of larger curvature ratio than coil of smaller curvature ratio. Salimpour [13] investigated experimentally the heat transfer coefficients of shell and helically coiled tube heat exchangers for three different pitches with three coil curvature ratios as 0.113 and 0.157- same for two coils. Total 75 test runs were performed for both parallel-flow and counter-flow configurations from which heat transfer coefficients were computed. He developed two correlations based on experimental data to predict the inner and outer heat transfer coefficients of such a coiled heat exchangers using least-square regression analysis. From the results, it was noticed that the shell-side heat transfer coefficients of the coils with larger pitches are higher as compared to smaller pitches for same flow rates.

Zachar [14] carried out numerically steady state heat transfer enhancement in helically coiled-tube heat exchangers with spirally corrugated wall in laminar and transitional flow regimes. He considered water and a water-ethylene glycol mixture with 50–50 % volumetric ratio as test fluids in this numerical analysis. Heat exchanger coils with helically corrugated wall configuration showed 80–100 % increase for the inner side heat transfer rate due to the additionally developed swirling motion while the relative pressure drop was 10–600 % larger compared to the common helically coiled heat exchangers. A new empirical correlation was proposed for fully developed inner side heat transfer prediction in case of helically corrugated wall configuration. Kumbhare et al. [15] reported an experimental work for heat recovery system in helical coils of circular and square cross section in laminar flow regime. Cold water in tube and hot water in shell side was used as working fluid. The inner diameter (10 mm), outer diameter (12 mm), mean diameter (178 mm) and stretched length of coil (3,334 mm) were taken same for both types of coils. They kept cold water flow rate constant and hot water flow rates were varied in the shell. Wilson plot technique was used to determine the overall heat transfer coefficients under various operating conditions. From their experimental results, they found that the convective heat transfer coefficients, overall heat transfer coefficients for coil of square cross section were higher than circular cross section for tube side Reynolds number. It was also noticed that the effects of bend in square coil improved the heat transfer coefficient.

A first comprehensive review on heat transfer and flow through a curved tube is presented by Berger et al. [16]. The latest review of flow and heat transfer characteristics has been provided by Naphon and Wongwises [17] and recently, a critical review of heat transfer through helical coils of circular cross section is presented by Pawar et al. [18]. Pimenta and Campos [19] carried out experimental work to determine, for Newtonian (glycerol-water mixture) as well non-Newtonian fluids (CMC and XG solution in water), the friction factor with simultaneous heat transfer under fully developed laminar flow inside a vertical helical coil. Their experimental data showed that the use of the bulk temperature or of the film temperature to calculate the physical properties of the fluid has a residual effect in the friction factor values.

Literature review reveals that considerable experimental work in general has been reported on heat transfer through helical coils. However, question of scalability remains unanswered because of practical difficulties in experimental work. The criterion of critical Reynolds number in helical coils was established by few investigators but none of these have given fix limit up to which laminar flow persists except ‘M’ number. It was also reported by earlier investigators that (under turbulent flow conditions) the increase in heat transfer rate in helical coil was not as significant as that under laminar flow conditions. Hence, present experimental study is undertaken to develop an innovative (Nu/Pr 0.4 vs. M) and some generalized correlations in laminar flow regime useful to design of industrial helical coil heat exchangers.

2 Critical Reynolds number in helical coil

Several researchers have found that a complex flow pattern exists inside a helical coil which is responsible for the enhancement of heat transfer. The curvature of the helical coil induces the centrifugal force, which further results in the development of secondary flow. Due to mixing of primary and secondary flow pattern simultaneously in coil, it becomes difficult to characterize the hydrodynamics of fluid flow. The critical Reynolds number has been introduced by some earlier investigators to identify the transition from laminar to turbulent flow in helical coils [20–24].

2.1 Dimensionless number “M”

In helical coil, a complex flow pattern exists in laminar as well as turbulent flow regimes which are responsible for the enhancement of heat transfer coefficient. Neither the Reynolds number nor the Dean number could characterize the hydrodynamics of flow through helical coils. Therefore, Mujawar and Rao [25] established for the first time, the criteria for laminar flow in coiled tubes on the basis of a new dimensionless number, M, deduced from a knowledge of the effect of coil curvature ratio on the flow curves. Based on their experimental results, the criteria for laminar flow in coiled tubes for any type of fluid, either Newtonian or non-Newtonian and for any practised curvature ratios in industries is given in generalized form as:

For Newtonian fluids, the Eq. (7) is simplified to set the criteria for laminar flow based on their experimental data as:

The criterion for laminar flow in coiled tubes given by Eq. (7) was satisfactorily tested with the results of their work.

