Abstract

In this study, hydrodynamic chromatography coupled to inductively coupled plasma mass spectrometry has been evaluated for the simultaneous determination of dissolved and nanoparticulate species of gold and silver. Optimization of mobile phase was carried out with special attention to the column recovery of the different species and the resolution between them. Addition of 0.05 mM penicillamine to the mobile phase allowed the quantitative recovery of ionic gold and gold nanoparticles up to 50 nm, whereas 1 mM penicillamine was necessary for quantitative recovery of ionic silver and silver nanoparticles up to 40 nm. The resolution achieved between ionic gold and 10-nm gold nanoparticles was 0.7, whereas it ranged between 0.31 and 0.93 for ionic silver and 10-nm silver nanoparticles, depending on the composition of mobile phase. Best-case mass concentration detection limits for gold and silver species were 0.05 and 0.75 μg L−1, respectively. The developed methods allowed the simultaneous detection of nanoparticulate and dissolved species of gold and silver in less than 10 min. Size determination and quantification of gold and silver species were carried out in different dietary supplements, showing good agreement with the results obtained by electron microscopy and total and ultrafiltrable contents, respectively. Due to the attainable resolution, the quality of the quantitative results is affected by the relative abundance of nanoparticulate and dissolved species of the element and the size of the nanoparticles if present.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The continuous advances in nanoscience involve the growing use of different engineered nanoparticles (ENPs) in an increasing number of consumer products. This fact requires the adaptation of existing techniques and methods, or the development of new ones, to monitor their occurrence, fate, and transformations in different scenarios. In order to understand the environmental impact or the toxicological mechanisms of inorganic ENPs, it is critical to discriminate among dissolved and particulate forms of the element involved. Different techniques and methodological approaches for the characterization and quantification of ENPs and its derivatives in complex samples have been recently reviewed [1,2,3,4,5].

Asymmetric flow field flow fractionation (AF4) and hydrodynamic chromatography (HDC) are commonly coupled to inductively coupled plasma mass spectrometry (ICP-MS) as an element-specific detector for the separation and determination of inorganic ENPs in a variety of samples [1, 3]. Gray et al. [6] compared HDC and AF4, both coupled with ICP-MS, with respect to their capacity to detect, quantify, and characterize gold nanoparticles (AuNPs). They found that, although HDC is a robust and versatile separation technique, its resolving power is much lower than AF4, being even lower in the smallest size range. On the other hand, recoveries for HDC were better than for AF4 on average, ranging from 77 to 96% for HDC and from 4 to 89% for AF4. An additional advantage of HDC over AF4 lies in the analysis time, which can be reduced to less than 10 min, in comparison with 30–45 min of AF4, and dissolved low molecular mass species are not lost, as in AF4 due to the ultrafiltration membranes used in its separation channel. Thus, HDC-ICP-MS can provide simultaneous information about dissolved and particulate species of an element in less than about 10 min, which is not the case of AF4.

HDC is a liquid chromatographic separation technique in which the sample is injected into a column packed with non-porous beads, building up flow channels, and separation is produced by the velocity gradient within the capillaries between beads. Thus, larger particles are transported faster than smaller ones, as they spend less time near the edges of the capillaries. In packed columns, the beads should be inert, that is, made of a material that minimizes non-HDC enthalpic interactions between the beads and the dissolved analytes. Such non-HDC effects can be minimized through the addition of salts and/or surfactants to the solvent/mobile phase to screen electrostatic and van der Waals interactions, which are especially common in aqueous media [7]. Separation in HDC arises from the parabolic or Poiseuille-like flow profile that develops, under laminar flow conditions in the interstitial medium of a packed column, where the fastest streamlines of flow are in the middle of the interstitial medium and the slowest ones are near the packing particles. The first experimental paper on HDC was published in 1974 by Small [8], who employed a series of packed columns to separate and determine the particle size of various polystyrene latexes, carbon black, and colloidal silica. Since the first application of HDC coupled to ICP-MS [9], HDC has become popular in environmental analysis to understand the behavior, occurrence, and fate of nanomaterials (NMs) and colloids [10,11,12,13,14]. Due to the simplicity of the separation mechanism, the size determination and method development are straightforward [7, 9, 11]. For instance, the coupling of HDC to ICP-MS in single-particle mode (SP-ICP-MS), first described by Pergantis et al. [15], was applied to characterize AuNPs in drinking water by determining particle mass, hydrodynamic diameter, and number concentration.

