Abstract

The mechanism by which modified wood resists decay has long been discussed, but is still not fully understood. A better understanding of decay resistance mechanisms could improve wood protection processes and product properties. In this study, the dynamics of brown rot decay in thermally modified wood was examined through measurements of mass loss, strength loss and gene expression. Close monitoring of mass loss over 120 days in thermally modified wood exposed to Postia placenta showed a delay in the onset of degradation compared to untreated wood, and once the degradation had started, the rate was lower. Thermally modified wood did not inhibit expression of wood degradation-related genes before mass loss and was similar to that in untreated wood once mass loss could be detected. Comparing gene expression as well as strength loss at the same stage of decay rather than at the same time after exposure showed smaller differences in decay patterns between thermally modified and untreated wood than previous results indicate. It is concluded that the key to understanding degradation resistance in thermally modified wood is to compare the decay patterns in thermally modified wood and untreated wood before mass loss occurs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biodegradation, or the decomposition of wood by microbes, is a natural process that is essential for nutrient cycling in forest ecosystems (Eriksson et al. 1990). When decomposition happens in wooden structures, it can lead to great economic losses. The fungal decay of wood products has traditionally been combated with broad-spectrum chemical preservatives. Because of restrictions and a growing environmental concern over toxic wood preservatives, new alternative wood protection systems are being developed that are based on technologies with low environmental impact (Hill 2006).

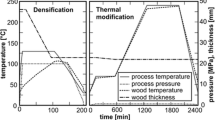

One of the most promising alternatives is wood modification, which is based on a non-toxic mode of action through a chemical and/or physical alteration of the wood (Hill 2006). Thermal modification is a heat treatment of wood using mild pyrolysis (>180 °C) (Militz 2002; Hakkou et al. 2006). During the process, hemicelluloses are degraded, lignin auto-condenses, and crosslinks with polysaccharides are created (Tjeerdsma et al. 1998; Hakkou et al. 2006; Mohareb et al. 2011). It is still not experimentally shown which mechanism(s) in the Postia placenta degradation process is affected by thermal modification. Mechanisms which might be affected include internal fungal processes such as gene regulation and expression as well as external processes such as the formation of radicals in the wood cell wall. With a better understanding of the fungal decay mechanisms in thermally modified wood, it can be revealed how fungal decay is inhibited or delayed, and subsequently, protection processes and product properties improved.

Brown rot fungi have been argued to be the most common and most destructive organisms involved in the degradation of softwood products (Goodell 2003; Vanden Wymelenberg et al. 2010). Brown rot fungi have traditionally been discriminated from white rot based on that white rot is able to degrade lignin, while brown rot is not. However, recent results show that there is rather a continuum between the two types of rot than a clear line (Riley et al. 2014). Furthermore, since brown rot fungi have evolved from white rot at least four times, the decay mechanisms may differ extensively between brown rot species (Eastwood et al. 2011). The brown rot wood degradation process has mainly been studied in Gloeophyllum trabeum, but certain aspects have been verified in, for example, P. placenta, Coniophora puteana and Serpula lacrymans (Hyde and Wood 1997; Cohen et al. 2002; Steenkjær Hastrup et al. 2013). However, certain differences have also been demonstrated as, for example, the amount of oxalic acid secreted and the role of laccase (Espejo and Agosin 1991; Green and Clausen 2005; Wei et al. 2010; Hastrup et al. 2012). P. placenta (Fr.) M.J. Larsen & Lombard is a very useful test organism because it has more capacity than most brown rot fungi to degrade thermally modified wood, but its ability to decay wood is adversely affected by thermal modification (Lekounougou and Kocaefe 2013, 2014a, b).

