Abstract

Bamboo is a fiber-reinforced bio-composite since its culm wall is mainly composed of parenchymatous ground tissue in which vascular bundles are embedded. In order to analyze the mechanical properties of bamboo as a function of its components, tensile tests were performed on bamboo blocks and the corresponding volume fractions of fiber and parenchymatous ground tissue were measured. More significant linear relationships were found between tensile properties and volume fractions of the bamboo components. The tensile strength and modulus of elasticity of bamboo fiber and parenchymatous tissue were estimated according to the linear equations obtained by regression analysis. The macrographs of fractured bamboo blocks and the micrographs of fracture surfaces obtained by scanning electron microscope were also analyzed. Further tensile tests on separated bamboo fiber bundles were analyzed. Results show that the tensile strength of bamboo fiber obtained from the tests on bamboo blocks was higher than that on separated fiber bundles. This might be due to the interaction between components in bamboo in which parenchymatous ground tissue can pass loads and distribute the stresses loaded on fibers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

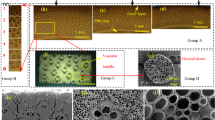

Moso bamboo (Phyllostachys pubescens) is the most widely used bamboo in China. It covers over 2.5 million square kilometer and accounts for more than 90% of total moso bamboo forest area in the world (Zhang 2003). Moso bamboo can be used as construction formwork, carriage sole plate, packing board, furniture panel and so on. The unique structure of bamboo culm determines its perfect mechanical characteristics. The culm is characterized by nodes. The internodes have a culm wall surrounding a large cavity, called lacuna. In the internodes, the cells are strongly axially oriented (Liese 1998). The moso bamboo culm wall is mainly composed of parenchymatous ground tissue in which vascular bundles are embedded (Liese 1998; Obataya et al. 2007). The vascular bundles are composed of metaxylem vessels and sheaths of sclerenchyma fibers which appear dark in contrast to the surrounding light parenchymatous ground tissue (Fig. 1). The sclerenchyma fibers are the main component determining the mechanical characteristics of bamboo, and the parenchymatous tissue can pass loads and take the role of a composite matrix. Therefore, in view of macro-mechanical behavior, bamboo is a typical unidirectional fiber-reinforced bio-composite. Its mechanical properties depend on the mechanical characteristics of its components, as well as on its microstructure characteristics, such as the volume fraction and the distribution of sclerenchyma fibers, and the interface properties of bamboo components (Shao et al. 2009).

The unique structure and the corresponding properties of bamboo give useful inspiration on artificial materials design. The composite structure optimizes the contribution of vascular bundle to the perfectly mechanical characteristics of bamboo. In the past 20 years, the structure and components of bamboo and its corresponding mechanical properties have been widely studied (Chuma et al. 1990; Inokuchi et al. 1997, 1999, 2002; Sui and Li 2003; Ahmad and Kamke 2005; Obataya et al. 2007; Shao et al. 2009). Chuma et al. (1990) have reported on the relationships between fiber volume fraction and mechanical properties. Inokuchi et al. (1997, 1999, 2002) have reported on the effects of volume fraction of bundle sheath on the vibrational properties and bending creep behavior of bamboo. In recent years, the development of artificial composites posed more requirements on reinforcing components, and the natural plant fibers have drew more attention as reinforcement used for artificial composites. Due to the excellent tensile strength and modulus of elasticity of bamboo fibers, bamboo flakes and fiber bundles have been used in polymeric composites (Deshpande et al. 2000), and some products have been used in wind turbine blade and boat industry (Jiang et al. 2006; Sun et al. 2008). However, precise studies on the mechanical properties of bamboo fiber and parenchymatous ground tissue with respect to its fiber-reinforced composite structure were not reported sufficiently as the previous results were estimated on a small quantity of specimens, and no study reported on the strength of separated bamboo fiber bundles. In this study, the tensile tests on bamboo blocks and the corresponding volume fractions of fiber and parenchymatous ground tissue were measured on a large quantity of specimens. The tensile properties of bamboo components and the macrographs of fractured bamboo blocks, as well as the micrographs of the fracture surfaces obtained by scanning electron microscope were analyzed. Further tensile tests on separated bamboo fiber bundles were performed. The results were compared with those on bamboo blocks and were discussed.

