Abstract

In this study, the ability of passive impregnation of Douglas fir (Pseudotsuga menziesii Franco) lumber was compared with a conventional full cell method. With an incising density of 10,000 holes/m2 carried out by CO2 laser, square Douglas fir lumber was treated by both passive impregnation and full cell method for 6 h and 50 min. Different incising densities were also used in passive impregnation to examine the optimum incising density. It was observed that there was no significant difference between these two methods regarding absorption of liquid, moisture content after dipping and penetrated area both at cross and longitudinal sections. However, the value was higher in case of full cell method. Regarding different incising densities, absorption and penetration of liquid was similar for 10,000 and 7,500 holes/m2 but it was low for 5,000 holes/m2. Therefore, it can be concluded that an incising density of 7,500 holes/m2 is the optimum for passive impregnation. The absorption of liquid and its distribution in wood indicates that this non-pressure passive impregnation method can be a good preservation method for impermeable lumber and can be an alternative to full cell method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Under proper use conditions, woods can provide centuries of good service. However, under unfavorable conditions, it may readily be damaged and destroyed by fungi, insects, and marine borers. These pests can attack in many ways, using the wood for food and/or shelter. Consequently, woods must be protected to ensure maximum service life when used under conditions favorable to these pests. The proper application of chemical preservatives can protect wood from decay and stain fungi, insects and marine borers, thus, prolonging the service life of wood for many years.

The effectiveness of preservative treatment depends on the chemical formulation selected, method of application, proportion of sapwood to heartwood, moisture content of the wood, amount of preservative retained, depth of chemical penetration and distribution. Sapwood of the most commercial species accepts preservatives much better than heartwood does, and non-refractory species are more receptive to impregnation than refractory woods. Preservative treatment by pressure is usually required for refractory woods used for structure and other applications exposed to high risk of attack by fungi, insects or marine borers.

Different pressure methods are now available for the preservation of refractory lumber such as Bethel process, Lowery process and Rueping process. Adequate level of chemical penetration and retention can be achieved by these methods but it is complicated and not suitable for treating small amounts of wood (Lahiry 2001) because of the higher initial investment. It is also difficult to drive out air from the cell lumen by these processes, even by hot and cold process. To solve these problems, a new method was developed by Hattori et al. (2005) named passive impregnation of wood preservation. With this new method a pressure tank is not necessary, instead a dipping tank which is usually much less capital cost compared with the pressure tank, will be necessary. A laser incising machine will be required for the method. Incredible level of impregnation could also be achieved by a simple dipping method compared to the conventional impregnation method for incised lumber (Islam et al. 2007). Thus, this method could be a good alternative in respect of cost and impregnation to the full cell method for treating wood, especially the refractory one.

In this study, incised Douglas fir (Pseudotsuga menziesii Franco) was treated by both passive impregnation and full cell method of wood preservation. The reduced degree of pitting (Krahmer 1961; Krahmer and Cote 1966) of Douglas fir is accountable for its refractory nature. It is impermeable for not only as solid wood but also as plywood (Mitchoff and Morrell 1991). Douglas fir wood has a high percentage of virtually untreatable heartwood (Miller and Graham 1963; Kumar and Morrell 1989; American Wood Preservers’ Association (AWPA) 1999). Incising helps to impregnate liquid deep into wood especially for refractory ones but excess incising may reduce the strength of the wood, which has a negative impact on its uses (Winandy and Morrell 1998). Therefore, different incising densities for passive impregnation were also used to find out the suitable incising density with regard to penetration and absorption. The objective of this study was to compare full cell and passive impregnation method of wood preservation regarding penetration and absorption of liquid. Determination of the optimum incising density of Douglas fir for passive impregnation was also undertaken in this study.

Experimental methods

Materials

Douglas fir (P. menziesii Franco) was selected for the study because of its highly refractory nature. The basic specific gravity of Douglas fir was 0.47 g/cm³ (water content = 0). A long post of square size (120 mm × 120 mm) was cut into 650 mm in length and used as specimen for both passive impregnation and full cell method. Specimens of same size were also used to find out the suitable incising density of Douglas fir. Both ends of specimens were sealed with urethane resin prior to steam injection/treatment by full cell method to prevent end penetration of liquid.

Methods

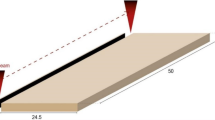

A through-hole was made with CO2 laser at longitudinal surface by controlling the irradiating time with a power of 1,500 W. The same incising pattern was used for all specimens as shown in Fig. 1.

