Abstract

Established maximum levels for the mycotoxin zearalenone (ZEN) in edible oil require monitoring by reliable analytical methods. Therefore, an automated SPE-HPLC online system based on dynamic covalent hydrazine chemistry has been developed. The SPE step comprises a reversible hydrazone formation by ZEN and a hydrazine moiety covalently attached to a solid phase. Seven hydrazine materials with different properties regarding the resin backbone, pore size, particle size, specific surface area, and loading have been evaluated. As a result, a hydrazine-functionalized silica gel was chosen. The final automated online method was validated and applied to the analysis of three maize germ oil samples including a provisionally certified reference material. Important performance criteria for the recovery (70–120 %) and precision (RSDr <25 %) as set by the Commission Regulation EC 401/2006 were fulfilled: The mean recovery was 78 % and RSDr did not exceed 8 %. The results of the SPE-HPLC online method were further compared to results obtained by liquid–liquid extraction with stable isotope dilution analysis LC-MS/MS and found to be in good agreement. The developed SPE-HPLC online system with fluorescence detection allows a reliable, accurate, and sensitive quantification (limit of quantification, 30 μg/kg) of ZEN in edible oils while significantly reducing the workload. To our knowledge, this is the first report on an automated SPE-HPLC method based on a covalent SPE approach.

SPE-HPLC online method for automatic analysis of the mycotoxin zearalenone in edible oils.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Zearalenone (ZEN; Fig. 1) is an estrogenic mycotoxin that contaminates cereal crops worldwide. Grains like wheat, barley, oats, sorghum, and particularly maize are frequently contaminated. ZEN is biosynthesized by several Fusarium species including Fusarium graminearum (Gibberella zeae), Fusarium culmorum, Fusarium cerealis, and Fusarium equiseti. In vitro and in vivo studies demonstrate ZEN to be estrogenic, hepatotoxic, immunotoxic, and carcinogenic. Humans and animals are exposed to ZEN by ingestion of contaminated food and feed [1, 2].

Previous findings suggest that maize germ oils provide a significant source of ZEN [3, 4]. The EFSA confirmed that vegetable oils present “an important contribution to the zearalenone exposure” in an evaluation on the risks of ZEN [5]. Consequently, the European Union (EU) introduced a maximum level for ZEN in refined maize germ oil (400 μg/kg) in 2006 [6]. Although this maximum level applies, there is no standard procedure for the analysis of ZEN in edible oils available to date. Therefore, the European Committee for Standardization (CEN) issued mandate M/520 to develop and validate a method for implementation as a European standard [7]. It should be noted that ZEN contains an ethylenic double bond and can isomerize upon the influence of light, thus occurring in two forms: trans and cis [8], yet the EU maximum level as well as mandate M/520 only consider the trans-isomer.

Different strategies for the analysis of ZEN in edible oils have been proposed. Regarding sample preparation liquid–liquid partitioning [3, 9], gel permeation chromatography and immunoaffinity cleanup [10] and dynamic covalent hydrazine chemistry (DCHC) [11] have been applied. A recent method comparison evaluated DCHC with fluorescence (FL) detection to be the best alternative among the proposed methods taking into account performance criteria as required by the EU and cost efficiency [12].

DCHC represents a solid-phase extraction (SPE) which retains the analyte based on the formation of covalent bonds rather than unspecific physisorption. ZEN contains an isolated keto group at C7 that readily reacts with hydrazine groups bound to a solid phase to form a ZEN hydrazone. Once ZEN is covalently bound to the solid phase, the oil matrix can be removed by several washing steps. In the last step, ZEN is released by displacement with acetone and analyzed by HPLC with FL detection.

In view of the official EU maximum level, the aim of the present study was to automate the quantification of ZEN in edible oils based on the DCHC approach. Whereas different online SPE-HPLC systems have been reported and reviewed [13], this is the first study to automate a SPE based on covalent chemistry.