The relative low size resolution of HDC compared to other size separation methods [5] is more relevant when analyzing NP mixtures [6, 9, 15, 16]. Gray et al. [6] showed the inability of HDC to separate a mixture of AuNPs, but also showed potential for separation of the Au dissolved from the AuNP standards. They suggested it might be possible to separate Au dissolved from NPs greater than 20 nm although without reporting any recoveries for dissolved Au. To the best of our knowledge, there are very few references in which the separation and potential quantification of ENPs and their corresponding metal ions using HDC-ICP-MS have been studied. Philippe et al. [11] studied the effect of the eluent composition on the retention factors of polystyrene nanoparticle standard, Rh3+ and AuNPs. They reported that when using a mobile phase without phosphate ions, the recovery for gold ions was 20% worse than when phosphate is used due probably to a stabilization effect of phosphate ions throughout the elution. In any case, they did not report any quantitative recoveries for AuNPs neither for ionic Au. Roman et al. [17] using HDC-SP-ICP-MS determined the concentration of dissolved Ag and the distribution of silver NPs (AgNPs), in terms of hydrodynamic diameter, mass-derived diameter, and number and mass concentration, in plasma and blood of burn patients. Peak from dissolved Ag in plasma (most probably complexed by proteins) could not be chromatographically resolved from those of 20-nm particles; thus, an innovative algorithm was implemented to deconvolute the signals of dissolved Ag and AgNPs and to extrapolate a multiparametric characterization of the particles in the same chromatogram. Pitkänen et al. [18] studied the quantitative characterization of AuNPs contrasting size-exclusion chromatography (SEC) and HDC coupled with ICP-MS. They obtained that column recoveries for AuNPs were complete and at least matched for both alternative methods. They reported a recovery value of 99 ± 2% for ionic Au using HDC-ICP-MS although no chromatogram of AuNPs and ionic Au all together was shown.

The aim of this work was to develop and evaluate separation methods based on the use of hydrodynamic chromatography coupled to ICP-MS for the simultaneous speciation of dissolved species and nanoparticles of gold and silver, the references being scarce in bibliography. The aim is focused in both nanoparticle size characterization and quantification of the different species. Optimization of the proposed HDC-ICP-MS method was carried out paying special attention on column recovery and resolution between dissolved species and nanoparticles. The methods were applied to the size characterization and quantitation of gold and silver species in dietary supplements containing nanoparticulate and/or ionic species.

Experimental

Materials and methods

Instrumentation

The high-performance chromatographic system used was a Waters 2796 Bioseparations Module (Waters Corporation, Milford, USA). HDC separations were performed in a PL-PSDA type 1 column (Agilent Technologies, Germany) with a nominal separation range of 5–300 nm, a length of 80 cm, and an internal diameter of 7.5 mm. The exit of the column was connected in series to an UV-visible detector (Waters 996 photodiode array detector) and to an ICP mass spectrometer (ELAN DRC-e, PerkinElmer, Toronto, Canada) for element-specific detection. The outflow from the system was delivered directly to the nebulizer of the spectrometer, and a glass concentric slurry nebulizer with a cyclonic spray chamber (Glass Expansion, Melbourne, Australia) was used. Table 1 summarizes the experimental ICP-MS and HDC conditions. Origin 8 (OriginLab, Northampton, MA, USA) was used for processing the chromatograms.

A gold dietary supplement was analyzed by transmission electron microscopy (TEM) with a JEOL-2000 FXII (JEOL Ltd., Tokyo, Japan) at 200 kV. The sample was prepared by placing 20 μL of the supplement suspension on a carbon-coated copper grid and drying at room temperature.

Silver dietary supplements were analyzed by field emission scanning electron microscopy (FESEM) with energy-dispersive spectrometry (EDS). The observations were performed in a Merlin™ FESEM microscope equipped with a Gemini column (Carl Zeiss Nano Technology Systems, Germany), working at 5 kV with the in-Lens secondary-electron detector, in order to improve resolution. FESEM was coupled with an X-Max X-ray microanalyzer (Oxford Instruments, UK). Twenty microliters of the product was deposited on a copper grid holder and, once the solvent was evaporated, coated with carbon. Image analysis was carried out using ImageJ software, and average particle diameter was determined by randomly measuring the area of a certain number of particles in the images, and calculated as equivalent circle diameter.

