Abstract

Bone is a dynamic tissue that is able to sense and adapt to mechanical stimuli by modulating its mass, geometry, and structure. Bone marrow stromal cells (BMSCs) are known to play an integral part in bone formation by providing an osteoprogenitor cell source capable of differentiating into mature osteoblasts in response to mechanical stresses. Characteristics of the in vivo bone environment including the three dimensional (3-D) lacunocanalicular structure and extracellular matrix composition have previously been shown to play major roles in influencing mechanotransduction processes within bone cells. To more accurately model this phenomenon in vitro, we cultured human BMSCs on 3-D, partially demineralized bone scaffolds in the presence of four-point bending loads within a novel bioreactor. The effect of mechanical loading and dexamethasone concentration on BMSC osteogenic differentiation and mineralized matrix production was studied for 8 and 16 days of culture. Mechanical stimulation after 16 days with 10 nM dexamethasone promoted osteogenic differentiation of BMSCs by significantly elevating alkaline phosphatase activity as well as alkaline phosphatase and osteopontin transcript levels over static controls. Mineralized matrix production also increased under these culture conditions. Dexamethasone concentration had a dramatic effect on the ability of mechanical stimulation to modulate these phenotypic and genotypic responses. These results provide increased insight into the role of mechanical stimulation on osteogenic differentiation of human BMSCs in vitro and may lead to improved strategies in bone tissue engineering.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Bone is a dynamic tissue that is able to sense and adapt to mechanical stimuli by modulating its mass, geometry, and structural strength [1, 2]. During skeletal loading, a variety of tissue level perturbations are generated including local deformations of the bone matrix [3], the creation of shear stresses due to load-induced fluid flow [4, 5], and the induction of electric fields caused by stress-generated streaming potentials [6, 7]. Each of these loading effects has been shown to influence various osteogenic responses of bone-derived cells (e.g., osteoblasts and osteocytes) and their progenitors in vitro [8, 9, 10, 11, 12].

A number of in vitro systems have been developed to simulate in vivo loading environments that have utilized primarily two dimensional (2-D) mechanical strains and/or fluid flows to stimulate bone cells in culture [13, 14, 15, 16, 17, 18, 19, 20]. These systems may not, however, represent ideal environments for studying mechanotransduction responses of bone cells, since they lack both the 3-D cellular network and the lacunocanalicular structure of native bone, which in combination have been shown to play major roles in influencing these mechanisms [21]. In addition, bone cells are known to exhibit variable responses in vitro to mechanical stimuli depending on the type of material to which they are attached [22]. This behavior is due in part to the properties of the cell–material interface which can influence the ability of cells to transmit biochemical signals from the extracellular matrix to cell surface receptors in response to mechanical stimulation [22, 23]. Therefore, it is important that in vitro approaches for mechanical stimulation of bone cells or their progenitors utilize substrates that mimic the properties of native bone matrix in order to accurately model the in vivo responses of these cells.

Recently, the field of tissue engineering has utilized mechanical stimulation as a tool for promoting the development of a number of tissue types including cartilage [24], ligament [25], skeletal muscle [26], cardiac muscle [27], and bone [28, 29] in vitro. Bone marrow stromal cells (BMSCs) have been identified as an attractive cell source for a wide variety of tissue engineering strategies, since they contain a pluripotent population of cells capable of differentiating along multiple mesenchymal lineages (e.g., bone [30, 31], ligament [25, 32], adipose [33], cartilage [34], muscle [35] tissue), and can be easily expanded ex vivo utilizing routine cell culture techniques [36]. It has been established in previous studies that BMSCs can upregulate markers specific for osteogenic differentiation through mechanical stimulation in vitro [37, 38, 39, 40]. These data suggest that this type of stimulation may be useful in tissue engineering of new osseous biomaterials that incorporate this cell source. However, since these previous studies utilized BMSCs in 2-D cell culture environments and/or cell scaffolds derived from nonosseous materials, they may not represent optimal environments for osteogenic differentiation by mechanical stimulation. Therefore, this phenomenon warrants further study in order to develop in vitro systems that more accurately simulate the in vivo environment of bone tissue.

The goal of the present study was to test the hypothesis that mechanical stimulation can promote osteogenic differentiation of human BMSCs within a 3-D partially demineralized bone (DMB) scaffold in vitro. We selected this 3-D matrix because it supports osteogenic differentiation of human BMSCs in medium supplemented with dexamethasone [41] and is derived from native bone matrix. Therefore, in conjunction with this model, we have developed a novel bioreactor capable of providing a four-point bending loading regimen during tissue cultivation, which in previous studies has been demonstrated to enhance in vivo bone formation [42, 43, 44, 45]. Osteogenic differentiation was examined at the biochemical and molecular levels to characterize both phenotypic and genotypic responses to mechanical stimulation.

Materials and Methods

Tissue Culture

Primary Cell Culture. Human BMSCs were obtained from commercially available bone marrow aspirates from donors ≤25 years of age (Clonetics-Poietics) by using methods previously reported [25]. Whole bone marrow aspirates were plated at 8–10 μL/cm2 on 185 cm2 tissue culture plates and cultivated until confluency (~12–14 days) in 40 mL of Dulbecco’s modified Eagle’s medium supplemented with 10% fetal calf serum (FCS), 100 U/mL penicillin, 100 μg/mL streptomycin, 0.25 μg/mL fungizone, and 1 ng/mL of basic fibroblast growth factor (bFGF) (Life Technologies, Rockville, MD). BMSCs were selected on the basis of their ability to adhere to the tissue culture plastic; nonadherent hematopoietic cells were removed during medium replacement after approximately 5 days in culture. Medium was changed twice per week thereafter. BMSCs were subsequently detached using 0.25% trypsin/1 mM ethylene diamine tetraacetic acid (EDTA) replated at 5 × 103 cells/cm2, and cultured as first passage cells (P1) until confluency. First passage (P1) BMSCs were trypsinized and replated at 5 × 103 cells/cm2 to yield second passage cells (P2), which were trypsinized near confluency and subsequently used for scaffold seeding.

Partially Demineralized Bone Scaffolds. Bovine cancellous bone was harvested from the femoral condyles of commercially obtained 2 to 3-year-old Angus steers (City Packing, Boston, MA). The samples were cleaned of residual tissue and sectioned into rectangular beams (length × width × height), (63 mm × 6 mm × 6 mm) The partially DMB scaffolds were prepared by using a modification of methods reported previously [41, 46]. Briefly, samples were incubated in anhydrous ethyl ether for 12 hours, partially demineralized in 0.6 N HCl for 15 minutes (50 mL/g of bone), and rinsed in distilled water for 2 hours. The scaffolds were then air-dried for 24 hours, sterilized in ethylene oxide for 16 hours at 4°C, and stored at 4°C until seeding.

Dynamic Cell Seeding. Partially DMB scaffolds were seeded with BMSCs in well-mixed spinner flasks by using a modification of methods reported previously [41, 47]. Scaffolds were threaded 1-mm deep onto 10-cm, 20-gauge stainless steel needles, embedded in a Fischer no 12 rubber stopper, and suspended in Bellco 250-mL spinner flasks. Four scaffolds per spinner flask were utilized. The flasks were filled with 350 mL, of α-MEM and placed into a vacuum chamber for 1 hour at 100 μm of Hg to remove residual air within the matrix. Spinner flasks were inoculated with 80 × 106 cells (2 × l05 cells/mL) in 400 mL of α-MEM supplemented with 10% FCS, 100 U/mL pencillin, 100 μg/mL streptomycin, and 0.25 μg/mL fungizone, and stirred with a 0.8-cm diameter × 4-cm long nonsuspended stir bar at 50 rpm in a humidified 37°C, 5% CO2 incubator for 12 hours.