Materials and methods

Chemical reagents

Certified Biopure solutions of ZEN (100.4 ± 0.6 μg/mL) supplied by RomerLabs (Tulln, Austria) were used for spiking of maize germ oils and for the preparation of calibration standards in order to quantify ZEN in edible oil samples. A certified Biopure solution of U-[13C18]-ZEN (25.1 ± 0.7 μg/mL) was obtained from Romer Labs. Deionized water was supplied by a Seralpur PRO 90CN (Ransbach-Baumbach, Germany). All standard chemicals were of p. A. grade and all solvents HPLC grade.

Hydrazine-functionalized materials

Hydrazine-functionalized materials were bought from Alfa Aesar GmbH & Co KG (PS2, Karlsruhe, Germany), Biotage (SLC2 and PS3, Uppsala, Sweden), Sigma-Aldrich (PS1, Steinheim, Germany), and SiliCycle (SLC1, Quebec City, Canada). Two materials (PS4 and PS5; Table 1) were synthesized according to the protocol of Emerson and colleagues [14]. As PS4 and PS5 were custom materials, important requirements of the online system in terms of particle size, pressure stability, and capacity were taken into account.

All materials were characterized with regard to pore size, particle size, specific surface area, and loading, as shown in Table 1. Pore size and specific surface area were either as specified by the manufacturer or as determined by N2 adsorption according to Brunauer, Emmett, and Teller (BET) on an ASAP 2010 instrument (Micromeritics, USA). Analysis of pore size and surface area was measured according to ISO 9277 and DIN 66134, respectively.

Edible oil samples

The developed SPE-HPLC online system was applied to the analysis of three refined maize germ oils: Two spiked oils (A and B) and the naturally contaminated provisionally certified reference material ERM®-BC715 (ERM) produced at BAM.

Spiking was done by weighing different amounts of a certified ZEN solution into Erlenmeyer flasks. After removal of the solvent (acetonitrile), a blank maize germ oil was added gravimetrically to obtain 100 μg/kg (oil A) and 602 μg/kg (oil B) ZEN-contaminated edible oils. The Erlenmeyer flasks were ultrasonicated for 30 min to re-dissolve ZEN completely. The blank maize germ oils were analyzed by the LC-MS/MS reference method and found to contain ZEN below the LOQ (1.2 μg/kg) which was assessed in a previous study [15].

The provisionally certified reference material ERM®-BC715 was determined to contain 362 ± 18 μg/kg in an interlaboratory comparison study with 14 participants. All maize germ oil samples were stored tightly closed at 4 °C in a dark place until further use.

Kinetic experiments

Prior to the kinetic experiments, all materials were activated. For this purpose, 1.5 g of resin was weighed into 15 mL reaction tubes. The resin was shaken twice for 30 min in a fresh solution of 10 mL MeOH/0.4 M HCl 90:10 (v/v). The supernatant was discarded, and the resin was washed successively with 15 mL methanol and diethyl ether. Finally, the resin was dried under a gentle stream of nitrogen.

The kinetic properties of the different hydrazine-functionalized materials were manually tested in 2 mL reaction tubes to assess the suitability for the online process. Weighed into the reaction tube was 100 ± 2 mg of functionalized, pre-treated material. One microliter of a solution of ZEN in methanol (c = 2 mg/L) was added, and the reaction tubes were shaken. Only PS2 required 5 % THF in order to swell the resin and make the pores accessible to ZEN. After t = 0, 5, 15, 30, 45, 60, and 120 min, 20 μL of the supernatant was taken and transferred to an HPLC vial to investigate the coupling process.

For investigation of the decoupling process, no supernatant was taken off during 120 min of coupling. Then, the supernatant was taken off and discarded. Methanol (1.6 mL) was added and the reaction tubes were vortexed for 10 s on an IKA Lab Dancer vortex (IKA, Staufen, Germany). After removal of the methanol, the resin was dried in a gentle nitrogen stream. One microliter of a freshly prepared mixture of acetone: 0.13 M HCL 70:30 (v/v) was added. The mixture was shaken, and at t = 0, 5, 15, 30, 45, 60, and 120 min, 20 μL of supernatant was transferred to a vial for HPLC injection. Five-point calibration curves in the respective injection solvent were constructed to analyze the coupling and decoupling procedure. In order to calculate the coupling rate constants, linear least squares regression of the term ln (A/A 0) = − k × t was performed with t being the incubation time (min), A the peak area, and A 0 the peak area at t = 0 min. Coupling and decoupling experiments were conducted in triplicates.

