Abstract

Viscoelastic thermal compression (VTC) is a type of thermal-hydro-mechanical (THM) processing that requires only a short processing time. THM processing causes some chemical transformations, the nature and extent of hydro-thermolysis depends on the special treatment conditions and the chemical nature of wood species. In the present study, the chemical transformations of the cell wall components and wood extractives during VTC treatment were investigated, and correlation between chemical characterizations and observed property changes was analyzed. For this purpose, the content of extractives and pH values were determined, and FTIR analysis was performed on extractable substances, extract-free wood, holocellulose, α-cellulose and lignin. Two temperatures and two steam exposure times were adopted to determine the influence of processing conditions on chemical characterization of Tsuga heterophylla. The results revealed that THM treatment caused a series of chemical reactions in extractives. Treatment temperature and conditioning time have significant influence on chemical changes of extractives. For all of the VTC treatments used in this study, no significant changes occurred in the lignin and α-cellulose components. The only significant chemical changes occurred in the hemicelluloses, which were primarily reduction of carbonyl and acetyl functional groups. This study also confirmed that the chemical transformation of wood correlates with property changes of VTC wood.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Thermal-hydro-mechanical (THM) processing has been established as an effective modification method to enhance the properties of wood, including improved strength and stiffness, reduced hygroscopicity and improved resistance to biological decay (Hsu et al. 1988; Navi and Sandberg 2012; Militz 2002). Moisture absorption of THM-treated wood in humid condition is often a problem. Various post-treatments combined with steam and heat in the temperature range of 180–240 °C with or without pressure in a sealed (Kutnar et al. 2008a) or open system (Fukuta et al. 2007; Inoue et al. 2008; Gong et al. 2010; Fang et al. 2012a) were exploited to eliminate the thickness recovery of densified wood (Li et al. 2013). A THM technology developed by Fang et al. (2012a)) combined heat and steam in an open system to improve the dimensional stability of densified wood. Fang et al. (2011, 2012b) also combined the THM treatment and oil-heat treatment (OHT) to improve the dimensional stability and enhance the biological decay resistance of densified wood. The viscoelastic thermal compression (VTC) process, which is a type of THM technology, is designed for rapid processing (<20 min) of thin wood lamina (<10 mm). Softening with steam and heat performed in a sealed system was used to improve the dimensional stability. The increased strength and stiffness of VTC densified wood is proportional to the increase in density (Kutnar et al. 2008a; Kamke and Rathi 2009). VTC processing also causes slight mass loss, EMC reduction and darker color (Kamke and Kutnar 2010; Liu et al. 2013). In addition, VTC processing has been reported to significantly reduce the surface energy of wood (more hydrophobic), but adhesive bond performance is equal to or better than that of untreated wood (Jennings et al. 2005, 2006; Kutnar et al. 2008a, b).

In the last decade, many studies have investigated thermal-induced chemical modification of the natural polymeric wood constituents (Nguila et al. 2007; Rumana et al. 2010; Tjeerdsma et al. 1998; Tjeerdsma and Militz 2005; Nuopponen et al. 2004; Tang et al. 2004; Esteves et al. 2008). Hemicelluloses are most heat sensitive, while at higher temperature α-cellulose and lignin are partly depolymerized. However, previously published results were for high temperature exposure for periods of hours, whereas VTC treatment is typically less than 20 min with the last stages of the process consisting of heating and cooling of the wood in direct contact with metal plates. The extent and nature of the chemical changes induced by high temperature and steam exposure during VTC treatment may be different from other wood heat treatment or THM processes.

Aside from the carbohydrate polymers and lignin, wood contains some heterogeneous substances which can be extracted by polar and non-polar solvents (Telmo and Lousada 2011). High-temperature exposure may cause extractives to undergo phase change, migration within the wood and thermal degradation reactions, which may lead to color change and modification of surface chemistry (Nuopponen et al. 2003). At present, few results have been reported on conversion of extractives when wood is exposed to heat and steam, and little information is available on the influence of extractives on the resulting product properties. In this study, the influence of THM processing (specifically VTC processing) on chemical modifications, including cell wall polymer and extractives of western hemlock (Tsuga heterophylla), was investigated. The purpose of the study was to identify some of the fundamental chemical changes that occur to wood during VTC processing that may influence mechanical properties, hygroscopicity, decay resistance, adhesive bonding behavior and other physical properties such as color change and volatile substance release. Chemical changes caused by VTC processing were assessed using Fourier transform infrared (FTIR) spectroscopy analysis of extractives, extract-free wood, holocellulose, α-cellulose and lignin obtained after two stages of the VTC process. Extractions were performed in separate samples using cold water, hot water, 1 % NaOH and an organic solvent (cyclohexane/ethanol). This approach targeted polar and non-polar extractives and provides information about low molecular weight carbohydrates (mainly originating from hemicelluloses), resulting from thermal degradation reactions.

Materials and methods

Preparation of specimens

The study material originated from fast-grown western hemlock (Tsuga heterophylla) that was peeled into veneer using a commercial rotary lathe. The veneer had the dimensions of 600 mm (longitudinal), 240 mm (tangential) and 4.2 mm (radial) with initial moisture content of approximately 45 % when received. The veneer was further cut into test specimens, and assigned to treatments, as shown in Fig. 1. Note that each matched specimen came from the same growth increment in the tree stem. One specimen was used as untreated reference material (control). Another specimen was exposed to a heat and steam treatment (conditioning), and the third specimen was treated with the full VTC process. Note that the VTC process includes conditioning treatment in addition to compression, annealing and cooling steps (Table 1). The specimens were cut to final dimensions (56 by 150 mm) as shown in Fig. 1 prior to treatment.