2.2 Mechanism of ‘M’ number

Equation (7) is derived from the power-law model proposed by Mujawar and Rao [25] as:

for coiled tubes, where \( {\text{K}}_{\text{c}}^{\prime } \), \( {\text{n}}_{\text{c}}^{\prime } \) and \( {\text{m}}_{\text{c}}^{\prime } \) are to be determined by experimental data, for Newtonian and non-Newtonian fluids. For Newtonian and non-Newtonian fluids, the power-law model in straight tube is well established as:

resulting in generalized Reynolds number as:

where gc is gravitational constant. For Newtonian fluids, \( {\text{n}}_{\text{s}}^{\prime } \) = 1, \( {\text{K}}_{\text{s}}^{\prime } \) = μ/gc resulting in,

By definition, the Fanning friction factor, \( f_{c} \) for coiled tubes could be written as:

where,

The logarithmic plot of \( f_{c} \) versus M gives a straight line for M ≤ 2,100 (laminar flow), having a slope = −1 and intercept = 16. These equations are tested by Mujawar and Rao [25] with their own 1200 readings covering all regimes for flow of Newtonian and non-Newtonian fluids flow, in straight and coiled tubes. Further, power-law model proposed by authors was compared and tested with earlier published literature since 1928.

The criteria for fluid flow in coiled tubes is required to study heat, mass and momentum transfer and arrive at handy correlations, useful for design of process equipments working in industries.

2.3 By dimensional analysis

Heat, mass and momentum transfer data processing is usually done through dimensional analysis. For example, film heat transfer coefficients are correlated as:

For laminar flow, and

for turbulent flow. The constants a, b and c are found experimentally and applied for design of straight-tube heat exchangers.

Similarly, to design helically coiled heat exchangers, one has to use generalized dimensionless groups like M, which incorporates inertia force/viscous force. It might be noted that both these inertia and viscous forces get affected due to geometry of the test-section. In helical coil, Reynolds number is replaced by M number to characterize the hydrodynamics of fluid flow. However, they could not develop heat transfer correlations relating Nusselt number to M number in their research work. Hence, this present work was undertaken to develop an innovative generalized heat transfer correlations in terms of M number and validation of these developed correlations with the work of earlier investigators.

It is well known fact that in coiled tube, the coil curvature ratio (a/R) has direct effect on flow-patterns and ‘M’ is in a position to give basic and fundamental idea for any fluid (Newtonian/non-Newtonian) and any coil curvature ratio (a/R) practised in industries. When helix diameter tends to infinity, it becomes a horizontal straight pipe flow, and when helix diameter tends to zero, it becomes a vertical straight pipe. In helical coil, Reynolds number is a particular case of M number. The physical significance of M number in helical coil is inertia force (primary and secondary force) by viscous force. Both these forces are the functions of coil curvature ratio (a/R).

Inertial forces perpendicular to the axis of liquid flow act on the liquid in curvilinear channels in particular, in a coiled tube. A larger secondary force (mv2/R), which is induced due to the curvature of the coil, acts on the faster-moving fluid near the tube center than on the slower moving fluid near the wall. As a result, the fluid in the central part of the tube moves towards the outer wall, while that near the wall moves towards the inner wall. Secondary flow induced due to secondary force arises in the form of a pair of symmetrical vortices in the cross-section; along the tube axis, the fluid trajectory is in the form of a double coil. The maximum axial flow velocity in a coiled tube takes place near the outer wall and the secondary flow velocity is constant in the core, but changes near the wall. The primary force in the coil fluid flow along the length of the coil is induced due to the longitudinal pressure gradient.

3 Materials and methods

3.1 Experimental set-up

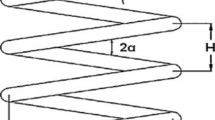

The physical dimensions of the three coils that were used in the experiments are given in Table 1. The coil length is calculated by using L = πDN. Each coil was made of mild steel material of 2.3 mm wall thickness with an average pitch of 29.15 mm and consisted of 9½ turns as shown in Fig. 1. A schematic diagram of the experimental setup is sketched in Fig. 2.