Instrumental analysis was done on an Agilent 1200 series HPLC. A Eurospher II 100-3 C18 P column (150 × 2 mm, 3 μm particle size; Knauer, Berlin, Germany) was used with a flow rate of 0.25 mL/min and an oven temperature of 50 °C. The mobile phase consisted of water with 0.1 % formic acid (A) and acetonitrile containing 0.1 % formic acid (B). An isocratic program at 62 % mobile phase A was used. HPLC-FLD runtime was 15 min per sample, and the injection volume was set to 10 μL. FL detection was done at λEx = 274 nm and λEm = 456 nm.

Online SPE-HPLC instrumentation

A schematic overview of the instrumentation is presented in “Development of the automation setup”. The online SPE model consists of multiple modules from Knauer: an autosampler Optimas, two AZURA Assistants with three high pressure 6-Port/3-channel valves, one multiposition valve for eluent selection, and one feed pump (P 4.1S). The three 6-port/3-channel valves enable the following: (1) the pumping at circular flow, (2) the switch of the hydrazine cartridge in the flow or not, and (3) the switch of the trapping cartridge between online SPE model or HPLC.

The 100 × 3 mm covalent SPE cartridge (further referred to as “hydrazine cartridge”) was filled with silica gel SLC1, and the 30 × 3 mm trapping cartridge was packed with 3 μm Knauer Eurospher-II 100–3 C18P (“trapping cartridge”). The analytical HPLC was a PLATINblue system equipped with two P-1 pumps, a T1 column thermostat, and a FLD RF-20Axs (Shimadzu, Kyoto, Japan). The column oven which holds the analytical column, hydrazine, and trapping cartridge was heated to 40 °C. As analytical column, a Eurospher-II 100-3 C18P column—150 × 3 mm, 3 μm particle size, and utilized with the respective pre-column—was applied.

Online SPE-HPLC-FLD procedure

The online SPE-HPLC was performed as described in Table 2. Prior to injection, the edible oil samples were diluted to a concentration of 0.72 to 0.74 g/mL with n-heptane in a 2-mL volumetric flask.

The analytical HPLC employed the following parameters: flow rate 0.7 mL/min, solvent A: water, solvent B: acetonitrile. A linear gradient program is applied which starts at 30 % solvent B to 60 % solvent B at 20 min. Then, the system is cleaned with 100 % B for 5 min and re-equilibrated for 5 min. FL detection was done at λEx = 274 nm and λEm = 456 nm. An external ten-point calibration was recorded after preparing different amounts of ZEN in water: acetonitrile 85:15 (v/v) ranging from 10 to 1000 μg/kg (R 2 = 0.999). Standards are injected from the autosampler to the HPLC-FLD system only. Taken together, one person can perform ten samples in 1 day if new hydrazine cartridges are used.

The hydrazine cartridges are recyclable up to 15 times by the procedure described in step 5 in Table 2. The recycling capability was determined using spiked maize germ oil. After 15 runs, the recovery value was determined to be below the 70 % mark which is required for official control methods as stated by the Commission Regulation EC 401/2006 [16].

Validation parameters

The limit of detection (LOD) was determined as a signal-to-noise ratio of 3:1, and the limit of quantification (LOQ) was determined as a signal-to-noise ratio of 10:1. Calculation of the recovery was done according to the formula ω edible oil/ω known value × 100. Regarding selectivity of the automated SPE-HPLC online coupling, interpretation of the chromatograms, i.e., presence/absence of interfering compounds, was conducted visually.