THM treatment

The VTC process and equipment have been previously described (Kamke and Kutnar 2010; Kamke and Rathi 2011; Liu et al. 2013). In the present study, two temperatures and two steaming duration times were adopted. The processing parameters are shown in Table 1. Four VTC treatments were used, with some specimens removed after the conditioning step and the others receiving the complete VTC process. Four replicates were made for each treatment. First, the wet specimens were dried and pre-compressed at 170 °C (temperature of metal plate surface) for 240 s. Drying was performed in the VTC machine with direct contact between a heated metal plate on one side and a two-layer fine wire screen and metal plate on the other side (Liu et al. 2013). The moisture content of the specimens reached approximately 10 %, and the thickness was reduced to approximately 3 mm. Then, specimens were exposed to saturated steam and high temperature in the sealed VTC chamber with the purpose of softening the specimens. This step is called “conditioning”. The steam pressure was then released during a period of 10 s, after which mechanical force (varies from 4 to 7 MPa depending on the degree of densification and conditioning treatment) was applied perpendicular to the grain for 300 s. The final specimen thickness was controlled by setting the gap between the metal plates, which was the same for all VTC specimens (1.7 mm). Next, the samples were annealed at 200 °C for 180 s and finally cooled until the plate temperature was reduced to 100 °C. The final specimen thickness was maintained throughout the compression, annealing and cooling steps. All specimens, including control specimens, were cut into small pieces and then ground with a rotary knife mill (Wiley). The fine wood dust was separated from the specimens by a sieve screen with 0.5-mm openings. The wood dust was placed in an environment chamber at 65 % relative humidity and 20 °C until equilibrium moisture content was reached.

Extraction with water and determination of pH values

The cold- and hot-water extractions were conducted according to ASTM standard D1110-84(R2007). The weight of wood dust was 2.0000 g, and the amount of distilled water used for extraction was 100 ml. The slurry was allowed to digest for 48 h at a temperature of 25 °C, and 3 h in a boiling water bath, respectively, for the cold- and hot-water extractions. The slurry was filtered by glass filter, which was then dried at 103 °C until the mass was constant to calculate the percentage composition of water extractives. The filtrate was tested for pH (Beckman Series No. 4353).

Extraction with organic solvents

Because of potential hazards associated with the use of benzene, cyclohexane was chosen as an alternative solvent for the determination of organic solvents soluble extractives. The wood dust of the control and treated specimens were extracted with a mixture of cyclohexane and 95 % ethanol (2:1 V/V) by the method described in TAPPI standard T 204 cm-97 (2007). The Soxhlet extraction thimble was filled with 3.000 g of wood dust, submerged in the cyclohexane/95 % ethanol solvent and then heated in an oil bath at 130 °C for 12 h.

Extraction with 1 % NaOH solution

The content of one percent sodium hydroxide soluble materials was measured according to TAPPI T212 om-2002 (2002). The alkali solution (100 mL of 1 % NaOH) and 2.0000 g wood mill were placed in a round-bottom flask. The flask was connected to a reflux condensing tube and then placed in an oil bath maintained at 100 °C for a period of 60 min. After extraction, the slurry was filtered by glass filter and washed by acetic acid and hot water. The glass filter was dried in an oven overnight at 103 °C and cooled in a desiccator and then weighed to the nearest 0.1 mg.

For each type of extraction, the moisture content determination was conducted at the same time in accordance with TAPPI standard T 264 cm-2007. The percent extractive content was calculated based on dry weight of the original sample. All samples were analyzed in duplicate, and average values were recorded.

Preparation of extract-free wood and separation of holocellulose, α-cellulose and lignin

The extract-free wood was prepared by extraction of wood using a mixture of cyclohexane and 95 % ethanol. Holocellulose was separated from the extract-free wood specimens by the chlorite method according to ASTM D1104-56 (1978). α-Cellulose and lignin were separated as described in GB-T 744-2004 (2004) and ASTM D 1106-96 (2007), respectively.

FTIR spectroscopy

Chemical characterization of the extracts, extract-free wood, holocellulose, α-cellulose and lignin were performed by FTIR spectroscopy. Prior to infrared spectra measurement, the water extracts were dried using a vacuum freeze dryer, after which the liquid extracts became a flocculent solid. For organic solvent and 1 % NaOH solution extracts, the liquid extracts were dried in the oven at 103 °C for approximately 2 h. Because of their hydrophilic nature, all samples were stored in a desiccator until analyzed. Each specimen was analyzed after embedding the samples in KBr pellets (1 mg/300 g). For each sample, three KBr pellet specimens were produced, and results revealed consistent spectra. Therefore, only one spectrum was chosen for analysis. The spectra were obtained in a Nicolet Nexus 470 FTIR spectrophotometer with a resolution of 16 cm−1, each with 40 scans, in the range 4,000 and 400 cm−1. The FTIR spectra were auto baseline-corrected and analyzed by software OMNIC 8.0.