It has been hypothesised that P. placenta, as well as some other species of the orders Gloeophyllales, Polyporales and Boletales, secretes iron reductants, oxalic acid and hydrogen peroxide to initiate the Fenton reaction inside the wood cell wall and therefore form hydroxyl radicals that will depolymerise the polysaccharides and make them accessible for the cellulases to degrade (Goodell et al. 1997; Kerem et al. 1999; Paszczynski et al. 1999; Jensen Jr. et al. 2001). Extracellular hydrogen peroxide may be produced by alcohol oxidase since it has a preference for methanol, a product that is potentially available from the demethylation of lignin during degradation (Martinez et al. 2009). The P. placenta alcohol oxidase has been shown to be up-regulated in the presence of cellulose and wood compared to glucose (Martinez et al. 2009; Vanden Wymelenberg et al. 2010). Iron reductants and oxalic acid are formed as by-products in the fungus metabolism, but exactly which genes are responsible for the increased formation and/or secretion of these molecules during wood degradation is not known (Martinez et al. 2009; Vanden Wymelenberg et al. 2010). However, after reduction in ferrous iron, some iron reductants (hydroquinones) may be recovered by a quinone reductase (Paszczynski et al. 1999; Jensen et al. 2002; Qi and Jellison 2004). A protein model in P. placenta has been identified as a putative quinone reductase (Martinez et al. 2009). Methoxyhydroquinones may be oxidised by laccase into semiquinones which are expected to be better reductants of ferrous iron (Wardman 1989). However, it has also been suggested that the main role of the P. placenta methoxyhydroquinone/laccase system is to produce hydrogen peroxide (Wei et al. 2010). Four putative laccases have been found in P. placenta (Martinez et al. 2009; Vanden Wymelenberg et al. 2010). The regulation of cellulases is not known in P. placenta, but in other filamentous fungi, genes encoding cellulases are induced by by-products from the cellulose catabolism, such as sophorose, and in P. placenta, these genes are generally up-regulated during mass loss (Ilmén et al. 1997; Margolles-clark et al. 1997; Ringman et al. 2014b).

Genes encoding alcohol oxidase (Ppl118723), quinone reductase (Ppl124517) and laccase (Ppl111314) were highly expressed in P. placenta growing on acetylated, furfurylated, DMDHEU-treated and thermally modified wood while little or no mass loss was recorded (Alfredsen and Fossdal 2010; Schmöllerl et al. 2011; Pilgård et al. 2012; Ringman et al. 2014a; Alfredsen and Pilgård 2014). Even though durability tests of thermally modified wood have been reported, the dynamics of brown rot degradation has not previously been studied through close monitoring of relevant parameters in thermally modified wood, and therefore, it is not known to what extent decay is initially inhibited, for how long it is inhibited and at which rate degradation occurs once it has started. When comparing expression of genes involved in CMF degradation over time, previous studies have shown higher levels of expression of CMF-related genes in modified wood compared to untreated wood (Alfredsen and Fossdal 2009; Schmöllerl et al. 2011; Pilgård et al. 2012; Ringman et al. 2014b). Furthermore, these measurements were done on samples with little or no mass loss. From the current literature, it is therefore not possible to draw any conclusions on the effect of modification on the gene expression once degradation has started (Alfredsen and Fossdal 2009; Schmöllerl et al. 2011; Pilgård et al. 2012; Ringman et al. 2014b). An obstacle in the research on the brown rot decay resistance of modified wood is the difficulty to measure the amount of CMF degradation.

The aim of this study was to examine the dynamics of P. placenta wood degradation, in terms of mass loss, structural integrity and gene expression, in thermally modified wood and compare it to untreated wood. In particular, incipient decay was studied and the following questions were addressed: (1) Are P. placenta fungi degrading thermally modified wood already from the beginning of exposure but slowly, or is the degradation inhibited for some time? (2) If degradation is inhibited in the beginning of exposure, is it the CMF, the enzymatic degradation or both that are inhibited? (3) Once degradation has started, is it as rapid as in untreated wood?