Chemicals

Diluted suspensions of gold and silver nanoparticles were prepared from commercially available suspensions. Suspensions of gold nanoparticles, stabilized in 2 mM citrate with nominal concentrations of 50 mg L−1 and nominal diameters of 10, 50, and 100 nm (11.6 ± 1, 52 ± 6, and 97 ± 11 nm, respectively), and suspensions of silver nanospheres (NanoXact), stabilized in 2 mM citrate with nominal concentrations of 20 mg L−1 and nominal diameters of 10, 20, 40, and 60 nm (10.3 ± 2.1, 18.6 ± 2.7, 39 ± 5, and 59 ± 6 nm), were all purchased from NanoComposix (San Diego, CA, USA). Ionic gold (1001 ± 4 mg L−1) and ionic silver (994 ± 3 mg L−1) standards were provided by Fluka BioChemika (Buchs, Switzerland).

Table 2 summarizes the different mobile phases tested for HDC separations. The pH of the mobile phases was in all cases 7.5. Na2HPO4, dl-penicillamine (PA), and Triton X-100 were obtained from Sigma-Aldrich Chemie (Stenheim, Germany); sodium dodecyl sulfate (SDS) from Bio-Rad Laboratories (Hercules, USA); and formaldehyde 37% (w/w) solution from Probus (Barcelona, Spain).

Ultrapure water (Milli-Q Advantage, Molsheim, France) was used for the preparation of the HDC mobile phases and dilutions.

Samples

A liquid nutritional supplement containing gold nanoparticles, with a nominal concentration of 20 mg L−1 and a nominal size of 3.2 nm, was purchased from a website distributor.

Three commercial colloidal silver products, purchased from different website distributors, were also analyzed. These products are recommended as health products intended for oral administration or as surface sanitizers for external use. The products were kept in a dark place at room temperature until analysis.

Determination of the total Au and Ag concentration in nanoparticle suspensions and nutritional supplements

Dissolution of gold nanoparticles was performed by adding 150 μL of nitric acid (69/70%, J.T. Baker (Phillipsburg, USA)) and 310 μL of hydrochloric acid (37%, J.T. Baker (Phillipsburg, USA)) to 100 μL of the suspension to be analyzed [11]. After 1 h at room temperature, solutions were diluted with ultrapure water up to 10 mL. The concentrations of total gold in AuNPs and the nutritional supplement were measured by ICP-MS using rhodium as the internal standard. Dissolution of AgNPs was performed by adding 750 μL of nitric acid to 750 μL of AgNP standard, and after 1 h at room temperature, solutions were diluted with ultrapure water up to 5 mL. For the nutritional supplements, between 500 μL and 1.5 mL of nitric acid were added to 500 μL of the supplement, after 1 h at room temperature, solutions were diluted with ultrapure water up to 5 mL. The concentrations of total silver in AgNPs and nutritional supplements were measured by flame atomic absorption spectroscopy (FAAS).

Determination of ionic gold and silver in nutritional supplements

The ionic species in the suspensions were isolated by removing gold and silver nanoparticles using Nanosep Pall centrifugal ultrafilter devices with cut-off membranes of 3 kDa (equivalent to 2-nm hydrodynamic diameter). Ultrafiltration devices were washed by centrifugation with 500 μL of ultrapure water twice. The second washing was kept to check for any potential contamination. Suspensions were sonicated for 2 min, and 500 μL was subjected to centrifugation for 30 min at 9000 rpm and 20 °C (in a Thermo Heraeus Multifuge X1R, equipped with a fixed angle rotor for Eppendorf tubes, Waltham, USA). For gold determination, the ultrafiltrate (ca. 500 μL) was diluted up to 10 mL with 5% HCl prior to ICP-MS analysis. For silver determination, the ultrafiltrate (ca. 500 μL) was diluted up to 5 mL with 1% HNO3 prior to FAAS analysis. The recovery of ionic gold and silver from the ultrafiltration devices under the operating conditions described above was better than 90% for both elements.

Column recovery calculation

Potential loses of analytes during the chromatographic separations were evaluated through the corresponding column recoveries, which were calculated from the ratio of the ICP-MS peak areas of standards injected into the chromatographic system with and without the HDC column, under the selected operational conditions. Three replicates of each measurement were performed. In total, 250 ng mL−1 of Au(III), AuNPs (10, 50, and 100 nm), Ag(I), and AgNPs (10, 20, 40, and 60 nm) solutions were used for recovery calculations. Au(III) and Ag(I) solutions were stabilized with different concentrations of PA depending on the mobile phase used.

Resolution calculation

In all cases, resolution was calculated as 2(t2−t1)/(w1+w2), where t1 and t2 are retention times, and w1 and w2 are peak widths of 10-nm AuNPs or AgNPs and ionic Au or Ag, respectively.

