Abstract

The investigation of genetically modified trees requires rapid and reliable techniques to measure the mechanical properties at an early age in order to give timely feedback to forest geneticists. In this study, transmittance near-infrared (NIR) spectroscopy was used to predict the green mechanical properties of 1- and 2-year-old transgenic and wild-type aspen. Green modulus of elasticity (MOE) in three-point bending and green ultimate compression strength (UCS) parallel to the grain were predicted from the NIR spectra of dry wood meal pellets. Green UCS had strong correlation (R 2 = 0.91) and green MOE had good correlation (R 2 = 0.78) with the spectra. The latter could be explained by the moderate correlation of MOE with the lignin content of the transgenic samples, suggesting that besides chemical composition MOE also depends on anatomical properties. The ratio of performance to deviation value suggested that the calibration model of both UCS (2.94) and MOE (1.91) could be used for screening.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The high cost associated with the removal of lignin from wood is a significant obstacle to the optimization of pulp and bio-fuel production. Lignin content and structure could be changed using genetic engineering (Hu et al. 1999; Chiang 2006). However, the altered chemistry can affect the mechanical properties of wood (Horvath et al. 2010; Koehler and Telewski 2006), which need to be investigated at an early age of transgenic trees in order to fully utilize this genetic modification.

Near-infrared (NIR) spectroscopy is a powerful tool for measuring the chemical and mechanical properties of wood. In addition to being a very rapid technique, NIR also allows for measurement of the mechanical properties using a small amount of material. Other advantages of NIR are that it is cost-effective, nondestructive, and requires minimal sample preparation. NIR spectroscopy measures the absorbance of near-infrared light (780–2,500 nm) and uses it to acquire chemical and physical information about the sample. The main parts of the near-infrared spectra are the overtone of the spectra and combination bands of fundamental stretching vibrations of the O–H, N–H and C–H functional groups observed in the mid-infrared region (Schimleck et al. 2001).

Two types of NIR spectroscopy have been mainly used by various authors: diffuse reflectance spectroscopy (Schimleck et al. 2005a; Bailleres et al. 2002) and reflectance spectroscopy (Hoffmeyer and Pedersen 1995; Kelley et al. 2004; Poke and Raymond 2006). One of the advantages of reflectance spectroscopy is the less time-consuming sample preparation. However, the accuracy of the reflectance spectroscopy may be lower than other spectroscopy techniques due to light scattering and surface effects (Hoffmeyer and Pedersen 1995). In the last few years, transmittance spectroscopy has been used in numerous studies (Yamada et al. 2006; Yeh et al. 2005) due to its accuracy and the small amount of sample required.

To improve the quality of the predictions of NIR spectroscopy, the spectra can be preprocessed to minimize spectra artifacts. There are several preprocessing techniques but the most frequently used technique is the second derivative mode of the spectra (Schimleck et al. 2001; Yeh et al. 2005; Yamada et al. 2006). However, Kelley et al. (2004) published strong correlations without using any preprocessing techniques.

Reduced near-infrared spectral range (650–1,159 nm) was utilized by Kelley et al. (2004) to allow field measurement using handheld NIR spectrometers. The reduced spectral range slightly decreased the quality of the calibration. However, the strength of the correlation between the reduced spectral range and the chemistry, mechanical properties, and the microfibril angle (MFA) remained significant.

Lignin content and the syringyl/guaiacyl (S/G) ratio were investigated and found to be strongly correlated with the NIR spectra using wood meal pellets (Yeh et al. 2005; Yamada et al. 2006), ground wood powder (Bailleres et al. 2002), as well as solid wood samples (Bailleres et al. 2002; Poke and Raymond 2006; Kelley et al. 2004). Several physical and mechanical properties of wood samples were correlated with NIR spectra for Eucalyptus globulus, Pinus radiata D. Don, and Pinus taeda (Schimleck et al. 2001, 2002b, 2005b; Kelley et al. 2004) and strong correlation was found between the spectra and the modulus of elasticity (MOE), modulus of rupture (MOR) in bending, and ultimate compression strength (UCS).