Materials and methods

Wood material and sample preparation

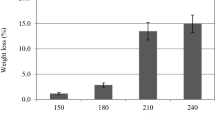

Miniblock specimens (10 × 5 × 25 mm3) (Bravery 1979) were prepared from untreated and thermally modified (tightly wrapped in aluminium foil and heated to 220 °C for 4 h, with a median mass loss of 6.1 % due to the heat treatment) southern yellow pine (Pinus elliotti, Pinus palustris, Pinus echinata, Pinus taeda, Pinus rigida and Pinus serotina) sapwood samples and leached according to EN 84 (1996). The samples were sterilised with gamma radiation and placed two by two with other samples subjected to the same treatment (Junga and Militz 2005) in Petri dishes (90 mm) containing sterile soil and inoculated with P. placenta (strain FPRL 280) liquid culture. Samples were incubated at 22 °C and 70 % RH. Samples exposed to fungi were harvested regularly for a period of up to 126 days or until a mass loss of approximately 25 %. Untreated samples were harvested more frequently than thermally modified samples due to their higher growth rate. At harvest, the mycelia covering the wood samples were manually removed, and the samples were either (1) weighed for moisture content, dried and weighed for mass loss before being subjected to high-energy multiple impact (HEMI) tests or (2) dipped in liquid nitrogen and then frozen at −80 °C, awaiting molecular analysis.

RNA analysis

Samples for RNA analysis were chosen in the range of −0.9 % to 3.2 % mass loss. Wood powder from the frozen samples was produced using a Mixer Mill MM 400 (Retsch GmbH, Haan, Germany) using 1.5-cm steel balls and 30 Hz for 2 min. Total RNA was isolated from the wood samples (four biological replicates), and DNA was removed using the MasterPure™ RNA Purification Kit (Epicenter). RNA from each sample was converted into cDNA using TaqMan Reverse Transcription Reagents (using Oligo d(T)16) (Applied Biosystems) with 10 times the standard dNTP concentration. The samples were subsequently amplified with PCR (Rotor-gene, Qiagen). Real-time PCR (Rotor-gene, Qiagen) was performed on cDNA samples (three technical replicates) using the Rotor-gene SYBRGreen PCR Kit (Qiagen). Primer sequences for target genes and endogenous controls were prepared based on the genomic sequence of P. placenta MAD 698-R (Martinez et al. 2009 and available at http://genome.jgi-psf.org/Pospl1/Pospl1.home.html) and are listed in Table 1. Standard curves were produced, and the original concentration of each gene was calculated. All target genes were normalised to the endogenous control, β-tubulin. Significant differences (p < 0.05) in gene expression were calculated using independent two-sample t tests assuming unequal variances.

High-energy multiple impact (HEMI) tests

Samples were chosen in the range of −0.9 to 10 % mass loss. Three specimens of 10 (axial) × 5 × 10 mm3 were cut from each of the four miniblock samples from untreated and thermally modified wood from each selected time point. The development and optimisation of the HEMI test have been described by Rapp et al. (2006). The following procedure was used: twelve oven-dried HEMI specimens were placed in the bowl of a heavy-impact ball mill, together with one steel ball of 40 mm, three of 12 mm and three of 6 mm diameter. The bowl was shaken for 60 s at a rotary frequency of 23.3 s−1 and a stroke of 12 mm. The fragments of the 12 specimens were fractionated on a slit screen (ISO 5223, 1996, slit width of 1 mm).

The following values were calculated: (1) the degree of integrity (I), which is the ratio of the mass of the 12 biggest fragments to the mass of all fragments after crushing, (2) the fine fraction (F), which is the ratio of the mass of fragments under 1 mm to the mass of all fragments, multiplied by 100, and (3) the resistance to impact milling (RIM), which is calculated from I and F as follows:

The threefold weighting of the fine fraction was according to earlier studies (Rapp et al. 2006) and can finely distinguish between different intensities of fungal decay. To ensure that RIM varies between 0 and 100 %, the constant 300 was added. The calculated value is a mean value of the structural integrity of the four samples that run together (harvested at the same time point).

