Abstract

For the first time, an interlaboratory comparison was performed in the field of quantitative metabolite profiling in Pichia pastoris. The study was designed for the evaluation of different measurement platforms integrating different quantification strategies using internal standardization. Nineteen primary metabolites including amino acids and organic acids were selected for the study. Homogenous samples were obtained from chemostat fermentations after rapid sampling, quenching and filtration, and hot ethanol extraction. Laboratory 1 (BOKU) employed an in vivo-synthesized fully labeled U13C cell extracts of P. pastoris for immediate internal standardization upon cell extraction. Quantification was carried out using orthogonal reversed-phase (RP-LC) and hydrophilic interaction chromatography (HILIC) in combination with tandem mass spectrometry. Laboratory 2 (Biocrates) applied a metabolomics kit allowing fully automated, rapid derivatization, solid phase extraction and internal standardization in 96-well plates with immobilized isotopically enriched internal standards in combination with HILIC-MS-MS and RP-LC-MS-MS for organic acids and derivatized amino acids, respectively. In this study, the obtained intracellular concentrations ranged from 0.2 to 108 μmol g−1 cell dry weight. The total combined uncertainty was estimated including uncertainty contributions from the corresponding MS-based measurement and sample preparation for each metabolite. Evidently, the uncertainty contribution of sample preparation was lower for the values obtained by laboratory 1, implementing isotope dilution upon extraction. Total combined uncertainties (K = 2) ranging from 21 to 48 % and from 30 to 57 % were assessed for the quantitative results obtained in laboratories 1 and 2, respectively. The major contribution arose from sample preparation, hence from repeatability precision of the extraction procedure. Finally, the laboratory intercomparison was successful as most of the investigated metabolites showed concentration levels agreeing within their total combined uncertainty, implying that accurate quantification was given. The application of isotope dilution upon extraction was an absolute prerequisite for the quantification of the redox-sensitive amino acid methionine, where no agreement between the two laboratories could be achieved.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Targeted analytical strategies in metabolomics refer to either qualitative or quantitative investigation of predefined metabolites. The latter approach, denoted as quantitative metabolite profiling, is the backbone of a cutting-edge strategy in biotechnological production optimization, the metabolic engineering, ultimately aiming at engineering cell fabrics with increased productivity [1]. In this specific application, metabolites of the central carbon metabolism are of key interest since the production rates and concentrations of microorganisms are always linked to the primary metabolism, independent if primary or secondary metabolic products are in demand. Starting from quantitative metabolite profiles, kinetic information regarding metabolite production and consumption rates can be inferred [1]. In this way, bottlenecks in the metabolic reaction network can be identified serving as targets for metabolic engineering.

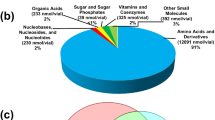

As comprehensively reviewed elsewhere [2], nowadays, the key analytical platform for metabolite profiling is mass spectrometry in combination with different chromatographic techniques [3–10] covering gas chromatography [9, 10], liquid chromatography [3, 6–8], and capillary electrophoresis [4, 5]. Among these, liquid chromatography was and still is the most versatile technique. As a matter of fact, primary intracellular metabolites show a high variation of chemical and physical properties (charge, polarity etc.); therefore, large coverage of metabolites often is accomplished following two main strategies: ion pairing chromatography or the implementation of at least two orthogonal separations (reversed-phase and hydrophilic interaction chromatography, HILIC).

Well-designed sampling, quenching, and extraction procedures are a prerequisite for successful quantitative metabolite profiling in cellular samples. Complex sample matrix, the high turnover rates of metabolites, and the instability of the extracted metabolites are the major challenges. Many efforts have been directed toward the development and optimization of cell leakage- and degradation-free protocols [11–13]. Optimized procedure for yeast including Pichia pastoris [12, 13], which was investigated in the presented analytical exercise here, consisted of (1) rapid sampling in combination with fast centrifugation or fast filtration methods, (2) quenching using cold methanol leading to minimal metabolite leakage in quenching and washing solutions, and (3) extraction using boiling ethanol [3, 11–13]. This hot extraction protocol demonstrated excellent recovery, extraction efficacy, and precision repeatability for a wide range of metabolites [11, 14].