Reference method LC-MS/MS

Liquid–liquid extraction (LLE) with subsequent stable isotope dilution analysis (SIDA) in combination with HPLC-MS/MS was used as reference method. The method has previously been applied to edible oils in our working group, and validation data including recovery, precision, LOD, and LOQ have been reported [8, 15]. Therefore, 50 μL of U-[13C18]-ZEN (ω = 3.3 μg/g) was weighed into 15 mL reaction tubes. After evaporation to dryness, 0.5 mL of the sample was added gravimetrically and diluted with 0.5 mL n-hexane. ZEN was extracted from the sample by LLE with 5 mL methanol/water 9:1 (v/v) for 30 min while shaken on a horizontal shaker (300 rounds/min). The tubes were centrifuged at 1378g, and 1 mL of the upper aqueous (methanol) layer was transferred into an HPLC vial. The solution was evaporated to dryness and re-dissolved in 0.4 mL of water/acetonitrile 62:38 (v/v).

HPLC-MS/MS analyses were performed on an Agilent 1200 series HPLC hyphenated to an API 4000 QTRAP® hybrid mass spectrometer (AB Sciex, Foster City, USA). A Gemini-NX C18 column (150 × 2 mm, 3 μm particle size, Phenomenex®) was used for separation in combination with a corresponding guard column. Chromatographic conditions were as follows: oven temperature 50 °C, injection volume 10 μL, flow rate 0.3 mL/min, solvent A: water + 0.1 % (v) formic acid, solvent B: acetonitrile + 0.1 % (v) formic acid. The following run conditions were chosen: 38 % B 0–15 min, 95 % B 15.1–19 min, 38 % A 19.1–27 min (re-equilibration).

The mass spectrometer was operated in SRM mode with ESI (negative) detection. For native ZEN, the monitored transitions were (m/z) 317.1 → 131.1 (quantifier) and 317.1 → 175.0 (qualifier). For the U-[13C18]-ZEN, (m/z) 335.2 → 140.2 was monitored.

The following ion source parameters were used: ion spray voltage, −4000 V; desolvation temperature, 500 °C; ion source gas 1, 50 arbitrary units (a.u.); ion source gas 2, 50 a.u.; curtain gas, 20 a.u. The optimized SRM compound-specific parameters were the following: declustering potential, −80 V; entrance potential, −10 V; dwell time, 50 ms. Collision energy and collision cell exit potential were differing for quantifier/qualifier/U-[13C18]-ZEN and were −42/−40/−42 V and −13/−13/−7 V, respectively.

Data acquisition was done using Analyst 1.5.2 software (AB Sciex, Foster City, USA).

Six-point calibration curves were obtained by weighing variable amounts of native ZEN corresponding to 70–1000 μg/kg edible oil and a constant amount of 60 μg/kg final content for U-[13C18]-ZEN (R 2 = 0.997). The acetonitrile was removed by a gentle nitrogen stream, and elution solvent was added gravimetrically. The content of the edible oil samples was calculated by using:

where A S is the peak area of the analyte, A IS is the peak area of the internal standard, m S is the mass of the analyte, m IS is the mass of the internal standard, b 1 is the slope, and b 0 is the y-axis intercept.

Results and discussion

Evaluation of hydrazine functionalized materials

Major challenges for the automation of the DCHC batch method arise from the reaction kinetics of the ZEN hydrazone formation and hydrolysis. According to the protocol of the manual DCHC method [11], 120 min is required for coupling of ZEN to the hydrazine moieties and 120 min for the hydrolytic release of ZEN. Therefore, seven different hydrazine materials were manually investigated for their coupling and decoupling kinetics. PS1 was used for the manual method.

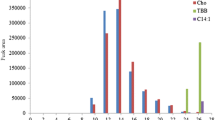

Regarding coupling, a comparison of all seven materials over a 120-min time course is shown in Fig. 2. As a result, five (SLC1, PS1, PS2, PS4, and PS5) out of seven materials bind ZEN almost completely within 60 min which can be seen by the exponential decay curve, indicating pseudo first-order kinetics. Two materials either couple low amounts of ZEN (SLC2) or no ZEN at all (PS3). In general, polymer-bound reagents like PS3 will have most of the available hydrazine sites inside the pores. PS3 seems to exclude ZEN from its pores as no binding occurs. The addition of 5 % THF in order to promote swelling of the pores did not enhance ZEN binding for PS3.

Coupling rates were calculated for the seven solid phases and summarized in Table 3. A ranking of the materials results in PS4 > SLC1 > PS1 > PS2 > PS5 >> SLC2 > PS3. Attempts to link the coupling rate to any of the material parameters from Table 1 showed no correlation.