Results and discussion

Mass loss

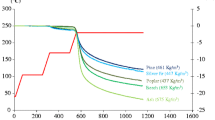

To study the dynamics of degradation in thermally modified wood exposed to P. placenta, mass loss was closely monitored over 126 days. In this paper, any negative deviation in mass compared to the dry weight before fungal exposure is described as mass loss. Mass loss was first detected after 9 days of incubation in untreated wood and after 28 days in thermally modified wood (Fig. 1). Untreated wood reached a mass loss of 20 % after 28 days, whereas thermally modified wood reached 27 % after 126 days. For untreated wood, this is in accordance with previous studies, but for thermally modified wood, the mass loss is dependent on several properties such as wood species, treatment temperature and time and therefore difficult to compare with results in the literature (Esteves and Pereira 2009; Ringman et al. 2014b). Mass loss was negative during the first week of exposure in both materials. This could be due to the fact that a mass loss will not show until the decrease in mass due to degradation becomes larger than the increase in mass due to the fungal colonisation, as shown earlier by Brischke et al. (2008). The standard deviation of mass loss in the thermally modified samples increased with time, which might be due to uneven treatment which becomes more visible the more mass is lost.

If a mass loss curve is plotted logarithmically, it is possible to detect three different stages similar to the phases seen in liquid fungal cultures; in the lag phase, the fungi adapt to the new environment, in the logarithmic phase, the growth rate of the fungi increases logarithmically, and in the stationary phase, the growth rate of the fungi decreases. In this experiment, untreated wood never reached the stationary phase. The mass loss curve for thermally modified wood resembled that of untreated wood, although thermally modified wood had a longer lag phase and a smaller gradient in the logarithmic phase. The results indicate that decay is initially inhibited by thermal modification, and, after degradation started, it has a reduced rate. In a recent review of established theories on mode of action of acetylated, furfurylated, DMDHEU-treated and thermally modified wood, it is suggested that moisture exclusion may inhibit decay for a certain amount of time, while, for example, micropore blocking and enzyme non-recognition might slow down degradation after its initiation (Ringman et al. 2014a).

Moisture content

Moisture content in thermally modified wood remained lower than that in untreated wood throughout the course of the experiment, with moisture contents of 20–40 % up to 15 % mass loss compared to 40–60 % in untreated wood with few exceptions (Fig. 2). The moisture content in untreated wood was significantly higher at 30 % mass loss than at negative mass loss due to an apparent increase in moisture content after approximately 20 % mass loss. Moisture content in thermally modified wood showed a similar trend, but due to large standard deviation there was no significant difference.

Structural integrity

Since CMF degradation causes loss of structural integrity even when mass loss cannot be detected, measurements of structural integrity were taken on exposed samples continuously throughout the experiment. The heat treatment itself decreased RIM by 28 % (Fig. 3), which is similar to previous results by Rapp et al. (2006). In untreated wood, HEMI results in samples with negative mass loss suggest a decrease in structural integrity compared to the zero-time sample (not inoculated with P. placenta, shown as large squares in Fig. 3). Since the presence of fungi was demonstrated by gene expression data (Fig. 4), the detected decrease in RIM could indicate CMF degradation. In thermally modified wood, there may be a slight increase in RIM for the negative mass loss samples, which might be explained by the gluing effect of ingrown mycelium (Brischke et al. 2008). Hence, no conclusion on whether CMF degradation was inhibited or not during incipient exposure of thermally modified wood could be drawn. When using tests of structural integrity, the problem with the gluing effect of the fungi must be considered and has to be overcome in order to use this method to determine the occurrence of CMF degradation. However, the structural integrity measurements of samples with positive mass loss support the findings in the mass loss measurements, since also the structural integrity shows similar patterns in thermally modified and untreated wood when compared at the same mass loss.

Levels of gene expression relative to the endogenous control for a alcohol oxidase Ppl 118723, b laccase Ppl 111314, c quinone oxidoreductase Ppl 124517, d β-glucosidase Ppl 112501, e endo-β-1,4-glucanases Ppl 103675. Black squares thermally modified wood, white squares untreated wood. Median values (n = 4) with error bars representing maximum and minimum values

Gene expression

Gene expression studies were carried out to (1) see whether degradation is inhibited on gene expression level and (2) compare gene expression levels in samples at the same degradation state, measured as mass loss. In general, there was little significance between samples both over time and between treatments at the same mass loss. However, looking at the median values, some trends could be seen (Fig. 4).

