Abstract

This paper has dealt with the natural convection heat transfer characteristics of microemulsion slurry composed of water, fine particles of phase change material (PCM) in rectangular enclosures. The microemulsion slurry exhibited non-Newtonian pseudoplastic fluid behavior, and the phase changing process can show dramatically variations in both thermophysical and rheological properties with temperature. The experiments have been carried out separately in three subdivided regions in which the state of PCM in microemulsion is in only solid phase, two phases (coexistence of solid and liquid phases) or only liquid phase. The complicated heat transfer characteristics of natural convection have appeared in the phase changing region. The phase change phenomenon of the PCM enhanced the heat transfer in natural convection, and the Nusselt number was generalized by introducing a modified Stefan number. However, the Nusselt number did not show a linear output with the height of the enclosure, since a top conduction lid or stagnant layer was induced over a certain height of the enclosure. The Nusselt number increased with a decrease in aspect ratio (width/height of the rectangular enclosure) even including the side-wall effect. However, the microemulsion was more viscous while the PCM was in the solid phase, the side-wall effect on heat transfer was greater for the PCM in the solid region than that for the PCM in the liquid region. The correlation generalized for the PCM in a single phase is \( Nu = 1/3(1 - C_1 )Ra^{{1 \over {3.5n + 1}}} , \) where C 1 = e –0.09AR for the PCM in solid phase and C 1 = e –0.33AR for the PCM in liquid phase. For the PCM in the phase changing region, the correlation can be expressed as \( Nu = CRa^{{1 \over {7n + 2}}} Ste^{ - (1.9 - 1.65n)} , \) where C = 1.22 – 0.035AR for AR > 10 and C = 0.55 – 16.4e –1.1AR for AR < 10. The enclosure height used in the present experiments was varied from H = 5.5 [mm] to 30.4 [mm] at the fixed width W = 120 [mm] and depth D = 120 [mm]. The experiments were done in the range of modified Rayleigh number 7.0 × 102 ≤ Ra ≤ 3.0 × 106, while the enclosure aspect ratio AR varied from 3.9 to 21.8.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

- a :

-

thermal diffusivity, m–2 s

- AR :

-

aspect ratio (AR = W/H)

- C :

-

coefficient in correlation

- C 1 :

-

coefficient in correlation

- C p :

-

specific heat, J kg–1 K–1

- C t :

-

mass concentration of microemulsion

- C s :

-

mass concentration of surfactant

- C w :

-

mass concentration of water

- D :

-

depth of enclosure, mm

- d :

-

particle diameter, μm

- g :

-

gravitational constant, m s–2

- H :

-

height of rectangular enclosure, mm

- k :

-

thermal conductivity, W m–1 K–1

- K :

-

consistency index of power law model fluid, Pa sn

- n :

-

pseudoplasticity index of power law model fluid

- Nu:

-

Nusselt number defined in Eq. (1)

- Pr:

-

Prandtl number

- q :

-

Net heat flux, W m–2

- Ra:

-

Raleigh number (Ra = ρ0β(T H – T C )H 2n+1/Ka 0 n)

- Ste:

-

Stefan number defined in Eq. (3)

- T :

-

temperature, K

- W :

-

width of enclosure, mm

- y:

-

coordinate in vertical direction, mm

- Y:

-

dimensionless coordinate in vertical direction

- α:

-

heat transfer coefficient (α = q/(T H – T C )), W m–2 K–1

- β:

-

volume expansion coefficient, K–1

- γ:

-

shear stain rate, s–1

- ρ:

-

density, kg m–3

- ν:

-

kinematic viscosity, m2 s

- τ:

-

shear stress (τ = Kγn), Pa

- H:

-

heating plate

- C:

-

cooling plate

- 0:

-

reference state

- cr:

-

critical

- cal:

-

calculated

- exp:

-

experimental

- r:

-

room

- f:

-

fluid

1 Introduction

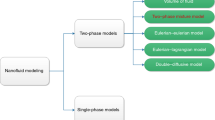

The idea of using very fine particles of phase change material (PCM) dispersed into water can obtain relatively structure stable and homogeneous fluid, which is expected to have some advantages over traditional single component or single-phase fluid in heat transfer, heat storage and fluid transportation [1, 2]. The practical feasibility had been experimentally demonstrated at least in a laboratory scale for forced convection in circular tubes using the microencapsulated phase change material slurry [3–5]. However, up to now, there are very few investigations on the natural convection heat transfer characteristics for the PCM slurry. One of main problems, which have to be overcome, is the effect of stratification and/or agglomeration due to a large size of particle for the natural convection in PCM slurry. The preliminary investigations conducted by Katz [6] and Datta et al. [7] showed that such slurry at low concentration (<5%) could indeed augment the heat transfer in natural convection. Recently, Datta et al. [8] extended the Rayleigh number range from 5 × 103 to 108 in their experiments for the PCM slurry with low volumetric concentrations (<4%). As a result, their experiments were with high Stefan numbers (20 ∼ 180). They found that heat transfer enhancement only in a couple of their experiments and in fact the slurry was detrimental to the heat transfer in most of the runs. A detailed discussion about their results and a comparison with ours will be given in the later section.

