Abstract

Behavior of lignin in supercritical methanol (250–270°C, 24–27 MPa) was studied by using lignin model compounds at the tin bath temperature of 270°C with a batch-type reaction vessel. Guaiacol and veratrole were selected as a guaiacyl type of aromatic ring in lignin, while 2,6-dimethoxyphenol and 1,2,3-trimethoxybenzene as a syringyl one. In addition, biphenyl and β-O-4 types of dimeric lignin model compounds were, respectively, studied as condensed and ether linkages between C6-C3 phenyl propane units. As a result, both guaiacyl and syringyl types of aromatic rings were very stable, and the biphenyl type was comparatively stable under supercritical conditions of methanol. However, β-ether linkage in the phenolic β-O-4 model compound was cleaved rapidly into guaiacol and coniferyl alcohol, which was further converted to its γ-methyl ether. Non-phenolic β-O-4 model compound was, on the other hand, converted initially into its α-methyl ether and degraded further to produce guaiacol. These lines of evidence imply that in lignin macromolecules, the new phenolic residues are continuously formed and depolymerized repeatedly in supercritical methanol into the lower molecular products, mainly by the cleavage of the dominant β-ether structure in lignin.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Supercritical fluids such as supercritical water and methanol are very effective in degradation of the biomass resources to achieve useful chemicals and fuels. Sakaki et al (1996) have suggested that ether and ester linkages of wood are rapidly hydrolyzed in subcritical water even without any catalyst added. Saka and Ueno (1999) have demonstrated that cellulose can be hydrolyzed into glucose very rapidly in supercritical water without any catalyst used. In addition, Adschiri et al (1993) have indicated that in the supercritical water, 1 or 2 orders higher decomposition rate of cellulose can be achieved than in subcritical water.

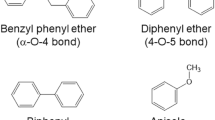

However, behaviors of lignin in woody biomass, which is a complex material with polymerized structure of phenyl propane units such as guaiacyl and syringyl moieties, remained unclear in supercritical fluid. Yokoyama et al (1998) have studied the degradation of organosolv lignin in supercritical water and supercritical methanol, and reported the yields of the oil and char relate to the reaction conditions. They also have investigated the mechanisms of lignin degradation in supercritical methanol by using model compounds including dibenzylether, benzaldehyde, benzyl methyl ether (Yokoyama et al 1994) and benzyl phenyl ether (Yokoyama et al 1997). However, aromatic rings of these model compounds do not have any substitutional groups such as hydroxyl and methoxyl groups, which are expected to play important roles in the reaction of lignin.

In this paper, therefore, reaction of lignin in softwood and hardwood was studied in supercritical methanol by using a series of simple aromatic model compounds and dimeric biphenyl and β-O-4 lignin model compounds.

Materials and methods

Materials

Guaiacol (1), veratrole (2), 2,6-dimethoxyphenol (3) and 1,2,3-trimethoxybenzene (4) were purchased from Nacalai Tesque as guaranteed grades. Phenolic and non-phenolic biphenyl types of lignin model compounds, 2,2’-dihydroxy-3,3’-dimethoxy-5,5’-dimethyl-biphenyl (5) and 2,2’,3,3’-tetramethoxy-5,5’-dimethyl-biphenyl (6) were prepared according to the method described by Kratzl and Vierhapper (1971). Phenolic and non-phenolic β-O-4 types of lignin model compounds, guaiacylglycerol-β-guaiacyl ether (7) and veratrylglycerol-β-guaiacyl ether (8) were prepared by the method described by Nakatsubo et al (1975). (Fig. 1)

Supercritical methanol treatment of lignin model compounds

Supercritical methanol treatment was conducted by using a biomass conversion system with a batch-type reaction vessel described in a previous paper (Saka and Kusdiana 2000). The reaction vessel with a 5 ml volume is made of Inconel-625. This system can cover a range in pressure and temperature up to 200 MPa and 500°C, respectively.

To start a treatment of model compounds in supercritical methanol, the reaction vessel with 10.0 mg lignin model compound dissolved in 5.0 ml of methanol was quickly heated by immersing it into the tin bath preheated at 270°C and maintained at supercritical conditions:

-

>Tc (critical temperature) = 239°C, and

-

>Pc (critical pressure) = 8.09 MPa

for 1 to 20 min. The obtained supercritical conditions of methanol were 250–270°C in temperature and 24–27 MPa in pressure. After an adequate reaction time, the reaction vessel was moved into the water bath to quench the reaction. During this treatment, the temperature of the reaction vessel was monitored by a thermocouple installed into the reaction vessel. At the same time, the pressure was also monitored by the pressure gauge attached to the reaction vessel, as described in a previous work (Saka and Kusdiana 2000).