In samples with negative mass loss and 3.25 % mass loss, no significant difference in alcohol oxidase (Ppl118723) gene expression could be seen between thermally modified wood and untreated wood. At 1.5 % mass loss, expression of this gene was approximately 10 times lower in two out of three untreated samples than in the thermally modified wood samples, but the third one was as high as the thermally modified wood samples and there was no significance. Looking at the data over time, the trend indicated that alcohol oxidase (Ppl118723) gene expression in thermally modified wood went up while going down in untreated samples, but again there was no significant difference. The level of expression of this gene at negative mass loss was similar to the results for thermally modified wood after 1 week of exposure in Ringman et al. (2014b).

The gene expression of laccase (Ppl111314) was similar both over time and between treatments, no matter if the expression was plotted against mass loss or time, all through the experiment, and no significant differences were found. Expression of laccase (Ppl111314) has not been studied in thermally modified wood at this time of exposure and/or mass loss before.

The median value of expression of quinone reductase (Ppl124517) was 10–100 times higher in thermally modified wood samples than in untreated samples with negative mass loss, but there was no significant difference due to large variation. At 1.5 % mass loss, expression of quinone reductase was only three times as high in thermally modified wood samples as in untreated ones, but this difference was significant. The levels were similar at 3.25 % mass loss, but then there was no significant difference between treatments. The results indicate that the gene expression levels of quinone reductase (Ppl124517) were somewhat higher in thermally modified wood than in untreated wood all through the experiment, but when mass loss started, they were quite similar. The gene expression levels in this experiment were similar to the results in Ringman et al. (2014b), in which elevated quinone reductase (Ppl124517) gene expression could be seen in thermally modified wood after six days of exposure to P. placenta. In Ringman et al. (2014b), the gene expression pattern of quinone reductase (Ppl124517) differed in the differently modified wood materials and from the expression pattern of alcohol oxidase. It was therefore suggested that quinone reductase (Ppl124517) may not be involved in wood degradation. Cohen et al. (2004) showed that the two quinone reductases in G. trabeum are induced by different factors, and therefore, one was suggested to play a role in wood degradation, while the other might be involved in stress response. In the P. placenta genome, only one quinone reductase gene has been found (Martinez et al. 2009). It is therefore possible that the P. placenta quinone reductase is rather involved in stress defence, perhaps caused by the modification. When looking at the gene expression values over time, similar differences in expression patterns can be detected in this study. However, in Ringman et al. (2014b) none of the thermally modified samples showed any mass loss. The role of quinone reductase (Ppl124517) therefore remains to be found out.

β-Glucosidase (Ppl112501) and endoglucanase (Ppl103675) had similar gene expression levels all through the experiment. There were neither significant differences between time points or treatments nor signs of trends. Compared to the results in Ringman et al. (2014b), the expression levels for these genes were approximately 10 times higher in this study.

As shown in Fig. 4, the range of variation in this experiment was large. This could be due to multiple factors. The weight loss was measured on one set of samples and gene expression was measured on another set, because RNA is degraded by heat. This means that it is possible that the weight loss of the gene expression samples was different from that in the weight loss samples and they may have varied within each set. Furthermore, the treatment levels may have differed between samples with the same treatment.