PS4 and SLC1 proved to be superior to the other materials in their coupling kinetics. Although PS4 shows the highest coupling rate constant, it might bear problems in the automation since PS-DVB materials are less pressure resistant compared to silica materials. Furthermore, swelling can undesirably increase the system pressure. On the other hand, silica functionalization is prone to cleavage due to acids or bases more easily. Therefore, it seemed adequate to include PS4 and SLC1 for assessing their decoupling kinetics. Figure 3 shows the decoupling of ZEN over a time course of 120 min where no significant differences between SLC1 and PS4 could be observed.

As SLC1 and PS4 display similar reaction kinetics, the functionalized silica was finally selected as SPE material for the automated system based on its better suitability for automation, i.e., higher pressure stability and rigidness of the particles.

Development of the automation setup

Due to the high viscosity of the edible oil, the first challenging step was the dilution of the sample for injection into the automated SPE-HPLC system. Apart from reducing the sample viscosity, the ZEN coupling reaction rate is the important parameter for an appropriate dilution solvent. Methanol, applied in the manual DCHC method [11], was not possible due to phase separation. After testing several solvents, the injection in the automated system was found to be satisfactorily using n-heptane as diluent for the edible oil.

Another critical aspect of the manual DCHC procedure was the use of HCl to supply the coupling reactions with catalytic protons. Due to its corrosiveness, HCl was replaced by acetic acid for the automated system. Thus, the hydrazine cartridge is activated prior to the coupling step by a mixture of methanol and acetic acid 95:5 (v/v).

Coupling and decoupling of ZEN each require about 60 min as seen in Figs. 2 and 3. Thus, after injection, the sample is pumped in circuit passing the activated hydrazine cartridge (Fig. 4). After the coupling process, the circular flow of the sample is stopped and the bypass valve opens to draw in 2-propanol in order to remove the oil matrix. The system is then flushed down to 15 % acetonitrile to prepare the decoupling process. Decoupling is achieved by drawing in 20 % acetone which reacts with the hydrazine groups, thereby displacing and releasing ZEN. A focused elution of ZEN onto the analytical column is achieved by switching a trapping cartridge packed with octadecyl (C18)-modified silica between the hydrazine cartridge and the analytical column where released ZEN will be retained (Fig. 5). Prior to analytical chromatography, the acetone is removed from the system to circumvent baseline problems. Finally, switching the trapping cartridge into the analytical system corresponds to the injection.

The HPLC pump begins to deliver a gradient of acetonitrile and water which ensures a chromatographic separation of ZEN from the remaining matrix components. Parallel to the chromatographic analysis of the sample, the hydrazine cartridge is recycled for the next run in an HPLC-independent circuit. Recycling and activation of the hydrazine cartridge are achieved in a single step by applying a mixture of methanol and acetic acid. Thereby, acetone is removed and the hydrazine moieties are converted to their corresponding acetates. One hydrazine cartridge can be reused up to 15 times without decreasing performance.

Validation data

The ZEN recovery of the automated method was assessed by analyzing oils A and B and ERM®-BC715 using the online system in comparison to the known amounts. The respective recovery values were determined in triplicates and found to be 78 ± 8, 81 ± 1, and 74 ± 2 % resulting in a mean recovery of 78 %. This average recovery is valid for refined maize germ oil over a range of 100–600 μg/kg. In Table 4, the spiked and analyzed ZEN contents of the three oil samples are summarized. According to the European Commission Regulation 401/2006, analytical procedures for official control of the ZEN maximum level should provide recovery values in the range of 70–120 % which is unequivocally met by the covalent SPE-HPLC online system. Furthermore, RSDs did not exceed 8 % which is well below 25 % as required by EC 401/2006. The mean repeatability RSDr (precision) was 4 %, being slightly higher than for the LC-MS/MS reference method (2 %). LOD and LOQ were determined to be 10 and 30 μg/kg, respectively.