The resulting reaction mixture was directly analyzed by high performance liquid chromatography (HPLC) with a Shimadzu LC-10A:

- Column:

-

STR ODS-II

- Flow rate:

-

0.8 ml/min

- Eluent:

-

MeOH/H2O=20/80→100/0(0 min→30 min), 100/0(30 min→35 min)

- Detector:

-

λ=280 nm

- Temperature:

-

40°C

Isolation of the products

Reaction products were separated by using preparative thin layer chromatography (TLC) on silica gel plate (Kieselgel 60 F254, Merck). The isolated compounds were acetylated with acetic anhydride and pyridine, and analyzed by 1H-NMR spectra taken with a Varian AC-300 with tetramethylsilane as an internal standard. Chemical shift and coupling constants are given in δ value (ppm) and Hz, respectively.

Acetate of γ-O-methyl coniferyl alcohol: 1H-NMR (CDCl3, 300 MHz) δ : 2.31(3H, s, -OAc), 3.39(3H, s, -OCH3), 3.84(3H, s, -OCH3), 4.09(2H, d, J=6.0, Cγ-H), 6.26(1H, dt, J=15.7, 6.0, Cβ-H), 6.58(1H, d, J=15.7, Cα-H), 6.97–7.06, (3H, m, aromatic H).

Acetate of α-O-methyl veratrylglycerol β-guaiacyl ether: 1H-NMR (CDCl3, 300 MHz) δ: 1.92(3H, s, -OAc), 3.23(3H, s, -OCH3), 3.70(3H, s, -OCH3), 3.77(3H, s, -OCH3), 3.81(3H, s, -OCH3), 4.37(4H, m, Cα-H, Cβ-H, Cγ-H), 6.65–6.87(7H, m, aromatic H).

Cis-2-(2’-methoxyphenoxy)-1-(3’,4’-dimethoxyphenyl)ethene: 1H-NMR (CDCl3, 300 MHz) δ: 3.89(6H, s, -OCH3), 3.91(3H, s, -OCH3), 5.56(1H, d, J=6.4, Cα-H), 6.55(1H, d, J=6.6, Cβ-H), 6.8–7.3(6H, m, aromatic H), 7.58 (1H, d, J=2.0, aromatic H).

Trans-2-(2’-methoxyphenoxy)-1-(3’,4’-dimethoxyphenyl)ethene: 1H-NMR (CDCl3, 300 MHz) δ: 3.87(3H, s, -OCH3), 3.88(3H, s, -OCH3), 3.90(3H, s, -OCH3), 6.28(1H, d, J=12.5, Cα-H), 7.02(1H, d, J=12.5, Cβ-H), 6.8–7.3(6H, m, aromatic H), 7.58(1H, d, J=2.0, aromatic H).

Results and discussion

Reactivity of the aromatic rings in lignin

Reactivity of the aromatic rings in lignin in supercritical methanol was evaluated by using guaiacol (1) and veratrole (2) as model compounds for guaiacyl nuclei, and 2,6-dimethoxyphenol (3) and 1,2,3-trimethoxybenzene (4) as those for syringyl nuclei.

The reaction mixtures obtained from compounds (1) and (2) treated in supercritical methanol were studied by the HPLC. As a result, 98% of guaiacol (1) and 99% of veratrole (2) were recovered after 10 min treatment, and only small amounts of catechol and guaiacol were, respectively, observed as a minor product. Although demethylation of methoxyl group proceeds as a very minor reaction, these results indicate that both phenolic and non-phenolic guaiacyl types of aromatic rings are very stable under supercritical conditions of methanol.

The reaction mixtures obtained from 2,6-dimethoxyphenol (3) and 1,2,3-trimethoxybenzene (4) were also studied by the HPLC. Although recovered yields are slightly lower than those of guaiacyl types of the model compounds, 91% and 97% of compounds (3) and (4), respectively, resulted after 10 min treatment. These results indicate that both phenolic and non-phenolic syringyl types of aromatic rings are also stable under supercritical conditions of methanol.

Consequently, aromatic rings of softwood and hardwood lignins consisting, respectively, of guaiacyl type of nucleus and guaiacyl and syringyl types of nuclei can be stable under supercritical conditions of methanol.