Experimental

Tensile tests parallel to grain were performed at two levels. One is at macroscopic level, i.e., on bamboo blocks; the other is at mesoscopic level, i.e., on bamboo fiber bundles. Meanwhile, fiber volume fraction was also measured on transverse sections. The moso bamboo (Phyllostachs pubescens) used in for the tests was 4-year-old and acquired from Lujiang, Anhui Province, China. The total height was about 15 m, and the diameter at breast height was 125 mm. The average air-dry density was 0.71 g/cm3.

Tensile tests on bamboo blocks

Experimental theory

Like in the internodes, the cells are strongly longitudinally oriented and no radial cell elements (such as rays in trees) exist (Liese 1998); the culm wall between nodes can be regarded as a typical unidirectional long-fiber-reinforced composite. An increasing distribution density of vascular bundles exists from the inner to the outer part of the culm wall along the radial direction (Fig. 1). When the radial thickness of the specimen collected from the culm wall is not big enough, the vascular bundles can be considered as being uniformly distributed. Normally, sclerenchyma fibers have high strength and modulus of elasticity (MOE), while parenchymatous ground tissue has low strength and MOE and high capability of deformation. It was found that in the tensile stress (σ)-strain (ε) curve of bamboo block, the part from the beginning of loading to the breaking point, was almost linear (see Fig. 8). Therefore, in view of mechanical behavior, the bamboo block can be simplified as a composite of parallel connection model composed of two elements, i.e., fibers and parenchymatous ground tissue, as shown in Fig. 2. σ C, E C, A C, σ f, E f, A f, σ p, E p and A p were noted as tensile stress, the corresponding MOE and area on the transverse section of the bamboo block specimen, fiber and parenchymatous ground tissue, respectively. So the volume fractions of fiber and parenchymatous ground tissue can be approximately calculated as V f = A f /A C and V p = A p /A C, and V f + V p = 1. According to the parallel connection model, loads on the composite should be shared by the two elements, i.e., fibers and parenchymatous ground tissue, and the strains of the two elements are equal. Thus, the following equations can be deduced:

After measuring the tensile strength and MOE of bamboo block specimen and the corresponding fiber volume fraction, according to Eqs. 1 and 2, the tensile strength and MOE of fiber and parenchymatous ground tissue can be estimated.

Experimental method

Specimens were taken from internode sections 9 and 10 (height ≈ 1.8 m) and the culm wall thickness was about 10 mm. After air-drying (equilibrium moisture content ≈ 12.5%), the culm sections were longitudinally split into 200 mm (L, longitudinal) × 10 mm (T, tangential) strips. Then, they were delaminated from the outer to the inner part of the culm walls, after cortex and pith periphery were removed. About six specimens were obtained for each strip. The final shape and dimension of the specimens for tensile tests are shown in Fig. 3. The dimension of the effective experiment part (middle section) was 80 mm (L) × 5 mm (T) × 1.5 mm (R, radial). In order to obtain high precision of the tensile strain, a displacement sensor was installed on the effective experiment section. Tensile tests were performed on a computer-controlled testing machine. The specimens were loaded at a constant crosshead speed of 3 mm/min until ruptured. In total, 60 specimens for the tensile test were performed. The test room temperature was 25°C and the humidity was 62%. The macrographs of fractured bamboo blocks and the micrographs of the fracture surfaces obtained by scanning electron microscope were taken after the tensile tests.

Fiber volume fraction (V f) measurements

Due to the different locations at the bamboo culm walls of the different specimens, especially along the radial direction, V f varied. In order to estimate the value of V f, A f/A C was measured on transverse sections. Samples were taken near the fracture surface of the bamboo specimens after the tensile tests. They were immerged in mixed solution of half 10% glacial acetic acid and half 10% hydrogen peroxide and put in an oven for 2–3 days at 60°C. Then they were softened by hot and cold water alternately for 1–2 h. 15-μm-thick transverse sections were cut with a microtome with disposable blades and stained with safranine. Sections were observed under an optical microscope equipped with a digital camera linked to an image analysis system. Sections’ images were taken and treated to distinguish bundle sheaths from parenchymatous ground tissue. The values of A f/A C were then measured by the image analysis software. Figure 4 shows an example of a series of treated sections’ images of the samples located along the radial direction from the inner to the outer part of a culm wall.