Bioreactor. A schematic view of the bioreactor is presented in Figure 1A. Mechanical loading of the partially DMB scaffold within the bioreactor is controlled with an Instron Model 8511 Material Tester, which consists of a computer-controlled, servomotor-driven linear actuator assembly with an interface controller that modulates vertical position and velocity. The linear actuator is coupled to a compression load cell that transmits a linear force through the external shaft to the transduction beam, which provides line contacts across the lateral face of the scaffold at axial distances of 19 mm from the center. The construct is supported by stationary bending supports positioned at 30 mm from its center in both positive and negative axial directions across the medial face. Prior to loading, the external shaft is allowed to contact the load cell by applying approximately 2 N of force; this relative position of the system is then defined as the minimum external displacement. The maximum external displacement of the linear actuator is then preset into the interface controller, and loading is accomplished by modulating between the maximum and minimum relative positions. During loading, the bioreactor translates the force of the linear actuator into four-point bending of the construct via the transduction beam and bending support contacts. The segment of the construct located within the transduction beam contacts is subjected to a uniform strain within each horizontal plane perpendicular to the applied load as predicted by theoretical four-point bending analysis [48]. However, the strain magnitude between these planes is predicted to increase proportionally from the central horizontal axis to maximum tensile and compressive stains at the external medial and lateral faces [48]. Gas and medium exchange are performed through sterile ports on the top of the bioreactor. An individual bioreactor vessel mechanically stimulated within the Instron Material Tester is displayed in Figure 1B.

Bioreactor Cultivation and Mechanical Loading. Seeded scaffolds were cultured for 8 and 16 days within independently maintained bioreactors containing 120 mL of α-MEM supplemented with 10% FCS, 100 u/mL penicillin, 100 μg/mL streptomycin, 0.25 μg/mL fungizone, 10 mM β-glycerophosphate (βGP), and 0.05 mM ascorbic acid-2-phosphate at 37°C in 5% CO2 in a humidified incubator. The effects of various dexamethasone concentrations previously shown to induce human BMSC osteogenic differentiation were investigated with mechanical stimulation to determine the role of this biochemical factor within our system [41, 49]. Three experimental groups were established by using medium containing 0 nM (group I), 10 nM (group II), or 100 nM (group III) dexamethasone. Each group was further subdivided into samples subjected to mechanical stimulation and unloaded static controls. Medium exchange was accomplished every 4 days of culture. Loading was applied in a triangular waveform at a rate of 5 mm/minute with a maximum external displacement of 0.2 mm for 250 cycles every 24 hours throughout the entire culture period. Maximum external displacement and loading rate were preset within the external Instron controller and maintained during stimulation. Following cultivation, the uniform bending region of each scaffold located between the transduction beam line contacts was dissected along the central axis perpendicular to the applied load into five equivalent sections for analytical analysis as described in the next section.

Analytical Methods

Mechanical Properties. Strain magnitudes at the external medial and lateral planes of the partially DMB scaffolds were measured during bioreactor loading by using modifications of methods reported previously for strain characterization of animal femurs subjected to four-point bending loads [42, 43, 50]. The surfaces of the partially DMB scaffolds were cleaned with alcohol and then air-dried. Single-element strain gauges (Measurements Group, Raleigh, NC) were connected in a Wheatstone bridge and glued (M-bond AE-10) to the medial and lateral surfaces. The gauges were aligned directly in the center of the construct, equidistant from the transduction beam line contacts and parallel to the longitudinal axis. The scaffolds were placed in the bioreactor, and the external shaft was allowed to contact the load cell by applying force of approximately 2 N. Strains on the external medial and lateral surfaces of the scaffolds during external loading were then measured at five external displacements (0, 0.2, 0.4, 0.6, and 0.8 mm) at a rate of 5 mm/minute for three cycles. The average peak strains on the medial and lateral surfaces were then recorded with a Strain Indicator P-3500 Device (Measurements Group).

Cell Numbers. The relative number of metabolically active cells within each scaffold section was determined by a 3-4,5 dimethylthiazol-2-yl-2,5-diphenyltetrazolium bromide (MTT) assay as described previously [41]. Briefly, sections were rinsed with PBS immediately after harvest and incubated in 10 mL of 0.5 mg/mL MTT in culture media for 2 hours at 37°C in 5% CO2. Sections were then immersed in 2 mL of 0.1 N HCl/isopropanol for 12 hours at 37°C for crystal dissolution. Aliquots (100-μL) were quantified spectrophotometrically for optical density in 96-well plates at 570 nm by a microplate reader (Spectramax 250, Molecular Devices). Relative cell numbers were expressed as the ratio of MTT absorbance units per scaffold section.

Alkaline Phosphatase Activity. Scaffold sections were assayed for the presence of alkaline phosphatase activity as described previously [41]. Sections were crushed and transferred to 1.5 mL of 0.2% Igepal CA 630 detergent with 5 mM MgCl2. Homogenization was carried out in a Minibead beater (Biospec Inc.) with three stainless steel beads (3.1 mm in diameter) for 10-second intervals at 50,000 rpm for a total of 12 cycles. The samples were immersed in a 4°C water bath for 30 seconds between cycles to remove excess heat and to avoid enzyme denaturation. Following homogenization, samples were centrifuged at 13,000 rpm for 10 minutes 4°C. The supernatant was assayed for alkaline phosphatase using p-nitrophenyl phosphate as a substrate [51]. Briefly, 80 μL of the supernatant was added to 100 μL of 5 mM p-nitrophenylphosphate in 150 mM 2-amino-2-methlyl-1-propanol buffer solution (Sigma) and incubated for 1 hour at 37°C. A 100-μL aliquot of 0.2 N NaOH was added to stop the enzymatic reaction, and the absorption at 405 nm was measured spectrophotometrically by a spectramax 250 microplate reader (Molecular Devices). Alkaline phosphatase activity per sample was normalized to the relative cell number and displayed as relative activity.

Total RNA Isolation and Reverse-Transcriptase Polymerase Chain Reaction. Total RNA was isolated from scaffold sections by first homogenizing samples in 1.5 mL,of Trizol reagent (Life Technologies) and then by using the RNEasy Mini Kit system (Qiagen) as described previously [41, 52]. (RT-PCR) analysis of bone-specific protein expression for alkaline phosphatase, osteopontin, osteocalcin, and the housekeeping gene GAPDH was carried out using the Access RT-PCR system (Promega). PCR reaction mixtures consisted of 2 μL of total RNA (0.033–33 ng) combined with 31 μL distilled water 10 μL of 5X AMV/Tfl reaction buffer, 1 μL of 10 mM dNTPs, 2 μL of 25 mM MgSO4, 1 μL of 5U/μL of AMV reverse transcriptase, 1 μL of 5U/μL Tfl DNA polymerase, and 50 pm of the respective forward and reverse primers. Primers were designed with Primer Select software from genes with the following Genebank Accession numbers: osteocalcin, X04143; osteopontin, D14813; and GAPDH, J04038. Alkaline phosphatase primers were used as previously reported [53]. Primers were as follows. Osteocalcin, forward primer = 5′ AGG GCA GCG AGG TAG TGA AGA 3′, and reverse primer = 5′ AAG GGC AAG GGG AAG AGG AAA GAA 3′. Alkaline phosphatase, forward primer = 5′ TGC TCC CAC GCG CTT GTG CCT GGA 3′, and reverse primer = 5′ CTG GCA CTA AGG AGT TAG TAA G 3′. Osteopontin, forward primer = 5′ CAC TCC AGT TGT CCC CAC AGT AGA 3′, and reverse primer = 5′ GGC CTT GTA TGC ACC ATT CAA CTC 3′. GADPH, forward primer = 5′ GGG CAT CCT GGG CTA CAC TGA G 3′ and reverse primer = 5′ GGC CCC TCC CCT CTT CAA G 3′ . PCR reactions were performed using a PTC-100 thermocycler (MJ Research).