Method validation is an integral part of any analytical method development; however, in this specific application, it is highly challenging to address the accuracy of the obtained quantitative values. As a matter of fact, there is a complete lack of reference materials. Even more, up to now, it is widely unexplored under which conditions and for which metabolites such material could be produced in the future.

The absolute amount of the metabolite, i.e., the best estimate of the true value, can only be obtained by investigating the efficiency and recovery of different extraction methods in a first step [15]. Several groups estimated accuracy by calculations of the mass action ratios from the obtained data and subsequent comparison with published equilibrium constants [12, 16]. Using the first approach, the procedure with the highest extraction efficiency and the best recovery and repeatability precision is then selected for quantification. Evidently, not only the accuracy concerning different sample preparation procedures have to be investigated but also the accuracy of the measurement procedure itself has to be proven. This is in the best case accomplished by a comparison of different analytical platforms either within one laboratory or in different laboratories.

While in other fields interlaboratory comparisons are well-established tools [17–20], this is not the case in targeted metabolomics. The few examples concerned not metabolite quantification but rather the assessment of differential metabolite profiles (relative measurement of different biological status) in order to compare the ability of different analytical platforms and/or laboratories to produce same data sets (metabolite features) by multivariate statistics [21]. Interlaboratory comparison regarding the relative quantification of amino acids using the CE-MS and GC-MS methods has been reported. Using both methods, relative peak areas were calculated employing the internal standard compound, ethionine. The obtained amino acid ratios were used to study cell culture response to stress [22].

In this work, to the best of our knowledge, the first attempt of interlaboratory comparison applied to quantitative metabolite profiling in yeast (P. pastoris) is presented. The sampling and the sample preparation were carried out with great care to ensure sample homogeneity. Extraction was performed using the boiling ethanol method that has been thoroughly studied for P. pastoris [12, 14]. The quantification of 19 primary metabolites consisting of amino acids and organic acids was studied in two different laboratories. The selection was based on the facts that these compounds were amenable to analysis with different methods in the two participating laboratories. Moreover, for all metabolites, extraction efficiency and recovery had been previously investigated. The requirement for the study was the highest extraction efficiency and stability upon the selected sample preparation procedure.

Experimental

Experiment design (sample collection and handling)

Three biological replicates of P. pastoris wild type were grown at BOKU. From each biological replicate, two samples were obtained using the filtration method on two parallel filtration units, A and B, at exactly the same time after quenching. The sample codes are shown in Table 1. Sample extraction was performed using the boiling ethanol method at BOKU Division of Analytical Chemistry. Extracts were evaporated to complete dryness using the vacuum centrifuge at BOKU. Samples that were obtained with filtration unit A were analyzed according to the protocol established at the BOKU Division of Analytical Chemistry, implementing the internal standardization with U13C-labeled yeast extract immediately after sampling. Samples from filtration unit B were sent to Biocrates. For these samples, immediate internal standardization was not possible due to the integrated internal standards on the Biocrates kit. Samples were shipped to Biocrates on dry ice; meanwhile, three samples from filtration unit A where stored in the same conditions as the shipped ones. Metabolite quantification was performed in both laboratories at the same time using two independent methods to exclude errors that can arise from the different sample storage times. Figure 1 shows the overall sample handling procedure.

Cultivation for cell sample

Three independent P. pastoris chemostat cultivations were performed as described elsewhere [14].