Results and discussion

Content of extractives

The percentage of extractive content, based on dry weight, by treatment and process step, is presented in Table 2. Untreated wood contained an average of 2.5, 0.6, 13.3 and 1.9 % extractives soluble in hot water, cold water, 1 % NaOH and organic solvent, respectively.

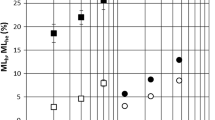

The trends of cold- and hot-water extractives at different temperature (165 and 185 °C) and conditioning duration time (180 and 600 s) during the entire VTC process are shown in Fig. 2a, b. With heating and steaming, the contents of both cold- and hot-water extracts increased, indicating that polymers have been partially degraded into substances which can be recovered by water extraction. It is apparent that the wood contained more water-soluble extractives after conditioning at 165 °C than at 185 °C. This phenomenon appeared for both cold- and hot-water extraction. Exposure time to steam has less impact on water extraction. However, longer exposure time did increase the amount of hot- and cold-water extractives after exposure to steam at 185 °C. During the following stages of compression and annealing, the trends of water extractive content were different at different temperatures. At 165 °C, the water-soluble extractives disappeared, but at 185 °C, the quantity of water-soluble extractives continued to increase up to 11.6 %. This suggests that there is equilibrium between the degradation or volatilization of original extractives and the generation of new extractable compounds. At lower temperature, some existing extractives degraded to volatilizable substances and evaporated into the surroundings, and there was no large amount of newly formed extractives. At higher temperature, the existing extractives evaporated as well but a large amount of new extractable compounds formed as a result of lignin and polysaccharide degradation. Esteves et al. also found an increase in extract content was followed by a decrease when Eucalyptus globulus (Esteves et al. 2008) and Pinus pinaster (Esteves et al. 2011) were submitted to heat treatment.

Cold- (a) and hot-water (b) extractive content, organic (c) and 1 % NaOH (d) extractive content for specimens treated as shown in Table 1; values of control specimens, after conditioning and after complete VTC process are shown

The contents of 1 % NaOH and organic solvent extractives, at different temperature and conditioning duration time applied, during the entire VTC process are shown in Fig. 2c, d. Throughout the progression of the entire VTC treatment, the yield clearly increased for both temperatures. The percentage content of NaOH extractives increased in a maximum value of 25.5 %, and the organic solvent extractives increased in a maximum amount of 7.2 %. The 165 °C/180 s treatment shows very little change from control to conditioning and to complete VTC processing. However, more extractives were recovered by NaOH and organic solvent extraction when the temperature was increased to 185 °C and the conditioning time increased to 600 s.

The increase in extractive content may, in part, give rise to the unique properties of THM-treated wood. For VTC wood, the wood became less hydrophilic, and the EMC at 20 °C and 65 % relative humility decreased. The temperature has significant effect on EMC and higher temperature results in lower EMC (Liu et al. 2013). Increased extractive content may explain decreased EMC at higher temperature because low molecular weight extractives are natural anti-swelling agents which prevent water from entering the void space in the cell wall (Fengel and Wegener 2003). In some wood species, higher extractive content is related to higher decay resistance (Thulasidas and Bhat 2007). However, increased extractives content of VTC-treated poplar wood did not improve decay resistance (Kutnar et al. 2011).

It is well known that heat-treated wood has darker color than untreated wood. During VTC process, the migration of extractives to the surface of wood was perceived. It made the color of VTC wood darker, and higher temperature produced higher amount of extractives and ultimately led to even darker color. It is notable that after extraction, the extract-free wood was still darker than untreated reference, which indicates that the color change of wood polymer also contributes to the darker color of wood specimens. In theory, the move of extracts to the surface during THM treatment would cause difficulties in gluing because low molecular weight wood extractives interfere with the penetration of glue and the curing of the bond line. Furthermore, the simultaneous effects of heat, steam and pressure changed the wood surface structure and surface chemical characteristics, thereby impacting the penetration of the adhesive and adhesion performance (Diouf et al. 2011). However, all previous studies concerned with the bonding properties of VTC-treated wood show that VTC-treated wood has similar or better bond performance than virgin wood (Jennings et al. 2005, 2006; Kutnar et al. 2008a, b). Fang et al. (2012c) investigated the bond performance of densified wood submitted to a type of THM treatment. They found that after THM treatment, adhesion sheer strength was reduced by 27 % compared with untreated wood. This opposite result revealed the fact that the bonding shear strength of THM-treated wood depends on various factors such as the special treatment conditions, various wood species, different compression ratios, disparate adhesive types and test methods and so on.

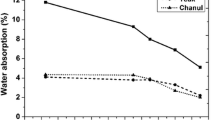

pH values of water extractives

The pH values of water-soluble extracts during VTC processing are displayed in Fig. 3. The pH values of both cold- and hot-water extracts were lower after conditioning, and even lower after VTC treatment, irrespective of the treatment conditions, which is consistent with the thermal degradation and hydrolysis of polyose and extractive compounds in wood. This has been attributed to the formation of carbonic acids, mainly acetic acid as a result of deacetylation during thermolysis, caused by the cleavage of acetyl groups of particular hemicelluloses (Bourgois and Guyonnet 1988; Tjeerdsma and Militz 2005). The released acids further promoted depolymerization of hemicelluloses and amorphous cellulose in the succeeding reactions and led to creation of some low molecular weight extractable compounds (Tjeerdsma et al. 1998; Sivonen et al. 2002; Nuopponen et al. 2004). In addition, the oxidation of some extractive compounds also tends to increase the acidity of wood.

