Abstract

A liquid chromatography–tandem mass spectrometry method with derivatization and a modified quick, easy, cheap, effective, rugged, and safe (QuEChERS) sample preparation was developed for the determination of mancozeb in fruits. The target compound was determined in less than 4.0 min with use of an electrospray ionization source in positive mode. The limits of detection and the limits of quantification ranged from 1.0 to 3.2 μg kg-1 and from 10 to 15 μg kg-1 in fruit respectively. The linearity was excellent for mancozeb (R 2 ≥ 0.9920). Recoveries in five matrices were obtained at three spiking levels (0.02, 0.1, and 1 mg kg-1). For all concentrations, the mean recoveries ranged from 84.0% to 95.9%, with repeatability relative standard deviation (n = 5) of 0.6 − 7.0%. The interday reproducibility relative standard deviation (n = 3) ranged from 1.4% to 5.5%. This method could be used for the routine detection of mancozeb residues in fruit.

The derivation of mancozeb and the detection process of derivative product by UPLC-MS/MS

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mancozeb is a typical representative of ethylenebisdithiocarbamate fungicides. It is a complex of manganese and zinc 1,2-ethylenebisdithiocarbamate. Mancozeb has a wide fungicidal spectrum, and has been used to protect many fruits against fungal diseases, including downy mildew (on grapes), spot leaf drop (on apples), leaf spot (on bananas), and scab (on apples, peaches, and citrus) [1]. Because it is a protective fungicide, it needs to be sprayed on the surfaces of leaves and crops. The toxicity of mancozeb is very low, and its oral median lethal dose is 11,200 mg kg−1 in rats [2]. Because of these properties, mancozeb is one of the most used pesticides for fruit in China.

Mancozeb is practically insoluble in common organic and inorganic solvents [3]. It is very difficult to extract directly from fruit, so it cannot be used for multiresidue extraction with other groups of pesticides [4]. Two methods are usually used for the determination of mancozeb. One is the decomposition of mancozeb to CS2 by reaction with SnCl2–HCl solution (Fig. 1). The liberated CS2 is absorbed in hexane, and then the concentration of CS2 in hexane is detected by UV spectrophotometry [5, 6], gas chromatography [7, 8], or gas chromatography–mass spectrometry (MS) [1]. But these methods are time-consuming and have poor stability and repetitiveness because of the volatility of CS2. The other is the transformation of mancozeb into water-soluble sodium salts and methylated species. The production of the methylated species, dimethyl ethylenebisdithiocarbamate (EBDC-dimethyl), is determined by liquid chromatography (LC)–MS [9]. Iodomethane [10] and dimethyl sulfate [9] are common derivation agents. Chen et al. [11] applied dimethyl sulfate as a derivation reagent to methylate mancozeb. Mancozeb residues can also be determined by diode-array detector spectrometry [6, 12] and LC–MS [9]. But these methods are time-consuming and have low sensitivity, the detection of each sample taking approximately 15 min, and the limits of quantification (LOQs) range from 0.02 to 0.5 mg kg−1.

The QuEChERS method is a quick, easy, cheap, effective, rugged, and safe sample preparation method. It has the advantages of high recovery for pesticides with different properties and the use of small amounts of organic solvent [13]. The QuEChERS method was developed in 2003 [14], and was modified by Lehotayin et al. [15] in 2005. Generally, the analytes are extracted with acetonitrile, and the liquid–liquid partitioning is conducted with NaCl and anhydrous MgSO4. The dehydration and cleanup are performed with MgSO4 and different sorbents, such as octadecylsilane (C18), graphitized carbon black (GCB), or primary–secondary amines (PSAs) [16]. The advantage of LC–MS/MS is that it has high sensitivity and selectivity. The QuEChERS method combined with LC–MS/MS has been successfully used for the rapid detection of pesticide residues in fruit and fruit juices [17, 18].