Transgenic materials give a unique opportunity to test the NIR technique on young trees with a wide range of chemical composition without the bias associated with different environmental conditions and species-specific characteristics. Poplar is the model tree species for genetic modification because its genome has been completely mapped, is easy to propagate, fast growing, and widely distributed in the United States. The chemical composition of transgenic aspen has been successfully correlated with transmittance NIR (Yamada et al. 2006) but the mechanical properties of 1- and 2-year-old aspen trees have not been investigated by NIR spectroscopy due to the difficulties of measuring the mechanical properties of young trees with small diameter.

The main objective of this study is to investigate the application of NIR spectroscopy to predict the mechanical properties of 1- and 2-year-old transgenic aspen trees with reduced lignin content and/or increased S/G ratio. The specific objective of the study is to analyze the relationship between the lignin content and the mechanical properties of transgenic aspen using the regression coefficients of samples.

Materials and methods

One- and 2-year-old quaking aspen (Populus tremuloides Michx.) clones were investigated, including a wild-type aspen (PtrWT) and transgenic lines with reduced lignin content (Ptr4CL), increased S/G ratio (PtrCAld5H), and both reduced lignin content and increased S/G ratio (Ptr4CL/CAld5H) (Li et al. 2003). The trees were grown in a controlled environment in a greenhouse at North Carolina State University. Seventy stems were harvested to test the mechanical properties. The average stem diameter of the sample trees including the bark varied between 7.2 and 10.0 mm. Each stem was debarked and divided into 250-mm sections along the length. The sections were cut to produce specimens with a length:diameter ratio of 15, with 10 mm overhang at each end. The specimens were kept at the green condition throughout the test. To maintain the moisture content and to prevent fungal decay, the specimens were kept in plastic bags and were placed in a freezer. The bags were removed from the freezer 2 h prior to the mechanical test and specimens were removed from the plastic bags just before the test.

Three-point bending test

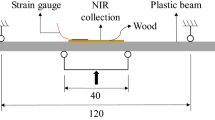

Modulus of elasticity (MOE) was obtained using a modified micro-mechanical three-point bending test (Kasal et al. 2007). Fixed rollers were used to support the specimens during the test. The diameter that was in line with the load was measured at the specimen midlength using a digital caliper. The specimen was loaded at midlength with a bearing block that was specifically designed to avoid surface crushing (Fig. 1).

An MTS Alliance RF/300 mechanical testing machine with a computerized data acquisition system (MTS Testworks 4) was used at a loading speed of 1.27 mm min−1. The load was measured by an OMEGA LC111-250 (1,100 N) load cell and the deflection of the specimen was based on crosshead movement. One specimen was loaded until failure to determine the proportional limit on the load–deflection diagram. The rest of the specimens were loaded to 50% of the proportional limit. To calculate the MOE, the following equation was used.

where S is the slope of the linear segment of the load–deflection diagram, L is the span between the two supports, D is the diameter of the specimen at midlength, and d p is the average diameter of the pith of the two ends of the specimen.

The MOE values of the stem sections were averaged by sample tree within each transgenic line and these values were used to build the NIR calibration.

Compression parallel to the grain

Compression specimens were cut from the straightest portion of the same specimens used in the bending test. To prevent buckling, the length of the specimens was cut with a circular saw to keep the length:diameter ratio around 3. The same mechanical testing machine described previously was used at a loading speed of 0.4 mm min−1. The load was recorded by an OMEGA LC101-2k (9,000 N) load cell and the deflection of the specimen was based on crosshead movement. The load was applied to the surface of the specimen by a fixed loadhead. The specimens were loaded until maximum compression load was reached. To calculate the ultimate compression strength, circular cross sections of the specimens were assumed. The pith was deducted from this cross-sectional area, assuming that the pith and the surrounding wood are concentric circles. The UCS was calculated based on the load at failure and the cross-sectional area without the pith (Kasal et al. 2007).

The maximum UCS values of the stem sections were averaged by sample tree within each transgenic line and these values were used to build the NIR calibration.