The same reaction conditions were used for each primer set: first strand cDNA synthesis—48°C for 45 min, 94°C for 2 minutes; second strand cDNA synthesis and PCR amplification—94°C for 30 seconds, amplification temperature for 1 minute, 68°C for 2 minutes; and final extension—68°C for 7 minutes. Forty amplification cycles were used for all markers and the amplification temperature for osteocalcin, alkaline phosphatase, and GAPDH, was 58°C and 50°C for osteopontin. The number of cycles used was in the linear range of amplification for each specific gene product, as preliminary experiments were carried out with each primer set. The expected product size for each gene was as follows: osteocalcin, 266 bp; GAPDH, 345 bp; alkaline phosphatase, 215 bp; and osteopontin, 183 bp. The expression of all osteogenic markers was normalized to GAPDH. For each PCR reaction, 9 μL of the reaction product was combined with 1 μL of loading buffer. The products were electrophoresed in a 2-mm thick, 2.2% agarose gel at 1.3 V/cm2 for 45 minutes in 1X Tris-borate-EDTA buffer. Molecular weight markers consisting of a 100-bp DNA ladder (Life Technologies) were run concurrently to estimate product length. The gels were then stained with 0.06 μg/mL ethidium bromide and visualized by using a Fluoro-S MultiImager (Biorad, Hercules, CA). Band intensities were then evaluated against background levels and quantified using MultiAnalyst software. Equivalent intensities of GAPDH between mechanical and control samples allowed semiquantitative comparison of the markers of interest expressed as a ratio to the reference gene (GAPDH) for each sample.

Mineralized Matrix Production. Alizarin Red S (sodium 1,2-dihydroxyanthraquinone-3-sulfonate) was used as a well-established colorimetric reagent for the determination of calcium salts [54]. Calcium intensity and distribution within the scaffold section were qualitatively determined by using modifications of procedures previously reported [55, 56]. Briefly, sections were fixed in 10% formalin for 24 hours and exposed to 40 mM alizarin red S solution (pH 4.2) for 5 minutes at room temperature. Sections were then washed in distilled water for 30 minutes to remove unreacted reagent and then air-dried, and photographed.

Statistical Analysis. All assays were repeated in two independent experiments with a minimum of n = 3 for each data-point. Data for RT-PCR and alkaline phosphatase activity were analyzed using a Student’s two-tailed t test with Microsoft excel software (Microsoft Corp, Redmond, WA). Statistically significant values were defined as P < 0.05.

Results

There was a significant linear relationship between the external displacement and the applied tensile (R2 = 0.997) and compressive (R2 = 0.998) strains within the medial and lateral external planes, respectively, within the partially DMB scaffolds during bioreactor stimulation (Fig. 2A). The range of external strain magnitudes produced by the bioreactor during four-point bending was measured as 44 ± 32 to 2151 ± 672 tensile με microstrain, 1 με = 0.1% strain within the external medial plane and −51 ± 41 to −2342 ± 400 compressive με within the external lateral plane. The maximum external displacement (0.2 mm) utilized during BMSC stimulation generated an average strain magnitude of 505 ± 196 tensile με within the external medial plane and −521 ± 216 compressive με within the external lateral plane. A schematic view of the compressive and tensile strains within the cross-section of the partially DMB scaffold during loading is displayed in Fig. 2B.

(A) Relationship between the external displacement and strain within the external medial and lateral planes of the partially demineralized bone (DMB) scaffolds during four-point bending within the bioreactor. Mean ± SD for n = 3. (B) Axial cross-sectional view of the compressive and tensile strains in the uniform bending region of a partially DMB scaffold during four-point bending as predicted by theoretical four-point bending analysis. The magnitude of strain generated during bending increases from 0 με in the central neutral axis to a maximal compressive strain (−με) within the external lateral plane and a maximal tensile strain (+με) within the external medial plane of the scaffold.

Osteogenic differentiation of BMSCs on the partially DMB scaffolds was assessed by use of biochemical analysis of relative alkaline phosphatase activity at 8 and 16 days of cultivation) (Fig. 3). Relative enzyme activity was found to be a function of both dexamethasone concentration and mechanical stimulation at 16 days of cultivation. All culture conditions with dexamethasone treatment demonstrated significantly higher alkaline phosphatase activity when compared to non–dexamethasone-treated static samples following 16 days of cultivation. Alkaline phosphatase activity was significantly elevated in mechanically stimulated BMSCs by 80% and 92% over static controls in the presence of 0 and 10 nM dexamethasone, respectively. In contrast, mechanically stimulated samples containing 100 nM of dexamethasone displayed no significant difference in enzyme activity in comparison to static controls at this time-point. Mechanically stimulated BMSCs containing 10 nM dexamethasone displayed significantly higher levels of alkaline phosphatase activity compared to samples within all other tested culture conditions. No significant differences in enzyme activity between mechanical and static controls at day 8 of cultivation were observed at any experimental dexamethasone concentration (data not shown).

Comparison of BMSC alkaline phosphatase activity in 0, 10, and 100-nM dexamethasone-treated groups after 16 days of bioreactor cultivation with mechanical stimulation or as static controls. Statistically significant difference (*) = compared to similar static control or (#) = compared to all other groups. Student’s two tailed t test. P < 0.05. Mean ± SD for n = 3--4.

Analysis of transcripts specific for alkaline phosphatase and the bone matrix proteins, osteocalcin and osteopontin, were assessed by semiquantitative RT-PCR (Figs. 4A and B). The results demonstrated that alkaline phosphatase transcript levels paralleled the responses obtained for alkaline phosphatase activity at 16 days of cultivation. Alkaline phosphatase transcript levels were significantly elevated in mechanically stimulated BMSCs by 218% and 257% over static controls in the presence of 0 and 10 nM dexamethasone, respectively. In contrast, mechanically stimulated BMSCs containing 100 nM of dexamethasone displayed no significant difference in transcript levels in comparison to static controls. Transcript levels for alkaline phosphatase were significantly higher in mechanically stimulated BMSCs with 10 nM dexamethasone in comparison to all other culture conditions after 16 days of cultivation.

RT-PCR analysis of osteogenic gene expression of BMSCs cultured in 0, 10, and 100-nM dexamethasone-treated groups after 16 days of bioreactor cultivation with mechanical stimulation or as static controls. (A) Agarose gel of representative ethidium bromide–stained products. M = mechanical stimulation, C = control groups. (B) Semiquantitative results of osteogenic transcript levels normalized to GAPDH expression. Statistically significant difference (*) = compared to similar static control, (+) = compared to 0 nM static control, and § = compared to all samples at other dexamethasone concentrations. Student’s two-tailed t test. P < 0.05. Mean ± SD for n = 3-4. ALP = alkaline phosphatase; OP = osteopontin; OC = osteocalcin.

BMSC osteopontin transcript levels were also a function of dexamethasone concentration and mechanical stimulation at 16 days of cultivation. Osteopontin transcript levels were shown to be negatively effected by dexamethasone with static samples containing 10 nM demonstrating significantly lower levels compared to static samples without dexamethasone. In addition, samples containing 100 nM displayed significantly lower transcript levels compared with samples at any other dexamethasone concentration. Osteopontin transcript levels were found to be significantly elevated by 55% in mechanically stimulated samples in comparison to static controls containing 10 nM dexamethasone. In addition, these levels were statistically similar to both mechanical and static samples containing 0 nM dexamethasone. In contrast, mechanical stimulation did not significantly increase osteopontin transcript levels in comparison to static controls at dexamethasone concentrations of 0 or 100 nM. Osteocalcin transcript levels showed no significant effects in response to mechanical stimulation over respective static controls at any dexamethasone concentration following 16 days of cultivation. Osteocalcin transcript levels were also not significantly effected by dexamethasone concentration following 16 days. No significant differences in osteopontin, alkaline phosphatase, or osteocalcin transcript levels were observed following 8 days of cultivation when comparing the mechanically stimulated and static controls at any experimental dexamethasone concentration (data not shown).