Incising density was the same for both passive impregnation and full cell method, i.e., 10,000 holes/m2. Moisture content was measured before and after dipping by oven dry method (JIS Z 2101-1994). To find the suitable incising density for passive impregnation method, incising densities of 5,000, 7,500 and 10,000 holes/m2 were used. Specimens were incised with different incising densities by controlling the numerically controlled (NC) table. The maximum moisture content of wood is reached when the cell walls and cell lumens are completely filled with water. The possible maximum moisture content was obtained by Eq. 1 (Eckelman 2005).

where mcmax = possible maximum moisture content and S g = basic specific gravity.

In case of the passive impregnation method, steam (made from saturated steam of 110°C through hot plate temperature of 120°C) was injected into samples for 20 min by a steam injection press (Kitagawa Seiki Co. Ltd; VH2-1449). Both temperatures were controlled by controlling the steam pressure with continuous observation of pressure sensors. The specimens were dipped into the water/Fuchsine solution (C19H17N3HCl) immediately after steam injection for 6.5 and 12 h. Fuchsine solution (0.05% w/w) was used to identify the penetrated area of liquid as it has a similar level of permeability to water (Kishima and Hayashi 1960). The same passive impregnation condition with 12 h of dipping was also used to find out the suitable incising density for Douglas fir.

In case of full cell method, a vacuum (2.7 kPa) was drawn for 20 min, then the treating solution (water/fuchsine) was added and the pressure was raised to 980.7 kPa and held for 5.5 h. After releasing the pressure, the excess liquid was drained and then the wood was subjected to a short vacuum (10 min) to hasten solution recovery. The total treating time was 6 h and 50 min. Each experiment was done at least three times repeatedly.

Penetrated area of fuchsine was measured for all samples both across and along the grain direction. For across the grain direction, it was measured at the center of a specimen. In the case of along the grain direction, the penetrated area was measured at different depths {0 (irradiating surface), 30, 60 and 90 mm} and the opposite surface from the laser-irradiating surface. For this, a sample of 120 mm in length was cut near the centre of the specimen and sliced according to the different depths along the grain. Samples were dried and smoothed by a planer before measuring the penetrated area. The penetrated area was calculated by image analysis using an image scanner (Epson, GT-9800F) and software (Adobe, Photoshop).

Results and discussion

Change in moisture content

The initial moisture content (15% oven dry-basis) was the same for all specimens, but after treatment it was different because of the variation in treatment type. The after-treatment moisture content was higher in full cell method (142%) than in the passive impregnation method for both 12 (126%) and 6.5 h (119%) of dipping, though there was no significant difference between them (F = 0.94, df = 2 and α = 0.05). The average change of moisture content due to the treatment by full cell method was 127%, and for passive impregnation method it was 111 and 104% for 12 and 6.5 h dipping, respectively. This may be because of the through-hole, which helps the air to come out at vacuum and penetrate liquid at pressure more easily in full cell method than in the passive impregnation method. Retaining the pressure for a long time may also be a cause of this higher moisture content in full cell method. It was observed that samples treated by full cell method reached very closely the possible maximum moisture content (146%) after treatment. Thus, cell wall and cell lumen were almost filled with the penetrated chemicals after treatment.

There was a positive relationship between incising density and after-treatment moisture content of Douglas fir for passive impregnation method of wood preservation. The highest after-treatment moisture content was 126% when the incising density was 10,000 holes/m2, and it was 120 and 98% for 7,500 and 5,000 holes/m2, respectively. Similar moisture content after treatment by means of passive impregnation for Douglas fir with 10,000 holes/m2 was also reported by Islam et al. (2006). This may be because of the higher holes in higher incising density which helps the air to come out and to penetrate liquid deep into wood more easily than the lesser one.

Liquid absorption

Liquid absorption was higher in case of full cell method (533 kg/m3) than in passive impregnation method for both 12 h (482 kg/m3) and 6.5 h (465 kg/m3) of dipping, though there was no significant difference (F = 0.57, df = 2 and α = 0.05) between them (Fig. 2). There was a diminutive difference between 12 and 6.5 h dipping time for passive impregnation. Therefore, 6.5 h dipping time is ample for passive impregnation of Douglas fir with an incising density of 10,000 holes/m2. Similar results were also reported by Islam et al. (2006) for passive impregnation of Douglas fir. Effective removal of air from the cell lumen by vacuum and retaining high pressure for long time may be the cause of this higher absorption in case of full cell method.

Among different incising densities for Douglas fir, samples with an incising density of 10,000 holes/m2 absorbed more liquid than the others (Fig. 3). More holes in an area create greater scope of removing air from the cell lumen than the smaller number of holes, which might be the cause of this higher absorption for higher incising density. The liquid absorption was 482, 460 and 365 kg/m³ for 10,000, 7,500 and 5,000 holes/m2, respectively. It was observed that there was little difference in absorption of liquid for 10,000 and 7,500 holes/m2 but it was noteworthy for the incising density of 10,000 and 5,000 holes/m2. Hence, incising density of 7,500 holes/m2 for Douglas fir would be the optimum incising density for passive impregnation.