Sampling and quenching

Samples for the analysis of intracellular metabolites were taken using a peristaltic pump and silicone tubes (diameter, 5 mm; length, 81 cm) at a pumping speed of 5 mL/s. Approximately 50 mL of the fermentation broth was quenched in 200 mL of 60 % (v/v) methanol at −27 °C. After quenching, 2 mL of cell suspension (corresponding to approximately 10 mg biomass) was filtered using two filtration units (Polycarbonate Filter Holders, Satorius Lab Technologies Product) with cellulose acetate filter (0.45 μm, Satorius Biolab Products). Negative pressure was applied using a vacuum pump. The cells were washed once with cold 60 % (v/v) methanol and then the filter was kept on dry ice. Biomass was determined by drying five replicates of 2 mL chemostat culture to constant weight at 105 °C in pre-weight glass tubes.

Extraction of intracellular metabolites

Quenched and washed cell pellets of P. Pastoris on filters were kept in 15-mL tubes on dry ice. Of the internal standard, 200 μL was added to samples A1–A3 and 200 μL of water was added to samples B1–B3 in order to ensure the same sample volume. Four milliliters of boiling ethanol (75 %, v/v) was poured onto the cell pellets in the tube. The cell pellets were completely resuspended by vortexing for approx. 20 s. The tubes containing the samples were put into the water bath set to 85 °C and heated for 3 min in total. It was vortexed for approx. 10 s after 1.5 min of heating and again for approx. 10 s after a total of 3 min of heating. The hot tube containing the extracted cell pellet was put directly into dry ice for 3 min for rapid cooldown. After cooling, the tube was put back on dry ice. Afterwards, the tubes were centrifuged at 4,000×g for 10 min at −20 °C. The supernatant was decanted into a pre-cooled 15-mL tube. The ethanolic extracts were stored on dry ice until they were evaporated to complete dryness in a vacuum centrifuge (Savant RVT400 from Thermo Scientific) operating at pressures below 1 mbar.

Preparation of U13C internal standard

Detailed description of U13C internal standard preparation procedure is available elsewhere [14]. In brief, the yeast cells grown on fully labeled U13C glucose in the fed batch cultivation were quenched and sampled using cold methanol. Metabolite extraction using boiling ethanol method was carried out and the obtained extracts were evaporated and reconstituted with water.

Quantitative analysis performed at laboratory 1 (BOKU) with immediate internal standardization

Sample preparation for LC-MS/MS analysis

Of the LC-MS grade water, 1,000 μL was added to the dried residue using a 1,000-μL piston pipette and disposal pipette tips (Eppendorf). The dried residue was then resuspended in the following steps: (1) vortexing, (2) vortexing again after 10 min, and (3) suspending by drawing–pushing and transferring to the reaction tube, 2 mL (Eppendorf test tube or equivalent), using the piston pipette. Insoluble particles were removed via centrifugation at 4,000×g for 10 min at 5 °C using a table centrifuge from Hettich (Tuttlingen, Germany). For HILIC measurement, one additional dilution step of 1:10 (v/v) was carried out using LC-MS acetonitrile.The clear reconstituted ethanolic extracts were transferred to HPLC glass vials.