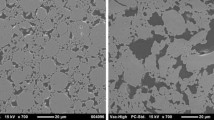

The production of calcified matrix by BMSCs within partially DMB was qualitatively analyzed following 16 days of cultivation by histochemical staining with alizarin red (Fig. 5). Relatively weak background staining was detected within the scaffold interior of all samples analyzed, due to the presence of residual bovine calcium prior to BMSC cultivation. Seeded scaffolds cultured in the presence of 10 nM dexamethasone and mechanical stimulation displayed substantially more intense alizarin red–positive staining along their external perimeters in comparison to internal background levels as well as to their respective static controls. No qualitative differences in staining intensity were observed between the mechanical and static controls at any other experimental dexamethasone concentration following 16 days of cultivation (data not shown).

Alizarin red–staining of axial cross-sections (6 × 6 cm) of seeded scaffolds cultured at 10-nM dexamethasone following 16 days of bioreactor cultivation. (A) mechanical and (B) static control. Mechanical samples are oriented similarly displaying their position during bioreactor stimulation. Arrows designate scaffold orientation: (a) = axis parallel to the direction of loading (b) = axis parallel to the external medial plane under maximum tensile strain (*) = qualitatively substantial increase in staining intensity at the external edges compared to internal background and respective static control (scale bar = 3 mm).

Discussion

In this present study, we have presented a novel in vitro bioreactor system capable of stimulating human bone marrow stromal cells mechanically within a 3-D partially DMB matrix. Our results show that cyclic mechanical stimulation within this culture system is capable of promoting osteogenic differentiation of BMSCs as well the formation of mineralized matrix, when cultured in the presence of specific dexamethasone concentrations. Mechanical stimulation in vivo has been shown previously to play an integral role in bone formation by stimulating osteoprogenitor cells in the marrow stroma to differentiate into osteoblasts at cortical bone surfaces [57]. In addition, skeletal unloading has also been demonstrated to modulate the osteogenic differentiation capacity of BMSCs ex vivo and to effect their ability to produce mineralized matrix in culture [58, 59, 60]. These results together with our present study suggest that mechanical stimuli plays a significant role in influencing both the osteogenic differentiation process of BMSCs as well as their production of mineralized matrix in vivo and in vitro.

The bioreactor system utilized in this study incorporates a four-point bending loading regime capable of inducing average strain magnitudes of 44 to 2151 tensile με and −51 to −2342 compressive με along the external medial and lateral surfaces of the partially DMB scaffolds examined. This range includes strain magnitudes (50–2000 με) routinely generated within the human skeletal system during vigorous activities [3] and, therefore, provides a useful 3-D in vitro system to mimic in vivo mechanical strains within bone tissue. Because the strain distribution during mechanical loading is nonuniform from the center to the periphery of the construct parallel to the applied load, the specific strain magnitude responsible for promoting osteogenic differentiation cannot be specified. However, since our results showed that the loading regimen utilized during BMSC stimulation generated maximum tensile and compressive strains of 505 ± 196 με and −521 ± 216, respectively, it can be suggested that these cells respond to similar magnitudes of strain within the range of routine skeletal loading in vitro. In addition, recent in vivo studies have shown that the application of bending forces within bone-loading systems significantly increased the ability of mechanical stimulation to promote bone formation in comparison to direct tissue compression (sham loading) [61, 62, 63]. This phenomenon is assumed to be caused by load-induced fluid flow effects (e.g., shear stresses and streaming potentials) generated as bending forces induce pressure gradients within the bone matrix [5, 57]. Although the characteristics of mechanical loading such as strain rate [18, 64], magnitude [65], and frequency [43, 66] have all been shown to play significant roles in osteogenic differentiation and bone formation, the incorporation of bending forces within our system may represent a critical feature in promoting osteogenic differentiation of BMSCs; however, this phenomenon warrants more study.

Characterization of the expression of several osteogenic markers was performed to provide an increased understanding of the events involved during osteogenic differentiation of BMSCs with mechanical stimulation in vitro. Alkaline phosphatase has been extensively used as a marker of osteogenic differentiation, with increases in enzymatic activity and protein expression corresponding to an osteoblastic phenotype within a number of cell culture systems [40, 50, 67, 68]. Alkaline phosphatase transcript levels were significantly elevated over static controls following 16 days of cultivation at dexamethasone concentrations of both 0 and 10 nM. In addition, transcript levels were significantly higher in mechanically stimulated samples containing 10 nM dexamethasone in comparison to all other culture conditions. These results suggest that alkaline phosphatase expression can be elevated by mechanical stimulation independent of dexamethasone, but that relatively low concentrations (10 nM) can have a synergistic effect, producing significantly higher transcript levels than mechanical stimulation alone. It is interesting to note that this effect was abolished with a 100-nM concentration, suggesting that dexamethasone inhibits this mechanism at higher concentrations. These trends were also observed in levels of alkaline phosphatase activity at similar culture conditions, suggesting that these effects also play a role in modulating enzyme activity. Mechanical stimulation in vitro has been shown previously to upregulate alkaline phosphatase protein expression and activity within BMSC cultures in the presence, of dexamethasone concentrations of both 0 and 10 nM [37, 38, 39]. Therefore, these results together with those of the present study demonstrate that alkaline phosphatase activity and expression are load-responsive within BMSCs in vitro, and that this effect can be modulated by dexamethasone concentration.

Osteopontin (OPN) is an RGD (arginine-glycine-aspartate)–containing phosphorylated sialoprotein, which has been shown to be present within mineralized bone matrix and, in particular, to be localized at sites of bone formation and resorption [69]. OPN has been shown to play a role in both cell attachment and mechanotransduction responses of osteoblasts in vitro [12, 23]. The expression of OPN has also been identified as an early marker of osteoblast differentiation [68]. Our results demonstrate that transcript levels of OPN mRNA increased in BMSCs in response to mechanical stimulation following 16 days of cultivation in the presence of 10 nM dexamethasone. These data are consistent with those of other cell culture systems involving various osteogenic cell types that generated increases in OPN expression levels in response to mechanical stimulation [17, 18, 39, 70]. Another important observation of this study is the inability of mechanical stimulation to effect OPN transcript levels at dexamethasone concentrations of 0 or 100 nM at similar culture conditions. These results suggest that mechanically stimulated OPN expression within BMSCs is dexamethasone-dependent, and that an optimal concentration range exists where OPN expression is load-responsive within this system. It is also interesting to note that the addition of dexamethasone significantly decreased BMSC OPN transcript levels independent of mechanical stimulation. Dexamethasone has previously been reported to stimulate increases in OPN expression within BMSCs during osteogenic differentiation on various substrates [71, 72, 73]. However, recent studies have shown that biomaterial surface characteristics (e.g., surface roughness, composition, and charge) can play a significant role in influencing OPN expression during osteogenic differentiation in vitro [74, 75]. Therefore, one possible explanation for this phenomenon may be the composition of DMB scaffolds, which are known to contain various matrix-incorporated factors (bone morphogenetic proteins and other noncollagenous proteins) capable of modulating osteogenic differentiation responses of BMSCs [76, 77, 78, 79, 80], and thus may have contributed to this effect of dexamethasone on OPN gene expression.