As early reported by Inaba et al. [9], the microemulsion slurry used in our experiments exhibited a non-Newtonian fluid behavior, and all the thermophysical and rheological properties showed their dramatic variations during phase changing processes of those PCM particles, which could result in a much complicated phenomenon in natural convection. Ostrach [10] presented a comprehensive review of natural convection in enclosures for some Newtonian fluids. As summarized by Shenoy and Mashelakar [11], however, only a very few investigations about the thermal convection in a non-Newtonian fluid can be available in the literature. In fact, the natural convection in temperature- and stress-dependent non-Newtonian fluids has been attracting many geophysicists' research interest because of the earth's upper mantle formation and evolution concerns. Some theoretical analyses had been performed [12–14]. However, all their analyses were based on the assumption of infinite Prandtl number, and the power law model used were different from that of the present study. The investigation on natural convection in enclosures for non-Newtonian fluids dispersed with PCM particles has not yet been reported so far to the authors' knowledge.

The present study aims to give an understanding of the natural heat transfer characteristics in the non-Newtonian PCM slurry experimentally. In order to get a systematical and comparable result for the already complicated phenomena even for the Newtonian fluid, the initial settings or configurations were simplified by classifying the temperature ranges into three subregions, in which the PCM was in only solid phase, solid-liquid phase change and only liquid phase, respectively, with increasing temperature. The upper cooling plate was fixed at a constant temperature in each region, and the lower heating plate temperature was varied by carefully adjusting the electric power input. An emphasis was given on the phase changing temperature range, and the experiments had been performed for six kinds of enclosures with various heights.

2 Properties of the microemulsion slurry with PCM particles

The microemulsion used in our experiment was the mixture of paraffin (C t = 30%), surfactant (C s = 5%) and water (C w = 65%). The external appearance is shown in Fig. 1. The particle size distribution measured at room temperature using an optical method shows that it ranges from d = 0.1 ∼ 1.2 μm, as shown in Fig. 2. It has a volumetric averaged diameter of d m = 0.51 μm, which is approximately 60 times smaller than the smallest one used by Datta et al. [8]. A 200 ml separatory funnel was used to check if any stratification occurred by carefully measuring the weight of the fluid flowed out of the funnel into a 10 ml flasket. The slurry both before and after heated (up to 328 K) was inspected. The separatory funnel had to be placed in a quiet place for two days (48 hours) before measuring. The results showed no evidences of any stratification.

The dramatic variations in the thermophysical and rheological properties for the microemulsion caused it difficult to express those in formula forms. Therefore, we simply plotted them against temperature in a graph form as shown in Fig. 3. Except for the specific heat capacity, which was measured by the differential scanning calorimetry (DSC), all the properties shown in Fig. 3 were measured in a thermal steady state. The density ρ was measured using a pycnometer, which has an accuracy of within ±1%. The viscosity coefficient of the fluid was measured using a rotary cylinder viscosity meter, and the measured data for water were in agreement with the reference values with a standard deviation of less than ±2.0%. The thermal conductivity was measured by the experimental apparatus itself and will be described in the later section. As can be seen in Fig. 3, the phase changing area almost covers the temperature range from 313 K to 323 K. Therefore, we intentionally divided the temperature range into three subregions according to the phase of PCM particles, which were the solid region (T < 313 K), the phase changing region (313 K < T < 323 K) and the liquid region (T > 323 K). The microemulsion slurry used shows a continuous variation of specific heat capacity or entropy with temperature. As it is well known, natural convection is a nonlinear dissipative dynamic system essentially coupled between flow and heat transport that any trivial differences in physical properties, configuration or imposed boundary conditions could lead to completely different evolution in the end. Therefore, much more complicated natural convection heat transfer characteristics are to be expected with these complicated physical properties.

