Abstract

The morphology of charcoals was investigated by scanning electron microscopy. Charcoal of Quercus variabilis was prepared in an electric furnace under nitrogen gas atmosphere at 400, 600, 800 and 1,000°C. Charring temperature greatly affects the structure of charcoal. In charcoal prepared at 400°C, most of the morphological characteristics remained relatively unchanged with the exception of the cell-wall layering. The cell walls appeared homogenous and glass-like. Above 400°C, there was an increase in cell-wall thinning and volumetric shrinkage with an increase in the charring temperature. These two factors were responsible for most of the observed changes in structure. Fracture surfaces became increasingly rough and disrupted. Vessel elements were increasingly distorted and tyloses disintegrated with increases in temperature. Parenchyma cells exhibited greater shrinkage except at the pits. This resulted in the appearance of distinctive small protuberances over the surface of the parenchyma cells. Rhomboidal calcium crystals were found to be abundant at all the temperatures studied, but at 800 and 1,000°C the crystals had a sponge-like appearance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In past decades, many researchers have studied the physical and structural characteristics of charcoals (Blankenhorn et al. 1972, 1978; Beall et al. 1974; Slocum et al. 1978; Cutter and McGinnes 1981). Such studies indicate that the manufacturing temperatures significantly affected the physical properties of charcoals, such as mass loss, dimensional change, sorption, density, specific area, porosity and electric resistivity. It was also suggested that the chemical structure of charcoal such as carbon double bonds and aromatic rings was changed by the carbonization temperature (Nishiyama et al. 1998).

Up to now, a few studies have provided information on the structural changes of charcoal prepared at different temperatures (McGinnes et al. 1971; Elder et al. 1979; Cutter et al. 1980). McGinnes et al. (1971) examined commercial charcoals from white oak and found that the original fibrillar arrangement of the cell walls was replaced with a smooth “amorphous-appearing” wall structure. Elder et al. (1979) found that dimensions of intervessel pits in black cherry decreased with increasing the charring temperature from 250 to 600°C. Cutter et al. (1980) studied the disappearance of discrete wall layers, double cell wall thickness and diameters in the tracheids of a Southern pine in relation to charring temperature and heating rate.

Recently, charcoal has been utilized as a means of species identification in archaeological studies (Prior and Alvin 1983, 1986; Prior and Gasson 1993; Angeles 2001).

In Korea, Quercus variabilis is one of the most plentiful hardwood species and an important material for producing commercial charcoal. To clarify the properties of Q. variabilis charcoal prepared at different temperatures, the anatomical characteristics should be fully understood. The primary purpose of this study, therefore, is to examine the effect of charring temperature on the structure of charcoal. Charcoal of Q. variabilis was prepared in an electrical furnace at different temperatures and the anatomical characteristics of charcoal were observed using a scanning electron microscope.

Materials and methods

The sample trees (Q. variabilis BL.) grew in the experimental forest of Kangwon National University in Chunchon, Korea. The density and moisture content of the specimens were about 0.95 g/cm3 (Wg/Vg) and about 45%, respectively, which are representative of the conditions used for production of commercial charcoal. Wood blocks with the dimensions of 20 mm in thickness and width and 40 mm in length were carbonized in an electric furnace (Supertherm, HT 16/16) under nitrogen gas atmosphere at 400, 600, 800 and 1,000°C. The samples were heated for 15 min to reach each treatment temperature, kept for 10 min at constant temperature, and then the samples were cooled for 10 min to ambient temperature.

Charcoal samples were split and coated with Au–Pd using an ion-sputtering coater (Denton Vacuum Desk II). The surfaces in three-plane were observed with a scanning electron microscope (JEOL JSM-5800LV, 15–25 kV). Uncoated or carbon coated charcoal samples were used for low-voltage observation (1.6 kV), back-scattered imaging, and X-ray analysis. The images were digitally recorded and stored.