An insulated water bath of size 550 mm diameter × 700 mm height was used to house the coils. It was made of mild steel material with 4 mm thickness. Three electrical heaters of total power, 11 kW were used. Two heaters of power 5 and 3 kW fixed at the bottom were switched on for all the time and third heater of power 3 kW fixed at side was used as and when needed to maintain a constant water bath temperature at 60 °C (estimated error ± 0.2 °C). For each experiment, the required coil was mounted on supporting platform made of angle (25 × 25 mm) and was fixed to the water bath. The threaded connections for inlet and outlet of coil ends were used. The inner diameters of the fittings were kept equal to the inner diameter of the test coil to prevent disturbance of the flow pattern of the fluid when entering and leaving the coils. Cold water was pumped through the coils using 1 HP centrifugal pump (Single phase, 2800 RPM, Head-30 m, Discharge- 3600 LPH, Laxmi Make) at 30 °C as the inlet fluid and was taken from a reservoir of size 500 × 500 × 500 mm3 of mild steel material. Temperature measurements were made using type K (nickel–chromium) thermocouples with 14-gauge extension wire (Digital system and Automation Make, SE-221) and were calibrated to meet limits of error ± 0.1 °C. Five thermocouples were attached to measure the wall temperatures of the coils at five different locations and digital temperature indicator was used to record the wall temperatures. These thermocouples were attached to each alternate coil turn at 180° apart to inner and outer side of coil. Holes up to 0.5 mm depth were drilled in the wall to the size of thermocouple probe to be inserted into the wall. After inserting thermocouple probe in the wall, it was tightly covered by stainless steel strip so that it could not leave the contact of the wall surface. Then it was tightly covered by five turns of thick Teflon tape which has low thermal conductivity (i.e. 0.25 W/m-K), to avoid penetration of water in the junction. The readings taken for surface wall temperature were found to be higher than inner cold water temperature and lower than hot water temperature in the vessel consistently at all points of location of the thermocouples. This is thermodynamically correct for heat transfer to occur from hot water to cold water flowing inside the coil. Also, it was not observed to have any temperature deviations (erratic manner) for any set of readings during experimentation. This will help to minimize uncertainty in the wall temperature measurements. The bath temperature, inlet and outlet temperatures were measured by mercury thermometers having a range of −10 to 150 °C and were calibrated to meet limits of error ± 0.1 °C.

3.2 Experimental procedure

In all, total 30 tests were conducted for different cold water flow rates in helical coils (3 coils, 10 flow rates for each coil at 60 °C bath temperature). The flow rate of cold water through the test section was adjusted by a bypass line to get mass flow rate in the range of 0.0338 to 0.1031 kg/s. This corresponds to a laminar flow regime with Reynolds number in the range of 3,166 to 9,658 as per criteria defined by Mujawar and Rao [25] and Ito [20]. The flow rate was measured by rota meter (capacity −0 to 10 lpm, Star Make, Sr. No. 238) and verified for each experiment by noting the time taken to fill a bucket of known volume located at the exit of the system. The purpose of using different flow rates was to change the temperature distribution along the tube wall and to change the inside heat transfer coefficient. However, the system was allowed to come to steady state condition (approximate time taken to come to steady state condition was 15 ± 2 min) before the temperatures were noted. Each experiment was repeated twice and reproducibility was found to be excellent.

4 Experimental data analysis

Thermo physical properties of water flowing inside the helical coil test section were assumed constant along the coil length and evaluated at an average bulk temperature. Heat loss from the hot water in the bath to the cold water flowing in the coil is calculated from:

All quantities were known except the heat transfer rate. The heat transfer rate calculated from above equation was then used to calculate the overall heat transfer coefficient, Uo as:

Ao is the outside surface area (Ao = πdo × πDN) of the coil and ∆T is an average temperature difference between the bulk temperature of fluid in the coil (an average of the inlet and outlet temperatures) and constant temperature of fluid in the bath. Inside heat transfer coefficient hi is calculated by using following relation as:

Ai is the inside surface area of the coil (Ai = πdi × πDN) and ∆Ti is an average temperature difference between the bulk temperature of fluid in the coil and an average wall temperature (an average of five thermocouple readings attached to five different locations on the surface of the coil). Due to small coil wall thickness, maximum difference in outer and inner coil surface temperature was found to be 0.102 °C by heat balance method and 0.1697 °C when calculated by using Eq. (5) of Austin and Soliman [26]. Hence, this minor deviation (<0.5 %) in temperatures of outer surface and inner surface of coil is neglected. Inner Nusselt number is then calculated from:

Outside heat transfer coefficient is calculated by using:

∆To is the temperature difference between the bath temperature and an average wall temperature of the coil.

5 Results and discussion

5.1 Correlations for estimation of Nusselt number based on experimental data

There are many correlations published on coiled tubes on fluid flow heat and mass transfer, whereas the present work is bringing single, simple and handy correlations useful in design of coiled tube heat exchangers.

Mori and Nakayama [4, 5] have reported that the increase in heat transfer rate in turbulent flow regime is not as significant as that under laminar flow regime under constant wall heat flux and constant wall temperature conditions. Most of the earlier studies were conducted for these two boundary conditions whereas present experimental work is presented neither of these two conditions. The third boundary condition is fluid-to fluid type heat transfer at a constant vessel temperature which is to be found in many industrial applications is presented in this paper.