Transcript levels of osteocalcin, a bone matrix protein indicative of mature osteoblasts [81] were also analyzed and demonstrated not to be significantly effected by mechanical stimulation at any dexamethasone concentration within the 16 days of cultivation. Other related studies have shown that osteocalcin expression is sensitive to mechanical loading within BMSCs and osteoblastic cell lines in vitro [38, 82, 83]; however, these studies have reported varying responses, possibly because of the type of experimental system utilized. The lack of response within our system may also depend on the characteristics of our study, including loading regimen and culture duration. Further investigation is needed to determine the role of mechanical stimulation on osteocalcin expression within our model system. It is interesting to note, however, that the same mechanical regimen utilized in this study was able to differentially promote increases in the expression of some but not all bone-specific proteins investigated. This suggests that mechanical stimulation acts through specific mechanisms within BMSCs, which allow for the selective modification of particular osteogenic transcript levels during the differentiation process. Indeed, components of complex mechanotransduction pathways have been demonstrated within mature osteoblasts in vitro [83]; however, the role of these mechanisms in BMSCs has yet to be fully elucidated.

Mineralized matrix production was demonstrated to increase substantially in mechanically stimulated BMSCs cultured in 10 nM dexamethasone in comparison to respective static controls. We recently reported that within this culture system, BMSCs become localized to layers 200–300 μm from the scaffold exterior following a 14-day culture period [41]. Therefore, the observed region of increased matrix staining is demonstrated to correspond to this external cell layer. However, it should be noted that due to the presence of residual bovine hydroxyapatite within the partially DMB matrix, we are unable to conclude if the BMSC-mediated mineralization represents physiological calcification similar in crystal structure to hydroxyapatite or is dystrophic in nature. These data suggest that mechanical stimulation in combination with specific dexamethasone concentrations promotes increases in BMSC-mediated mineralization in comparison to static culture conditions. It is interesting to note that no apparent spatial differences in mineralization were detected along the exterior perimeter of the constructs, despite the nonuniform strain distribution parallel to the loading axis. However, these data are consistent with the results of Wozniak and colleagues; they observed a spatially homogeneous increase in BMSC mineralization in response to a nonuniform mechanical strain distribution within a 2-D culture system [40]. These observations in conjunction with this current study provide further evidence of the previous notion that strain-induced factors that are independent of strain magnitude may exist, which promote matrix mineralization in human BMSCs. Such factors in our current system may include potential load-induced fluid-flow effects, which may have significantly contributed to the uniform effect of mechanical stimulation on matrix mineralization. The ability of mechanical stimulation to promote mineralization beyond that produced with dexamethasone alone may provide a new tool in bone tissue engineering for accelerating the development of mineralized tissues in vitro prior to clinical use.

In summary, this study describes a novel bioreactor for investigating osteogenic differentiation of BMSCs in vitro on 3-D partially DMB matrices. Mechanical stimulation induced increased levels of alkaline phosphatase activity, bone-specific protein transcript levels (alkaline phosphatase and osteopontin), and mineralized matrix production by BMSCs. Dexamethasone was also found to have a significant effect on the ability of mechanical stimulation to promote osteogenic differentiation within this system.

References

A Heinonen H Sievanen H Kyrolainen J Perttunen P Kannus (2001) ArticleTitleMineral mass, size, and estimated mechanical strength of triple jumpers’ lower limb. Bone 29 279–285 Occurrence Handle10.1016/S8756-3282(01)00574-9 Occurrence Handle1:STN:280:DC%2BD3MrgvFynsw%3D%3D Occurrence Handle11557373

E Tanck J Homminga GH Lenthe Particlevan R Huiskes (2001) ArticleTitleIncrease in bone volume fraction precedes architectural adaptation in growing bone. Bone 28 650–654 Occurrence Handle10.1016/S8756-3282(01)00464-1 Occurrence Handle1:STN:280:DC%2BD3MzmsFSgtQ%3D%3D Occurrence Handle11425654

DB Burr C Milgrom D Fyhrie M Forwood M Nyska et al. (1996) ArticleTitle In vivo measurement of human tibial strains during vigorous activity. Bone 18 405–410 Occurrence Handle10.1016/8756-3282(96)00028-2 Occurrence Handle1:STN:280:BymA3Mbhsl0%3D Occurrence Handle8739897

L Wang SP Fritton SC Cowin S Weinbaum (1999) ArticleTitleFluid pressure relaxation depends upon osteonal microstructure: modeling an oscillatory bending experiment. J Biomech 32 663–672 Occurrence Handle10.1016/S0021-9290(99)00059-7 Occurrence Handle1:STN:280:DyaK1MzisF2nsg%3D%3D Occurrence Handle10400353

ML Knothe Tate R Steck MR Forwood P Niederer (2000) ArticleTitle In vivo demonstration of load-induced fluid flow in the rat tibia and its potential implications for processes associated with functional adaptation. J Exp Biol 203 2737–2745

LA MacGinitie GD Stanely WA Bieber DD Wu (1997) ArticleTitleBone streaming potentials and currents depend on anatomical structure and loading orientation. J Biomech 30 1133–1139 Occurrence Handle10.1016/S0021-9290(97)85605-9 Occurrence Handle1:STN:280:DyaK1c7hslCqtQ%3D%3D Occurrence Handle9456381

BR Beck YX Qin KJ McLeod MW Otter (2002) ArticleTitleOn the relationship between streaming potential and strain in an in vivo bone preparation. Calcif Tissue Int 71 335–343

J Klein-Nulend CM Semeins EH Burger (1996) ArticleTitleProstaglandin mediated modulation of transforming growth factor-metabolism in primary mouse osteoblastic cells in vitro. J Cell Physiol 168 1–7 Occurrence Handle10.1002/(SICI)1097-4652(199607)168:1<1::AID-JCP1>3.0.CO;2-T Occurrence Handle1:CAS:528:DyaK28XjvVSqu7o%3D Occurrence Handle8647903

Q Wang S Zhong J Ouyang L Jiang Z Zhang et al. (1998) ArticleTitleOsteogenesis of electrically stimulated bone cells mediated in part by calcium ions. Clin Orthop 348 259–268 Occurrence Handle9553560

R Smalt FT Mitchell RL Howard TJ Chambers (1997) ArticleTitleInduction of NO and prostaglandin E2 in osteoblasts by wall-shear stress but not mechanical strain. Am J Physiol 273 751–758

M Hartig U Joos HP Wiesmann (2000) ArticleTitleCapacitively coupled electric fields accelerate proliferation of osteoblast-like primary cells and increase bone extracellular matrix formation in vitro. Eur Biophys J 29 499–506 Occurrence Handle10.1007/s002490000100 Occurrence Handle1:CAS:528:DC%2BD3cXosVOls7s%3D Occurrence Handle11156291

CD Toma S Ashkar ML Gray JL Schaffer LC Gerstenfeld (1997) ArticleTitleSignal transduction of mechanical stimuli is dependent on microfilament integrity: identification of osteopontin as a mechanically induced gene in osteoblasts. J Bone Miner Res 12 1626–1636 Occurrence Handle1:CAS:528:DyaK2sXmvVSkt7k%3D Occurrence Handle9333123

D Murray N Rushton (1990) ArticleTitleThe effect of strain on bone cell prostaglandin E2 release: a new experimental method. Calcif Tissue Int 47 35–39

C Neidlinger-Wilke H Wilke L Claes (1994) ArticleTitleCyclic stretching of human osteoblasts affects proliferation and metabolism: a new experimental method and its applications. J Orthop Res 12 70–78 Occurrence Handle1:STN:280:ByuC2Mjnt1Y%3D Occurrence Handle8113944