3 Experimental apparatus and procedures

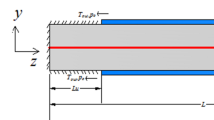

The experimental setup is shown schematically in Fig. 4. The test chamber mainly consisted of a square side-wall frame (W = 120 mm, D = 120 mm) made of 10.0 mm thick transparent acrylic plates, and two 10 mm thick copper plates, which fitted the top and bottom ends of the supporter. The temperature of the top cooling copper plate is maintained by circulating the cooling brine through a water bath. A 0.7 mm thick electric film heater was mounted at the bottom of the lower heating copper plate. Between the film heater and the lower heating plate, a film heat flux sensor was inserted, which was 0.2 mm thick and 50 mm in square, and had the accuracy of 1.0 W/m2. The backside of the film heater was covered with 5 mm thick foamed thermal insulating material, and a 15 mm thick bakelite plate was mounted below it. The whole test section was covered with 50 mm thick foamed thermal insulating material. A glass pipe, 8.0 mm in inner diameter, was designed as a reservoir of microemulsion slurry. The average temperatures of the heating and cooling copper plates were measured, respectively, by six 0.1 mm-in diameter Cu–Co thermocouples, and two of the six thermocouples were buried in the middle, and four of them were located around of the heating or the cooling plate. The temperature of the heating copper plate was adjusted by controlling the electric power input of the heater. The height of the rectangular enclosure H or the aspect ratio AR was varied by selecting the acrylic side-wall frame with a suitable height. Two T-type thermocouples supported by a 1.06 mm in outer diameter and 0.18 mm thick stainless pipe were installed to measure the vertical temperature distribution in the center of the enclosure, and their positions were controlled with a micrometer.

Since the accurate measurement in heat transfer is important in the present study. The experimental apparatus was firstly calibrated using the distilled water as the test fluid. To this end, the heat-loss from the experimental apparatus to the surrounding was measured by running steady heat conduction experiments with top heating and bottom cooling. The experiments were repeated with different electric power inputs and temperature differences between the heating copper plate and the surrounding, and the results showed that the heat-loss was an approximately linear function of the temperature difference between the heating copper plate and the surrounding. This function was used as a correction formula for the convective heat transfer experiments. The corrected part of heat was in general less than 5% of the total electric power input. The measured thermal conductivities of water by using the method described above were in agreement with the reference values with a standard deviation of ±1.5%. The thermal conductivity of the microemulsion slurry was measured by the calibrated experimental apparatus in the same way. The measured Nu number against Ra number for the enclosure of H = 8.4 mm or AR = 14.3 is shown in Fig. 5, which are about 4.5% systematically lower than the calculated using Holland's equation [15] due to the side-wall effect, because the equation was for natural convection between two infinite plates. Based on this, it is believed that the precision of the experimental apparatus is enough to resolve changes in the Nusselt number due to different Rayleigh numbers.

The experiments were done from low to high temperatures, where the PCM particles were in solid phase, two-phase (solid and liquid), and liquid phase. In the solid phase region, the top cooling plate temperature was fixed at about T C = 303 K, and the bottom heating plate temperature was varied by controlling the electric heating power input. The top cooling plate temperature was controlled at T C = 313 K in the phase changing region, and T C = 323 K in the liquid region, respectively. Data acquisition was started while the whole system was considered at a thermal steady state, generally, at which the heating plate had a temperature fluctuation within ±0.05 K in an hour. In addition to the averaged heating plate temperature T H the electric heating flux q, the room temperature T r and the fluid temperature T f at the center of the enclosure were also monitored dynamically from the beginning to the end of an experiment in every 30 seconds. These data were useful for analyzing the evolution process of a natural convection system. Without a specification, all of the data in the paper are for thermally steady conditions. The experimental parameters were ranged as follows: T C = 303 ∼ 323 K, T H = 303 ∼ 333 K, H = 5.5 ∼ 30.4 mm or AR = 3.9 ∼ 21.8.

4 Experimental results and discussion

5 Natural convection for the PCM in solid phase

The experimental results of natural convection heat transfer are generalized by Nu number against Ra number, where Nusselt number Nu and Rayleigh number Ra are defined respectively as

This definition of Rayleigh number can be obtained easily by a standard normalization of N–S equation if the velocity scale is given by a o /H, pressure scale by ρ o a o 2/H 2 and time scale by H 2/a o [17]. However, the volumetric expansion coefficient \( {\bar \beta} \) is an integral averaged from the temperature of top cold plate to the temperature of bottom hot plate instead of arithmetic averaged, because it is believed that it is more reasonable in dealing with the slurry having a nonlinear change in density with temperature. Nevertheless, it does not mean as simple as it is described when it is to be used in the phase changing region, where the density varies dramatically with temperature. The detailed discussion about this will be given in the next section. Since the effective viscosity for a pseudoplastic non-Newtonian fluid is closely related to the velocity distribution in space, i.e. more dependent on the configuration and boundary conditions. It is still difficult to get a generalized dependency to evaluate the natural convection in a non-Newtonian fluid. Parmentier [18] proposed a definition named apparent Rayleigh number by using the normal Rayleigh number divided by an average dimensionless viscosity in the domain of a single wavelength. For Newtonian fluids with a large viscosity variation, Booker and Stengel [19] had suggested a normalization called supercriticality (Ra/Ra cr ) defined by the ratio of the Rayleigh number to the critical Rayleigh number instead of the Rayleigh number alone, which was considered to be even more remarkable independent of viscosity variation. It was also successfully used for correlating their data for the natural convection in an enclosure (200 mm × 100 mm × 12.5 mm) filled with the golden syrup, a strongly temperature-dependent viscosity fluid [20]. This method even was used for the natural convection in non-Newtonian fluids in numerical modeling [14, 21]. However, as early pointed out by Parmentier and Turcotte [12], the thermal instabilities in a non-Newtonian fluid could not be characterized by a critical Rayleigh number alone but must also depend on the form of the disturbance initiating the motion, since the inherently nonlinearity of viscosity law could cause the fluid flow more locally. Besides, the microemulsion used in the present study has a large variation in pseudoplastic index n with temperature for the PCM in the phase changing region. Hence, the simply form of Eq. (2) was accepted.