Near-infrared spectroscopy

Specimens from the compression test were used for NIR spectroscopic analysis. A total of 70 specimens were analyzed: 11 specimens of the wild-type aspen, 26 specimens with reduced lignin content, 15 specimens with increased S/G ratio, and 18 specimens with increased S/G ratio and decreased lignin content. The specimens were ground into powder through an 80-mesh screen using a Wiley mini mill. A 100 mg yield was obtained from the grinding of the 20 mm long compression specimen. The extractives were removed from the ground wood using the method described in TAPPI T 264 om-94 (1994). The powdered samples were dried at 105°C for 24 h and were pressed into 75 ± 0.5 mg (oven-dry weight) pellets with diameter of 13 mm. The average thickness of the pellets was 0.49 mm with a coefficient of variation of 3.5%. The wood pellets were conditioned in a desiccator under P2O5 for at least 48 h (Yamada et al. 2006).

The pellets were analyzed using transmittance Foss NIRSystems NIR spectrometer equipped with an InTact Single Tablet Module (NIR- and monochromator NR-6500-V/H). Thirty-two transmittance scans were collected for each pellet and averaged at 2.0 nm interval over the 600- to 1,900-nm wavelength range.

NIR calibration development

The Unscrambler 9.7 software was used to conduct the analysis. The second derivative of the spectra was calculated using the gap–segment method (gap = 0 nm, segment = 10 nm). The score plots of principal component analysis (PCA), partial least squares (PLS) regression, and the residual-leverage plot were used to identify six outliers that were removed from the analyses. Partial least squares (PLS) regression was used to build the calibration model. The calibration model was tested using external validation, where 20 samples were left out of the calibration process and used to validate the calibration model. The difference between the measured and predicted values was averaged to produce the root mean square error of calibration (RMSEC) and the root mean square error of prediction (RMSEP). The number of PLS factors was determined using the lowest RMSEP number. The calculation of RMSEP is provided in the following equation.

where n is the number of samples, e i is the residual of the predicted property of interest. The RMSEP provides an estimate of prediction accuracy. If the samples to be used for future prediction were similar to the ones used in the calibration, the prediction error will be ±2RMSEP.

The coefficient of determination (R 2), the standard error of calibration (SEC), and the standard error of prediction (SEP) were also used to evaluate the performance of the calibration model. The R 2 is the proportion of the variability of the property of interest that is explained by the calibration model. The SEC measures how well the calibration fits the data and the SEP evaluates how well the calibration predicts the constituents of interest for a set of samples.

The ratio of performance to deviation (RPD) value was also calculated to get more information about the performance of the model. The RPD is the ratio of the standard deviation of the original data and the SEP. If the ratio is below two, the model cannot provide an adequate prediction. A model with RDP value between two and three can be used for rough screening, between three and five for screening, between five and eight for quality control analysis, and above eight for analytical purposes (Bailleres et al. 2002).

An uncertainty test with full cross validation was used to find the significant wavelength using all of the 64 samples (Esbensen 2002). In the uncertainty test, the mean regression coefficient and the uncertainty limit for all wavelengths were calculated. The regression coefficient is a numerical coefficient that creates a link between the predictor (wavelength) and the response (property of interest). When one sample is predicted, the remaining samples are used to create regression coefficients for each variable. Since every sample is predicted once, the number of created regression coefficients for each wavelength is equal to the number of samples. Afterward, the mean regression coefficient is calculated for each wavelength. The uncertainty limit corresponds with two standard deviations of the regression coefficient. If the regression coefficients with uncertainty limit crosses zero, the corresponding wavelength is not significant in predicting the property of interest.

Results and discussion

Mechanical model

The mechanical properties of the samples varied over a wide range (Table 1). The MOE varied from a minimum of 1,504 MPa to a maximum of 6,283 MPa (average 3,656, COV 28%). The UCS values ranged between 4.58 and 15.14 MPa (average 9.56, COV 32%). The coefficient of variation of MOE for each genetic group was calculated to provide information about the accuracy of the measurement. The average of the coefficient of variation of each genetic group was 17% for bending test and 12% for compression test (Horvath et al. 2010). Figure 2 shows the correlation between the measured mechanical properties and the mechanical properties from the NIR spectra. The UCS parallel to the grain showed strong correlation with the predicted UCS (R 2 = 0.89, SEC = 0.96 MPa) (Fig. 2a). The slope of the calibration curve was 0.89. The correlation between the measured MOE and the predicted MOE was good with R 2 = 0.79 and SEC = 448 (Fig. 2b). The slope of the calibration curve was 0.79. The slope indicated that the model underestimated the MOE.