Expression levels of genes involved in wood degradation could also be detected in thermally modified wood, which supports previous studies showing that expression of genes involved in wood degradation is not inhibited by wood modification. However, results from previous studies that defined degradation as a function of time instead indicated that expression of genes involved in CMF degradation was induced by acetylated, furfurylated, DMDHEU-treated and thermally modified wood (Alfredsen and Fossdal 2010; Schmöllerl et al. 2011; Pilgård et al. 2012; Ringman et al. 2014a; Alfredsen and Pilgård 2014). When looking at the gene expression levels in this study as a function of mass loss, there was no significant difference in P. placenta gene expression between thermally modified wood and untreated wood over the mass loss range of −0.9 to 20 %. Therefore, it is suggested that differences seen in previous studies could have been because samples in different degradation stages were compared. In this study, samples with the same mass loss were compared, and the results could indicate that once degradation has started, the fungi degrade thermally modified wood and untreated wood in a similar manner, a finding that is also supported by the analysis of structural integrity. Before mass loss can be detected, there are results that indicate that quinone reductase and laccase may be expressed at higher levels in modified wood than in untreated wood, but in this experiment there were no significant differences at negative mass loss. However, it should be noted that gene expression levels are related to the endogenous control, β-tubulin, that is supposed to but may not be expressed at similar levels in all cells at all times.

In this experiment, only one set of exposed replicates with negative mass loss from each treatment was analysed for gene expression. However, previous studies have shown that P. placenta expresses genes involved in CMF degradation at high levels in modified wood up to 36 weeks without being able to degrade the wood (Alfredsen and Fossdal 2010; Schmöllerl et al. 2011; Pilgård et al. 2012; Ringman et al. 2014b; Alfredsen and Pilgård 2014). This indicates that CMF degradation may hold the answer as to why modified wood resists brown rot fungi.

Conclusion

In this paper, the dynamics of degradation in thermally modified wood was addressed and compared to untreated wood. Mass loss results from this study showed that P. placenta degradation in thermally modified wood is initially inhibited, causing a longer lag phase than in untreated wood. Measurements of structural integrity using HEMI tests could not detect CMF degradation before mass loss was detected in thermally modified wood, probably due to a gluing effect of the fungal mycelia, but there were indications of CMF in untreated wood using this technique. However, more research is needed to confirm the finding and to verify the potential of HEMI as a reliable tool for CMF degradation analysis. Expression of neither genes involved in CMF degradation nor genes involved in enzymatic degradation was inhibited by thermal modification. Once the degradation started, the rate was lower than in untreated wood, but both structural integrity and gene expression showed similar patterns in both materials. This indicates that, once degradation has started, P. placenta uses the same mechanisms for degrading thermally modified wood as for degrading untreated wood. It is concluded that the key to understanding the decay resistance mechanism in thermally modified wood lies in the time from inoculation to detectable mass loss.

References

Alfredsen G, Fossdal CG (2009) Postia placenta gene expression of oxidative and carbohydrate metabolism related genes during growth in furfurylated wood. Document No. IRG/WP 09-10701. The International Research Group on Wood Protection. Stockholm, Sweden

Alfredsen G, Fossdal CG (2010) Postia placenta gene expression during growth in furfurylated wood. Document No. IRG/WP 10–10734. The International Research Group on Wood Protection. Stockholm, Sweden

Alfredsen G, Pilgård A (2014) Postia placenta decay of acetic anhydride modified wood—effect of leaching. Wood Mater Sci Eng 9(3):162–169

Bravery AF (1979) A miniaturised wood-block test for the rapid evaluation of wood preservative fungicides. In: Screening techniques for potential wood preservative chemicals. Proceedings of a special seminar held in association with the 10th annual meeting of the IRG, Peebles 1978. Swedish Wood Preservation Institute Report No. 136. Stockholm

Brischke C, Welzbacher CR, Huckfeldt T (2008) Influence of fungal decay by different basidiomycetes on the structural integrity of Norway spruce wood. Holz Roh Werkst 66:433–438

Cohen R, Jensen KA, Houtman CJ, Hammel KE (2002) Significant levels of extracellular reactive oxygen species produced by brown rot basidiomycetes on cellulose. FEBS Lett 531:483–488

Cohen R, Suzuki MR, Hammel KE (2004) Differential stress-induced regulation of two quinone reductases in the brown rot basidiomycete Gloeophyllum trabeum. Appl Environ Microbiol 70:324–331

Eastwood DC et al (2011) The plant cell wall-decomposing machinery underlies the functional diversity of forest fungi. Science 333(6043):762–765