LC MS/MS analysis

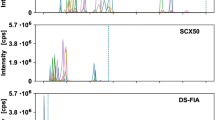

The quantitative analysis of amino acids and organic acids was performed using reversed-phase chromatography coupled with tandem mass spectrometric detection. The analysis was carried out on the LC-MS/MS system consisting of a Thermo Scientific CTC PAL autosampler, Thermo Scientific Accela 1259 pump, and Thermo Scientific TSQ Vantage ESI-MS/MS. Separation was performed on an Atlantis T3® analytical column (150 × 4.6 mm, 3-μm particle size, 100-Å pore size) equipped with an Atlantis T3 guard column (20 × 4.6, 3-μm particle size; Waters, Milford, MA) with eluent A (water, 0.1 % (v/v) formic acid) and eluent B (methanol). The following gradient was applied in LC-MS/MS: 0 % B was constant for 2 min and then was increased to 40 % within 8 min and was held for 2 min. A subsequent increase to 100 % within 0.1 min and holding for 1.9 min to flush the column, followed by reconstitution of the starting conditions within 0.1 min and re-equilibration with 0 % B for 5.9 min, resulted in a total analysis time of 20 min. For MS detection, TSQ Vantage tandem mass spectrometer from Thermo Scientific was used, featuring a heated ESI interface. The ion source parameters for the positive and negative modes were set as follows: vaporizer temperature, 350 °C; ion transfer tube temperature, 350 °C; aux gas pressure, 15 arbitrary units; sheath gas pressure, 40 arbitrary units; ion sweep gas pressure, 0 arbitrary unit; declustering voltage, 0 V; and spray voltage values for positive polarity and negative polarity, 3,300 and 3,000 V (respectively); collision gas pressure for multiple reaction monitoring (MRM) was set to 1.5 mTorr. MRM transitions of all compounds have been determined via flow injection of 10 μM single standards using a syringe pump coupled to the LC pump using a zero volume T-piece connector. XCalibur tune software was used to optimize the MRM transitions for each compound. The precursor ion, product ion, as well as collision energy values and polarity are listed in Table 2. Quantitative analysis of highly abundant amino acids was performed using HILIC coupled with tandem mass spectrometric detection. An Agilent G1312A Binary Pump 1200 series from Agilent Technologies (Waldbronn, Germany), together with an Agilent G1367B high-performance autosampler and an Agilent G1316A column compartment, was employed for HPLC. For MS detection, an Agilent 6410 Triple Quad LC/MS (Agilent Technologies) was used featuring an ESI interface. Separation was carried out on a ZicHILIC© analytical column (150 × 4.6 mm, 3.5-μm particle size, 100-Å pore size) from SeQuant (Marl, Germany) and a ZicHILIC© guard column (20 × 2.1 mm, 5-μm particle size), with eluent A (98 % (v/v) water, 1 % (v/v) acetonitrile (CAN), and 1 % (v/v) formic acid) and eluent B (98 % (v/v) ACN, 1 % (v/v) water, and 1 % (v/v) formic acid) applying the following gradient: 90 % B was constant for 2 min and then was reduced to 10 % within 7 min and was held for 1 min. Subsequent reconstitution of the starting conditions within 0.1 min and re-equilibration with 90 % B for 9.9 min resulted in a total analysis time of 20 min. A flow rate of 0.6 mL min−1, an injection volume of 3 μL, and a column temperature of 40 °C were applied. Mass spectrometer source parameters in positive ionization mode were set as follows: drying gas temperature, 300 °C; drying gas flow, 10 L min−1; nebulizer pressure, 25 psi; and capillary voltage, 4,000 V. MRM transitions were determined via flow injection of 20 μM single standard (isocratic conditions: 0.05 % formic acid in MeOH/H2O 50:50, v/v). For optimization, the Mass Hunter Optimizer Software (Agilent) was applied. The precursor and product ions as well as specific values for fragmentor voltage and collision energy are listed in Table 2. Data processing was performed using XCalibur Quan Browser software (Thermo Scientific) and Agilent MassHunter (Agilent Technologies). Quantification was performed using a six-point calibration curve with internal standardization. Internal standardization of the calibration solutions were carried out with the same amount of internal standard as for the samples. Internal standardization was performed using the in-house-produced U13C cell extract.

Quantitative analysis performed at laboratory 2 (Biocrates) with internal standardization prior measurements

Sample preparation for LC-MS/MS analysis

Dried frozen extracts of P. pastoris cells stored on dry ice were provided by BOKU. According to the agreement, samples were redissolved in 1,000 μL Milli-Q water (Milli-Q Synthesis, Millipore, Molsheim, France), shaken for 20 min at 900 rpm, and placed in an ultrasonic bath on ice for 10 min. The resulting suspensions were centrifuged (5 min, 2,900 rpm, 2 °C) and the supernatant was transferred to another vial. The pellet was discarded. Clear supernatants were diluted 1:5 (v/v) and 1:10 (v/v) with Milli-Q water.