The results of the model validation are also shown in Fig. 2. The summary statistic of the validation model of MOE and UCS is shown in Table 2. The UCS had a strong correlation for the validation set with R 2 = 0.91, SEP = 0.99, factors = 4, and RMSEP = 1.04 MPa (Fig. 2a). The slope of the regression line was 0.81. The R 2 is comparable to the values of 0.93 and 0.97 that were reported by Hoffmeyer and Pedersen (1995) and Gindl and Teischinger (2001), respectively. Despite the strong correlation between the measured UCS and the NIR-predicted UCS, the RPD value suggests that the model can only be used for screening purposes (Bailleres et al. 2002).

The MOE showed good correlation for the validation set, with R 2 = 0.78, SEP = 521, factors = 4, RMSEP = 538 MPa, Slope = 0.77 (Fig. 2b). Similar R 2 value was published by Kelley et al. (2004) for six softwoods with r = 0.84 (R 2 = 0.7) using standard ASTM three-point bending. Meanwhile, higher correlation was found for MOE using various softwood species by Gindl and Teischinger (2001), Via et al. (2003), and Schimleck et al. (2005b). Thumm and Meder (2001) also predicted the MOE of lumber using three-point bending and reported poor correlation (R 2 = 0.38) when collecting the spectra at the middle of the bending specimen. However, moderate correlation (R 2 = 0.71) was obtained when the sample was moving in front of a detector and spectra were collected from the full length. High R 2 values were published for Eucalyptus delegatensis by Schimleck et al. (2001, 2002a) and for Pinus radiata D. Don by Schimleck et al. (2002b) when the MOE was obtained from SilviScan-2 measurement in which a combination of X-ray densitometry and diffraction was used on wood strip to determine the MOE. However, when the range of densities was limited (300–400 kg/m3), lower accuracy (R 2 = 0.67) for Pinus taeda was reported by Schimleck et al. (2005a). It has to be mentioned that in the previous studies, the spectra were collected from the radial face of the solid wood while in our experiment the sample was ground to eliminate possible scattering caused by the surface. Despite the strong correlation between the measured and the NIR-predicted properties, the prediction accuracy of the model (SEP = 521) and the RDP value suggest that the model could only be used for screening of the MOE of young transgenic aspen trees at the green condition.

The strong predictability of the models for MOE and UCS is surprising due to the fact that previously published NIR models for juvenile wood samples had moderate quality (R 2 = 0.61) and poor predictability (R 2 = 0.23). The poor predictability of the models was explained by the narrow range of wood property variation (Via et al. 2003; Schimleck et al. 2005a). The MOE for this study ranged from 1,504 to 6,283 MPa; those of Schimleck et al. (2005a) were between 2,400 and 5,300 MPa, while Via et al. (2003) reported values between 5,000 and 28,000 MPa. It is also important to mention that all previous studies used dry mature wood specimens and it is known that the mechanical properties are altered by the moisture content, which could affect the correlation with the NIR spectra.

Significant wavelengths

One way to determine the contribution of the chemical components to the mechanical performance of wood is to compare the NIR spectra of wood and the NIR spectra of pure chemical components such as lignin, cellulose, extractives, and xylan. This has been done by various authors (Yamada et al. 2006; Yeh et al. 2004; Michell and Schimleck 1996). Another way to investigate this contribution is to determine which wavelengths are associated with major chemical components such as lignin and cellulose. This could be done by investigating the correlation between the known mid-infrared wavelengths (MIR) and the unknown wavelengths of NIR spectra (Michell and Schimleck 1996). It was found that the absorbances near 1,668 and 2,132 nm were associated with lignin and extractives. In addition, the band at 1,668, 1,684, and 2,132 nm correlated with the 1,735 cm−1 in MIR spectra, which was associated with the acetyl and carboxyl groups in non-cellulosic polysaccharides.