Tensile tests on bamboo fiber bundles

The tests were performed on fiber bundles separated from ground tissues. Specimens were collected from the same culm walls where samples had been taken for tensile tests on bamboo blocks. Culm walls were immerged in water for 1 day and then split along the fiber direction into small strips. During the splitting, some fiber bundles were detached from ground tissues and then pulled out of the bamboo strips at an angle of 10° (the fiber bundle will be damaged or broken if the angle is too large) between the detached fiber bundle and the bamboo strip. The fiber bundles more than 60 mm long were chosen and air-dried. Due to the fragility of the small specimens and the difficulty of installation for the tensile test, a special method was used with great care. The fiber bundle was fixed with strong glue in a paper casing made of coordinate grid paper with two quadratic holes in the middle of the two paper halves as shown in Fig. 5. The paper was folded in the middle, so that the fiber bundle was fixed with glue inside the paper casing except for the middle part. This method protected well the fiber bundle from being damaged or broken during the installation on the tensile test machine. After being installed in the clamps of test machine and before being loaded, the paper casing was snipped through the middle part. Details are shown in Fig. 5. The tensile test conditions of fiber bundles were the same as those for bamboo blocks. In total, 71 specimens of fiber bundles were prepared.

After the tensile test, the broken fiber bundle was stained with safranine, then air-dried and embedded in resin. Cross sections were cut perpendicular to axial direction of the fiber bundle. The cross area of fiber bundle was measured under microscope with image analysis system. Therefore, tensile stress can be calculated. Figure 6 shows an example of σ–ε curve where the part from the beginning of loading to the breaking point was entirely linear. High rupture strength and high MOE were observed. However, there were two possibilities which might cause the fallibility of MOE value calculated from the figure. First, the specimen, including the paper casing, might have some movement inside the clamps of the test machine. Second, the MOE of fiber bundle was much higher than that of the glue inside the paper casing used for fixing fiber bundle. Thus, under tensile loading the part of fiber bundle covered by glue might have slight but not negligible strain, although no fiber bundle was pulled out of the paper casing during the tests. Therefore, in order to estimate the MOE of fiber bundle, according to “shear-lag theory” of composites mechanics (Qiao 1997), it was assumed that no movement of the specimen happened inside the clamps of the test machine and the fiber bundle was covered uniformly by glue so that the interface shearing stresses loaded on fiber bundle were distributed uniformly. As shown in Fig. 7, L g and L o were noted as the lengths of the part of fiber bundle inside glue and the middle part without glue, respectively. The total length under loading L = 2L g + L o. A fb and S fb were noted as the cross area and perimeter of fiber bundle, respectively, τ as the shearing stress on the interface of fiber bundle inside glue, σ o as the axial tensile stress on the middle part of fiber bundle without glue, and E as the MOE of fiber bundle. In order to keep the balance inside the glue, τ and tensile stress σ(x) should meet Eq. 3 (x is shown in Fig. 7). For the middle part of fiber bundle without glue, Eq. 4 should be met.

Thus, the tensile stress σ(x) loaded on position x far from the left end of the fiber bundle should be:

Therefore, the total length change of fiber bundle (ΔL) under the tensile stress should be:

where ΔL was measured as the displacement of the crosshead of the test machine. Thus, according to Eq. 6, the MOE of fiber bundle can be calculated.

Results and discussion

An increasing distribution density of vascular bundles from the inner to the outer part of the culm wall along the radial direction was found (Fig. 4). Figure 8 shows some σ–ε curves measured on bamboo blocks with different V f values. The parts from the beginning of loading to the breaking point were entirely linear. Figure 9 shows the relationships of V f with tensile strength and MOE, respectively. Very significant (at 0.01 level) positive linear relationships were found between them as shown in Eqs. 7 and 8.