Correlation for estimation of Nusselt number in terms of Dean number and Prandtl number is proposed based on experimental data. Since coiled tubes are usually characterized by Dean number (De = Re √ (a/R)), hence it is necessary to develop a correlation based on combined experimental data (30 tests) of three coils.

The experimental data points of three coils are presented in Fig. 3, by plotting Nu/Pr 0.4 against De on a logarithmic scale as per method given by Kern [27], for Nu/Pr 0.4 versus Re. The proposed correlation is in the form of y = a(x)b. The solid line presents the fitting curve through the experimental data points using a least-squares power law fit which was resulted into the following correlation, where the correlation coefficient R = 99.59 %.

valid for the range 871 ≤ De ≤ 2,657, 0.055 ≤ δ ≤ 0.0757 and 3.81 ≤ Pr ≤ 4.8. It is observed from Fig. 3 that the Nusselt number increases as the Dean number increases. The correlation for estimation of Nusselt number in terms of Re, Pr and δ based on experimental data generated from three coils is proposed as: Nu = a Re b Pr 0.4 δc, where a, b and c are to be evaluated experimentally. The data generated from three coils (30 tests) were well correlated by using multiple-regression analysis of MATLAB software which was resulted into the equation as:

over the range 3,166 < Re < 9,658; 0.055 < δ < 0.0757 and 3.81 ≤ Pr ≤ 4.8.

For the first time, an innovative approach of correlating Nusselt number with M number and Prandtl number based on experimental data is proposed. The plot of Nu/Pr 0.4 versus M based on experimental data points of three coils was plotted on logarithmic scale as shown in Fig. 4. The same procedure is used to develop correlation (24) as explained for correlation (22). Dimensionless number M is calculated by using Eq. (8) for laminar regime defined by Mujawar and Rao [25] and Ito [20]. The solid line presents the fitting curve through the experimental data points using a least-squares power law fit and it was resulted into the following correlation, where the correlation coefficient R = 96.92 %.

valid for the range 1,064 ≤ M ≤ 2,302, 0.055 < δ < 0.0757 and 3.81 ≤ Pr ≤ 4.8.

Further, as a part of standardization of the experimental setup, an attempt was made in Fig. 5 to compare (for coil of δ = 0.0757, comparisons for other two coils are not shown here) our developed correlations (22, 23 and 24) with the work of earlier investigators.

It is quite clear from the Fig. 5 that the proposed correlation (22, 23 and 24) gives good agreement with the work of earlier investigators. Thus, dimensionless number ‘M’ is successfully tested for heat transfer correlation (24) and from Fig. 5; it is found to be good in agreement with the work of earlier investigators. Hence, use of M number in helical coil for development of heat transfer correlations and to characterize hydrodynamics of fluid flow of any type of fluids as well as for any practical coil curvature ratio is significant. The conditions of applicability of the correlations developed by Mori and Nakayama [5], and Seban and McLaughlin [2] are Re (a/R)2.5 > 0.4 and Re (a/R) > 6 respectively and were satisfied by present range of experimental parameters. Hence, these Eqs. (2, 5 and 6) are taken for validation purpose. The average of Nusselt numbers for coil with δ = 0.0757 are calculated by using Eqs. (22, 23, 24) and compared with the work of earlier investigators as shown in Table 2.

From Table 2, Fig. 5, it can be seen that the developed Eqs. (22, 23 and 24) predicts reasonably well with the work of earlier investigators. The minimum and maximum deviations of Eq. (24) with the work of earlier correlations are found to be 11.86 and 13.76 % respectively. Other correlations are having less deviation as compared to Eq. (24) and therefore all three correlations are recommended for design of industrial helical coil heat exchanger for specified conditions.

5.2 Development of correlations for estimation of Nusselt number based on data generated beyond the experimental range of parameters

Unfortunately there are few correlations available in the literature under laminar flow regime to calculate Nusselt number. It is also difficult to conduct experiments for wide range of coil curvature ratios and flow rates due to costly experimentation. Hence, to solve the scalability issue, the earlier published relevant correlations are used to just generate sufficient heat transfer data for the development of generalized heat transfer correlations (Eqs. 25, 26 and 27) for a wide range of coil curvature ratios, Re, M and De numbers beyond the present experimental range of parameters as: 0.01 ≤ δ ≤ 0.2, 316 ≤ Re ≤ 10,000, 31 ≤ De ≤ 4,472, 350 ≤ M ≤ 2,041 and 3.0 ≤ Pr ≤ 5.0. The developed generalized equations (Eqs. 25, 26 and 27) are validated with the work of earlier investigators and are found to be in good agreement.