LC-MS/MS analysis

Amino acids were quantitatively analyzed using reversed-phase LC-MS/MS to obtain chromatographic separation of isobaric (the same MRM ion pairs) metabolites for individual quantification performed by external calibration and by the use of internal standards. A 10-μL sample volume (processed sample) is required for the analysis using the following sample preparation procedure. Samples were added on filter spots placed in a 96-well Solvinert plate (internal standards were placed and dried down under nitrogen before) and fixed above a 96-deep well plate (capture plate). Twenty microliters of 5 % phenyl–isothiocyanate derivatization reagent was added. The derivatized samples were extracted after incubation by 5 mM ammonium acetate in methanol into the capture plate. Ten-microliter sample extracts were analyzed using LC-ESI-MS/MS in positive MRM detection mode with a 4000 Q Trap® tandem mass spectrometry instrument (AB Sciex, Darmstadt, Germany). Chromatographic separation was performed using an Agilent Zorbax Eclipse XDB C18 column (Agilent Technologies) at a flow rate of 500 μL/min. Mobile phase A consisted of 0.2 % formic acid in water and mobile phase B consisted of 0.2 % formic acid in acetonitrile. A linear gradient from 0 to 95 % B over 5 min was applied. For the quantitative analysis of organic acids, a HILIC-ESI-MS/MS method in highly selective negative MRM detection mode was used. MRM detection was performed using a 4000 Q Trap® tandem mass spectrometry instrument (AB Sciex). Twenty microliters sample volume (processed sample) was protein-precipitated and extracted simultaneously with 80 % methanol (v/v) in a 96-well plate format. Finally, 20 μL sample extract was used as the injection volume for HILIC-ESI-MS/MS analysis. Chromatographic separation was achieved using an Atlantis HILIC Silica column (Waters GmbH, Eschborn, Germany) at a flow rate of 500 μL/min. Mobile phase A consisted of water/acetonitrile (95:5, v/v) containing 15 mM ammonium acetate and mobile phase B consisted of 95:5 (v/v) acetonitrile/water containing 15 mM ammonium acetate. A linear gradient from 7 to 100 % mobile phase A over 10 min was applied. Internal standards (ratio of external to internal standard) and external calibration were used for accurate quantitation. LC-MS/MS data were processed with Analyst 1.4.2 software (AB Sciex). All methods have been validated for human plasma considering FDA Guidance for Industry—Bioanalytical Method Validation [23]. Metabolite concentrations were determined in micromolar units. The concentrations of all independent measurements per sample (N = 6) were recalculated according to the dilution factor and averaged. Subsequently, in relation to the initial cell concentration in each strain and the fermentation process, the mean values were converted into micromoles per gram cell.