A third approach is the direct comparison of the regression coefficients of prediction generated from the PLS model. In this study, the model constructed by Yamada et al. (2006) was used to provide the regression coefficients of chemical component predictions. The spectra were treated the same way as described by Yamada et al. (2006). Figure 3 compares the regression coefficients of lignin and of the UCS prediction. It could be concluded that similar wavelengths contributed to the lignin and the UCS prediction. The calibration model for cellulose was not used due to the limited range of cellulose content that was used to build the model. In addition to lignin and cellulose, the hemicelluloses and the microfibril angle could have a significant effect on the mechanical properties; however, these properties were not measured in this study.

When the regression coefficients of lignin content prediction and MOE prediction were compared, it could be seen that the correlation was strong (Fig. 4). These results suggested that for this specific set of transgenic trees, both the MOE in three-point bending and the UCS correlate well with the lignin content of the samples. Lignin content has a strong correlation (R 2 = 0.80) with the UCS while the MOE only had a moderate correlation (R 2 = 0.65) (Fig. 5). The strong correlation was not entirely unexpected because the compressive strength of wood is widely known to depend on the lignin content (Wardrop 1971; Gindl 2001, 2002; Gindl and Teischinger 2002).

Summary and conclusion

The modulus of elasticity (MOE) in three-point bending and the UCS parallel to the grain were measured using micro-mechanical testing methods. NIR spectra were collected from 70 samples using 75-mg wood meal pellets. PLS models were constructed to correlate the NIR spectra and the mechanical properties. The measured UCS showed strong correlation with the NIR-predicted ultimate compression strength, with a coefficient of determination of 0.91 for the validation set. The RPD value of the validation model (2.94) indicated that NIR spectroscopy could be used for screening the green UCS of young, small diameter transgenic aspen trees. Good correlation was found between the measured and predicted MOE, with a coefficient of determination of 0.78 for the validation set. The RPD value of this model indicated that the model could be used only for screening of the green modulus of elasticity.

Further investigation of the correlation between the mechanical properties and the chemical composition suggested that the UCS highly correlates with the lignin content while the correlation between the MOE and the lignin content was moderate.

Based on these results it appears that transmittance NIR spectroscopy can be successfully used for rapid screening of the UCS of young, small diameter transgenic aspen in the green condition. The calibration model for MOE was not as good as that for the ultimate compression strength, which suggests that MOE depends on other chemical and anatomical factors, which could not be accurately predicted by NIR spectroscopy. To further improve the prediction ability of mechanical properties, a larger sample size is needed in order to expand the range of chemical composition and to be able to construct a more robust model.

References

Bailleres H, Davrieux F, Ham-Pichavant F (2002) Near infrared analysis as a tool for rapid screening of some major wood characteristics in a eucalyptus breeding program. Ann For Sci 59:479–490

Chiang VL (2006) Monolignol biosynthesis and genetic engineering of lignin in trees, a review. Environ Chem Lett 4:143–146

Esbensen KH (2002) Multivariate data analysis in practice: an introduction to multivariate data analysis and experimental design, 5th edn. CAMO Press, Norway, p 579

Gindl W (2001) The effect of lignin on the moisture-dependent behavior of spruce wood in axial compression. J. Mater. Sci. Lett 20:2161–2162

Gindl W (2002) Comparing mechanical properties of normal and compression wood in Norway spruce: the role of lignin in compression parallel to the grain. Holzforschung 56:395–401

Gindl W, Teischinger A (2001) The relationship between near infrared spectra of radial wood surfaces and wood mechanical properties. J Near Infrared Spec 9:255–261

Gindl W, Teischinger A (2002) Axial compression strength of Norway spruce related to structural variability and lignin content. Composites Part A 33:1623–1628

Hoffmeyer P, Pedersen JG (1995) Evaluation of density and strength of Norway spruce by near infrared reflectance spectroscopy. Holz Roh Werkst 53:165–170

Horvath L, Peszlen I, Peralta P, Kasal B, Laigeng L (2010) Mechanical properties of young genetically engineered aspen with modified lignin content and/or structure. Wood Fiber Sci (in print)

Hu W-J, Harding SA, Lung J, Popko JL, Ralph J, Stokke DD, Tsai C-J, Chiang VL (1999) Repression of lignin biosynthesis promotes cellulose accumulation and growth in transgenic trees. Nat Biotechnol 17:808–812