Results and discussion

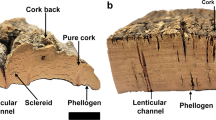

Gross structure

Figure 1 shows pieces of charcoal prepared at each of the temperatures studied. Significant splits and cracks along the broad rays are quite evident and produce a honeycombed appearance. This honeycombed appearance becomes more severe with increasing charring temperature. Volumetric shrinkage was considerable and also increased with increasing the charring temperature (Table 1). Further, the shrinkage was anisotropic with the greatest amount being in the tangential direction even with the honeycomb effects. These results agree with those of McGinnes et al. (1971) and Slocum et al. (1978). McGinnes et al.(1971) examined white oak in a commercial charring kiln and found that dimensional changes from wood to charcoal are –26% in the tangential direction, −15% in the radial direction, and –11% in the longitudinal direction. Slocum et al. (1978) reported that volumetric shrinkage of oak and hickory increased with increasing the charring temperature and the values were greater for hickory than for oak.

Cell wall morphology of charcoal

Libriform fibers and fiber tracheids

The cell walls of both fiber tracheids and libriform fibers from charcoal prepared at all the temperatures studied lost the distinctive cell-wall layering which is so evident in wood. The cell walls in charcoal were changed into a homogenous glass-like appearance. There was no distinction between the middle lamella and the cell wall. Charcoal did, however, retain all other morphological features. In fiber tracheids, aspirated bordered pits were easily observed, as were simple pits in the libriform fibers.

Charcoal prepared at 400°C retained most morphological features and when broken it exhibited a smooth clean cross-section. As the charring temperature increased, the cross-section became rougher and increasingly disrupted (Fig. 2). There were also more separations (disruptions) at the ray–fiber interface. The fibers exposed in these separations exhibited wrinkled cell walls, which were probably the result of excessive shrinkage and the accompanying stresses, as proposed by Beall et al. (1974). There was increased cell-wall thinning with increased charring temperature. The increase in cell-wall thinning can also be seen in Table 1 where the weight loss increases from 74% at 400°C to 84% at 1,000°C. Our results agree very well with those of Cutter et al. (1980). They examined the morphology of tracheids in a Southern Yellow Pine charred at 250–600°C and reported that the disappearance of discrete cell-wall layers depended on the heating rate and the charring temperature. They also indicated that the thickness of double cell walls decreased with increasing temperature at 250–600°C.

Vessels

In charcoal prepared at 400°C, the vessel elements appear to have retained their original morphological characteristics. The cell walls are intact and tyloses buds are very evident (Fig. 3a). With increasing preparation temperature, the elements began to shrink and separate from adjacent fibers. In charcoal prepared at 800 and 1,000°C, there were severe ruptures and tearing of the element cell wall (Fig. 3b, arrows). The tyloses also exhibited increasing disruption/disintegration with increasing charring temperature (Fig. 2).

Parenchyma cells

Uniseriate ray parenchyma cells

As with the vessel element, the uniseriate rays appear to retain their morphological characteristics in the charcoal prepared at 400°C. The ray cells show very little separation from each other and the cellular components are also visible (Fig. 4a). At 600°C and above, there is cell-wall thinning and an apparent disintegration of the middle lamella resulting in a separation of the ray cells (Fig. 4b). The cellular contents have disintegrated and the lumens of the ray cells demonstrate a folded appearance. This characteristic folded appearance is probably the result of a softening of the cell wall and compressive stresses resulting from the severe shrinkage of the adjacent thick-walled fibers.

Multiseriate ray parenchyma cells

As with the other tissues, the multiseriate rays exhibit a characteristic morphological appearance in charcoal prepared at 400°C. This appearance increasingly changes with an increase in the charring temperature. Cellular contents are evident in the charcoal prepared at 400°C and are totally absent in the charcoal prepared at 800 and 1000°C (Fig. 5). There is also a distinct increase in cell-wall thinning and disintegration with an increase in temperature.

If one examines the multiseriate rays in the area where the large cracks and splits occurred (to produce the honeycombed appearance), several distinctive features can be seen. With increasing charring temperature, the combination of cell-wall thinning and increased shrinkage results in a greater separation between the ray cells (Fig. 5). At 600°C and above, we begin to observe strands in the spaces between the ray cells. These strands are apparently the remnants of the plasticized primary wall of the middle lamella.

Most striking are the 2–4 μm small protuberances on the surfaces of the ray cells (Fig. 6, arrows). These protuberances are the remnants of simple pits, which resisted shrinkage and remained joined longer than the adjacent cell-wall material resulting in these small protuberances. These structures were seen in the charcoal prepared at all the temperatures studied. There are many simple pits on the parenchyma cell walls of wood (Fig. 7a, arrows) and they changed into small protuberances during charring. We can observe some opened protuberances, which indicate simple pits (Fig. 7b, arrows).