After the enclosure was filled up completely with the microemulsion slurry, cooling brine was circulated through the top cooling plate to make its temperature T C at about 303 K. Then, the heating power was put on to heat the bottom plate. The first experiment was for enclosure H = 11.2 mm or AR = 10.7. It was interesting to find that the microemulsion slurry showed a nonlinear behavior when it was subjected to different heating rates. Steadily and slowly increasing the heating power could only lead to a pure conduction state. However, a suddenly large initial heating power, even for a few minutes, could cause the convection inside the enclosure to start. The convection state remained thereafter even that the heating power was decreased to a small value. In other words, different initial settings made different evolvement for this case. It was considered that the amplitude of initial random perturbations imposed on the enclosure was not great sufficiently to induce convection, thus the height of enclosure H was increased to 13.4 mm. However, still the same phenomenon had been observed in this case. Figure 6 shows the measured Nusselt number Nu versus the Rayleigh number Ra. It could be seen that the same Rayleigh number can correspond to two different thermal steady states either conduction or convection. The center vertical temperature distributions for the points A (convection) and A′ (conduction) for Ra = 4770, B (convection) and B′ (conduction) for Ra = 8028 are shown in Figure 7. The convection state of point A was induced from a large initial heating power soon followed with a small heating power that the maximum Rayleigh number approximately Ra = 14,760 is actually somewhere higher than its critical Rayleigh number, as plotted in Figure 8. The two dynamic evolutions for the final conduction and convection states at different initial heating methods are shown in Figure 9(a, b). The final heating powers were the same, which was about 300 W/m2 for the two cases. And, their center vertical temperature distributions are shown in Fig. 10, which were measured in approximately 2.5 hours later.

Vertical temperature distributions at the center for enclosure H = 13.4 mm evolved from various initial heating rates (for caption A, A′, B, B′ refer to Fig. 6)

Dynamic features of natural convection for different initial heating methods (a) beginning with a low heating rate, (b) beginning with a high heating rate and followed soon with a low heating rate for enclosure H = 13.4 mm (for caption A → B → C see Fig. 8)

Then the enclosure height was increased to 23.2 mm. A convection state was finally evolved into no matter how slowly to increase the heating power, at least in the limitation of the present experimental facilities. The experiments were done also for the lower height of the enclosure, e.g. H = 5.5 mm and 8.4 mm. For the enclosure of H = 5.5 mm, it was found that no convection occurred even through a large initial heating power was as imposed as before. Figure 11 shows the measured Nusselt number Nu versus the Rayleigh number Ra for five enclosures with various heights.

It is shown in Fig. 11 that different thermal steady states can be induced depending on initial starting conditions at the same Rayleigh numbers. This kind of phenomenon described as an imperfect bifurcation by physicists happens frequently in natural convection due to small but significant departures for the fluid from the Boussinesq approximation. The critical Raleigh number Ra cr can be greater than that at convection state or the subcritical convection could exist. Some previous studies had been done in order to determine the critical Rayleigh number for real fluids, and a summarization about this can be referred to Getling [22]. Stengel et al. [23] discussed in detail on the linear stability of various variable-viscosity fluids. Richter et al. [20] experimentally demonstrated the theory using golden syrup as the working fluid which has a great viscosity variation that up to 105 within the temperature from 273 K to 353 K. But, all the researches mentioned above were for Newtonian fluids.

Based on the very limited experimental data and numerical calculations [17, 24], Solomatov [21] proposed a very simple equation Ra cr (1)nRa cr (0)1–n which can be easily used for determining the critical Rayleigh number for power law non-Newtonian fluids with dragless vertical boundaries, where Ra cr (1) ≈ 1708 is the critical Rayleigh number for a Newtonian fluid with constant viscosity, and Ra cr (0) is the fitting coefficient corresponding to a formal asymptotic critical Rayleigh number Ra cr in the limit n → 0, which is equal to 27.2 calculated by Stengel et al. [19]. By using this equation one can know that Ra cr is approximately 493 for the PCM microemulsion slurry used (n ≈ 0.7). However, the present experimental results showed that the critical Rayleigh number Ra cr can be more than 104. It is hard to believe that it can be reduced to as small as the calculated one even if the side-wall effect (AR = 10.7) is assumed. In order to check if it is true for other non-Newtonian fluids, a 200 ppm Cetyltrimethylammonium Bromide (CTAB) solution with a pseudoplastic index n = 0.7 at temperature 298 K was used as the test fluid for natural convection in an enclosure 120 mm × 120 mm × H (8.3 mm). It was found that natural convection had surely been induced upon giving a heating power as small as usual. The curve for the measured Nusselt numbers against Rayleigh numbers showed that the critical Rayleigh number Ra cr from an extrapolation method for crossing the line Nu = 1 was in several tens, which was much smaller than the value calculated above. That is to say the onset problem for a non-Newtonian fluid is still far from a complete understanding. Various kinds of non-Newtonian fluids could result in much different critical Rayleigh numbers. It is not quite clear for us why the microemulsion slurry manifest a very obvious imperfect bifurcation as described above, because all the other properties are almost constant in the solid region from 303 K to 313 K except for the flow index n. A preliminary explanation seems that the effective viscosity for a shear-thinning power law fluid goes to infinity when the initial perturbations approach zero. It is more difficult to start the flow for a shear-thinning power law fluid with a smaller flow index n, however, once the flow has been started it is easier to change the flow. The easy onset of convection for the enclosure with a larger height is probably because the initial perturbation of heating condition is somewhere near the critical Rayleigh number or its threshold.