EN 84 (1996) Wood preservatives—accelerated ageing of treated wood prior to biological testing. Leaching procedure. European Committee for Standardization (CEN), Brussels

Eriksson KEL, Blanchette RA, Ander P (1990) Microbial and enzymatic degradation of wood and wood components. Springer, Berlin

Espejo E, Agosin E (1991) Production and degradation of oxalic acid by brown rot fungi. Appl Environ Microbiol 57:1980–1986

Esteves BM, Pereira HM (2009) Wood modification by heat treatment: a review. BioResources 4:370–404

Goodell B (2003) Brown-rot fungal degradation of wood: our evolving view. In: Goodell B, Nicholas DD, Schultz TP (eds) Wood deterioration and preservation. ACS symposium series, vol 845. American Chemical Society, Washington, pp 9–118

Goodell B, Jellison J, Liu G, Daniel A, Paszcynski F, Fekete S, Krishnamurthy L, Jun L, Xu G (1997) Low molecular weight chelators and phenolic compounds isolated from wood decay fungi and their role in the fungal biodegradation of wood. J Biotechnol 53:133–162

Green F, Clausen CA (2005) Copper tolerance of brown-rot fungi: oxalic acid production in southern pine treated with arsenic-free preservatives. Int Biodeterior Biodegrad 56:75–79

Hakkou M, Petrissans M, Gerardin P, Zoulalian A (2006) Investigations of the reasons for fungal durability of heat-treated beech wood. Polym Degrad Stab 91:393–397

Hastrup ACS, Green F, Lebow PK, Jensen B (2012) Enzymatic oxalic acid regulation correlated with wood degradation in four brown-rot fungi. Int Biodeterior Biodegrad 75:109–114

Hill C (2006) Wood modification: chemical, thermal and other processes. Wiley, Chichester

Hyde SM, Wood PM (1997) A mechanism for production of hydroxyl radicals by the brown-rot fungus Coniophora puteana: Fe(lll) reduction by cellobiose dehydrogenase and Fe(ll) oxidation at a distance from the hyphae. Microbiology 143:259–266

Ilmén M, Saloheimo ANU, Onnela M, Penttilä M (1997) Regulation of cellulase gene expression in the filamentous fungus Trichoderma reesei. Appl Environ Microbiol 63:1298–1306

ISO 5223 (1996) Test sieves for cereals. International Organization for Standardization, Geneve

Jensen KA, Houtman CJ, Ryan ZC, Hammel KE (2001) Pathways for extracellular Fenton chemistry in the brown rot basidiomycete Gloeophyllum trabeum. Appl Environ Microbiol 67:2705–2711

Jensen KA, Ryan ZC, Vanden Wymelenberg A, Cullen D, Hammel KE (2002) An NADH: quinone oxidoreductase active during biodegradation by the brown-rot basidiomycete Gloeophyllum trabeum. Appl Environ Microbiol 68:2699–2703

Junga U, Militz H (2005) Particularities in agar block tests of some modified woods caused by different protection and decay principles. In: Militz H, Hill C (eds) Proceedings of the 2nd European conference on wood modification, Göttingen, Germany, Oct 6–7, pp 354–362

Kerem Z, Jensen KA, Hammel KE (1999) Biodegradative mechanism of the brown rot basidiomycete Gloeophyllum trabeum: evidence for an extracellular hydroquinone-driven Fenton reaction. FEBS Lett 446:49–54

Lekounougou S, Kocaefe D (2013) Bioresistance of thermally modified Populus tremuloides (North American Aspen) wood against four decay fungi. Int Wood Prod J 4:46–51

Lekounougou S, Kocaefe D (2014a) Durability of thermally modified Pinus banksiana (Jack pine) wood against brown and white rot fungi. Int Wood Prod J 5:92–97

Lekounougou S, Kocaefe D (2014b) Impact of thermal modification on bioresistance of North American wood species, Pinus banksiana, Populus tremuloides, and Betula papyrifera, against wood-rotting basidiomycete fungi. Wood Mater Sci Eng 9:67–75