According to Eqs. 1 and 2, the tensile strength and MOE of fiber and parenchymatous ground tissue were estimated as σ f = 581.7 Mpa, E f = 40.4 GPa, σ p = 19. MPa and E p = 0.22 GPa, respectively. These results suggest that fiber plays the determinant role in tensile properties of bamboo and the ground tissue is the low-strength-and-modulus matrix material.

The results of the tensile tests on fiber bundles are shown in Table 1. The average tensile strength of bamboo fiber was 482.2 MPa, which was 18% less than the value calculated by the tests on bamboo blocks. This is mainly due to the fibers in bamboo blocks are embedded in parenchymatous ground tissue, which can pass loads and distribute the stresses loaded on vascular bundles. Such effectiveness is not possessed by a single tissue. Besides, the damage on the surfaces of some fiber bundles may be produced during separation process of fiber bundles. This could cause the low tensile strength measured on bamboo fibers. The average MOE of bamboo fiber was 33.9 GPa, which was also 16% less than the value measured by the test on bamboo blocks. Such a low value may be caused by the discrepancy between the hypothesis and the practice. During the tensile tests on fiber bundles, some slight movements of the specimens and some slight shearing deformations of the glue might have happened inside the clamps of the test machine. These could influence the result of MOE of bamboo fiber measured on fiber bundles.

Figure 10 shows the tension fracture pictures of three specimens with different V f. The corresponding σ–ε cures of the three specimens are shown in Fig. 8. The fracture surface of the specimen with low V f (11.5%) was trimmed, which indicates that the specimen was brittle. The specimen with medium V f (20.4%) showed an uneven fracture surface, which was caused by the interaction of parenchymatous ground tissue and fibers. When the V f (49.3%) was high, fracture surface of the specimen was split along the longitudinal direction, meaning that the specimen had high toughness. The micrographs of the fracture surfaces obtained by scanning electron microscope are shown in Fig. 11. The left part of Fig. 11a shows the parenchymatous tissue and the right part shows the sclerenchyma fibers. Figure 11b and c shows the parenchymatous tissue and fibers, respectively, with bigger magnification. In Fig. 11b, the incompact multilayer thin-walled structure of parenchymatous tissue can be seen clearly. By axial tensile stress action, the cell walls got fractured along the cross-section. Like the matrix in artificial composites, parenchymatous ground tissue can pass and buffer loads among vascular bundles. However, under loads the cell walls of parenchymatous tissue are prone to buckle. However, in live bamboo tissue the buckling resistance of the cell walls would be reinforced by the effect of the interior static hydraulic pressure caused by water. The fracture surface of sclerenchyma fibers was dense but rough in general (Fig. 11a). In the individual fibers, different layers were also rough (Fig. 11c). This indicates the low strength of the interface bond between different fiber layers and among different fibers notwithstanding the high tensile strength of bamboo fibers. Furthermore, for the high-modulus bamboo fibers, the multilayer structure can improve the flexibility.

Tension fracture pictures of 3 specimens with different V f. The corresponding stress-strain curves of the three specimens are shown in Fig. 8

Bamboo internode tissues are arranged along the longitudinal direction and are conglutinated together by the non-cellulose component in an effective but somehow not very effective manner, which makes the strength of the interface much weaker than that of bamboo longitudinal direction (Shao et al. 2009). However, it is the weakened interface that causes the high fracture toughness in transverse direction of bamboo (Gordon 1984), making bamboo tolerant towards gnawing of wild animals and knife wound. Meanwhile, the deficiency of the weak interface strength of culm wall can be offset by the nodes. The unique macrostructure of a large cavity surrounded by culm wall and the increasing distribution density of vascular bundles from the inner to the outer part of the culm wall along the radial direction make bamboo adapt to bending load caused by snow or wind. This reflects the optimization of nature selection, and the structure formed is in accordance with the principle of most efficiency with least materials.