The decrease in pH values during thermolysis tends to be dependent on both the temperature and conditioning duration. Higher temperature and longer conditioning time caused more substantial degradation of wood polymers and extractives.

FTIR spectra of water extractives

By now, GC–MS technique has been widely used to investigate composition changes of wood extractives. However, GC technique can only detect relatively highly volatile ingredients, and preparation of samples is usually laborious. In order to represent the extractives comprehensively and understand the chemical transformations of extractives during THM process, this study employed FTIR technique to characterize bands of certain functional groups and skeletal structures in the extractives. Through analyzing those functional groups, the chemical characterization and transformation of extractives during THM treatment can be deduced. Two treatment conditions, 165 °C/600 s and 185 °C/600 s were used to study the effects of different temperatures.

The FTIR spectra of substances recovered by hot water from western hemlock before and after VTC treatment are shown in Fig. 4. Peak assignments are marked in Fig. 4, and peak interpretations are described in Table 3; (Ajuong and Redington 2004). Comparing control and conditioning-treated counterparts at 185 °C/600 s (spectra “d” and “e”), the intensity of the peak at 3,416 cm−1 increased, indicating increased content of hydroxyl groups, which might result from formation of alcohol compounds by hydrolysis of esters or anhydrides and formation of oligomeric and monomeric sugar units from thermolysis of polysaccharide (mainly hemicelluloses) under the effect of heat and steam (Klauditz and Stegmann 1955; Bobleter and Binder 1980; Carrasco and Roy 1992). The hydrolysis of esters or anhydrides is also supported by the decrease in peaks at 1,065 cm−1, which represent C–O single bond stretching/vibration of saturated ester or non-conjugated straight chain anhydrides. The lower peak intensity at 1,264 cm−1 indicates evaporation of carboxylic acid under the effect of steam and heat. Furthermore, the increased absorbance at 1,653 cm−1 suggests increased C=C double bonds in olefins, which may be a result of dehydration of alcohol groups. Finally, the peak at 1,513 cm−1 represents the backbone of aromatic rings, and reduced intensity at this position may be due to crosslinking within the cell wall or further degradation into other compounds after heat and steam treatment.

FTIR spectra of hot-water extracted compounds from western hemlock, including non-treated, after conditioning, and after full VTC treatment samples, at 165 °C/600 s and 185 °C/600 s; a. 165 °C/600 s, control; b. 165 °C/600 s, after conditioning; c. 165 °C/600 s, after VTC; d. 185 °C/600 s, control; e. 185 °C/600 s, after conditioning; f. 185 °C/600 s, after VTC

Compared with hot-water extracts after conditioning, the intensities of peaks at 3,416 and 1,653 cm−1 slightly increased in spectra of extracts after full VTC treatment at 185 °C/600 s (spectra “e” and “f”). Besides, the intensity of peaks at 1,264 and 1,065 cm−1 increased and is probably due to the production of new carboxylic acid, ester or anhydrides.

Similarly, in FTIR spectra of hot water extractives after conditioning treatment at 165 °C/600 s, the absorbance band at 3,416 and 1,653 cm−1 increased and the absorbance band at 1,513 and 1,264 cm−1 decreased, compared with control (spectra “a” and “b”). However, those changes are less obvious than at 185 °C, and the intensity of the peak at 1,065 cm−1 is almost unchanged which is different from the results of 185 °C treatments. These differences indicate that higher temperature would promote degradation of extracts and polysaccharide and ultimately generate more new compounds which can be extracted by hot water. However, more water-soluble extractive was obtained at 165 °C than at 185 °C after conditioning (Fig. 2). The reason might be that more water-soluble compounds volatilized at 185 °C than at 165 °C.

No significant difference was observed between FTIR spectra of hot-water extracted compounds after conditioning and full VTC treatment (spectra “b” and “c”) at 165 °C/600 s. This suggests that unlike at 185 °C, there was no obvious new substance formation at 165 °C. During compression and annealing stages, the temperature reached 200 °C, and a lot of compounds were likely to evaporate. During 165 °C treatments, most existing extractives evaporated into the surroundings and little new extractable compounds were produced. While at 185 °C, existing extractable compounds evaporated as well but considerable amount of new extractable compounds formed. This is perhaps the reason why the extract amount decreased at 165 °C, whereas it continued to increase at 185 °C during compression, annealing and cooling stages as shown in Fig. 2.

FTIR spectra of 1 % NaOH solvent extractives

FTIR spectra of 1 % NaOH extracted compounds in the region of 400–2,200 cm−1 after 165 °C/600 s and 185 °C/600 s treatments are shown in Fig. 5. Main peaks are marked in the figure, and peak assignments are described in Table 3. Comparing spectra after each step of treatment at 185 °C (spectra “d”, “e” and “f”), the following differences can be observed. (1) The wave number of the peak at 1,439 cm−1 shifted to a lower position after conditioning, which may suggest that carbonyl groups were produced. When a methylene group is next to a carbonyl group, the conjugated effect will cause its peak shift to a lower wave number than usual. After VTC process, this peak turned back to its initial position in the control spectra (spectra “d”). Possible reasons may be that carbonyl groups were converted into other groups or that carbonyl-group-containing compounds evaporated. (2) The intensity of the peak at 1,638 cm−1 increased first and decreased afterward during the entire VTC process. The reason may be that double bonds were produced by dehydration of alcohol groups during the conditioning step, as mentioned in the water extracts section, and then double bonds containing compounds evaporated. (3) Intensity of peaks at 1,596 cm−1 increased after each step of the treatment, which is possibly due to the formation of aromatic substances, and breakdown of lignin may be one of the reasons. (4) A new peak at 1,300 cm−1 appeared after VTC treatment, suggesting that carboxylic acid was generated as a result of VTC treatment due to oxidation of aldehydes or hydrolysis of esters. (5) Conditioning caused increase in peak intensity at 1,021 cm−1, suggesting increased primary alcohols as a result of hydrolysis of ester and/or hemicelluloses. The 1,021 cm−1 peak after the VTC process was lower than that after conditioning, possibly because the primary alcohols evaporated or alternatively were converted to other function groups.