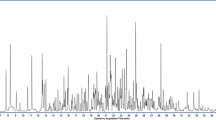

The covalent SPE approach proves to be of distinct selectivity as seen from the chromatograms of the three maize germ oils investigated in this study (Fig. 6). Due to the general nature of the employed reaction, all carbonyl group-containing compounds might react with the hydrazine moieties. This also includes the cis-isomer of ZEN which is generated upon the influence of light. Up to date, cis-ZEN is often neglected but should be considered in the routine analysis to better assess its occurrence in food and feed. Nevertheless, carbonyl groups connected to heteroatoms as in lactones or carboxylic acids show a higher electron density than isolated keto groups and will not react under the mild conditions employed for the online system [17–20].

Comparison of online coupling with the manual method

Although one sample run takes 150 min, the online coupling offers significant advantages compared to the manual method. Firstly, the online coupling does not necessarily require trained personnel. The only practical step required for sample analysis is dilution of the sample with n-heptane which can be done without expert analytical knowledge. The manual method, on the other hand, requires trained personnel with practical expertise in sample preparation and analytical instrumentation. Secondly, the online coupling reduces the workload, thereby minimizing personnel costs. As personnel costs are the major factor in the overall costs of analytical analyses, online coupling will be less expensive.

Conclusion

In summary, an accurate, selective, and reliable SPE-HPLC online system for the quantification of ZEN in maize germ oils has been developed. Even though single steps of the automated procedure, as for example the decoupling step (40 min), need to be accelerated, the system offers a reduction in workload, thereby reducing personnel costs. Furthermore, performance criteria as requested by EC 401/2006 are unequivocally fulfilled. Thus, the developed SPE-HPLC online system contributes to the goal to control ZEN contamination in edible oils and, by this, to improve the food safety system.

Due to the underlying principle of chemisorption, the online system may be expanded to other liquid matrices that are prone to ZEN contamination like beer or milk [21, 22] or to other carbonyl-containing analytes. The developed online system may also be used for automated preparative purification of carbonyl compounds if an automatic fraction collector is connected.

References

Maragos C (2010) Zearalenone occurrence and human exposure. World Mycotoxin J 3:369–383. doi:10.3920/wmj2010.1240

Zinedine A, Soriano JM, Molto JC, Manes J (2007) Review on the toxicity, occurrence, metabolism, detoxification, regulations and intake of zearalenone: an oestrogenic mycotoxin. Food Chem Toxicol 45:1–18. doi:10.1016/j.fct.2006.07.030

Lauren DR, Ringrose MA (1997) Determination of the fate of three Fusarium mycotoxins through wet-milling of maize using an improved HPLC analytical technique. Food Addit Contam 14:435–443. doi:10.1080/02652039709374549

Schollenberger M, Muller HM, Rufle M, Suchy S, Plank S, Drochner W (2006) Natural occurrence of 16 fusarium toxins in grains and feedstuffs of plant origin from Germany. Mycopathologia 161:43–52. doi:10.1007/s11046-005-0199-7

EFSA (2011) EFSA Panel on Contaminants in the Food Chain. Scientific opinion on the risks for public health related to the presence of zearalenone in food. EFSA J 9(6):2197. doi:10.2903/j.efsa.2011.2197, 124 pp

Commission Decision (2007) No 1126/2007 amending Regulation (EC) No 1881/2006 setting maximum levels for certain contaminants in foodstuffs as regards Fusarium toxins in maize and maize products. Off J Eur Union L255:14–17

European Committee for Standardization (2013) Mandate for Standardisation Addressed to CEN for Methods of Analysis for Mycotoxins in Food, M/520. European Commission, Health and Consumers Directorate-General, Brussels

Köppen R, Riedel J, Proske M, Drzymala SS, Rasenko T, Durmaz V, Weber M, Koch M (2012) Photochemical trans-/cis-isomerization and quantitation of zearalenone in edible oils. J Agric Food Chem 60:11733–11740. doi:10.1021/jf3037775

Majerus P, Graf N, Krämer M (2009) Rapid determination of zearalenone in edible oils by HPLC with fluorescence detection. Mycotoxin Res 25:117–121

Kappenstein O, Klaffke HS, Mehlitz I (2005) Bestimmung von Zearalenon in Speiseölen mit GPC und LC-ESI-MS/MS. Mycotoxin Res 21:3–6. doi:10.1007/bf02954804