Penetrated area indicated by fuchsine

The penetrated area was clearly visible because of the color of fuchsine at the cross section of the wood. There was no significant difference between samples treated by full cell and passive impregnation methods of wood preservation for Douglas fir, though it was little higher in case of full cell method both at radial (Fig. 4) and longitudinal (Fig. 5) surfaces.

The penetrated area was 80 and 82% of the total surface area at cross section for passive impregnation and full cell method, respectively. Among the longitudinal surfaces, the highest penetrated area was observed at the centre of the sample, i.e., at 60 mm of depth, and it was 80 and 91% for passive impregnation and full cell method, respectively. For different incising densities, it was observed that the penetrated area increased with increasing incising density, though the differences were not significant. At cross section, it was 78, 72 and 71% for 10,000, 7,500 and 5,000 holes/m2, respectively (Fig. 6). At longitudinal surfaces, it was also observed that inner surfaces of wood had a higher penetrated area than the outer surfaces (Fig. 7).

It followed the similar results of penetrated area reported by Islam et al. (2006). It was also observed that sapwood absorbed more liquid than heartwood does for all cases. The sapwood to heartwood ratio of the liquid impregnated sample was 23:2, and liquid penetrated completely into the sapwood. The change of color in wood due to fuchsine was more apparent along the incising hole done by CO2 laser. These holes exposed additional area for liquid penetration for both longitudinal and lateral direction within the lumber.

Conclusions

Previous tests have shown that preservative treatment of Douglas fir by non-pressure method poses a major challenge. Preservation of Douglas fir by passive impregnation method demonstrates the way of preserving refractory species which attain the same level of penetration and absorption done by full cell method. Through incising helps to penetrate the liquid into the wood. However, it might weaken the strength of wood and therefore, optimum penetration and absorption is to be ensured by minimum number of holes. There are many variables other than incising density during treatment which also need to be optimized for a good penetration and retention. The implications of the study are as follows:

-

1.

There was no significant difference between full cell and passive impregnation method of wood preservation as regards penetration and absorption. Hence, passive impregnation method of wood preservation can be applied to preserve the refractory species rather than full cell method.

-

2.

Incising density of 7,500 holes/m2 is sufficient concerning absorption and penetration of liquid into wood among the different incising densities.

References

American Wood Preservers’ Association (AWPA) (1999) Lumber, timber and bridge ties, and mine ties - preservative treatment by pressure processes. Standard C2, AWPA Book of Standards, Granbury

Eckelman CA (2005) Wood moisture calculations. Forestry and Natural Resources, FNR 156, Purdue University

Hattori N, Morinaka Y, Ando K, Yamauchi H, Kobayashi N (2005) Passive impregnation of liquid into laser incised lumber. Seventeenth International Wood Machining Seminar, September 26–28, 2005, Germany

Islam MN, Ando K, Yamauchi H, Kobayashi Y, Hattori N (2006) Passive impregnation of liquid in impermeable lumber by laser incising. The 56th Annual Meeting of Japan Wood Research Society, August 8–10, 2006, Akita, Japan

Islam MN, Ando K, Yamauchi H, Kobayashi Y, Hattori N (2007) Passive impregnation of liquid in impermeable lumber incised by laser. J Wood Sci (Online first). doi:10.1007/s10086-006-0878-0

Japanese Standards Association (JSA) (1994) Methods of test for woods JIS Z 2101-1994

Kishima T, Hayashi S (1960) Microscopic observation on the courses of water penetration into woods. Mokuzai Kenkuyu (Japanese) 24:33–45

Krahmer RL (1961) Anatomical features of permeable and refractory Douglas-fir. For Prod J 11(9):439–441

Krahmer RL, Cote WA (1966) Changes in coniferous wood cells associated with heartwood formation. Tappi 46(1):42–49

Kumar S, Morrell JJ (1989) Penetration and absorption of different CCA compositions in six western conifers. For Prod J 39(10):19–24

Lahiry AK (2001) Applied wood preservation. Magnum Opus, Dhaka, pp 428

Miller DJ, Graham RD (1963) Treatability of Douglas-fir from western United States. Proc Am Wood Preserv Assoc 59:218–222

Mitchoff ME, Morrell JJ (1991) Preservative treatment of plywood panels from the Pacific Northwest. For Prod J 41(9):11–18

Winandy JE, Morrell JJ (1998) Effects of incising on lumber strength and stiffness: relationships between incision density and depth, species, and MSR grade. Wood Fiber Sci 30(2):185–197

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Islam, M.N., Ando, K., Yamauchi, H. et al. Comparative study between full cell and passive impregnation method of wood preservation for laser incised Douglas fir lumber. Wood Sci Technol 42, 343–350 (2008). https://doi.org/10.1007/s00226-007-0168-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-007-0168-z