Results and discussion

Selection of mobile phases

Although different mobile phases have been reported for the separation of metallic nanoparticles by HDC, the column manufacturer recommends a mobile phase consisting of 0.5 mM Na2HPO4, 0.45 mM SDS, 0.05% Triton X-100, 0.05% formaldehyde, and pH 7.5 (CM mobile phase), which is used in most of the published works as such or with small modifications [6, 9, 11, 12, 17]. The low ionic strength of this mobile phase reduces electrostatic interactions between the NPs and the packing material because of the increase of the double layer [19]; the non-ionic surfactant Triton X-100 is used to prevent the aggregation of nanoparticles, whereas the anionic surfactant SDS prevents the sorption of nanoparticles onto the column packing material. Formaldehyde is used for its bactericidal properties and sodium hydrogen phosphate helps to maintain the neutral pH of the mobile phase.

Whereas most of works have focused on the separation of nanoparticles, the objective of this work was the development of chromatographic methods that allowed the separation of dissolved forms of gold and silver from their nanoparticle counterparts with adequate resolution and recoveries of the different species. Figure 1a shows the separation of AuNPs using the manufacturer mobile phase at a flow rate of 1.6 mL min−1. AuNPs standards of 10, 50, and 100 nm were eluted at 8.26, 8.08, and 7.94 min, respectively. Recoveries for the AuNPs ranged from 68 to 77% (Table 3), whereas ionic gold was fully retained in the column.

By using a simpler mobile phase containing 0.45 mM SDS at pH 7.5 (based on our previous experience [20]), AuNPs were eluted at slightly different retention times (8.10, 7.90, and 7.82 min for 10-, 50-, and 100-nm AuNPs, respectively), as it can be shown in the chromatogram of Fig. 1b. Better recoveries were obtained for AuNPs of 10 and 50 nm, except for 100 nm (88, 83, and 44%, respectively, see Table 3), although ionic gold was still retained into the column and no peak was obtained.

Although the nature of the packing material is not available from the manufacturer, cation exchange resin beads have been reported as a typical packing in HDC [21]. Thus, it seems feasible that both the nature of the packing and the instability of the cationic gold in the media contribute to its irreversible retention into the column. Different ligands (e.g., PA, thiosulfate) have been used for stabilization of cationic forms of elements subjected to separation by micellar electrokinetic [22] or reversed-phase chromatography [23]. The addition of l-cysteine, methionine, and PA to a mobile phase consisting of 0.45 mM SDS at pH 7.5 was studied in order to stabilize ionic gold without affecting the elution of the nanoparticles. PA was finally selected, since using l-cysteine or methionine ionic gold was not eluted or irreproducible results were obtained.

Three concentrations of PA (0.05, 0.2, and 0.5 mM) were investigated. Recoveries obtained for the AuNPs of 10, 50, and 100 nm and ionic gold at different PA concentrations are shown in Table 3. Recoveries in the range of 88–116% were obtained for ionic Au and 10-nm AuNPs at any PA concentration. For 50-nm AuNPs, the recovery was around 100% with a PA concentration of 0.05 mM and decreased down to 76% at the highest PA concentration of 0.5 mM. Recoveries for the 100-nm AuNPs were low at any PA concentration (72–61%), but this was also the case for the manufacturer mobile phase and 0.45 mM SDS mobile phase without PA (69% and 44%, respectively), as it is also shown in Table 3). Best recoveries for ionic Au and AuNPs were obtained by using a PA concentration of 0.05 mM, being used in all further experiments.

Figure 1c shows the chromatogram obtained using a mobile phase containing 0.45 mM SDS and 0.05 mM PA. Using this mobile phase at 1.6 mL min−1, an acceptable resolution of 0.70 between 10-nm AuNP and ionic Au was obtained (see Fig. 1c), which could be improved by working at lower flow rates (up to 1.03 at 1.0 mL min−1, as it can be seen in Fig. S1 of Supplementary Information (ESM)).