Conclusion

Bamboo is a fiber-reinforced bio-composite since its culm wall is mainly composed of parenchymatous ground tissue in which vascular bundles are embedded. An increasing distribution density of vascular bundles from the inner to the outer part of the culm wall along the radial direction was found. The sclerenchyma fibers play the determinant role in tensile properties of moso bamboo. Very significant positive relationships were found between volume fraction of fiber and bamboo tensile strength and MOE. According to the tensile tests on bamboo blocks, the tensile strength and MOE of fiber and parenchymatous tissue were estimated as 581.7 MPa, 40.4 GPa, 19.0 MPa and 0.22 GPa, respectively. The results of the tensile tests on fiber bundles separated from bamboo parenchymatous ground tissue show that the tensile strength and MOE of fiber were 482.2 MPa and 33.9 GPa, respectively, which were lower than the ones obtained on bamboo blocks. This might be due to the interaction between components in bamboo where parenchymatous ground tissue can pass loads and distribute the stresses loaded on fibers. The unique structure of bamboo reflects the optimization of nature selection in accordance with the principle of most efficiency with least materials.

References

Ahmad M, Kamke FA (2005) Analysis of calculate bamboo for structural composite materials: physical and mechanical properties. Wood Sci Technol 39(6):448–459

Chuma S, Hirohashi M, Ohgama T, Kasahara Y (1990) Composite structure and tensile properties of mousou bamboo (in Japanese). Zairyou 39:847–851

Deshpande AP, Rao MB, Rao CL (2000) Extraction of bamboo fibers and their use as reinforcement in polymeric composites. J Appl Polym Sci 76:83–92

Gordon JE (1984) The new science of strong materials or why you don’t fall through the floor. Princeton University Press, USA, p 287 (ISBN 0-691-02380)

Inokuchi Y, Fushitani M, Chuma S, Ozawa M, Kubo T, Sato K (1997) Effects of volume fraction of bundle sheath on the vibrational properties of bamboo (in Japanese). Mokuzai Gakkaishi 43(5):391–398

Inokuchi Y, Fushitani M, Kubo T, Sato K (1999) Effects of water extractives on the moisture-content dependence of vibrational properties of bamboo (in Japanese). Mokuzai Gakkaishi 45(2):77–84

Inokuchi Y, Fushitani M, Kubo T, Sato K (2002) Effects of volume fraction of bundle sheath and water extractives on bending creep behavior of bamboo under changing moisture conditions (in Japanese). Mokuzai Gakkaishi 48(6):413–424

Jiang ZH, Sun ZJ, Ren HQ (2006) Application of advanced bio-composites in wind blades (in Chinese). Acta Mater Compos Sin 23(3):127–129

Liese W (1998) The anatomy of bamboo culms. International Network for Bamboo and Rattans (INBAR), Beijing, Tech rep no. 18

Obataya E, Kitin P, Yamauchi H (2007) Bending characteristics of bamboo (Phyllostachys pubescens) with respect to its fiber–foam composite structure. Wood Sci Technol 41:385–400

Qiao SR (1997) Micromechanical properties of composites. Northwestern Polytechnical University Press, China, p 187 (ISBN 978-7-5612-0913-4)

Shao Z-P, Fang C-H, Tian G-L (2009) Mode I interlaminar fracture property of moso bamboo (Phyllostachys pubescens). Wood Sci Technol 45(5–6):527–536

Sui S, Li R (2003) A study of structure and performance of bamboo fibers (in Chinese). J Text Res 24(6):535–537

Sun ZJ, Chen Q, Jiang ZH (2008) Processing and properties of engineering bamboo products (in Chinese). Acta Mater Compos Sin 25(1):80–83

Zhang QS (2003) Attaching importance to science and innovation in the processing and utilization of bamboo timber in China (in Chinese). J Zhejiang For Coll 20(1):1–4

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, ZP., Fang, CH., Huang, SX. et al. Tensile properties of Moso bamboo (Phyllostachys pubescens) and its components with respect to its fiber-reinforced composite structure. Wood Sci Technol 44, 655–666 (2010). https://doi.org/10.1007/s00226-009-0290-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-009-0290-1