The QuEChERS method is seldom used for the detection of mancozeb. Chen et al. [10] applied dimethyl sulfate as a derivation reagent and detected the residues of mancozeb in apple by ultraperformance LC–MS/MS with QuEChERS purification. Because dimethyl sulfate is highly toxic and carcinogenic, it is regulated by national agencies in China. This method cannot be widely applied to routine analysis of samples. In this work, mancozeb was transformed into nabam with an alkaline EDTA-Na2 solution. Nabam reacted with iodomethane to generate EBDC-dimethyl (Fig. 1). A modified QuEChERS method was applied to extract EBDC-dimethyl from fruits for the first time. EBDC-dimethyl was detected by ultraperformance LC–MS/MS. The method developed could be widely applied to analyze mancozeb in actual fruit samples.

Experimental

Reagents and materials

The analytical standard mancozeb (88.1%, w/w) was supplied by Riedel-de Haën (Seelze, Germany). Acetonitrile was high-performance LC grade (Fisher Scientific, USA). Analytical-grade NaCl, EDTA-Na2, acetic acid, and anhydrous MgSO4 were purchased from Beijing Chemical Co. (Beijing, China). Iodomethane was purchased from Shanghai Yolen Co. (Shanghai, China). Tetrabutylammonium hydrogen sulfate was obtained from Tianjin Guangfu Fine Chemical Research Institute (Tianjin, China). l-Cysteine (98.5%) was supplied by Sinopharm Chemical Reagent Co. (Beijing, China). Ultrapure water was prepared with a Milli-Q reagent water system (Millipore, Bedford, MA, USA). PSA, GCB, and C18 were obtained from Agela Technologies (Beijing, China).

Instrumentation

A Waters (Milford, MA, USA) Xevo TQD triple-quadrupole tandem mass spectrometer equipped with an electrospray ionization source and a Waters ACQUITY UPLC system equipped with an ACQUITY UPLC binary solvent manager, an ACQUITY UPLC manager, an ACQUITY column heater, and an ACQUITY UPLC HSS T3 column (2.1 mm × 100 mm, 1.8-μm particle size). The mobile phase consisted of chromatography-grade acetonitrile (solvent A) and 0.2% formic acid in water (solvent B) (pH 2.64). The gradient program was as follows: 0 − 2.0 min, 5% to 95% solvent A; 2.0 − 2.5 min, 95% to 5% solvent A; 2.5 − 4.0 min, 5% solvent A. The flow rate was 0.4 mL min-1, and the amount of injected sample was 5 μL. The column was maintained at 40 °C, and the temperature in the sample manager was maintained at 4 °C. MS/MS detection was performed in positive ionization mode; the nebulizer gas was 99.99% nitrogen and the collision gas was 99.99% argon in the T-Wave cell. The capillary voltage was set at 2.0 kV, the source temperature was maintained at 150 °C, and the desolvation temperature was maintained at 500 °C. The flow rates of the cone gas and the desolvation gas were 50 and 800 L/h respectively. Multiple reaction monitoring mode was used for the target compounds. Under the described conditions, the retention time of EBDC-dimethyl was approximately 2.15 min. Table 1 gives the optimal mass-spectrometric conditions used to determine EBDC-dimethyl.

Preparations of solutions

For preparation of the alkaline extraction solution, 74.4 g EDTA-Na2 was dissolved in 600 − 700 mL water and the pH was adjusted to 9.6 − 10.0 with 1 mol L-1 NaOH, with dilution with water to 1 L.

Tetrabutylammonium hydrogen sulfate solution (0.41 mol L-1) was prepared by dissolution of 136 g tetrabutylammonium hydrogen sulfate in 1 L water.

Sample preparation procedure

Samples were chopped and homogenized in an Ultra-Turrax homogenizer (IKA-Werke, Staufen, Germany). Prepared samples were stored at -20 °C in the dark until analysis. Samples (10 ± 0.1 g) were added to a 50-mL Teflon centrifuge tube, and 15 mL alkaline extraction solution and 0.1 g l-cysteine were added. The tubes were capped, and the contents were stirred for 5 min. Then, 1.5 mL tetrabutylammonium hydrogen sulfate and 150 μL iodomethane were added. The tubes were capped, and the contents were stirred for 10 min and allowed to stand for 30 min. Then, 10 mL acetonitrile, 4 g anhydrous MgSO4, and 2 g NaCl were added to extract the EBDC-dimethyl. The tubes were capped, and the contents were stirred for 5 min. This was followed immediately by centrifugation (5000 rpm) for 5 min, and 2 mL of the upper layer (acetonitrile) was transferred into a 5-mL centrifuge tube, which contained sorbent (50 mg PSA and 200 mg MgSO4), and the extracts were vortexed again for 1 min and subsequently centrifuged for 2 min at 5000 rpm. The upper extract was filtered by a 0.22-μm nylon syringe filter and subsequently transferred to an autosampler vial for injection into the ultraperformance LC–MS/MS system.