C Brighton B Strafford S Gross D Leatherwood J Williams et al. (1991) ArticleTitleThe proliferative and synthetic response of isolated calvarial bone cells of rats to cyclic biaxial mechanical strain. J Bone Joint Surg 73 320–331 Occurrence Handle1:STN:280:By6C287mtlw%3D Occurrence Handle1848246

H Glantschnig F Varga M Rumpler K Klaushofer (1996) ArticleTitleProstacyclin (PGI2): a potential mediator of c-fos expression induced by hydrostatic pressure in osteoblastic cells. Eur J Clin Invest 26 544–548 Occurrence Handle10.1046/j.1365-2362.1996.165312.x Occurrence Handle1:CAS:528:DyaK28Xltlaiu7Y%3D Occurrence Handle8864415

J Klein-Nulend J Roelofsen C Semeins A Bronckers E Burger (1997) ArticleTitleMechanical stimulation of osteopontin mRNA expression and synthesis in bone cell cultures. J Cell Physiol 170 174–181 Occurrence Handle10.1002/(SICI)1097-4652(199702)170:2<174::AID-JCP9>3.0.CO;2-L Occurrence Handle1:CAS:528:DyaK2sXhtVeltro%3D Occurrence Handle9009146

I Owan D Burr C Turner J Qiu Y Tu et al. (1997) ArticleTitleMechanotransduction in bone: osteoblasts are more responsive to fluid forces than mechanical strain. Am J Physiol 273 810–815

K Sakai M Mohtai Y Iwamoto (1998) ArticleTitleFluid shear stress increases transforming growth factor beta 1 expression in human osteoblast-like cells: modulation by cation channel blockades. Calcif Tissue Int 63 515–520 Occurrence Handle10.1007/s002239900567 Occurrence Handle9817947

I Westbroek NE Ajubi MJ Albas CM Semeins J Klein-Nulend et al. (2000) ArticleTitleDifferential stimulation of prostaglandin G/H synthase-2 in osteocytes and other osteogenic cells by pulsating fluid flow. Biochem Biophys Res Commun 268 414–419 Occurrence Handle10.1006/bbrc.2000.2154 Occurrence Handle1:CAS:528:DC%2BD3cXhtFGjt7s%3D Occurrence Handle10679219

EH Burger J Klein-Nulend (1999) ArticleTitleMechanotransduction in bone—role of the lacuno-canalicular network. FASEB J 13 S101–112 Occurrence Handle1:CAS:528:DyaK1MXjtFGku7c%3D

VI Sikavitsas JS Temenoff AG Mikos (2001) ArticleTitleBiomaterials and bone mechanotransduction. Biomaterials 22 2581–2593 Occurrence Handle10.1016/S0142-9612(01)00002-3 Occurrence Handle1:CAS:528:DC%2BD3MXlsFymu7s%3D Occurrence Handle11519777

RS Carvalho JL Schaffer LC Gerstenfeld (1998) ArticleTitleOsteoblasts induce osteopontin expression in response to attachment on fibronectin: demonstration of a common role for integrin receptors in the signal transduction processes of cell attachment and mechanical stimulation. J Cell Biochem 70 376–390 Occurrence Handle10.1002/(SICI)1097-4644(19980901)70:3<376::AID-JCB11>3.0.CO;2-J Occurrence Handle1:CAS:528:DyaK1cXkvFCqsLY%3D Occurrence Handle9706875

T Davisson S Kunig A Chen R Sah A Ratcliffe (2002) ArticleTitleStatic and dynamic compression modulate matrix metabolism in tissue engineered cartilage. J Orthop Res 20 842–848 Occurrence Handle10.1016/S0736-0266(01)00160-7 Occurrence Handle1:CAS:528:DC%2BD38XltlertLg%3D Occurrence Handle12168676

GH Altman RL Horan I Martin J Farhadi PR Stark et al. (2002) ArticleTitleCell differentiation by mechanical stress. FASEB J 16 270–272 Occurrence Handle1:CAS:528:DC%2BD38XhsVCjsb8%3D Occurrence Handle11772952

BS Kim DJ Mooney (2000) ArticleTitleScaffolds for engineering smooth muscle under cyclic mechanical strain conditions. J Biomech Eng 122 210–215 Occurrence Handle10.1115/1.429651 Occurrence Handle1:STN:280:DC%2BD3M%2Fkt1Wmsw%3D%3D Occurrence Handle10923287

WH Zimmermann K Schneiderbanger P Schubert M Didie F Munzel et al. (2002) ArticleTitleTissue engineering of a differentiated cardiac muscle construct. Circ Res 90 223–230 Occurrence Handle10.1161/hh0202.103644 Occurrence Handle1:CAS:528:DC%2BD38Xhtl2lsro%3D Occurrence Handle11834716

K Tang G Dang Z Guo (2002) ArticleTitleThe effects of intermittent hydromechanics on the differentiation and function of bone marrow stromal derived osteoblasts in porous calcium phosphate ceramics. Zhonghua Yi Xue Za Zhi 82 665–668 Occurrence Handle1:CAS:528:DC%2BD38XptFSgsL8%3D Occurrence Handle12133462

Y Yang JL Magnay L Cooling HA El (2002) ArticleTitleDevelopment of a “mechano-active” scaffold for tissue engineering. Biomaterials 23 2119–2126 Occurrence Handle10.1016/S0142-9612(01)00342-8 Occurrence Handle1:CAS:528:DC%2BD38XhvVWhs7Y%3D Occurrence Handle11962652

SE Haynesworth J Goshima VM Goldberg AI Caplan (1992) ArticleTitleCharacterization of cells with osteogenic potential from human marrow. Bone 13 81–88 Occurrence Handle1:STN:280:By2B2Mngs1Y%3D Occurrence Handle1581112

DJ Prockop (1997) ArticleTitleMarrow stromal cells as stem cells for nonhematopietic tissues. Science 276 71–74 Occurrence Handle1:CAS:528:DyaK2sXitlyqt7g%3D Occurrence Handle9082988

AI Caplan DJ Fink T Goto AE Linton RG Young et al. (.) Mesenchymal stem cells and tissue repair. The anterior cruciate ligament: current and future concepts Raven Press N.Y.

JN Beresford JH Bennett C Devlin PS Leboy ME Owen (1992) ArticleTitleEvidence for an inverse relationship between the differentiation of adipocytic and osteogenic cells in rat marrow. J Cell Sci 102 341–351 Occurrence Handle1:CAS:528:DyaK38XlsVekt7w%3D Occurrence Handle1400636

S Wakitani T Goto SJ Pineda RG Young JM Mansour et al. (1994) ArticleTitleMesenchymal cell-based repair of large, full-thickness defects of articular cartilage. J Bone Joint Surg 76 579–592 Occurrence Handle1:STN:280:ByuB3c7itF0%3D Occurrence Handle8150826

B Seshi S Kumar D Sellers (2000) ArticleTitleHuman bone marrow stromal cell: coexpression of markers specific for multiple mesenchymal cell lineages. Blood Cells Mol Dis 26 234–246 Occurrence Handle10.1006/bcmd.2000.0301 Occurrence Handle1:CAS:528:DC%2BD3cXlslCqtbk%3D Occurrence Handle10950944

P Bianco P Gehron Robey (2000) ArticleTitleMarrow stromal stem cells. J Clin Invest 105 1663–1668 Occurrence Handle1:CAS:528:DC%2BD3cXkt1Wqs74%3D Occurrence Handle10862779

GP Thomas AJ el Haj (1996) ArticleTitleBone marrow stromal cells are load responsive in vitro. Calcif Tissue Int 58 101–108