FTIR spectrum of 1 % NaOH extracted compounds from western hemlock, including non-treated, after conditioning, and after full VTC treatment samples, at 165 °C/600 s and 185 °C/600 s; a. 165 °C/600 s, control; b. 165 °C/600 s, after conditioning; c. 165 °C/600 s, after VTC; d. 185 °C/600 s, control; e. 185 °C/600 s, after conditioning; f. 185 °C/600 s, after VTC

The spectra of NaOH extracts at different temperatures again proved that the temperature has an important effect on chemical transformations of extracts during the VTC process. The trends of changes in peak intensity at 165 °C (spectra “a”, “b” and “c”) have huge differences from 185 °C. First, peaks of 1,638 and 1,021 cm−1 were almost unaltered or only slightly altered after full VTC treatment, compared to conditioning. Second, there is no wave number shift at near 1439 cm−1 during the whole VTC treatment. Third, the intensity of the peak at 1,596 cm−1 increased first and decreased afterward during the entire VTC process. Finally, no new peak at 1300 cm−1 showed up after the VTC process. Overall, there was less carbonyl group and carboxylic acid formation, and there was a smaller amount of aromatics produced at 165 °C compared to 185 °C. Probably that is why higher amount of NaOH extracts were generated at 185 °C than at 165 °C during the VTC process.

FTIR spectra of organic solvent extractives

Figure 6 shows the FTIR spectra of organic solvent extracts. Peak assignments are described in Table 3. After conditioning and VTC treatment, peak intensity at 3,431 cm−1 increased due to ester hydrolysis or thermolysis of polysaccharide. Intensities at 1,727 and 1,032 cm−1 were also increased, representing carboxyl groups and primary alcohols, respectively, indicating hydrolysis of ester and production of carboxyl acids and alcohols. There was also an increase in peak intensity at 1,601 and 1509 cm−1, suggesting that more aromatic compounds in extractives appeared after treatment. VTC treatment also affected peak intensity at 2,925 and 2,854 cm−1, which represent methylene groups. Considering methylene groups commonly existing in compounds ever found in western hemlock extractives, it is hard to attribute them to specific molecules. However, they may be an indicator of the amount of aliphatic chains.

FTIR spectrum of organic solvent extracts from western hemlock, including non-treated, after conditioning, and after full VTC treatment samples, at 165 °C/600 s and 185 °C/600 s; a. 165 °C/600 s, control; b. 165 °C/600 s, after conditioning; c. 165 °C/600 s, after VTC; d. 185 °C/600 s, control; e. 185 °C/600 s, after conditioning; f. 185 °C/600 s, after VTC

Spectra of organic solvent extracted compounds from 185 °C treated samples are shown in Fig. 6 (spectra “d”, “e” and “f”). Similarly, VTC modification resulted in higher absorbance at 3,431 and 1,032 cm−1, and the alteration was more obvious than that at 165 °C, suggesting that higher temperature would prominently enhance ester hydrolysis and thermolysis of polysaccharide. Intensity of peaks at 1,727 cm−1 was slightly decreased by VTC treatment, indicating minus decline of carboxyl acid, which might be a result of evaporation at higher temperature. VTC treatment of 185 °C significantly increased the peak intensity at 1,601 cm−1, indicating more aromatic compounds, which, as mentioned above, may come from the breaking down of large molecules such as lignin. Overall, higher temperature promoted ester hydrolysis, thermolysis of polysaccharide and production of aromatics compounds. This may explain why more organic solvent extractives were produced at 185 °C than at 165 °C during the VTC process.

FTIR characterization of wood

The present study also employed FTIR technique to investigate chemical reactions of wood cell wall substance during THM treatment. The FTIR spectra of extract-free wood, holocellulose, α-cellulose and lignin of non-treated samples, after conditioning, and after full VTC treatment at 185 °C/600 s in the finger print region of 1,800–600 cm−1, are shown in Fig. 7. After the treatments, FTIR spectra of extract-free wood (Fig. 7A) show strong decrease in absorption at 1,740 cm−1. The peak at 1,740 cm−1 is caused by ester carbonyl groups and is a characteristic of hemicelluloses, considering that polysaccharides of hemicelluloses (mainly xylans) are attached by ferulic, acetyl and uronic ester groups (Ma et al. 2012). The intensity of such a peak is diminished by conditioning and VTC treatment, suggesting cleavage of ester groups associated with decomposition of polysaccharides. The intensity of the carbonyl peak (1,740 cm−1) of VTC-treated wood at moderate temperature (165 °C) was unaltered compared with the carbonyl peak of non-treated wood (data not shown). However, considerable diminishment of the carbonyl peak in VTC-treated wood at 185 °C was observed (Fig. 7A). This observation further confirmed the strong influence of temperature on pH of extracts (Fig. 3) which is also an indication of carboxyl acid formation due to thermal degradation (Hill 2006; Windeisen et al. 2008).