Preparation of matrix-matched standard solutions

The standard stock solution of mancozeb (10 mg L−1) was prepared in acetonitrile. The sample blank solutions (apple, peach, grape, citrus, and banana were not contaminated with mancozeb) were prepared by the sample preparation procedure. Water (10 mL) instead of sample (10 g) and five (0.01, 0.05, 0.1, 0.5, 1, and 2 mg kg−1) concentrations of mancozeb standard solution were added and the water samples were considered as the standard solutions samples. Then the standard solutions samples were prepared by the same sample preparation procedure.Correspondingly, standard working solutions were produced at 0.01, 0.05, 0.1, 0.5, 1, and 2 mg kg−1. One milliliter of the standard working solution was pipetted into a 2-mL autosampler vial and dried under nitrogen. Then 1 mL sample blank solution was added to the 2-mL autosampler vial and mixed, the standard working solution was corresponding matrix-matched standard solutions [19].

Method validation

Five fruits (apple, peach, grape, citrus, and banana) were selected for method validation. The validation of the method was done through the following parameters: linearity, matrix effect, recovery, LOQ, limit of detection (LOD), precision, and accuracy. The linearity of the method was studied by our analyzing the blank standard and the matrix-matched standard at five concentrations (0.01, 0.05, 0.1, 0.5, 1, and 2 mg kg-1). The accuracy and precision of the method were estimated by recovery experiments. The recovery experiments were performed with five matrices in five replicates at three spiking levels (0.02, 0.1, and 1 mg kg-1). The LODs were based on the minimum amount of target compound that produced a chromatogram peak with a signal-to-noise ratio three times the background chromatographic noise. The LODs were defined as the lowest validated concentration. Matrix effects were evaluated through comparison of the slopes of the calibration curves obtained in the matrix and in the solvent.

Results and discussion

Optimization of MS/MS and chromatography conditions

In our system, positive mode was the optimal mode for EBDC-dimethyl in multiple reaction monitoring mode. It offered higher precursor ion signal intensities than the negative mode. The cone voltages and collision voltages can influence the sensitivity of MS/MS. EBDC-dimethyl can be protonated and obtained as the most intense transitions under the optimal cone voltages and optimal collision voltages. The molecular weights, precursor ions, cone voltages, and corresponding collision voltages are listed in Table 1.

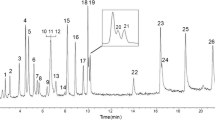

The different mobile phase compositions can significantly affect the peak shapes and retention [20]. In our experiment, methanol–water, methanol–0.2% formic acid aqueous solution, acetonitrile–water, and acetonitrile–0.2% formic acid aqueous solution were compared in the gradient program with a flow rate of 0.4 mL min-1. The peak shapes and the retention behavior of EBDC-dimethyl were optimal when acetonitrile–0.2% formic acid aqueous solution was used (pH 2.64). Therefore, acetonitrile–0.2% formic acid aqueous solution was selected as the mobile phase. EBDC-dimethyl was chromatographically separated from the matrix. The retention time of EBDC-dimethyl was 2.15 min, and there was no interference peak (Fig. 2).

Optimization of QuEChERS sample preparation

Optimization of the extraction solvent

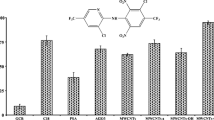

A recovery experiment was performed for optimum extraction and purification of EBDC-dimethyl from the samples. Acetonitrile, acetonitrile containing 0.1% (v/v) formic acid, and methanol were tested as the extraction solvents [21]. Three extraction solvent was assessed at a spiking level of 0.02 mg kg−1. From the result of Fig. 3, we know that the recoveries of acetonitrile as extraction solvent were the highest for five fruits. So we chose acetonitrile as the extraction solvent. Additionally, 2 g NaCl was used to induce a phase separation, 4 g MgSO4 was used to absorb water in the solvent, and the sorbents were not used in the five matrices. Figure 3 presents the results for the mean recoveries of the three extraction solvents without sorbents in the five matrices. Considering all factors, acetonitrile was selected as the extraction solvent.