Separation conditions for ionic silver and silver nanoparticles were based on the previous experience gained with gold. To evaluate the behavior of AgNPs in the HDC column, both the manufacturer mobile phase and 0.45 mM SDS were studied by using UV-visible detection. The best recoveries were obtained with the manufacturer mobile phase, ranging from 100 to 92% for 10–60-nm AgNPs (Table S1 of ESM). Therefore, the manufacturer mobile phase with different PA concentrations (0.05, 0.2, 0.5, and 1 mM) was considered for stabilizing ionic silver and studying its separation from AgNPs using ICP-MS detection. Recoveries for the different PA concentrations are shown in Table 3. As it can be observed, good recoveries for ionic Ag (106%) were achieved by using 1 mM PA, higher than for ionic gold (0.05 mM). The recoveries for AgNPs were around 80% for 10 and 40 nm and 47% for 60 nm. In spite of the good recovery obtained by stabilizing the ionic silver with 1 mM of PA, resolution between 10-nm AgNPs and ionic Ag was too low (R = 0.16) (Fig. S2 of ESM). The use of a lower flow rate (1 mL min−1) did not improved the resolution in this case (R = 0.17). As an alternative for improving resolution, the reduction of the retention time of the nanoparticles by decreasing the ionic strength of the mobile phase was investigated, because at high ionic strength, strong van der Waals interactions dominate over the hydrodynamic effect, increasing the retention times of nanoparticles [19]. Mobile phases with lower ionic strength than manufacturer’s one, containing 1 mM PA for stabilization of ionic silver and different SDS concentrations, were studied. The resolution between 10-nm AgNPs and ionic Ag peaks increased from 0.31 up to 0.93 by decreasing SDS concentrations from 0.45 down to 0.22 mM. Although the best resolution was achieved for the mobile phase containing 0.22 mM SDS and 1 mM PA, recoveries were acceptable just for 10-nm AgNPs and ionic Ag (101 and 90%, respectively), whereas for 20-, 40-, and 60-nm AgNPs, recoveries were below 20%, most probably because of the instability and sorption of the larger NPs onto the column packing material. Thus, a mobile phase containing 0.34 mM SDS and 1 mM PA was selected as a compromise between resolution and recovery. The chromatograms obtained under such conditions are presented in Fig. 2. The resolution achieved between the 10-nm AgNPs and ionic Ag peaks was 0.63, with recoveries for Ag(I), 10-nm AgNP, and 20-nm AgNP of 103%, 102%, and 72%, respectively.

Analytical performance

Both logarithmic [9, 10, 13] and linear [11] fittings (by plotting retention time vs. diameter, or retention time vs. square root of diameter, respectively) have been applied for size calibration in HDC. Although some improvement in linearity has been reported when using the latter approach, no significant differences were observed in this work, with good logarithmic and linear fits, showing correlation coefficient in the range of 0.986 to 1 in both cases (Table S2 of ESM).

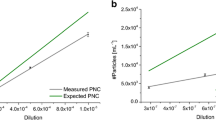

The retention times obtained for the different mobile phases studied are summarized in Tables S3 and S4 of the ESM for gold and silver species, respectively. In all cases, retention time repeatability was about 0.1% (n = 3). Gold and silver mass concentration calibrations were performed by using ionic standards prepared in the mobile phase selected for each element and injected in flow injection mode without column. Flow injection and chromatographic peaks were processed through their peak areas for mass concentration determination, showing good linearity in the range of 50 to 300 μg L−1 (R = 0.999).

Limits of detection (LOD) and quantification (LOQ) were related to the detectability of the peaks according to their height, and they were calculated as 3 and 10 times the baseline standard deviation divided by the slope of the peak height calibration. Under such conditions, best-case limits of detection and quantification for gold were 0.05 and 0.16 μg L−1, respectively, and 0.75 and 2.5 μg L−1 for silver.

Analysis of gold and silver species in nutritional supplements

One gold and three silver nutritional supplements were analyzed using the mobile phases optimized in the study and the operating conditions described in the “Experimental” section. Table 4 summarizes the concentrations and sizes obtained for the different species found in the nutritional supplements.

According to the manufacturer, the gold nutritional supplement contained 20 mg L−1 of gold as gold nanoparticles of 3.2 nm, whereas ionic gold was absent. Total content of gold was determined by ICP-MS following the procedure described in the “Experimental” section, obtaining a concentration of 21.0 ± 0.8 mg L−1, in agreement with the value given by the manufacturer. The nutritional supplement was analyzed by HDC-ICP-MS using 0.45 mM SDS and 0.05 mM PA as mobile phase. Figure 3a shows the chromatogram corresponding to a 1:150 dilution of the product in mobile phase. The chromatogram consisted of a peak at 7.99 min and a small shoulder at 8.47 min. The peak at 7.99 min corresponds to nanoparticles of 6.5 ± 0.1 nm (using linear fitting calibration), in agreement with the size of 6 nm found by France et al. using MECK-ICP-MS [22]. The small shoulder at 8.47 min would correspond to ionic gold, whose presence was also reported by France et al. [22]. This peak was not resolved from the nanoparticle peak due to the low size of the nanoparticles in the sample and the relative low abundance of the ionic gold. The nutritional supplements were also studied by electron microscopy in order to compare NP sizes. The NP size was determined by calculating the equivalent circle diameter by randomly measuring 87 particles in the images. In this way, the study of the gold supplement by TEM also showed a distribution maximum in a similar size (Fig. 4), with 5.1 ± 2.4-nm diameter, even though some bigger particles appeared in the TEM images. Quantification of the peak corresponding to AuNPs was 20.4 ± 0.8 mg L−1 in the original supplement, in agreement with the total concentration found by ICP-MS (21.0 ± 0.8 mg L−1). Although the determination of Au(III) by ultrafiltration and ICP-MS was attempted, it was below the detection limit of the method (2.3 μg L−1). To check the capability of the method for detection and quantification of ionic gold, the nutritional supplement was spiked with ionic gold (155 μg L−1) (see Fig. 3b). Ionic gold was eluted in the sample at 8.78 min with a mass recovery of 88.7 ± 4.5%.