FTIR spectra of extract-free wood, holocellulose, α-cellulose and lignin of non-treated (a), after conditioning (b), and after full VTC treatment (c) samples of hemlock at 185 °C and 600 s. A FTIR spectra of extract-free wood, B FTIR spectra of holocellulose, C FTIR spectra of α-cellulose, D FTIR spectra of lignin

The absorbance in the region from 1,200 to 900 cm−1, which is characteristic for the polysaccharide region (Faix 1991; Naumann et al. 1991), was strongly diminished. This revealed that polysaccharose was degraded (Tang et al. 2004). The peak at 1,510 cm−1 suggests existence of aromatic rings and may come from lignins and/or ferulic ester groups on hemicelluloses. Peaks at 1,266 cm−1 may come from guaiacyl units in lignin, as well as C–O stretching of esters on hemicelluloses polysaccharides. Those two peaks were slightly reduced during treatments. Lignin modification might be a possible reason (Windeisen et al. 2008). However, considering that lignin was largely intact (Fig. 7D), reductions of those peaks are more likely a result of hydrolysis of ferulic esters and other ester groups from hemicelluloses during treatments. Tjeerdsma and Militz (2005) also determined the chemical transformations of wood polymer during hydrothermal treatment of wood using FTIR technology, and a noticeable increase in the carbonyl peak (1,740 cm−1) was apparent. It was suggested that esterification reactions may have occurred due to a newly formed lignin complex (Diouf et al. 2011). In this study, this phenomenon was not observed because different types of THM treatment were employed.

In Fig. 7B, C, the FTIR spectra of holocellulose and α-cellulose before and after each treatment are shown. As expected, FTIR spectra of holocellulose exhibit absence of the aromatic peak at 1,510 cm−1 in comparison with extract-free wood, and the FTIR spectra of α-cellulose exhibit absence of the carbonyl functional peak at 1,735 cm−1 in comparison to holocellulose. VTC treatments caused changes at 1,735, 1,374 and 1,062 cm−1 in spectra of holocellulose, compared with untreated samples. The decrease in 1,735 cm−1 peak was supposed to be caused by cleavage of ester carbonyl groups associated with polysaccharides. The peaks at 1,374 and 1,062 cm−1 are from C–O stretching in primary and secondary alcohols in polysaccharides. Increases of these peaks suggest more alcohol groups were formed. Ester hydrolysis may be one of the reasons. Spectra of α-cellulose are unchanged by treatments. Those results indicate that hemicelluloses were predominantly involved in thermolysis, and α-cellulose is almost unaffected, as one would expect from previous research (Tjeerdsma et al. 1998). This result is fortuitous because structural integrity of VTC wood is dependent on ability of α-cellulose to withstand the treatment process.

In Fig. 7D, the FTIR spectra of lignin are shown. Comparing spectra of lignin with spectra of extract-free wood, the bands of the carbonyl peak (1,740 cm−1) and β-glycosidic bond (895 cm−1) disappeared. FTIR spectra of lignin have strong peaks at 1,608 and 1,504 cm−1, which are signs of aromatic rings and peaks at 1,267 and 1,214 cm−1,which come from C–O, C=O and C–C stretching in guaiacyl units. Peaks at 1,137 and 866 cm−1 are supposed to be caused by C–H vibration within guaiacyl units and C–H bending of aromatic rings (Kline et al. 2010). Those peaks are characteristic for lignin and are absent in spectra of holocellulose and α-cellulose. No apparent changes in FTIR spectra of lignin were caused by VTC process steps in the range 1,800–600 cm−1, which suggest that lignin was largely unaffected by the conditions used in the VTC process.

Conclusion

Conditioning time had a significant impact on the liberation of water-soluble extractives. However, higher temperature in the range from 165 to 185 °C had a greater impact than conditioning time in the range from 180 to 600 s. At 165 °C, the later steps in the VTC process reduced the amount of water-soluble extractives, while 185 °C liberated more. There was a lower concentration of non-polar extractives than polar extractives, and the non-polar extractives increased in concentration with each step of the VTC process. Extraction with 1 % NaOH revealed less stability of the polysaccharides at 185 °C compared with 165 °C, with little influence of conditioning time.

As expected, the wood became more acidic after heat and steam exposure. The decrease in pH values during thermolysis tends to be dependent on both the temperature and conditioning duration. While the identities of the acidic extractive compounds are unknown, FTIR results showed a reduction of acetyl groups in VTC wood, which is consistent with thermal decomposition of hemicelluloses.

THM treatment caused a series of chemical reactions in extractives, among which ester hydrolysis, thermolysis of polysaccharide, dehydration of alcohol, crosslinking reactions within the cell wall and breaking down of aromatic ring containing large molecules seem to be the most prominent ones. A consequence of these reactions was the production of new extractable substances such as alcohol, carboxylic acid, monosaccharide and aromatic compounds. At the same time, some extractable substances evaporated or decomposed. The temperature influenced the concentration of functional groups in the extractives. Higher temperature caused a greater degree of volatilization. But higher temperature caused more yield of 1 %NaOH and organic solvent extractable compounds because more new extracts were generated.