Reactivity of condensed and β-O-4 structures in lignin

Reactivity of lignin was then investigated, focusing on the linkages between phenyl propane (C6-C3) units in lignin by using biphenyl and β-O-4 types of dimeric lignin model compounds (5)–(8). β-ether structure which is represented by β-O-4 model compounds (7) and (8), is the most abundant linkage of the natural lignin. Erickson et al (1973) have reported that 49–51 units of β-ether structure exist in 100 C6-C3 units in spruce lignin. Thus, behavior of this structure in supercritical methanol is very important to understand the nature of the products obtained from lignin. On the other hand, condensed structure, which is represented by biphenyl model compounds (5) and (6), is an important linkage of lignin, especially in softwood. Erickson et al (1973) have reported for this condensed structure that 9.5–11 units exist in 100 C6-C3 units in spruce lignin.

As condensed structures in lignin, phenolic and non-phenolic biphenyl model compounds (5) and (6) were recovered 78% and 91%, respectively, after 10 min treatment. Although any remarkable peak was not observed, many small peaks were present in the HPLC chromatograms, particularly in the phenolic form. Thus, condensed structure in lignin is comparatively stable, but is more stable in non-phenolic form than that in phenolic form under the supercritical treatment of methanol.

As to β-O-4 model compounds, they were found to be very reactive in supercritical conditions especially in phenolic form. Figure 2 shows the HPLC chromatograms of the reaction mixture obtained from the phenolic β-O-4 type of lignin model compound (7). As reaction proceeds, the model compound (7) decreased and completely disappeared after 20 min treatment. The products observed at 17.8 min and 15.7 min in the retention time were identified to be guaiacol (1) and coniferyl alcohol (9), respectively, by comparison with the authentic samples. Although the amount of guaiacol observed at 17.8 min increased and levelled-off after 3 min treatment, coniferyl alcohol increased up to 10 min treatment and then decreased somewhat by further treatment. In turn, the product observed at 22.2 min was gradually produced. This newly formed product at 22.2 min was found to be coniferyl alcohol γ-methyl ether determined by 1H-NMR analysis of the isolated product after acetylation.

Figure 3 shows the yields of the starting phenolic β-O-4 model compound (7) and degradation products as treated in various treatment times. At 20 min treatment, yields of guaiacol (1) and the sum of coniferyl alcohol (9) and coniferyl alcohol γ-methyl ether (10) were both 87%. Thus, phenolic β-O-4 model compound (7) was first converted into guaiacol and coniferyl alcohol (9), and the latter product was further methylated at γ-position as shown in Fig. 4.

Degradation products of phenolic β-O-4 type of lignin model compound (7) in supercritical methanol. Filled circles: Phenolic β-O-4 model compound (7), Open triangles: Guaiacol (1), Open squares: Coniferyl alcohol (9), Filled squares: Coniferyl alcohol γ-methyl ether (10), Open circles: Sum of (9) and (10)

Conversion of coniferyl alcohol into its γ-methyl ether is considered to be due to the acidic character of the supercritical methanol. Supercritical methanol has been reported to act as an acid catalyst without adding any catalyst (Wu et al 1990). Acid-labile hydroxyl groups such as γ-hydroxyl group in coniferyl alcohol are considered to be eliminated to form quinonemethide-type intermediate under such an acidic condition, which is easily converted into methyl ether by solvolysis. These lines of evidence indicate that phenolic β-ether structure is easily cleaved to give coniferyl alcohol type of structure and that this structure is further methylated at γ-position.

Figure 5 shows the HPLC chromatograms obtained by supercritical methanol treatments of non-phenolic β-O-4 type of lignin model compound (8). This compound (8) appeared at 22.2 min decreased as the reaction time proceeded and completely disappeared after 5 min treatment. The initially produced product observed at 25.3 min was found to be α-methyl ether of the compound (8) by 1H-NMR analysis of the isolated product after acetylation. Acid-labile α-hydroxyl group is easily methylated via a quinonemethide intermediate as discussed in the methylation of coniferyl alcohol due to acidic character of supercritical methanol.

After supercritical methanol treatment of this product (11), the peaks observed at 29.9 min and 31.0 min appeared. These two products were found to be cis and trans isomers of 2-(2’-methoxyphenoxy)-1-(3’,4’-dimethoxyphenyl)ethene (12) and (13), respectively, by 1H-NMR analysis after isolation. They were cleaved off to produce guaiacol (1) after 3 min supercritical methanol treatment. Therefore, it can be supposed that guaiacol (1) was produced after cleavage of the β-ethers of these vinyl ether compounds (12) and (13). The initial formation rate of guaiacol, which is evidence of the β-ether cleavage, is very small. However, at the longer reaction time over 10 min, guaiacol (1) appears to be produced with a decrease in the amount of the vinyl ethers. Thus, non-phenolic β-O-4 model compound (8) must be converted into its α-methyl ether (11), and then, into vinyl ethers (12) and (13), followed by the successive cleavage of β-ether linkage, as shown in Fig. 6.