6 Natural convection for the PCM in phase changing

The microemulsion slurry shows very complex thermophysical and rheological properties within the phase changing temperature range from 313 K to 323 K, as shown in Fig. 3. The density ρ, which plays the primary role in natural convection due to the gravitational buoyant force, draws down quickly with the melting of PCM inside the particles dispersed in water. Correspondingly, the volumetric expansion coefficient β shows a local maximum around 319 K. Also, what should be noted is the complex rheological behavior. The pseudoplastic index n increases rather than decreases as it does in the solid region, and the viscosity consistency K decreases with PCM melting in microemulsion slurry. The more complicated natural convection phenomena are to be expected based on those complex thermophysical and rheological properties.

The cooling plate was fixed at about T C = 313 K which was considered to be the phase-change beginning temperature, and the heating plate temperature T H was varied by supplying different heating power. To the contrary with those while the PCM was in solid phase, there was no pure conduction state observed in the experiments within the phase changing temperature range. Even for the enclosure H = 5.5 mm, the natural convection occurred surely as shown in Fig. 12(a). Figure 12(a–f) are the vertical fluid temperature distributions in the center at various heating fluxes for six kinds of enclosures, respectively. The aspect ratios are covered in a range of 3.9 ≤ AR ≤ 21.8.

One of the common features, which can be read from these figures, is that the bottom heating plate temperature T H has a big jump from about 321 K to 323 K or even higher while the increment of electric heating flux is not so high. This becomes less apparent for the higher enclosures. As a result, the heat transfer coefficient decreases as the heating plate temperature T H is over about 321 K. There seem two possible explanations on this. One is that most of the PCM in the microemulsion slurry has been changed into liquid phase near the heating plate with a temperature of over 323 K. The heat transfer enhancement due to the phase change material on the bottom heating plate side is getting reduced. The other is due to that the density draws down asymptotically rather than rapidly while the heating plate temperature is over 323 K. It is certainly difficult to clarify which is the main contributor through the experiments, since both the density and the enthalpy (or the specific heat) are inherently correlated with temperature. Unless a fluid that has the same other properties except of enthalpy or density could be found, this cannot be done. However, a theoretical research can provide a means to achieve the goal [25], which will be discussed in detail later.

The typical convective temperature distributions can be shown in most of the figures when the heating plate temperature T H were changed from about 315 K to 321 K. However, with increasing the enclosure height H, a conduction-like temperature gradient had been observed in the upper most of the top cold thermal boundary as shown in Figs. 12(e, f). It obviously indicates that stratified layers appeared. Referring to the results observed by Richiter et al. [20] for a Newtonian fluid having a large viscosity variation with temperature, this should be to a certain extent accepted. Stengel et al. [19] and more recently Ogawa et al. [26] had theoretically demonstrated the conduction (or stagnant) lid phenomenon by using the linear stability theory and numerical method, respectively. The later group also obtained a critical criterion if the viscosity ratio (viscosity based on the top cold boundary temperature to that of based on the bottom hot boundary temperature) is greater than a critical pivot. Unfortunately, it cannot be applied for a non-Newtonian fluid. The viscosity consistency K for the PCM microemulsion slurry is decreased by approximately three times from about 18 × 10–3 Pa·sn to 6 × 10–3 Pa·sn, while the pseudoplastic index n is increased from about 0.7 to 0.9 with an increase in temperature from 313 K to 323 K. It has a smaller pseudoplastic index n and higher viscous consistency K that in the top near the cooling plate part than that in the bottom part. Therefore, it would become very difficult to start the convection in the top.