Effect of different types of extraction solvent for the target compounds in different fruit matrices at the 0.02 mg kg-1 level (n = 5). The significance test was done with SPSS Statistics(i.e., version 17). Different lowercase letters in the same fruit matrix indicate significant differences (P ≤ 0.05), and different uppercase letters in the same fruit matrix indicated significant differences (P ≤ 0.01)

Optimization of dispersive solid-phase extraction sorbent

The amounts of PSA, C18, GCB, and anhydrous MgSO4 had great influences on the recoveries. We used four types of sorbents: 10 mg GCB and 200 mg MgSO4; 50 mg PSA and 200 mg MgSO4; 50 mg C18 and 200 mg MgSO4; and 20 mg PSA, 30 mg C18, and 200 mg MgSO4. The different sorbents were added to the five matrices at a spiking level of 0.02 mg mL-1. The influence of the different sorbents was estimated by the recovery in the five matrices. As shown in Fig. 4, when the 50 mg PSA and 200 mg MgSO4 sorbent and the 20 mg PSA, 30 mg C18, and 200 mg MgSO4 sorbent were used in the treatment of the matrices of the five fruits, the recovery and relative standard deviation (RSD) were both satisfactory [19]. Because the recoveries and RSD were better when the 50 mg PSA and 200 mg MgSO4 sorbent was used, this sorbent was selected to purify EBDC-dimethyl.

Effect of different sorbents for the target compounds in different matrices at the 0.02 mg kg-1 level (n = 5). Different lowercase letters in the same fruit matrix indicate significant differences (P ≤ 0.05), and different uppercase letters in the same fruit matrix indicated significant differences (P ≤ 0.01). GCB graphitized carbon black, PSA primary–secondary amine

Method validation

The validation of the analytical method was performed by means of the following parameters: linearity, matrix effect, recovery, LOQ, LOD, precision, and accuracy.

Matrix-matched calibration is a common approach to compensate for matrix effects. In this study, the linearity was assessed with a standard solution and a matrix-matched standard solution in the range from 0.01 to 2 mg kg-1. As shown in Table 2, the regression equations and coefficients (R 2) of all matrix-matched curves indicate that satisfactory linearity was attained for mancozeb (R 2 ≥ 0.9920 in all cases). The LOD was the concentration of the target analyte that produced a chromatogram peak with a signal-to-noise ratio of 3. The LOQ was defined as the lowest validated concentration. The estimated LODs for mancozeb in fruits were 1.0 − 3.2 μg kg-1, and the LOQs for mancozeb were 10 − 15 μg kg-1.

The matrix effect was evaluated by the ratio of the slope in the solvent and the matrix. The scale and the type of the matrix effect can be derived from the following equation [20]:

According to the slope ratio, we can determine the type of matrix effect. If the slope ratio is greater than 1, there is an enhancement effect. If the slope ratio is less than 1, there is a suppression effect. If the slope is between −20% and 20%, there is a mild signal suppression or enhancement effect, if the slope is between −50% and 50%, there is a medium effect, and if the slope is below −50% or above +50%, there is a strong signal suppression or enhancement effect [22]. The data in Table 2 indicate that the slope ratios ranged from 0.32 to 1.04, and the matrix effect ranged from − 67.78% to 4.31%. Different samples have different matrix effects for mancozeb: grape and banana showed a strong signal suppression effect (matrix effect −67.78% for grape and −64.18% for banana), citrus showed a medium signal suppression effect (matrix effect −35.58%), peach showed a mild signal suppression effect (matrix effect −2.94%), and apple led to mild signal enhancement (matrix effect 4.31%). Because the matrix effect was different in different fruits, it was necessary to use matrix-matched standard calibration for accurate quantitation.