Kasal B, Peszlen I, Peralta P, Li L (2007) Preliminary tests to evaluate the mechanical properties of young trees with small diameter. Holzforschung 61:390–393

Kelley SS, Rials TG, Groom LH, So C-L (2004) Use of near infrared spectroscopy to predict the mechanical properties of six softwoods. Holzforschung 58:252–260

Koehler L, Telewski FW (2006) Biomechanics of transgenic wood. Am J Bot 93:1433–1438

Li L, Zhou Y, Cheng X, Sun J, Marita JM, Ralph J, Chiang VL (2003) Combinatorial modification of multiple lignin traits in trees through multigene cotransformation. P Natl Acad Sci USA 100:4939–4944

Michell AJ, Schimleck LR (1996) NIR spectroscopy of woods from Eucalyptus globulus. Appita J 49:23–26

Poke F, Raymond CA (2006) Predicting extractives, lignin, and cellulose content using near infrared spectroscopy on solid wood in Eucalyptus globulus. J Wood Chem Technol 26:187–199

Schimleck LR, Evans R, Ilic J (2001) Estimation of Eucalyptus delegatensis wood properties by near infrared spectroscopy. Can J For Res 31:1671–1675

Schimleck LR, Evans R, Ilic J, Matheson AC (2002a) Estimation of wood stiffness of increment cores by near-infrared spectroscopy. Can J For Res 32:129–135

Schimleck LR, Evans R, Matheson AC (2002b) Estimation of Pinus radiata D. Don clear wood properties by near-infrared spectroscopy. J Wood Sci 48:132–137

Schimleck LR, Evans R, Jones PD, Daniels RF, Peter GF, Clark A III (2005a) Estimation of microfibril angle and stiffness by near infrared spectroscopy using sample sets having limited wood density variation. IAWA J 26:175–187

Schimleck LR, Jones PD, Clark A III, Daniels RF, Peter GF (2005b) Near infrared spectroscopy for the nondestructive estimation of clear wood properties of Pinus taeda L. from the southern United States. For Prod J 55:21–28

TAPPI T 264 om-94 (1994) Preparation of wood for chemical analysis

Thumm A, Meder R (2001) Stiffness prediction of radiata pine clearwood test pieces using near infrared spectroscopy. J Near Infrared Spectrosc 9:117–122

Via BK, Shupe TF, Groom LH, Stine M, So C-L (2003) Multivariate modeling of density, strength and stiffness from near infrared spectra for mature, juvenile and pith wood of longleaf pine (Pinus palustris). J Near Infrared Spectrosc 11:365–378

Wardrop AB (1971) Occurrence and formation in plants. In: Sarkanen KV, Ludwig CH (eds) Lignins: occurrence, formation, structure, reactions. Wiley, New York, pp 19–41

Yamada T, Yeh T-F, Chang H-M, Li L, Kadla JF, Chiang VL (2006) Rapid analysis of transgenic trees using transmittance near-infrared spectroscopy (NIR). Holzforschung 60:24–28

Yeh T-F, Chang H-M, Kadla JF (2004) Rapid prediction of solid wood lignin content using transmittance near-infrared spectroscopy. J Agric Food Chem 52:1435–1439

Yeh T-F, Yamada T, Capanema E, Chang H-M, Chiang V, Kadla JF (2005) Rapid screening of wood chemical component variations using transmittance near-infrared spectroscopy. J Agric Food Chem 53:3328–3332

Acknowledgments

This project was supported by the National Research Initiative of the USDA-CSREES, Grant number 2005-35504-16145. Partial financial support was provided by FORBIRC Member Companies: Aracruz, Brazil; Arborgen, USA; Arauco, Chile; CMPC, Chile; FOSA, Uruguay; Mondi, South Africa; Oji Paper, Japan; Sappi, South Africa; VCP, Brazil; Weyerhaeuser, USA. The plants and greenhouse facilities were provided by Dr. Vincent Chiang, North Carolina State University, Forest Biotechnology Group.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Horvath, L., Peszlen, I., Peralta, P. et al. Use of transmittance near-infrared spectroscopy to predict the mechanical properties of 1- and 2-year-old transgenic aspen. Wood Sci Technol 45, 303–314 (2011). https://doi.org/10.1007/s00226-010-0330-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-010-0330-x