For an enclosure with a lower height, the viscosity variation is getting less dominant, for example, the temperature distribution is somewhat like a straight line and no conduction lid occurs for the enclosure H = 5.5 mm. The reason is that both the heat and momentum dissipations are faster for an enclosure with a lower height. Therefore, the less time is used for the self-organization of a fluid flow inside the enclosure. The measured Nusselt number versus Rayleigh number for various enclosure heights is shown in Fig. 13. As discussed above, the temperature jump while the bottom hot plate temperature T H exceeded about 321 K results in a rapid decrease in Nusselt number, which are clearly shown in Fig.13 (dash arrows). But, it restored increasing again with an increase in Rayleigh number thereafter. For enclosures with the larger height, the Nusselt number depends mainly on the top part resulting from the appearance of a conduction lid.

Another observation is that the Nusselt numbers for H = 11.4 mm was higher than that for H = 5.5 mm. This is contrary to the results observed when the PCM is in a solid phase region or to an ordinary Newtonian fluid that an enclosure with a higher aspect ratio should have a higher Nusselt number due to the side-wall effect. In order to make sure that this was not caused by any inaccuracies or a systematical misreading, the experiments for the two height enclosures had been done once again in two consecutive days. The heat transfer coefficients versus temperature differences are plotted in Figure 14. Almost the same results were obtained as the last time that the Nusselt numbers for enclosure H = 11.4 mm are approximately double those for enclosure H = 5.5 mm at the same temperature difference. There seems no way for us to give this for an explanation but to raise a problem for Boussinesq assumption, because the density variation with temperature showed neither linear nor satisfying Δρ/ρ ≪ 1 for the PCM microemulsion slurry during phase changing. As a matter of fact, the fluid flow in natural convection was also called buoyancy-induced (or buoyancy-driven) flow by some researchers. Most of real fluids such as water and air do satisfy the Boussinesq approximation in a wide range of temperature, and both theoretical and experimental results obtained based on the Boussinesq approximation can reflect the happenings in real. However, a problem could be posed to apply the Boussinesq theory to the PCM microemulsion slurry used. This means that the enclosure height or the distance for the local buoyancy working has to be taken into account. The enclosure height H is, therefore, no longer an independent parameter to the Nusselt numbers for these fluids having a large density variation with temperature.

It could be said that the heat transfer enhancement of natural convection in the PCM microemulsion slurries is mainly due to the melting and solidification of the PCM near the heating and cooling boundaries, respectively. The enhancement should be different depending on the different latent heat or the enthalpy of the PCM slurry in phase changing confined by the two boundary temperatures. Some numerical results [24] showed that it is the phase changing process rather than the density variation that is responsible for the heat transfer enhancement, and the Nusselt number can be correlated with the modified Stefan number defined as below. The Stefan number will approach unity by further increasing the heating plate temperature after 323 K that Raleigh number can be again the only main dependency of the Nusselt number. The phase changing process in this case shifts upwards and happens in the middle part of the enclosure that the heat transfer enhancement is reduced.

Where C p0 is a reference specific heat capacity, which is taken at 313 K. The specific heat capacity is considered to be continuous with respect to temperature for the PCM microemulsion slurry.

7 Natural convection for the PCM in liquid phase

All the phase change materials in the microemulsion slurry are considered being in a liquid phase at temperature over 323 K, even the temperature read from DSC scan of specific heat capacity shows a little bit shifting forward. The viscosity and other properties show that there is no much variation against temperature in the range of 323 K to 333 K. But one point should be noted that the volumetric expansion coefficient in this range is smaller than that of water. Especially, it is noticed that the volumetric expansion coefficient reaches its local minimum at temperature of about 327 K, and it is about three times smaller than that of water.

Since the volumetric expansion coefficient is small for the PCM in liquid phase, the integral averaged volumetric expansion coefficient becomes more important in correlating Nusselt number with Rayleigh number for getting a physically meaningful result, as shown in Fig. 15. Since the slurry is getting less viscous for the PCM in liquid phase than that for the PCM in solid phase, the side-wall effect on heat transfer is reduced.

8 Experimental correlations

There is not yet a reference available on the experimental correlation for natural convection in non-Newtonian fluids in a rectangular enclosure. Moreover, the PCM microemulsion slurry used was a kind of much more complicated fluid having a great variation both in thermophysical and rheological properties in the phase changing temperature range. The numerical results obtained by Inaba et al. [24] based on Boussinesq assumption showed that the Nusselt number is proportional to the Rayleigh number with a power index of 1/(3.5n + 1) and to the modified Stefan number with a power index of –(1.9 – 1.65n), respectively. However, the side-wall effect had not been considered in the numerical simulation. The power index of the Rayleigh number was located in between 1/(3n + 2) and 1/(3n + 1), those values respectively suggested by Dale and Emery [27], Reilly et al. [28] in an experimental correlation for a free convection in non-Newtonian fluids from a heated vertical plate. Hence, for the PCM in the non-phase changing regions, Ra and AR are the only two parameters used in the correlation. In addition, while the PCM is in liquid phase, the side-wall effect becomes less dominant than that for the PCM in solid phase. The correlations for the two cases could be generalized as follows.

in which C 1 is exp(–0.09AR) for the PCM in solid phase and exp(–0.33AR) for the PCM in liquid phase. The standard deviations using the correlation equation (4) were ±6.2% and ±3.3% for the PCM in solid phase and liquid phase, respectively. The plots of calculated results from Eq. (4) against the experimental data are shown in Fig. 16.