Three different nutritional supplements containing colloidal and/or ionic silver were analyzed. According to the manufacturer, supplement 1 contained colloidal and ionic silver with a silver concentration of 25 mg L−1, supplement 2 contained colloidal silver with a concentration of 10 mg L−1 and a size range between 0.6 and 5 nm, and supplement 3 contained colloidal silver with a concentration of 30 mg L−1 and a size range between 1 and 100 nm. The three supplements were firstly analyzed by ultrafiltration and flame atomic absorption spectroscopy (FAAS) to determine ionic and total silver, obtaining the concentrations shown in Table 4. The three nutritional supplements were analyzed by HDC-ICP-MS using the mobile phase containing 0.34 mM SDS and 1 mM PA at a flow rate of 1.6 mL min−1 after dilution in the same mobile phase. The chromatograms obtained are shown in Fig. 5. The chromatogram of supplement 1 showed two peaks at 7.99 and 8.48 min, corresponding to AgNPs of 23.7 ± 0.8 nm and ionic Ag. In this case, with AgNPs of 23.7 nm, good resolution was obtained between AgNPs and ionic Ag, and the quantification gave good results as it is discussed below. The chromatogram of supplement 2 just showed a peak at 8.46 min with a small shoulder at 8.1 min which can be assigned to ionic Ag and AgNPs of 11.6 ± 2.2 nm, whereas the chromatogram of supplement 3 showed two peaks at 7.89 and 8.48 min, corresponding to AgNPs of 47.9 ± 0.03 nm and ionic Ag, respectively. In all cases, size linear fitting calibrations have been used.

The silver supplements were studied by FESEM, due to the expected bigger AgNP sizes. Figure 6 shows FESEM micrographs from supplements 1 and 2. AgNP size distributions were also calculated using ImageJ software (diameters of 82 and 67 particles were randomly measured, respectively, for supplements 1 and 2), showing mean sizes of 23.4 ± 5.8 and 14.2 ± 6.8 nm, which were in fair agreement with the sizes obtained by HDC-ICP-MS (see Table 4). AgNPs in supplement 1 were quite regular in size. However, in FESEM images, silver distribution of supplement 2 was heterogeneous. No reliable electron images were obtained for Supplement 3, most probably due to the composition of the sample.

The concentrations of different silver species obtained for each supplement are shown in Table 4, where results obtained for total and ionic silver by ultrafiltration and FAAS are also included for comparison. HDC-ICP-MS quantification for supplements 1 and 2 was in good agreement with the results obtained by ultrafiltration and FAAS. The small shoulder obtained for supplement 2 by HDC-ICP-MS, corresponding to 11.6-nm AgNPs, was not quantified due to the overlapping with the dissolved silver peak. Different batches from the same supplements had been previously analyzed by anodic stripping voltammetry [24], obtaining similar results. The presence of dissolved silver together with larger amounts of AgNPs was confirmed in supplement 3, although dissolved silver could not be quantified properly due to the overlapping with the peak corresponding to the nanoparticles. In this supplement, concentrations obtained by HDC-ICP-MS were lower than the total silver concentration determined by FAAS due to the low recoveries achieved for nanoparticles over 40 nm.

Conclusions

Although HDC-ICP-MS has been used successfully for the separation and quantification of inorganic nanoparticles, this hyphenated technique suffers from the inherent low resolution of hydrodynamic chromatography. However, the capability of HDC-ICP-MS for the simultaneous determination of dissolved species and nanoparticles of the same element had still not been exploited in depth. In this study, a HDC-ICP-MS methodology has been developed for the separation and determination of dissolved species and nanoparticles of gold and silver, by stabilizing the ionic forms of both elements by adding penicillamine to the mobile phases. Using a mobile phase containing penicillamine at 0.05 mM, ionic gold was eluted quantitatively from the HDC column, whereas a higher concentration, up to 1 mM, was required for ionic silver. Fair resolution (ca. 0.7–0.6) between dissolved species and 10-nm metallic nanoparticles was obtained with the optimized mobile phases, although the partial overlapping of the peaks corresponding to dissolved species and nanoparticles below 10 nm can hamper the quantification of the lower abundance species, especially when the latter are present at concentrations closed to the limit of quantification. In such cases, decreasing of the elution flow rate can improve the resolution but at the cost of increasing the separation time.