Axial parenchyma cells

The axial parenchyma cells exhibit all of the structural changes that were observed in the uniseriate and mulitseriate ray. The disappearance of the cellular contents above 400°C and increased shrinkage and cell separation with increased charring temperature. The axial parenchyma also exhibited the distinctive small protuberances in the pit areas (Fig. 8, arrows).

Crystals

Rhomboidal crystals were very prevalent in the parenchyma cells (Fig. 9). The crystals exhibit a great deal of contrast when viewed in the back-scattered mode of operation (Fig. 10) and were found to be comprised of calcium (most likely calcium oxalate) when subjected to energy-dispersive X-ray analysis (EDXA). The EDXA spectra of crystals at different temperatures showed the same pattern, with a strong peak at 3.69 KeV as shown in Fig. 11. Prior and Alvin (1983) reported that the crystals in the charcoal of Dichrostachys cinerea were remarkably persistent up to 700°C but very few at 800°C and they exhibited a spongy appearance. In this study, we observed numerous crystals in the charcoal prepared at all the temperatures studied including 800 and 100°C. In those specimens prepared at 400 and 600°C, the crystals generally exhibited a smooth surface although cracks were seen occasionally. In those specimens prepared at 800 and 1,000°C, the specimens exhibited the distinctive spongy appearance (Fig. 9) reported by Prior and Alvin (1983).

Conclusion

Charring temperature greatly affects the structure of charcoal. In charcoal prepared at 400°C, most of the morphological characteristics remained relatively unchanged with the exception of the cell-wall layering. The cell walls appeared homogenous and glass-like. Above 400°C, there was an increase in cell-wall thinning and volumetric shrinkage with an increase in charring temperature. These two factors were responsible for most of the observed changes in the structure. Calcium crystals were found to be abundant at all the temperatures studied, but at 800°C and 1,000°C, the crystals had a sponge like appearance.

References

Angeles G (2001) New techniques for the anatomical study of charcoalified wood. IAWA J 22(3):245–254

Blankenhorn PR, Jenkins GM, Kline DE (1972) Dynamic mechanical properties and microstructure of some carbonized hardwoods. Wood Fiber 4(3):212–224

Blankenhorn PR, Barnes DP, Kline DE, Murphey WK (1978) Porosity and pore size distribution of black cherry carbonized in an inert atmosphere. J Wood Sci 11(1):23–29

Beall FC, Blankenhorn PR, Moore GR (1974) Carbonized wood—physical properties and use as an SEM preparation. J Wood Sci 6(3):212–219

Cutter BE, McGinnes EA Jr (1981) A note on density change patterns in charred wood. Wood Fiber 13(1):39–44

Cutter BE, Cumbie BG, McGinnes EA Jr (1980) SEM and shrinkage analyses of southern pine wood following pyrolysis. Wood Sci Technol 14:115–130

Elder TJ, Murphey WK, Blankenhorn PR (1979) A note on the thermally induced changes of intervessel pits in black cherry (Prunus serotina EHRH.). Wood Fiber 11(3):179–183

McGinnes EA Jr, Kandeel SA, Szopa PS (1971) Some structural changes observed in the transformation of wood into charcoal. Wood Fiber 3(2):77–83

Nishiyama K, Hata T, Imamura Y, Ishihara S (1998) Analysis of chemical structure of wood charcoal by X-ray photoelectron spectroscopy. J Wood Sci 44:56–61

Prior J, Alvin KL (1983) Structural changes on charring woods of dichrostachys and salix from southern Africa. IAWA Bull 4(4):197–206

Prior J, Alvin KL (1986) Structural changes on charring woods of dichrostachys and salix from southern Africa: the effect of moisture content. IAWA Bull 7(3):243–250

Prior J, Gasson P (1993) Anatomical changes on charring six African hardwoods. IAWA J 14(1):77–86

Slocum DH, McGinnes EA Jr, Beall FC (1978) Charcoal yield, shrinkage, and density changes during carbonization of oak and hickory woods. J Wood Sci 11(1):42–47

Acknowledgments

This work was supported by Kangwon National University Grant [3004113-1-1(2004494)].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, NH., Hanna, R.B. Morphological characteristics of Quercus variabilis charcoal prepared at different temperatures. Wood Sci Technol 40, 392–401 (2006). https://doi.org/10.1007/s00226-005-0062-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-005-0062-5