For the development of Eqs. (25, 26 and 27), the experimental correlations (22, 23 and 24) so developed are clubbed with the relevant published correlations to generate the required data. For correlation (25), Nusselt number values were calculated by using Eqs. 2, 3, 5, correlation developed by Xin and Ebadian [6] for water and air as test fluids and present Eq. (23). The range of parameters considered to cover laminar flow regime are: 0.01 < δ < 0.2, 316 < Re < 10,000 and 3 < Pr < 5. Multiple-regression analysis based on the data generated from the range of parameters considered was performed by using MATLAB software. The correlation so developed for computing Nusselt number was resulted as:

The correlation for Nusselt number with Dean number, Prandtl number and coil curvature ratio is in the desired form as: Nu = a Deb Pr 0.4 δc. For data generation to develop this combined correlation for Nusselt number as function of Dean number, Prandtl number and curvature ratio; the same procedure was adopted as discussed for the Eq. (25), (except Eq. 23, Eq. 22 was used). Using multiple regression analysis of MATLAB software, the following correlation was resulted as:

valid for the range 0.01 < δ < 0.2, 31 < De < 4,472 and 3 < Pr < 5.

The procedure for the development of Eq. (27) is the same as used for the Eq. (24). The generalized correlation was resulted as shown in Fig. 6 with the correlation coefficient, R = 98.22 %.

valid for the range 0.01 < δ < 0.2, 350 ≤ M ≤ 2,041 and 3 < Pr < 5. The comparison of developed generalized correlations (25), (26) and (27) with the relevant published correlations in laminar flow regime by Dravid et al. [28], Kalb and Seader [29], and Xin and Ebadian [6] are as shown in Fig. 7.

New generalized correlation, Nu = 0.00009 (M)1.7035 Pr 0.4, Eq. (27) developed by using data generated from earlier published correlations for the range of parameters beyond experimental data

The average values of Nusselt numbers for these six equations for coil with δ = 0.0757 are as shown in Table 3.

Correlations so developed were compared with the work of earlier investigators and experimentally calculated Nusselt numbers to check the validity of developed correlations and are as shown in Table 3. Here, from Table 3 it can be observed that the generalized Eqs. (25), (26) and (27) predicts best results with Xin and Ebadian [6] as compared to Dravid et al. [28] and Kalb and Seader [29]. The minimum and maximum range of deviation of Eq. (27) is 7.71 and 16.61 % respectively which is practically acceptable. The results of earlier correlations shown in Table 3 are lower (as they were developed for lower range of Reynolds number compared to present range of correlations) than the results predicted by Eqs. (25), (26) and (27). Hence, new generalized correlations (25, 26 and 27) are recommended for the design of helical coil fluid-to-fluid heat exchanger under isothermal condition in laminar flow regime.

Finally, we recommend all these correlations developed (22–27) with full confident for the design of helical coil heat exchangers for the specified conditions where the constant vessel temperature is required to maintain. These correlations developed are based on isothermal steady state condition of fluid-to fluid heat transfer type heat exchanger which is useful in industrial applications, such as in exothermic and endothermic chemical reaction vessels in chemical industries, food processing equipments etc.

5.3 Comparison of heat transfer coefficients for different helix diameters

The comparison of inner, outer and overall heat transfer coefficients for different helix diameters of coil (i.e. δ = 0.0757, 0.064 and 0.055) are presented in Table 4. The effect of coil diameter is to influence the centrifugal force on the moving fluid which will further affect the secondary flow along the coil cross-section. It can be seen from Table 4 that as coil diameter increases, all three heat transfer coefficients decreases. This is due to the fact that as coil diameter increases, centrifugal force plays a lesser role in flow characteristics and reduces effects of secondary flow motion (which is responsible for higher heat transfer rate in helical coil) on fluid flowing inside the coil. Outside heat transfer coefficient, ho, is inversely proportional to the coil length and is given by Ali [30] as:

Equation (28) clearly shows that as the coil length increases due to increase in helix diameter of coil for the fixed number of turns, value of ho decreases. Ali [30] also reported that as outer surface area of coil increases, outside heat transfer coefficient, ho, decreases.

Heat transfer from hot water in bath to outer coil surface takes place by pure natural convection, conduction through coil wall and from inner wall to water inside the coil by forced convection.