T Yoshikawa SA Peel JR Gladstone JE Davies (1997) ArticleTitleBiochemical analysis of the response in rat bone marrow cell cultures to mechanical stimulation. Biomed Mater Eng 7 369–377

GN Bancroft VI Sikavitsas J Dolder Particlevan den TL Sheffield CG Ambrose et al. (2002) ArticleTitleFluid flow increases mineralized matrix deposition in 3D perfusion culture of marrow stromal osteoblasts in a dose-dependent manner. Proc Natl Acad Sci U S A 99 12600–12605 Occurrence Handle10.1073/pnas.202296599 Occurrence Handle1:CAS:528:DC%2BD38XnvFGiu7g%3D Occurrence Handle12242339

M Wozniak A Fausto CP Carron DM Meyer KA Hruska (2000) ArticleTitleMechanically strained cells of the osteoblast lineage organize their extracellular matrix through unique sites of alphavbeta3-integrin expression. J Bone Miner Res 15 1731–1745 Occurrence Handle1:CAS:528:DC%2BD3cXmsF2mtL4%3D Occurrence Handle10976993

JR Mauney J Blumberg M Pirun V Volloch G Vunjak-Novakovic et al. (2003) ArticleTitleOsteogenic differentiation of human bone marrow stromal cells on partially demineralized bone scaffolds in vitro. Tissue Eng 00 00

CH Turner MP Akhter DM Raab DB Kimmel RR Recker (1991) ArticleTitleA noninvasive, in vivo model for studying strain adaptive bone modeling. Bone 12 73–79 Occurrence Handle1:STN:280:By6B1M7ltF0%3D Occurrence Handle2064843

MP Akhter DM Raab CH Turner DB Kimmel RR Recker (1992) ArticleTitleCharacterization of in vivo strain in the rat tibia during external application of a four-point bending load. J Biomech 25 1241–1246 Occurrence Handle1:STN:280:ByyD3MnhvVU%3D Occurrence Handle1400526

DM Cullen RT Smith MP Akhter (2001) ArticleTitleBone-loading response varies with strain magnitude and cycle number. J Appl Physiol 91 1971–1976

RR Miles CH Turner R Santerre Y Tu P McClelland et al. (1998) ArticleTitleAnalysis of differential gene expression in rat tibia after an osteogenic stimulus in vivo: mechanical loading regulates osteopontin and myeloperoxidase. J Cell Biochem 68 355–365 Occurrence Handle10.1002/(SICI)1097-4644(19980301)68:3<355::AID-JCB6>3.0.CO;2-T Occurrence Handle1:CAS:528:DyaK1cXosVWitA%3D%3D Occurrence Handle9518261

R Rosenthal J Folkman J Glowacki (1999) ArticleTitleDemineralized bone implants for nonunion fractures, bone cysts, and fibrous lesions. Clin Orthop 364 61–69 Occurrence Handle10.1097/00003086-199907000-00009 Occurrence Handle10416393

G Vunjak-Novakovic B Obradovic I Martin PM Bursac R Langer et al. (1998) ArticleTitleDynamic cell seeding of polymer scaffolds for cartilage tissue engineering. Biotechnol Prog 14 193–202 Occurrence Handle10.1021/bp970120j Occurrence Handle1:CAS:528:DyaK1cXhs1Grsrg%3D Occurrence Handle9548769

Gere JM (1990) Mechanics of materials. PWS-KENT Pub. Co, Boston.

N Jaiswal SE Haynesworth AI Caplan SP Bruder (1997) ArticleTitleOsteogenic differentiation of purified, culture-expanded human mesenchymal stem cells in vitro. J Cell Biochem 64 295–312 Occurrence Handle1:CAS:528:DyaK2sXpt1Kqsw%3D%3D Occurrence Handle9027589

MR Forwood MB Bennett AR Blowers RL Nadorfi (1998) ArticleTitleModification of the in vivo four-point loading model for studying mechanically induced bone adaptation. Bone 23 307–310 Occurrence Handle10.1016/S8756-3282(98)00090-8 Occurrence Handle1:STN:280:DyaK1cvgsleksQ%3D%3D Occurrence Handle9737355

A Sabokbar PJ Millett B Myer N Rushton (1994) ArticleTitleA rapid, quantitative assay for measuring alkaline phosphatase activity in osteoblastic cells in vitro. Bone Miner 27 57–67 Occurrence Handle1:CAS:528:DyaK2MXhsVSkt78%3D Occurrence Handle7849547

I Martin M Jakob D Schafer W Dick G Spagnoli et al. (2001) ArticleTitleQuantitative analysis of gene expression in human articular cartilage from normal and osteoarthritic joints. Osteoarthritis Cartilage 9 112–118 Occurrence Handle10.1053/joca.2000.0366 Occurrence Handle1:STN:280:DC%2BD3M3lvFGntQ%3D%3D Occurrence Handle11237658

N Sato Y Takahashi S Asano (0000) ArticleTitlePreferential usage of bone-type leader sequence for the transcripts of liver/bone/kidney-type alkaline phosphatase gene in neutrophilic granulocytes. Blood 83 1093–1994

S Pri-Chen S Pitaru F Lokiec N Savion (1998) ArticleTitleBasic fibroblastic growth factor enhances the growth and expression of the osteogenic phenotpe of dexamethasone-treated human bone marrow-derived bone-like cells in culture. Bone 23 111–117 Occurrence Handle10.1016/S8756-3282(98)00087-8 Occurrence Handle1:CAS:528:DyaK1cXlsVKgtbk%3D Occurrence Handle9701469

EA Botchwey SR Pollack EM Levine CT Laurencin (2001) ArticleTitleBone tissue engineering in a rotating bioreactor using a microcarrier matrix system. J Biomed Mater Res 55 242–253 Occurrence Handle10.1002/1097-4636(200105)55:2<242::AID-JBM1011>3.3.CO;2-4 Occurrence Handle1:CAS:528:DC%2BD3MXhs1OmtrY%3D Occurrence Handle11255176

PV Bodine SK Vernon BS Komm (1996) ArticleTitleEstablishment and hormonal regulation of a conditionally transformed preosteocytic cell line from adult human bone. Endocrinology 137 4592–4604 Occurrence Handle1:CAS:528:DyaK28Xms1Cqt7c%3D Occurrence Handle8895322

CH Turner I Owan T Alvey J Hulman JM Hock (1998) ArticleTitleRecruitment and proliferative responses of osteoblasts after mechanical loading in vivo determined using sustained-release bromodeoxyuridine. Bone 22 463–469 Occurrence Handle10.1016/S8756-3282(98)00041-6 Occurrence Handle1:STN:280:DyaK1c3mtFCjtA%3D%3D Occurrence Handle9600779

PJ Kostenuik BP Halloran ER Morey-Holton DD Bikle (1997) ArticleTitleSkeletal unloading inhibits the in vitro proliferation and differentiation of rat osteoprogenitor cells. Am J Physiol 273 1133–1139

R Zhang SC Supowit GL Klein Z Lu MD Christensen et al. (1995) ArticleTitleRat tail suspension reduces messenger RNA level for growth factors and osteopontin and decreases the osteoblastic differentiation of bone marrow stromal cells. J Bone Miner Res 10 415–423 Occurrence Handle1:CAS:528:DyaK2MXmvVWnsLo%3D Occurrence Handle7785463

S Keila S Pitaru A Grosskopf M Weinreb (1994) ArticleTitleBone marrow from mechanically unloaded rat bones expresses reduced osteogenic capacity in vitro. J Bone Miner Res 9 321–327 Occurrence Handle1:STN:280:ByuB2cbksVY%3D Occurrence Handle8191925

DM Raab-Cullen MP Akhter DB Kimmel RR Recker (1994) ArticleTitlePeriosteal bone formation stimulated by externally induced bending strains. J Bone Miner Res 9 1143–1152 Occurrence Handle1:STN:280:ByqD28jgtFc%3D Occurrence Handle7976496