Siegel D, Andrae K, Proske M, Kochan C, Koch M, Weber M, Nehls I (2010) Dynamic covalent hydrazine chemistry as a selective extraction and cleanup technique for the quantification of the Fusarium mycotoxin zearalenone in edible oils. J Chromatogr A 1217:2206–2215. doi:10.1016/j.chroma.2010.02.019

Penkert M (2014) Vergleich und Bewertung verschiedener Analysenverfahren zur Bestimmung von Zearalenon in Speiseölen. Master’s thesis, Humboldt-Universität zu Berlin, Berlin, Germany, 2014

Pan J, Zhang C, Zhang Z, Li G (2014) Review of online coupling of sample preparation techniques with liquid chromatography. Anal Chim Acta 815:1–15. doi:10.1016/j.aca.2014.01.017

Emerson DW, Emerson RR, Joshi SC, Sorensen EM, Turek JE (1979) Polymer-bound sulfonylhydrazine functionality. Preparation, characterization, and reactions of copoly(styrene-divinylbenzenesulfonylhydrazine). J Org Chem 44:4634–4640. doi:10.1021/jo00393a036

Drzymala SS, Riedel J, Köppen R, Garbe LA, Koch M (2014) Preparation of 13C-labelled cis-zearalenone and its application as internal standard in stable isotope dilution analysis. World Mycotoxin J 7:45–52. doi:10.3920/wmj2013.1610

Commission Regulation (EC) 401/2006 (2006) Laying down the methods of sampling and analysis for the official control of the levels of mycotoxins in foodstuffs. Off J Eur Union L70:12–34

Brady OL (1931) The use of 2, 4-dinitrophenylhydrazine as a reagent for carbonyl compounds. J Chem Soc 756–759. doi:10.1039/JR9310000756

van Leeuwen SM, Hendriksen L, Karst U (2004) Determination of aldehydes and ketones using derivatization with 2,4-dinitrophenylhydrazine and liquid chromatography-atmospheric pressure photoionization-mass spectrometry. J Chromatogr A 1058:107–112. doi:10.1016/j.chroma.2004.08.149

Peters R, Hellenbrand J, Mengerink Y, Van der Wal S (2004) On-line determination of carboxylic acids, aldehydes and ketones by high-performance liquid chromatography-diode array detection-atmospheric pressure chemical ionisation mass spectrometry after derivatization with 2-nitrophenylhydrazine. J Chromatogr A 1031:35–50. doi:10.1016/j.chroma.2003.10.100

Miwa H (2000) High-performance liquid chromatographic determination of mono-, poly- and hydroxycarboxylic acids in foods and beverages as their 2-nitrophenylhydrazides. J Chromatogr A 881:365–385. doi:10.1016/S0021-9673(00)00284-3

Zöllner P, Berner D, Jodlbauer J, Lindner W (2000) Determination of zearalenone and its metabolites α-and β-zearalenol in beer samples by high-performance liquid chromatography–tandem mass spectrometry. J Chromatogr B 738:233–241. doi:10.1016/S0378-4347(99)00521-6

Shreeve B, Patterson D, Roberts B (1979) The ‘carry-over’ of aflatoxin, ochratoxin and zearalenone from naturally contaminated feed to tissues, urine and milk of dairy cows. Food Cosm Toxicol 17:151–152. doi:10.1016/0015-6264(79)90215-3

Acknowledgments

The authors would like to thank the ZIM program (Zentrales Innovationsprogramm Mittelstand) of the Federal Ministry for Economic Affairs and Energy for funding (no. KF2201035SB1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Sarah S. Drzymala and Stefan Weiz should be considered co-first authors.

Sarah S. Drzymala and Stefan Weiz contributed equally to this work.

Rights and permissions

About this article

Cite this article

Drzymala, S.S., Weiz, S., Heinze, J. et al. Automated solid-phase extraction coupled online with HPLC-FLD for the quantification of zearalenone in edible oil. Anal Bioanal Chem 407, 3489–3497 (2015). https://doi.org/10.1007/s00216-015-8541-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-015-8541-5