5.4 Error and uncertainty analysis

Error and uncertainty analysis of the results is done with reference to present work data using equation 3.2 given in Holman [31]. Probable uncertainties involved in the measurement of various parameters are taken into consideration. To verify the repeatability of the experiments, few runs for each test fluids were repeated which yielded excellent results. Estimated errors in temperature measurements were; 60 ± 0.2 °C for hot water bath, inlet/outlet temperature of cold water with limits of error 30 ± 0.1 °C, thermocouple readings for wall temperature, the limits of error estimated by calibration was ±0.1 °C. The calculations done for above estimated errors in the measurements showed that the uncertainties taking part in the results of heat transfer parameters like Q, Nu, hi, ho and Uo were found to be less than approximately ±3 % whereas for volumetric flow rate, it was ±5.6 %. Hence, it will produce insignificant effect on the correlations deduced from the experimental data.

5.5 Comparison of Nusselt number

Inner Nusselt number of the present experimental work for helical coil of outside diameter 300 mm is compared with Nusselt number obtained using correlations of earlier investigators for straight tube and helical duct of rectangular cross section. For comparison of Nusselt number of helical duct of rectangular cross section, correlation of Kadambi et al. [32] as given below is used:

valid for the range 3,000 ≤ Re ≤ 25,000, 0.0378 ≤ b/R ≤ 0.068, Pr = 0.7 for air. Nusselt number for straight tube is calculated by using correlation developed by Colburn which is given as:

applicable for: 0.5 < Pr < 100, 1 × 104 ≤ Re ≤ 1 × 105. Equations (29) and (30) are compared with Eqs. (2), (5) and (22) using experimental data.

Figure 8 shows comparison of Nusselt number for duct of rectangular cross section and straight tube given by Eqs. (29) and (30) respectively with correlations developed by earlier investigators and Eq. (22), based on the present work. From Fig. 8, an average % enhancement in Nusselt number calculated by using correlations developed by Sebhan and McLaughlin [2], Mori and Nakayama [5], Kadambi et al. [21] and present Eq. (22) over straight tube (Eq. 30) were found to be 32.57, 31.29, 50.35 and 24.43 % respectively. Comparison of Nusselt number for helical coils of circular cross section over helical duct of rectangular cross section is also presented in the same Fig. 8. Percentage increment in Nusselt number for duct of rectangular cross section over coils of circular cross section for present work, Eq. (22) and correlations of Sebhan and McLaughlin [2], Mori and Nakayama [5] were found to be 33.91, 26.24 and 27.68 % respectively.

The increased Nusselt number of helical coils is the effects of the curvature of the coil, which induces centrifugal force to act on the moving fluid, resulting in the development of secondary flow. This secondary flow enhances heat transfer due to increased mixing, especially in laminar flow. This is the main difference between the straight pipe and helical pipe. In helical coil of rectangular cross section, one prominent feature is the generation of the secondary flow, which mainly results from the dynamic interplays of pressure gradient, centrifugal force and viscous effects. In curved ducts, more vortices are formed at higher Dean numbers as compared to coil of circular cross section (two vortices) which enhances heat transport processes in coil of rectangular cross section. Because of secondary flow achieved by fluid moving along spiraling paths as they evolve in the main (longitudinal) flow direction, convective transports are generally more effective in a curved duct than in a coil of circular cross section. Also, formation of eddies at the corners of the rectangular cross section enhance the heat transfer coefficients. Due to all these reasons, the heat transfer coefficients in helical ducts of rectangular cross section are higher than coil of circular cross section.

However, friction factor in helical coil is considerably higher than friction factor in straight tube as shown in Fig. 9 (for δ = 0.0757).

The main objective of Fig. 9 is to compare the relation proposed by Mujawar and Rao [25] for friction factor in laminar regime in helical coil with the work of earlier investigators; White [33], and Mishra and Gupta [34]. From Fig. 9, it can be seen that the relation (31) predicts best results with White [33] and reasonably well with Mishra and Gupta [34].

From Fig. 9, it is observed that the Eq. (31) which is similar to well established relation (32) in straight tube for friction factor as:

in laminar flow gives good agreement with the work of earlier researchers. Hence, hypothesis proposed for developing an innovative heat transfer correlation as Nu versus M number have been validated with the work of earlier investigators.

6 Conclusions

-

1.

Experimental set up was fabricated to develop correlations (22, 23 and 24) to calculate Nusselt number based on present experimental data (for laminar flow) under isothermal steady state condition.

-

2.

To increase the range of parameters beyond the present experimental work to cover more common industrial applications, the generalized suitable correlations (25, 26 and 27) are developed using Multiple-regression analysis in MATLAB software and least-squares power-law fit for the range of parameters 316 ≤ Re ≤ 10,000, 0.01 ≤ δ ≤ 0.2 and 3 ≤ Pr ≤ 5.

-

3.