The chemical characterization and transformation of extractives correlate closely with the property changes of THM-treated wood. Extractives underwent chemical changes and migrated to the surface, and subsequently changed the color and surface properties of wood, but did not weaken its bond performance. Larger amount of extractive content may contribute to lower EMC. The thermal degradation of polysaccharides and extractable compounds caused the release of some volatile materials, such as polycyclic aromatic hydrocarbons (Tjeerdsma et al. 1998; Kamdem et al. 2000), and they may give THM-treated wood persistent odor and cause mass loss.

For all of the VTC treatments used in this study, no significant changes occurred in the lignin and α-cellulose components. The only significant chemical changes occurred in the hemicelluloses, which were primarily reduction of ester carbonyl functional groups. The unaffected cellulose and lignin ensured the high strength of VTC wood, and the degradation of hemicelluloses reduces hydrophilicity of wood.

The results may be used to modify the VTC schedule to promote or retard chemical modifications to the wood with the goal of improving water resistance or dimensional stabilization with efficient use of energy and processing time. In this regard, more control over chemical change can be obtained with saturated steam at 185 °C than at 165 °C, and duration of exposure, up to 600 s, has secondary importance.

References

Ajuong E-MA, Redington M (2004) Fourier transform infrared analyses of bog and modern oak wood (Quercuspetraea) extractives. Wood Sci Technol 38:181–190

ASTM D1104-56 (1978) Method of test for holocellulose in wood (Withdrawn 1985)

ASTM D 1106-96 (2007) Standard test method for acid-insoluble lignin in wood

ASTM D1110-84 (2007) Standard test methods for water solubility of wood

Bobleter O, Binder H (1980) Dynamischer hydrothermaler Abbau von Holz. Holzforschung 34:48–51

Bourgois J, Guyonnet R (1988) Characterization and analysis of torrified wood. Wood Sci Technol 22:143–155

Carrasco F, Roy C (1992) Kinetic study of dilute-acid prehydrolysis of xylan-containing biomass. Wood Sci Technol 26:189–208

Diouf PN, Stevanovic T, Cloutier A, Fang CH, Blanchet P, Koubaa A, Mariotti N (2011) Effects of thermo-hygro-mechanical densification on the surface characteristics of trembling aspen and hybrid poplar wood veneers. Appl Surf Sci 257:3558–3564

Esteves B, Graca J, Pereira H (2008) Extractive composition and summative chemical analysis of thermally treated eucalypt wood. Holzforschung 62:344–351

Esteves B, Videria R, Pereira H (2011) Chemistry and ecotoxicity of heat-treated pine wood extractives. Wood Sci Technol 45:661–676

Faix O (1991) Classification of lignins from different botanical origins by FTIR spectroscopy. Holzforschung 45:21–27

Fang CH, Cloutier A, Blanchet P, Koubaa A, Mariotti N (2011) Densification of wood veneers combined with oil-heat treatment. Part I: Dimensional stability. BioResources 6(1):373–385

Fang CH, Mariotti N, Cloutier A, Koubaa A, Blanchet P (2012a) Densification of wood veneers by compression combined with heat and steam. Eur J Wood Prod 70:155–163

Fang CH, Cloutier A, Blanchet P, Koubaa A (2012b) Densification of wood veneers combined with oil-heat treatment. Part II: hygroscopicity and mechanical properties. BioResources 7(1):925–935

Fang CH, Blanchet P, Cloutier A, Barbuta C (2012c) Engineered wood flooring with densified surface layer for heavy-duty use. BioResources 7(4):5843–5854

Fengel D, Wegener G (2003) Wood chemistry, ultrastructure, reactions. Oberwinter: Verl. Kessel

Fukuta S, Takasu Y, Sasaki Y, Hirashima Y (2007) Compressive deformation process of Japanese cedar (Cryptomeria japonica). Wood Fiber Sci 39(4):548–555

GB-T 744-2004 (2004) Pulps-determination of α-cellulose

Gong M, Lamason C, Li L (2010) Interactive effect of surface densification and post-heat-treatment on aspen wood. J Mater Process Technol 210(2):293–296

Hill CAS (2006) Wood modification: chemical, thermal and other processes. In: Stevens C (ed), John Wiley & Sons Ltd., Chichester

Hsu WE, Schwald W, Schwald J, Shields JA (1988) Chemical and physical changes required for producing dimensionally stable wood-based composites. Wood Sci Technol 22:281–289

Inoue M, Sekino N, Morooka T, Rowell RM, Norimoto M (2008) Fixation of compressive deformation in wood by pre-steaming. J Trop Forest Sci 20(4):273–281

Jennings JD, Zink-Sharp A, Kamke FA, Frazier CE (2005) Properties of compression densified wood. Part 1: bond performance. J Adh Sci Tech 19(13–14):1249–1261

Jennings JD, Zink-Sharp A, Frazier CE, Kamke FA (2006) Properties of compression densified wood. Part 2: surface energy. J Adh Sci Tech 20(4):335–344

Kamdem P, Pizzi A, Triboulot MC (2000) Heat treated timber potentially toxic side products presence and wood cell wall degradation. Holz RohWerkst 58:253–257

Kamke FA, Kutnar A (2010) Transverse compression behavior of wood in saturated steam at 150–170°C. Wood Fiber Sci 42(3):377–387