Using the developed methods, it was possible to detect the presence of nanoparticulate and/or dissolved species of gold and silver at the microgram per liter level in less than 10 min, as well as the simultaneous determination of the nanoparticle size and the mass concentration of both species, although the latter depending on their relative abundance and the size of the nanoparticles present. The analysis of different dietary supplements containing gold and silver confirmed the presence of nanoparticulate and/or dissolved species in the samples. The sizes of the gold and silver NPs found by HDC-ICP-MS in the dietary supplements were in good agreement with those found by TEM or FESEM, respectively. Quantitative results were compared with those obtained by ultrafiltration and AAS, although the quality of the results obtained depended on the relative abundance of the species in the sample and the size of the nanoparticles if present. Despite their limitations, the HDC-ICP-MS methods developed can be considered a feasible alternative to other methods based on techniques like single-particle ICP-MS, where the detectability of nanoparticles is more seriously affected by the presence of dissolved species.

Data availability

Not applicable

References

Laborda F, Bolea E, Cepriá G, Gómez MT, Jiménez MS, Pérez-Arantegui J, et al. Detection, characterization and quantification of inorganic engineered nanomaterials: a review of techniques and methodological approaches for the analysis of complex samples. Anal Chim Acta. 2016;904:10–32.

Gajdosechova Z, Mester Z. Recent trends in analysis of nanoparticles in biological matrices. Anal Bioanal Chem. 2019;411:4277–92.

Monikh FA, Chupani L, Vijver MG, Vancová M, Peijnenburg WJGM. Analytical approaches for characterizing and quantifying engineered nanoparticles in biological matrices from an (eco)toxicological perspective: old challenges, new methods and techniques. Sci Total Environ. 2019;660:1283–93.

Costa-Fernández JM, Menéndez-Miranda M, Bouzas-Ramos D, Ruiz J, Sanz-Medel A. Mass spectrometry for the characterization and quantification of engineered inorganic nanoparticles. Trends in Anal Chem. 2016;84:139–48.

López-Sanz S, Guzmán Bernardo FJ, Rodriguez Martí-Doimeadios RC, Rios A. Analytical metrology for nanomaterials: present achievements and future challenges. Anal Chim Acta. 2019;1059:1–15.

Gray EP, Bruton TA, Higgins CP, Halden RU, Westerhoff P, Ranville JF. Analysis of gold nanoparticle mixtures: a comparison of hydrodynamic chromatography and asymmetric flow field flow fractionation coupled to ICP-MS. J Anal At Spectrom. 2012;27:1532–9.

Striegel AM, Brewer AK. Hydrodynamic chromatography. Annu Rev Anal Chem. 2012;5:15–34.

Small H. Hydrodynamic chromatography. A technique for size analysis of colloidal particles. J Colloid Interface Sci. 1974;48:147–61.

Tiede K, Boxall ABA, Tiede D, Tear SP, David H, Lewis J. A robust size-characterization methodology for studying NP behaviour in real environmental samples, using HDC coupled to ICP-MS. J Anal At Spectrom. 2009;24:964–72.

Tiede K, Boxall ABA, Wang X, Gore D, Tiede D, Baxter M, et al. Application of hydrodynamic chromatography-ICP-MS to investigate the fate of silver nanoparticles in activated sludge. J Anal At Spectrom. 2010;25:1149–54.

Philippe A, Schaumann GE. Evaluation of HDC coupled with UV-visible, fluorescen and ICP-MS detectors for sizing and quantifying colloids in environmental media. Plos One. 2014;9:e90559.

Lewis DJ. HDC-ICP-MS with post-column injection capability for simultaneous determination of NP size, mass concentration and particle number concentration (HDC-PCi-ICP-MS). Analyst. 2015;140:1624–8.

Proulx K, Hadioui M, Wilkinson KJ. Separation, detection and characterization of nanomaterials in municipal wastewaters using HDC coupled to ICP-MS and single particle ICP-MS. Anal Bioanal Chem. 2016;408:5147–55.