The correlations proposed (22–27) were compared with the published correlations of earlier investigators and were found to be excellent in agreement. Hence, all six correlations developed are recommended for the design of industrial helical coil fluid-to-fluid type heat exchanger for the specified range of parameters.

-

4.

From Table 4, it is observed that as helix diameter increases, all three heat transfer coefficients (hi, ho and Uo) decreases due to decrease in centrifugal force which is a function of helix diameter. Induced centrifugal force inside the coil is inversely proportional to the helix diameter of the coil.

-

5.

Comparison of Nusselt number for helical coil of circular cross section and duct of rectangular cross section to straight tube are presented in Fig. 8 and this change in geometries shows significant enhancement in Nusselt number over straight tube. However, friction factor is considerably higher in helical coil as compared to straight tube for same conditions as shown in Fig. 9.

-

6.

From the exhaustive literature survey, it is found that there is no evidence of Nusselt number correlation to dimensionless number M, though it plays significant role to characterize the hydrodynamics of flow in helical coil for any type of fluids and any practical coil curvature ratios used in industries. In this paper, for the first time, correlations (24 and 27) correlating Nusselt number with M number and Prandtl number are developed. These correlations (24 and 27) were tested with the work of earlier investigators and are found to be in good agreement. In this research work, M number was found to be useful for developing heat transfer correlations, predicting friction factor using relation (31) and to characterize the hydrodynamics of fluid flow in coils. However, further research work is required to develop more correlations relating Nusselt number with M number to cover a wider range of parameters for Newtonian as well as non-Newtonian fluids under isothermal steady state and non-isothermal unsteady state conditions to meet the industrial requirements.

Abbreviations

- a:

-

Inner radius of tube (m)

- a, b, c:

-

Correlation constants

- b:

-

Width of rectangular duct

- cp :

-

Specific heat at constant pressure (J/kg-K)

- D:

-

Mean helix diameter (m)

- Do :

-

Outer helix diameter (m)

- Di :

-

Inner helix diameter (m)

- De:

-

Dean number, De = Re √ (a/R)

- di :

-

Inner diameter of coil (m)

- hi :

-

Innner convective heat transfer coefficient (W/m2 K)

- ho :

-

Outer convective heat transfer coefficient (W/m2 K)

- k:

-

Thermal conductivity (W/m-K)

- L:

-

Length of coil (m)

- \( \dot{\hbox{m}} \) :

-

Mass flow rate of cold water (Kg/s)

- M:

-

Dimensionless number, \( M = \frac{{Re^{0.64} }}{{0.26\left( {a/R} \right)^{0.18} }} \)

- \( {\text{m}}_{\text{c}}^{\prime } \) :

-

Rheological constant of the test solution

- N:

-

Number of coil turn

- Nui :

-

Nusselt number (hidi/k)

- Pr :

-

Prandtl number (ν/α)

- Q:

-

Heat transferred to cold water (W)

- R:

-

Mean helical radius of the coil (m)

- Re :

-

Reynolds number (v di/ν)

- Re cr :

-

Critical Reynolds number

- T:

-

Temperature (°C)

- Uo :

-

Overall heat transfer coefficient (W/m2 K)

- V:

-

Water velocity inside the coil (m/s)

- δ:

-

Coil curvature ratio, δ = a/R (=di/D)

- α:

-

Thermal diffusivity (m−2 s−1)

- ν:

-

Kinematic viscosity (m2 s−1)

- c:

-

Coil

- s:

-

Straight

- in:

-

Inlet

- out:

-

Outlet

- cr:

-

Critical

- i:

-

Inner

- o:

-

Outer

References

Jeschke H (1925) Warmeubergang un Druckverlust in Rohrschlagen. VDI Zeitschrift VDI 69:24–28

Seban RA, McLaughlin EF (1963) Heat transfer in tube coils with laminar and turbulent flow. Int J Heat Mass Transf 6:387–395

Rogers GFC, Mayhew YR (1964) Heat transfer and pressure loss in helically coiled tubes with turbulent flow. Int J Heat Mass Transf 7:1207–1216

Mori Y, Nakayama W (1967) Study on forced convective heat transfer in curved tubes (2nd report, turbulent region). Int J Heat Mass Transf 10:37–59

Mori Y, Nakayama W (1967) Study on forced convective heat transfer in curved tubes (3rd report, theoretical analysis under the conditions of uniform wall temperature and practical formulae). Int J Heat Mass Transf 10:681–695

Xin RC, Ebadian MA (1997) The effects of Prandtl numbers on local and average convective heat transfer characteristics in helical pipes. J Heat Transf 119:467–474