Comparison between the measured Nusselt number and the calculated using Eq. (4) for the PCM in a single phase (The solid symbols are for solid phase, and the open symbols are for liquid phase)

Because there is a great density variation while the PCM is in phase changing, the power index of the Rayleigh number was left for the last one to be determined. First the power index of the Stefan number was fixed as –(1.9 – 1.65n), which was taken from the numerical simulation, and then tried to find the power indexes of the Rayleigh number and the corresponding coefficients for various enclosures through the least-square approximation. Finally, the best function with the power index and the coefficient was obtained. The best correlation is as follows.

where C = 1.22 – 0.035AR for AR > 10 and C = 0.55 – 16.4e –1.1AR for AR < 10. While T H is higher than 323 K, Ste is given as unity, since it is believed that the enhancement for the PCM slurry can be negligible.

It is shown that the power index of Rayleigh number is smaller than (or the half of) that obtained from the numerical simulation, because the numerical results obtained were based on the Boussinesq assumption. By using the Boussinesq assumption in the numerical simulation, the intensity of natural convection indicated by the value of Rayleigh number seems to be over predicted for the PCM in phase changing region. The preliminary explanation about this has already been discussed in the former section. The standard deviation for the total experimental data using the Eq. (5) is ±5.3%. The coefficient C against the enclosure height is plotted in Fig. 17. This figure clearly shows that the multiplier coefficient C increases with increasing the enclosure height for low enclosures, but it decreases again owing to the appearance of conduction lid at about the height between H = 11.2 mm and H = 13.4 mm.

The coefficient C in Eq. (5) against the height of enclosure H (The solid line in the left shows the non-Boussinesq effect due to density and the solid line in the right shows the effect of the stagnant lid appearance and the dash line in the middle shows the unstable transition area)

From the data obtained by Datta et al. (1996) for the microencapsulated PCM slurry, it is found that the maximum enhancement in heat transfer is about 1.2% for the case of Ste* = 20, and 0.2% for the case of Ste* = 180 (Note that Ste* is the term defined by Datta et al. (1996), it can be transferred to the present definition by using Ste = Ste*/(Ste* + 1)). Hence, it is interesting that only few enhancement runs had been observed in their experiments, because it is quite reasonable for those amplitudes of enhancement being immersed in experimental deviations. They also considered that the decrease in heat transfer for high Rayleigh numbers was due to either the poor quality of particles or the low Pr. However, they did not mention if the conduction lid or stratification appeared in their experiments. Anyway, this is in agreement with the present results that the heat transfer enhancement at high Rayleigh numbers is expected to be much difficult for the PCM slurries despite the reasons for this may be different. Based on the present conclusions, the mass concentration of the PCM slurry isn't a criterion for evaluating the heat transfer enhancement in natural convection. The enhancement in heat transfer is clearly shown even for the PCM slurry with a high concentration as used in the present experiment.

9 Conclusions

The very complex flow and transport phenomena had been exposed for the natural convection in the PCM microemulsion slurry. The heating rate dominated onset of natural convection for the PCM in the solid region; the imperfect bifurcation; the instability of natural convection while the heating plate temperature was over 321 K and the appearance of conduction lid had been observed for the same fluids in the present study. In a dynamic point of view and strictly speaking, the natural convection was different from case to case that it would be better to consider it individually even for the Boussinesq fluids. In phase changing region, the PCM microemulsion slurry showed also the apparent departure from the Boussinesq fluids in density that the Nusselt number could be related to the value of enclosure height. The evaluation for natural convection, therefore, becomes much more complicated, and can't be completely relied upon the Rayleigh number, the Prandtl number as used quite often in the previous studies. The difference due to density from a Boussinesq fluid was alleviated with an increase in enclosure height that the Nusselt number increased rather than decreased. The Nusselt number would become asymptotically close to that of the Boussinesq fluids for an enclosure with an infinite large height.

The dispersed PCM particles in microemulsion slurry can improve the heat transfer in natural convection since the latent heat is a contribution to some extent. Besides the Rayleigh number, a modified Stefan number defined in the paper had been proved to be a good dependency in correlating the present data. However, due to the low conductivity for most of phase changing materials and the easy formation of a stagnant lid in the upper most part near the top cold plate when the enclosure height was over a threshold, the enhancement at high Rayleigh number was still difficult to be realized in practice. Much more data are needed for a better understanding of the fluid flow and natural convection heat transfer characteristics in the PCM microemulsion slurry.