The accuracy and precision of the method were obtained by recovery studies by spiking in five matrices at levels of 0.02, 0.1, and 1.0 mg kg-1. The repeatability of the method was evaluated by five replicate samples (n = 5) at each level (Table 3). The reproducibility of the method was assessed on three analysis days and for three operators. The accuracy of the method was evaluated by the recovery, and the precision of the method was evaluated by the repeatability RSD, and the reproducibility RSD. As Table 3 shows, for all concentrations, the mean recoveries ranged from 84.0% to 95.9% with a repeatability RSD (n = 5) of 0.6 − 7.0%. The interday reproducibility RSD (n = 3) for the method ranged from 1.4% to 5.5%. The mean recoveries (n = 15) for the method ranged from 87.7% to 94.5%. The results demonstrated that the sensitivity, accuracy, and repeatability of the method were suitable for pesticide residue analysis for mancozeb in fruits, and that it is easy to perform in practice.

Analysis of real samples

To demonstrate its practicality, the method was used to analyze 50 real samples (ten each of apple, peach, grape, citrus, and banana), which were collected from local markets in Huludao (China). Residues of mancozeb were found in two apple samples, three peach samples, and two grape samples, ranging in concentration from 4.3 to 103.2 μg kg-1.

The residues of mancozeb in four samples (one apple sample, two peach samples, and one grape sample) were below the respective LOQ. The residues of mancozeb in the other samples (seven apple samples, seven grape samples, ten citrus samples, and ten banana samples) were below the respective LOD. The chromatograms of EBDC-dimethyl in a blank peach sample and a real peach sample are shown in Fig. 5.

Conclusions

A simple, rapid, and reliable residue analytical method based on a modified QuEChERS method was developed to determine mancozeb in fruit using ultraperformance LC–MS/MS. In this method, mancozeb was transformed into EBDC-dimethyl by iodomethane. EBDC-dimethyl was determined in less than 4.0 min with use of an electrospray ionization source in positive mode. Compared with previous methods, this method is simple, rapid, stable, and sensitive, with the advantage of a relatively low consumption of organic solvents and also relatively small amounts of sample. In addition, iodomethane instead of the highly toxic chemical dimethyl sulfate was used as the derivation agent. This method has satisfactory recovery, precision, linearity, and analytical limits (LODs and LOQs). The recoveries ranged from 84.0% to 95.9% in different matrices. The LOQs ranged from 10 to15 μg kg-1 in different matrices. Matrix-matched calibration could compensate for the strong matrix effect. Consequently, this method could satisfy international regulations and detection requirements for the routine analysis of real samples.

References

Mujawar S, Utture SC, Fonseca E, Matarrita J, Banerjee K. Validation of a GC–MS method for the estimation of dithiocarbamate fungicide residues and safety evaluation of mancozeb in fruits and vegetables. Food Chem. 2014;150(5):175–81.

Edwards IR, Ferry DG, Temple WA. Fungicides and related compounds. In: Hayes WJ, Laws ER, editors. Handbook of pesticide toxicology. New York: Academic; 1991.

Moros J, Armenta S, Garregues S, Guardia M. Comparison of two vibrational procedures for the direct determination of mancozeb in agrochemicals. Talanta. 2007;72(1):72–9.

Armenta S, Moros J, Garregues S, Guardia M. Direct determination of mancozeb by photoacoustic spectrometry. Anal Chim Acta. 2006;567(2):255–61.

Caldas D, Conceição MH, Miranda MCC, SouzaL CKR, Joaquim FJ, Lima F. Determination of dithiocarbamate fungicide residues in food by a spectrophotometric method using a vertical disulfide reaction system. J Agric Food Chem. 2001;49(10):4521–5.

López-Fernández O, Rial-Otero R, González-Barreiro C, Simal-Gándara J. Surveillance of fungicidal dithiocarbamate residues in fruits and vegetables. Food Chem. 2012;134(1):366–74.

Qin S, Qiao XW, Wang X, Zhao LJ. Determination of 4 dithiocarbamate residues in 22 matrices by gas chromatography. Chin J Chromatogr. 2010;28(12):1162–7.

Vryzas Z, Papadakis EN, Papadopoulou-Mourkidou E. Microwave assisted extraction (MAE)-acid hydrolysis of dithiocarbamates for trace analysis in tobacco and peaches. J Agric Food Chem. 2002;50(8):2220–6.