Prabhanjan DG, Raghavan GSV, Rennie TJ (2002) Comparison of heat transfer rates between a straight tube heat exchanger and a helically coiled heat exchanger. Int Comm Heat Mass Transf 29:185–191

Sahoo PK, MdIA Ansari, Datta AK (2003) A computer based iterative solution for accurate estimation of heat transfer coefficients in a helical tube heat exchanger. J Food Eng 58:211–214

Devanahalli GP, Rennie TJ, Raghavan GSV (2004) Natural convection heat transfer from helical coiled tubes. Int J Therm Sci 43:359–365

Rennie TJ, Raghavan GSV (2005) Experimental studies of a double-pipe helical heat exchanger. Exp Therm Fluid Sci 29:919–924

Naphon P (2007) Thermal performance and pressure drop of the helical- coil heat exchangers with and without helically crimped fins. Int Commun Heat Mass Transf 34:321–330

Coronel P, Sandeep KP (2008) Heat transfer coefficient in helical heat exchangers under turbulent flow conditions. Int J Food Eng 4:1–12

Salimpour MR (2009) Heat transfer coefficients of shell and coiled tube heat exchangers. Exp Therm Fluid Sci 33:203–207

Zachar A (2011) Analysis of coiled-tube heat exchangers to improve heat transfer rate with spirally corrugated wall. Int J Heat Mass Transf 53:3928–3939

Kumbhare BP, Purandare PS, Mali KV (2012) Experimental analysis of square and circular coil for the heat recovery system. Int J Sci Res 2:318–327

Berger SA, Talbot L, Yao LS (2006) Flow in curved pipes. Ann Rev Fluid Mech 15:461–512

Naphon P, Wongwises S (2006) A review of flow and heat transfer characteristics in curved tubes. Renew Sustain Energy Rev 10:463–490

Pawar SS, Sunnapwar VK, Mujawar BA (2011) A critical review of heat transfer through helical coils of circular cross section. J Sci Ind Res 70:835–843

Pimenta TA, Campos JBLM (2012) Friction losses of Newtonian and non-Newtonian fluids flowing in laminar regime in a helical coil. Exp Therm Fluid Sci 36:194–204

Ito H (1959) Friction factors for turbulent flow in curved pipes. J Basic Eng Trans ASME 18:123–134

Schmidt EF (1967) Warmeubergang and Druckverlust in Rohrschbugen. Chem Eng Technol 13:781–789

Srinivasan PS, Nandapurkar SS, Holland FA (1970) Friction factor for coils. Trans Inst Chem Eng 48:T156–T161

Ito H (1987) Flow in curved pipes. JSME Int J 30:543–552

Cioncolini A, Santini L (2006) An experimental investigation regarding the laminar to turbulent flow in helically coiled pipes. Exp Therm Fluid Sci 30:367–380

Mujawar BA, Rao RM (1978) Flow of non-Newtonian fluids through helical coils. Ind Eng Chem Process Des Dev 17:22–27

Austin DS, Soliman HM (1988) Laminar flow and heat transfer in helically coiled tubes with substantial pitch. Exp Therm Fluid Sci 1:183–194

Kern DQ (1955) Process heat transfer. McGraw Hill Inc, New York

Dravid AN, Smith KA, Merril EW, Brian PLT (1971) Effect of secondary fluid motion on laminar flow heat transfer in helically coiled tubes. AIChE J 17:1114–1122

Kalb CE, Seader JD (1974) Fully developed viscous-flow heat transfer in curved circular tubes with uniform wall temperature. AIChE J 20:340–346

Ali ME (2006) Natural convection heat transfer from vertical helical coils in oil. Heat Transf Eng 27:79–85

Holman JP (1989) Experimental methods for engineers, 5th ed, Ch 3. McGraw Hill, Singapore

Kadambi V, Levi EK, Neti S (1996) Heat transfer and pressure drop in a helically coiled rectangular duct. J Heat Transf 108:343–349

White CM (1929) Streamline flow through curved pipes. Proc Roy Soc A 123:645–663

Mishra P, Gupta SN (1979) Momentum transfer in curved pipes. 1. Newtonian fluids. Ind Eng Process Develop 18(1):130–136

Acknowledgments

The authors would like to express their cordial thanks to Dr. B. A. Mujawar for introducing the problem and his excellent help during experimentation and data analysis. The authors also acknowledge University of Mumbai and Lokmanya Tilak College of Engineering, Navi-Mumbai, India for the financial support to this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pawar, S.S., Sunnapwar, V.K. Studies on convective heat transfer through helical coils. Heat Mass Transfer 49, 1741–1754 (2013). https://doi.org/10.1007/s00231-013-1210-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-013-1210-3