Time-course change in the amount of guaiacol, which directly indicates the β-ether cleavage during supercritical methanol treatment is shown in Fig. 7. Guaiacol is produced very quickly from phenolic β-O-4 model compound (7); whereas, the formation rate of guaiacol is comparatively small for non-phenolic model compound (8), especially in the early stage of the reaction, as shown in Fig. 7. This shows that phenolic β-ether bonding is more easily cleaved than non-phenolic one.

Although the content of phenolic structure in lignin is only about 10% as reported in spruce lignin (Whiting and Goring 1982), the most dominant β-ether structure in lignin is considered to be cleaved very quickly, breaking phenolic β-ether linkage. By this cleavage, another phenolic β-O-4 structure would be newly produced, and its β-ether cleavage may occur continuously.

Consequently, lignin in wood would be depolymerized quickly by cleaving the most abundant β-ether structure under supercritical conditions of methanol (250–270°C and 24–27 MPa); whereas, aromatic rings of guaiacyl and syringyl nuclei and condensed structure of lignin, particularly in the non-phenolic form would be stable under the similar conditions.

Acknowledgements

This research was supported by a Grant-in-Aid for Exploratory Research (No. 11876039, 1999.4–2000.3) and a Grant-in-Aid for Scientific Research (B)(2) (No. 12460144, 2000.4–2003.3) from the Ministry of Education, Culture, Sports, Science and Technology, Japan. This research was also supported in part by a research program for the development of technologies for establishment eco-system based recycling in rural villages for the twenty-first century from the Ministry of Agriculture, Forestry and Fisheries, Japan.

References

Adschiri T, Hirose S, Malanan R, Arai K (1993) Noncatalytic conversion of cellulose in supercritical and subcritical water. J Chem Eng Japan 26(6):676–680

Erickson M, Larsson S, Miksche GE (1973) Gaschromatographische Analyse von Ligninoxydations-Produkten. VIII: Zur Struktur des Lignins der Fichte. Acta Chem Scand 27(3):903–914

Kratzl K, Vierhapper FW (1971) Synthese von 14C-kernmarkierten Vanillinen und Bikreosolen. Monatsh Chem 102:425–430

Nakatsubo F, Sato K, Higuchi T (1975) Synthesis of guaiacylglycerol-β-guaiacyl ether. Holzforsch 29(5):165–168

Saka S, Ueno T (1999) Chemical conversion of various celluloses to glucose and its derivatives in supercritical water. Cellulose 6(3):177–191

Saka S, Kusdiana D (2000) Biodiesel fuel from rapeseed oil as prepared in supercritical methanol. Fuel 80(2):225–231

Sakaki T, Shibata M, Miki T, Hirosue H (1996) Decomposition characteristics of woody biomass in hot compressed liquid water. In: Proc 2nd Int Conf On Solvotherm Reactions, 18–20 Dec 1996, Takamatsu, Japan, pp 180–183

Whiting P, Goring DAI (1982) Phenolic hydroxy analysis of lignin by pyrolytic gas chromatography. Paperi ja Puu (10):592–595

Wu BC, Klein MT, Sandler SI (1990) The benzylphenylether thermolysis mechanism: insights from phase behavior. Am Inst Chem Eng J 36(8):1129–1136

Yokoyama C, Nishi K, Otake K, Takahashi S (1994) Thermolysis of dibenzyl ether in supercritical methanol. Sekiyu Gakkaishi 37(1):34–44

Yokoyama C, Nishi K, Takahashi S (1997) Thermolysis of benzyl phenyl ether in subcritical and supercritical water and supercritical methanol. Sekiyu Gakkaishi 40(6):465–473

Yokoyama C, Nishi K, Nakajima A, Kiyono K (1998) Thermolysis of organosolv lignin in supercritical water and supercritical methanol. Sekiyu Gakkaishi 41(4):243–250

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsujino, J., Kawamoto, H. & Saka, S. Reactivity of lignin in supercritical methanol studied with various lignin model compounds. Wood Sci Technol 37, 299–307 (2003). https://doi.org/10.1007/s00226-003-0187-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-003-0187-3