Blasco C, Font G, Pico YJ. Determination of dithiocarbamates and metabolites in plants by liquid chromatography–mass spectrometry. J Chromatogr A. 2004;1028(2):267–76.

Zhu WX, Yang JZ, Liu YF, Wei W. Determination of 6 ethylenebisdithiocarbamates residues in tea by liquid chromatography tandem mass spectrometry with solid-phase extraction purification. J Instrum Anal. 2010;29(11):1109–13.

Chen WY, Dong FS, Liu XG, Qin DM, Liao XL, Cheng L, et al. Simplified method for determination of mancozeb residues in apple using ultra performance liquid chromatography-mass spectrometry. Chin J Anal Chem. 2011;38(4):508–12.

Garcinuno RM, Fernandez-Hernando P, Camara C. Simultaneous determination of maneb and its main metabolites in tomatoes by liquid chromatography using diode array ultraviolet absorbance detection. J Chromatogr A. 2004;1043(2):225–9.

Cajka T, Riddellova K, Zomer P, Mol H, Hajslova J. Direct analysis of dithiocarbamate fungicides in fruit by ambient mass spectrometry. Food Addit Contam. 2011;28(10):1372–82.

Anastassiades M, Lehotay SJ, Stajnbaher D, Schenck FJ. Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for the determination of pesticide residues in produce. J AOAC Int. 2003;86(2):412–31.

Lehotay SJ, Maštovsk K, Lightfield AR. Use of buffering and other means to improve results of problematic pesticides in a fast and easy method for residue analysis of fruits and vegetable. J AOAC Int. 2005;88(2):615–29.

Pang NN, Wang TL, Hu JY. Method validation and dissipation kinetics of four herbicides in maize and soil using QuEChERS sample preparation and liquid chromatography tandem mass spectrometry. Food Chem. 2016;190:793–800.

Zhu YL, Liu XG, Xu J, Dong FS, Liang XY, Li MM, et al. Simultaneous determination of spirotetramat and its four metabolites in fruits and vegetables using a modified quick, easy, cheap, effective, rugged, and safe method and liquid chromatography/tandem mass spectrometry. J Chromatogr A. 2013;1299(14):71–7.

Zhang YH, Zhang XL, Jiao BN. Determination of ten pyrethroids in various fruit juices: comparison of dispersive liquid–liquid microextraction sample preparation and QuEChERS method combined with dispersive liquid–liquid microextraction. Food Chem. 2014;159(11):367–73.

European Commission. Guidance document on analytical quality control and method validation procedures for pesticides residues analysis in food and feed. SANTE/11945. 2015.

Wu XH, Xu J, Dong FS, Liu XG, Li YB, Zheng YQ. Simultaneous determination of oxathiapiprolin and two metabolites in fruits, vegetables and cereal using a modified quick, easy, cheap, effective, rugged, and safe method and liquid chromatography coupled to tandem mass spectrometry. J Chromatogr A. 2014;1329(3):30–7.

Amirahmadi M, Shoeibi S, Abdollahi M, Rastegar H, Khosrokhavar R, Hamedani MP. Monitoring of some pesticides residue in consumed tea in Tehran market. Iran J Environ Health. 2013;10:1–6.

Li MM, Liu XG, Dong FS, Xu J, Kong ZQ, Li YB, et al. Simultaneous determination of cyflumetofen and its main metabolite residues in samples of plant and animal origin using multi-walled carbon nanotubes in dispersive solid-phase extraction and ultrahigh performance liquid chromatography–tandem mass spectrometry. J Chromatogr A. 2013;1300:95–103.

Acknowledgements

This work was financially supported by the National Program for Quality and Safety Risk Assessment of Agricultural Products of China (GJFP2016003) and the Agricultural Science and Technology Innovation Program of the Chinese Academy of Agricultural Sciences (CAAS-ASTIP).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Xu, G., Nie, J., Li, H. et al. Determination of mancozeb residue in fruit by derivatization and a modified QuEChERS method using ultraperformance liquid chromatography–tandem mass spectrometry. Anal Bioanal Chem 409, 5057–5063 (2017). https://doi.org/10.1007/s00216-017-0451-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-017-0451-2