References

Inaba H; Morita S (1995) Flow and cold heat-storage characteristics of phase-change emulsion in a coiled double-rube heat exchanger. ASME J Heat Transfer 117: 440–446

Inaba H (2000) New challenge in advanced thermal energy transportation using functionally thermal fluids. Int J Thermal Sci 39: 991–1003

Charunyakorn P; Sengupta S; Roy SK (1991) Forced convection heat transfer in microcapsulated phase change material slurries: flow in circular ducts. Int J Heat Mass Transfer 34: 819–833

Choi E; Cho Y; Lorsch HG (1994) Forced convection heat transfer with phase-change-material slurries: tubulent flow in a circular tube. Int J Heat Mass Transfer 37: 207–215

Inaba H; Kim MJ; Horibe A (2002) Melting heat transfer characteristics of latent heat microcapsule-water mixed slurry flowing in a pipe with constant wall heat flux (experimental study). JSRAE 19(1) (in press)

Katz L (1968) Natural convection heat transfer with fluids using particles while undergoing phase change. Ph.D. Dissertation, Department of Mechanical Engineering; Massachusetts Institute of Technology, Massachusetts

Datta P; Sengupta S; Roy SK (1992) Natural convection heat transfer in an enclosure with suspensions of microcapsulated phase change materials. ASME General Papers Heat Transfer HTD 204: 133–144

Datta P; Sengupta S; Singh T (1996) Raleigh and Prandtl number effects in natural convection in enclosures with microencapsulated phase change materials slurries. Symp 33rd Heat Transfer Japan: 225–226

Inaba H; Morita S; Nozu S (1993) Viscosity evaluation of phase-change emulsion as a low temperature heat-storage materials. Trans JSTP 7(4): 239–244

Ostrach S (1988) Natural convection in enclosures. ASME J Heat Transfer 110: 1175–1190

Shenoy AV; Mashelkar RA (1982) Thermal convection in non-newtonian fluids. Adv Heat Transfer 15: 143–225

Parmentier EM; Turcotte DL (1976) Studies of finite amplitude non-newtonian thermal convection with application to convection in the earth mantle. J Geophys Res 81(11): 1839–1846

Christensen U (1983) Convection in a variable-viscosity fluid: Newtonian versus power-law Rheology. Earth Planet Sci Lett 64: 153–162

Dumoulin C; Doin MP; Fleitout L (1999) Heat transport in stagnant lid convection with temperature- and pressure-dependent Newtonian or non-Newtonian Rheology. J Geophys Res 104(B6): 12,759–12,777

Kondepudi D; Prigogine I (1998) Modern thermodynamics: from heat engine to dissipative structure. New York, John Wiley & Sons

Hollands KGT; Raithby GD; Konicek L (1975) Correlation equation for free convection heat transfer in horizontal layers of air and water. Int J Heat Mass Transfer 18: 879–884

Ozoe H; Churchill SW (1972) Hydrodynamic stability and natural convection in Ostwald-de Waele and Ellis fluids: the development of a numerical solution. AIChE J 18(6): 1196–1206

Parmentier EM (1978) A study of thermal convection in non-Newtonian fluids. J Fluid Mech 84: 1–11

Booker JR; Stengel KC (1978) Further thoughts on convective heat transport in a variable viscosity fluid. J Fluid Mech 86: 289–312

Richter FM; Nataf HC; Daly SF (1983) Heat transfer and horizontally averaged temperature of convection with large viscosity variations. J Fluid Mech 129: 173–192

Solomatov VS (1995) Scaling of temperature- and stress-dependent viscosity convection. Phys Fluid 7: 266–274

Getling AV (1998) Rayleigh-Bénard convection: structures and dynamics. Advanced Series in Nonlinear Dynamics 11: World Scientific, Singapore, 1998

Stengel KC; Oliver DS; Booker JR (1982) Onset of convection in a variable-viscosity fluid. J Fluid Mech 120: 411–431

Tien C; Tsuei HS; Sun ZS (1969) Thermal instability of a horizontal layer of non-Newtonian fluid heated from below. Int J Heat Mass Transfer 12: 1173–1185

Inaba H; Dai C; Horibe A (2002) Numerical simulation of Rayleigh-Bénard convection in non-Newtonian phase-change-material slurries. Int J Thermal Sci (in press)

Ogawa M; Schubert G; Zebib A (1991) Numerical simulations of three-dimensional thermal convection in a fluid with strongly temperature-dependent viscosity. J Fluid Mech 233: 299–328

Dale JD; Emery AF (1972) The free convection of heat from a vertical plate to several non-Newtonian "Pseudoplastic Fluid". ASME J Heat Transfer 94: 64–72

Reilly IG; Tien C; Adelman M (1965) Experimental study of natural convection heat transfer from a vertical plate in non-Newtonian fluid. Can J Chem Eng 43: 157–160

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Inaba, H., Dai, C. & Horibe, A. Natural convection heat transfer in enclosures with microemulsion phase change material slurry. Heat and Mass Transfer 40, 179–189 (2004). https://doi.org/10.1007/s00231-003-0419-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-003-0419-y