Chang Y, Shih Y, Su C, Ho H. Comparison of three analytical methods to measure the size of silver nanoparticles in real environmental water and wastewater samples. J Hazard Mater. 2017;322:95–104.

Pergantis SA, Jones-Lepp TL, Heithmar EM. HDC with SP-ICP-MS for ultratrace detection of metal-containing nanoparticles. Anal Chem. 2012;84:6454–62.

Proulx K, Wilkinson KJ. Separation, detection and characterisation of engineered NPs in natural waters using HDC and multi-method detection (light scattering, analytical ultracentrifugation and SP-ICP-MS). Environ Chem. 2014;11:392–401.

Roman M, Rigo C, Castillo-Michel H, Munivrana I, Vindigni V, Micetic I, et al. HDC coupled to SP-ICP-MS for the simultaneous characterization of AgNPs and determination of disssolved Ag in plasma and blood of burn patients. Anal Bioanal Chem. 2016;408:5109–24.

Pitkänen L, Montoro Bustos AR, Murphy KE, Winchester MR, Striegel AM. Quantitative characterization of gold nanoparticles by size-exclusion and hydrodynamic chromatography coupled to inductively coupled plasma mass spectrometry and quasi-elastic light scattering. J Chromatogr A. 2017;1511:59–67.

Small H. Discoveries concerning the transport of colloids and new forms of chromatography. Acc Chem Res. 1992;25:241–5.

Abad-Alvaro I, Trujillo C, Bolea E, Laborda F, Fondevila M, Latorre MA, et al. Silver nanoparticles-clays nanocomposites as feed additives: characterization of silver species released during in vitro digestions. Effects on silver retention in pigs. Microchem J. 2019;149:104040.

McGowan GR, Langhorst MA. Development and application of an integrated, high-speed computerized hydrodynamic chromatography. J Colloid Interface Sci. 1982;89:94–106.

Franze B, Engelhard C. Fast separation, characterization and speciation of gold and silver nanoparticles and their ionic counterparts with micellar electrokinetic chromatography coupled to ICP-MS. Anal Chem. 2014;86:5713–20.

Yang Y, Luo L, Li HP, Wang Q, Yang ZG, Qu ZP, et al. Analysis of metallic nanoparticles and their ionic counterparts in complex matrix by reversed-phase liquid chromatography coupled to ICP-MS. Talanta. 2018;182:156–63.

Hernandez D, Cepriá G, Laborda F, Castillo JR. Detection and determination of released ions in the presence of nanoparticles: selectivity or strategy? Electroanalysis. 2019;31:405–10.

Acknowledgments

The authors would like to acknowledge the use of Servicio General de Apoyo a la Investigación-SAI, Universidad de Zaragoza.

Funding

This work was supported by the Spanish Ministry of Science Innovation and Universities and the European Regional Development Fund, project RTI2018-096111-B-I00 (MICINN/FEDER) and project EFA 183/16/OUTBIOTICS, Program Interreg-POCTEFA 2014-2020, funded by FEDER.

Author information

Authors and Affiliations

Contributions

M.S. Jimenez is the supervisor and coordinator of all experimental work and data revision. She did the experimental work regarding the analysis of gold dietary supplement. She is responsible of writing the manuscript.

M. Bakir is responsible for the experimental work regarding the characterization and quantification of silver nanoparticles and dissolved silver and the analysis of silver dietary supplements. She is the author of all figures.

D. Isabal did the experimental work regarding the characterization of gold nanoparticles and dissolved gold.

M.T. Gómez is the coordinator of the work in the group laboratory, being responsible for the supplies and has collaborated in the writing and revision of the manuscript.

J. Perez-Arantegui is responsible for FESEM and TEM measurements and data interpretation. She has collaborated in the revision of the manuscript.

F. Laborda is the main researcher of project RTI2018-096111-B-I00 (MICINN/FEDER). He has supervised the experimental work and the writing and revision of the manuscript.

J.R. Castillo is the main researcher of project EFA 183/16/OUTBIOTICS, Program Interreg-POCTEFA 2014-2020, funded by FEDER. He has supervised the writing and revision of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Not applicable

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

In memory of Juan R. Castillo who passed away a few days before the publication of this article.

Supplementary information

ESM 1

(PDF 415 kb)

Rights and permissions

About this article

Cite this article

Jiménez, M.S., Bakir, M., Isábal, D. et al. Evaluation of hydrodynamic chromatography coupled to inductively coupled plasma mass spectrometry for speciation of dissolved and nanoparticulate gold and silver. Anal Bioanal Chem 413, 1689–1699 (2021). https://doi.org/10.1007/s00216-020-03132-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-020-03132-3