Kamke FA, Rathi VM (2009) Modified hybrid poplar for structural composites//4th European Conference on Wood Modification. Stockholm, Sweden, April 27–29, 2009. pp 397–400

Kamke FA, Rathi VM (2011) Apparatus for viscoelastic thermal compression of wood. Eur J Wood Prod 69(3):483–487

Klauditz W, Stegmann G (1955) Beiträgezur kenntnis des ab-laufes und der wirkungthermischer reaktionenbei der bil-dung von holzwerkstoffen. Holz Roh-Werkst 13:434–440

Kline LM, Hayes DG, Womac AR, Labbé N (2010) Simplified determination of lignin content in hard and soft woods via UV-spectrophotometric analysis of biomass dissolved in ionic liquids. BioResources 5(3):1366–1383

Kutnar A, Kamke FA, Sernek M (2008a) The mechanical properties of densified VTC wood relevant for structural composites. Holz Roh Werkst 66(6):439–446

Kutnar A, Kamke FA, Petrič M, Sernek M (2008b) The influence of viscoelastic thermal compression on the chemistry and surface energetics of wood. Colloids Surf A: Physicochem Eng Aspects 329:82–86

Kutnar A, Humar M, Kamke KA, Sernek M (2011) Fungal decay of viscoelastic thermal compressed (VTC) wood. Eur J Wood Prod 69:325–328

Li L, Gong M, Yuan N, Li D (2013) An optimal thermo-hydro-mechanical densification (THM) process for densifying balsam fir wood. BioResources 8(3):3967–3981

Liu H, Kamke FA, Guo K (2013) Integrated drying and thermo-hydro-mechanical modification of western hemlock veneer. Eur J Wood Prod 71:173–181

Ma GM, Jia N, Zhu JF, Li SM, Peng F, Sun RC (2012) Isolation and characterization of hemicelluloses extracted by hydrothermal pretreatment. Bioresour Technol 114:677–683

Militz H (2002) Heat treatment technologies in Europe: scientific background and technological state of art. In: Enhancing the durability of lumber and engineered wood products, FPS/Madison US, Conference, Florida, pp 11–13

Naumann D, Labischinski H, Giesbrecht P (1991) The characterization of microorganisms by Fourier transform infrared spectroscopy (FTIR). In: Nelson WH (ed) Modern techniques for rapid microbiological analysis. VCH, New York, pp 43–96

Navi P, Sandberg D (2012) Thermo-hydro-mechanical processing of wood. EPFL Press, Lausanne, Switzerland, p 376

Nguila IG, Petrissans M, Gerardin P (2007) Chemical reactivity of heat-treated wood. Wood Sci Technol 41:157–168

Nuopponen M, Vuorinen T, Jämsä S, Viitaniemi P (2003) The effects of a heat treatment on the behaviour of extractives in softwood studied by FTIR spectroscopic methods. Wood Sci Technol 37:109–115

Nuopponen M, Vuorinen T, Jamsä S, Viitaniemi P (2004) Thermal modifications in softwood studied by FT-IR and UV resonance Raman spectroscopies. J Wood Chem Technol 24:13–26

TAPPI T212 om-2002 (2002) One percent sodium hydroxide solubility of wood and pulp

TAPPI T264 cm-2007 (2007) Preparation of wood for chemical analysis

TAPPI T204 cm-97 (2007) Solvent extractives of wood and pulp

Rumana R, Rosemarie LH, Reiner F, Andrea P (2010) FTIR spectroscopy, chemical and histochemical characterisation of wood and lignin of five tropical timber wood species of the family of Dipterocarpaceae. Wood Sci Technol 44:225–242

Sivonen H, Maunu S, Sundholm F, Jämsa S, Viitaniemi P (2002) Magnetic resonance studies of thermally modified wood. Holzforschung 56:648–654

Tang X, Zhao G, Nakao T (2004) Changes of chemical composition and crystalline of compressed chinese fir wood in heating fixation. For Stud China 6(4):39–44

Telmo C, Lousada J (2011) The explained variation by lignin and extractive contents on higher heating value of wood. Biomass Bioenergy 35:1663–1667

Thulasidas PK, Bhat KM (2007) Chemical extractive compounds determining the brown-rot decay resistance of teakwood. Holz Roh Werkst 65:121–124

Tjeerdsma BF, Militz H (2005) Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood. Holz Roh- Werkst 63:102–111

Tjeerdsma BF, Boonastra M, Pizzi A, Tekely P, Militz H (1998) Characterization of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh Werkst 56:149–153

Windeisen E, Bächle H, Zimmer B, Wegener G (2008) Relations between chemical changes and mechanical properties of thermally treated wood. 10th EWLP, Stockholm, Sweden, August 25–28, pp 773–778

Acknowledgments

The authors are grateful for the funding support from the State Scholarship Fund from China Scholarship Council (CSC) and Oregon Built Environment and Sustainable Technology Center, Oregon State University (Corvallis, OR, USA). Technical assistance from Chuan Li, Darrell Lowe, Jesse Paris and Adam Scouse is appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, H., Shang, J., Chen, X. et al. The influence of thermal-hydro-mechanical processing on chemical characterization of Tsuga heterophylla . Wood Sci Technol 48, 373–392 (2014). https://doi.org/10.1007/s00226-013-0608-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-013-0608-x