CH Turner MR Forwood MW Otter (1994) ArticleTitleMechanotransduction in bone: do bone cells act as sensors of fluid flow? FASEB J 8 875–878 Occurrence Handle1:STN:280:ByuA2M%2FhvVY%3D Occurrence Handle8070637

AG Robling DB Burr CH Turner (2001) ArticleTitleRecovery periods restore mechanosensitivity to dynamically loaded bone. J Exp Biol 204 3389–3399

YF Hsieh T Wang CH Turner (1999) ArticleTitleViscoelastic response of the rat loading model: implications for studies of strain-adaptive bone formation. Bone 25 379–382 Occurrence Handle10.1016/S8756-3282(99)00181-7 Occurrence Handle1:STN:280:DyaK1Mvitlegtw%3D%3D Occurrence Handle10495144

HM Frost (1987) ArticleTitleBone “mass” and the “mechanostat”: a proposal. Anat Rec 219 1–9 Occurrence Handle1:STN:280:BieD2srhslw%3D Occurrence Handle3688455

Y Umemura T Ishiko T Yamauchi M Kurono S Mashiko (1997) ArticleTitleFive jumps per day increase bone mass and breaking force in rats. J Bone Miner Res 12 1480–1485 Occurrence Handle1:STN:280:ByiH3s3ovVE%3D Occurrence Handle9286765

LF Cooper CT Harris SP Bruder R Kowalski S Kadiyala (2001) ArticleTitleIncipient analysis of mesenchymal stem-cell-derived osteogenesis. J Dent Res 80 314–320 Occurrence Handle1:CAS:528:DC%2BD3MXivVOmt70%3D Occurrence Handle11269722

JE Aubin F Liu L Malaval AK Gupta (1995) ArticleTitleOsteoblast and chondroblast differentiation. Bone 17 77S–83S Occurrence Handle1:CAS:528:DyaK2MXns1OgsLc%3D Occurrence Handle8579903

J Chen K Singh BB Mukherjee J Sodek (1993) ArticleTitleDevelopmental expression of osteopontin (OPN) mRNA in rat tissues: evidence for a role for OPN in bone formation and resorption. Matrix 13 113–123 Occurrence Handle1:CAS:528:DyaK3sXhs1GrtLc%3D Occurrence Handle8492741

RS Carvalho A Bumann JL Schaffer LC Gerstenfeld (2002) ArticleTitlePredominant integrin ligands expressed by osteoblasts show preferential regulation in response to both cell adhesion and mechanical perturbation. J Cell Biochem 84 497–508 Occurrence Handle10.1002/jcb.10031.abs Occurrence Handle1:STN:280:DC%2BD38%2FosFClsw%3D%3D Occurrence Handle11813255

JN Beresford CJ Joyner C Devlin JT Triffitt (1994) ArticleTitleThe effects of dexamethasone and 1,25-dihydroxyvitamin D3 on osteogenic differentiation of human marrow stromal cells in vitro. Arch Oral Biol 39 941–947 Occurrence Handle1:CAS:528:DyaK2MXjs12ks70%3D Occurrence Handle7695507

O Frank M Heim M Jakob A Barbero D Schafer et al. (2002) ArticleTitleReal-time quantitative RT-PCR analysis of human bone marrow stromal cells during osteogenic differentiation in vitro. J Cell Biochem 85 737–746 Occurrence Handle10.1002/jcb.10174 Occurrence Handle1:CAS:528:DC%2BD38Xjs1Whs78%3D Occurrence Handle11968014

G Lisignoli N Zini G Remiddi A Piacentini A Puggioli et al. (2001) ArticleTitleBasic fibroblast growth factor enhances in vitro mineralization of rat bone marrow stromal cells grown on non-woven hyaluronic acid based polymer scaffold. Biomaterials 22 2095–2105 Occurrence Handle10.1016/S0142-9612(00)00398-7 Occurrence Handle1:CAS:528:DC%2BD3MXlt1Kmt7Y%3D Occurrence Handle11432589

S Ozawa S Kasugai (1996) ArticleTitleEvaluation of implant materials (hydroxyapatite, glass-ceramics, titanium) in rat bone marrow stromal cell culture. Biomaterials 17 23–29 Occurrence Handle10.1016/0142-9612(96)80751-4 Occurrence Handle1:CAS:528:DyaK28XhvFyjtw%3D%3D Occurrence Handle8962943

Q Qiu M Sayer M Kawaja X Shen JE Davies (1998) ArticleTitleAttachment, morphology, and protein expression of rat marrow stromal cells cultured on charged substrate surfaces. J Biomed Mater Res 42 117–127

J Becerra JA Andrades DC Ertl N Sorgente ME Nimni (1996) ArticleTitleDemineralized bone matrix mediates differentiation of bone marrow stromal cells in vitro, effect of age of cell donor. J Bone Miner Res 11 1703–1714 Occurrence Handle1:CAS:528:DyaK28XnsV2js7c%3D Occurrence Handle8915778

NK Harakas (1984) ArticleTitleDemineralized bone-matrix-induced osteogenesis. Clin Orthop 188 239–251 Occurrence Handle6380863

MR Urist (1965) ArticleTitleBone formation by autoinduction. Science 150 893–899 Occurrence Handle1:STN:280:CCmD3Mbjsl0%3D Occurrence Handle5319761

MR Urist RF DeLange GA Finerman (1983) ArticleTitleBone cell differentiation and growth factors. Science 220 680–686 Occurrence Handle1:CAS:528:DyaL3sXktlKgsLc%3D Occurrence Handle6403986

E Solheim (1998) ArticleTitleOsteoinduction by demineralized bone. Int Orthop 22 335–342 Occurrence Handle1:STN:280:DyaK1M7htleksg%3D%3D Occurrence Handle9914941

JB Lian GS Stein (1992) ArticleTitleConcepts of osteoblast growth and differentiation: basis for modulation of bone cell development and tissue formation. Crit Rev Oral Biol Med 3 269–305 Occurrence Handle1:STN:280:By2B3sbmtFM%3D Occurrence Handle1571474

LV Harter KA Hruska RL Duncan (1995) ArticleTitleHuman osteoblast-like cells respond to mechanical stain with increased bone matrix protein production independent of hormonal regulation. Endocrinology 136 528–535 Occurrence Handle1:CAS:528:DyaK2MXjtleitLw%3D Occurrence Handle7530647

D Kaspar W Seidl C Neidlinger-Wilke A Ignatius L Claes (2000) ArticleTitleDynamic cell stretching increases human osteoblast proliferation and CICP synthesis but decreases osteocalcin synthesis and alkaline phosphatase activity. J Biomech 33 45–51 Occurrence Handle10.1016/S0021-9290(99)00171-2 Occurrence Handle1:STN:280:DC%2BD3c%2FnsFKjug%3D%3D Occurrence Handle10609517

CH Turner FM Pavalko (1998) ArticleTitleMechanotransduction and functional response of the skeleton to physical stress: the mechanisms and mechanics of bone adaptation. J Orthop Sci 3 346–355 Occurrence Handle10.1007/s007760050064 Occurrence Handle1:STN:280:DyaK1M%2FjtVOltw%3D%3D Occurrence Handle9811988

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mauney, J.R., Sjostorm, S., Blumberg, J. et al. Mechanical Stimulation Promotes Osteogenic Differentiation of Human Bone Marrow Stromal Cells on 3-D Partially Demineralized Bone Scaffolds In Vitro . Calcif Tissue Int 74, 458–468 (2004). https://doi.org/10.1007/s00223-003-0104-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00223-003-0104-7