Margolles-Clark E, Ihnen M, Penttilä M (1997) Expression patterns of ten hemicellulase genes of the filamentous fungus Trichoderma reesei on various carbon sources. J Biotechnol 57:167–179

Martinez D et al (2009) Genome, transcriptome, and secretome analysis of wood decay fungus Postia placenta supports unique mechanisms of lignocellulose conversion. Proc Natl Acad Sci USA 106:1954–1959

Militz H (2002) Thermal treatment of wood: European processes and their background. In, Document No. IRG/WP 02–40241. The International Research Group on Wood Protection. Stockholm, Sweden

Mohareb A, Sirmah P, Pétrissans M, Gérardin P (2011) Effect of heat treatment intensity on wood chemical composition and decay durability of Pinus patula. Eur J Wood Prod 70:519–524

Paszczynski A, Crawford R, Funk D, Goodell B (1999) De novo synthesis of 4,5-dimethoxycatechol and 2,5-dimethoxyhydroquinone by the brown rot fungus Gloeophyllum trabeum. Appl Environ Microbiol 65:674–679

Pilgård A, Alfredsen G, Fossdal CG, Long II CJ (2012) The effects of acetylation on the growth of Postia placenta over 36 weeks. Document No. IRG/WP 12–40589. The International Research Group on Wood Protection. Stockholm, Sweden

Qi W, Jellison J (2004) Induction and catalytic properties of an intracellular NADH dependent 1,4-benzoquinone reductase from the brown-rot basidiomycete Gloeophyllum trabeum. Int Biodeterior Biodegrad 54:53–60

Rapp AO, Brischke C, Welzbacher CR (2006) Interrelationship between the severity of heat treatments and sieve fractions after impact ball milling: a mechanical test for quality control of thermally modified wood. Holzforschung 60:64–70

Riley R et al (2014) Extensive sampling of basidiomycete genomes demonstrates inadequacy of the white-rot/brown-rot paradigm for wood decay fungi. Proc Natl Acad Sci USA 111:9923–9928

Ringman R, Pilgård A, Brischke C, Richter K (2014a) Mode of action of brown rot decay resistance in modified wood: a review. Holzforschung 68:239–246

Ringman R, Pilgård A, Richter K (2014b) Effect of wood modification on gene expression during incipient Postia placenta decay. Int Biodeterior Biodegrad 86:86–91

Schmöllerl B, Alfredsen G, Fossdal CG, Westin M, Steitz A (2011) Molecular investigation of Postia placenta growing in modified wood. Document No. IRG/WP 11-10756. The International Research Group on Wood Protection. Stockholm, Sweden

Steenkjær Hastrup AC, Jensen TØ, Jensen B (2013) Detection of iron-chelating and iron-reducing compounds in four brown rot fungi. Holzforschung 67:99–106

Tjeerdsma BF, Boonstra M, Pizzi A, Militz H (1998) Characterisation of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh Werkst 56:149–153

Vanden Wymelenberg A et al (2010) Comparative transcriptome and secretome analysis of wood decay fungi Postia placenta and Phanerochaete chrysosporium. Appl Environ Microbiol 76:3599–3610

Wardman P (1989) Reduction potentials of one-electron couples involving free radicals in aqueous solution. J Phys Chem Ref Data 18:1637–1755

Wei D, Houtman CJ, Kapich AN, Hunt CG, Cullen D, Hammel KE (2010) Laccase and its role in production of extracellular reactive oxygen species during wood decay by the brown rot Basidiomycete Postia placenta. Appl Environ Microbiol 76(7):2091

Acknowledgments

The authors would like to thank Paul-Simon Schroll for his outstanding work in the laboratory. We also gratefully acknowledge financial support from the Swedish Research Council Formas 213-2011-1481.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ringman, R., Pilgård, A., Kölle, M. et al. Effects of thermal modification on Postia placenta wood degradation dynamics: measurements of mass loss, structural integrity and gene expression. Wood Sci Technol 50, 385–397 (2016). https://doi.org/10.1007/s00226-015-0791-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-015-0791-z