Results and discussion

Design of interlaboratory comparison

The interlaboratory comparison was designed for the comparison of different measurement platforms integrating different quantification strategies for internal standardization. Based on a thoroughly studied sample preparation protocol—with known sample extraction efficiencies and recoveries for the metabolites of the carbon cycle and on the offered analytical methods in the two participating laboratories—19 compounds including amino acids and organic acids were selected for the exercise. For these compounds, Canelas et al. [11] had previously shown that hot ethanol extraction delivered the highest extraction efficiency. Moreover, the sample preparation recovery of metabolites using hot ethanol extraction was assessed in laboratory 1 (BOKU) using in vivo-synthesized U13C yeast extract as the tracer [14]. For the selected metabolite panel, extraction recoveries from 66 to 115 % were assessed. Therefore, for these compounds, both strategies of internal standardization, i.e., before extraction—as established in laboratory 1 (BOKU)—and before measurement—as established in laboratory 2 (Biocrates), could be applied. The different time points of internal standardization had practical reasons. Laboratory 2 applied the metabolomics kit, which is an own analytical development. The kit provided an automated workflow integrating immobilized isotopically enriched metabolite standards and amino acid derivatization and solid phase extraction. In this study, it was used in combination with LC-MS-MS analysis; however, targeted analysis of biogenic amines, acylcarnitines, phosphatidylcholines, lyso-phosphatidylcholines, and sphingomyelins in combination with flow injection MS analysis would be possible. Laboratory 1 performed LC-MS-MS analysis implementing orthogonal reversed-phase and hydrophilic interaction chromatography [14]. As internal standard, the in vivo-synthesized U13C yeast extract was used. Using this strategy, potential metabolite loss during sample preparation, storage, and measurement fluctuation was compensated. The time between extraction and measurement was kept as short as possible. The limits of detection (LODs) of both methods are given in Table 3. In the case of BOKU, LODs were calculated using the 3σ criteria of the baseline signal calibrated by the peak height of the lowest calibration point; for Biocrates, LODs were calculated within the measurements with water-based zero samples. Moreover, Table 3 summarizes the sample preparation recoveries for the compounds under investigation.

LC-MS quantification using in vivo-synthesized U13C internal standard (laboratory 1)

Table 4 gives an overview of the quantitative measurements of three biological replicates using internal standardization with the U13C-labeled yeast cell extract. As a prerequisite in this study, basic measurement criteria for the in vivo-synthesized internal standard in the resulting yeast extracts were set for all investigated metabolites: a signal-to-noise ratio of U13C metabolite peaks >10 and a signal-to-noise ratio for U12C metabolite impurity peaks <3. As a matter of fact, these criteria were fulfilled for all compounds that were used for interlaboratory comparison. Standard solutions, spiked with the U13C cell extract, i.e., the internal standard (added at the same concentration as in the samples), served as quality control (QC) samples. The measurement of QC samples (n = 5) was evenly distributed through the measurement sequence (roughly amounting to 20 % of each sequence). It is commonly accepted that QC samples monitor the overall performance of instruments and set criteria for acceptable measurement deviation (relative standard deviation, RSD). As a rule of thumb, the RSD for the repeated sample injections should not exceed the RSD of QC samples. In this study, the RSD values for samples were in the range of 0.5–10 % and were, thus, in good agreement with the QC samples. Typically, standard uncertainties of 5 % deriving from repeated measurements were reported for LC-MS-based quantitative metabolite profiling [8, 24]. Next, the obtained standard uncertainty for the N = 3 LC-MS determinations were compared to the total combined uncertainties calculated for the LC-MS quantification in order to evaluate the performance of a given LC-MS method. This was considered as an additional test of whether the developed method was under control. Estimation of the total combined uncertainty (TCU) was performed according to the ISO GUM [25]. Calculations were carried out using Kragten’s [26] approach via a spreadsheet. The model equation defining the uncertainty budget (Eq. 1) gave the metabolite concentration as an extractable intracellular metabolite fraction (in micromolars) per gram cell dry weight (gCDW). R S is the chromatographic response of the sample that was calculated according to Eq. 2, where A Sample is the peak area of the metabolite in the sample and A IS is the peak area of the corresponding U13C-labeled compound. The intercept B 0 and the slope B 1 of the calibration curve were calculated using linear regression (see Eqs. 3 and 4). V vial is the volume of the measured extract; V Sample is the volume of the quenched cell suspension that was sampled. Additionally, the dilution factor of the cell extract (d) and the cell dry weight of the quenched cell suspension (CDW) were taken into account. The experimentally assessed uncertainties for all input quantities are summarized in Electronic supplementary material Tables S1 and S2.

For almost all measurements calculated, the TCU of the LC-MS measurement results was greater than the experimentally assessed measurement repeatability precision RSD, implying good measurement quality and method control. Even though the LODs of an applied reversed-phase-based method were lower than the ones for a HILIC-based method, the measurement deviation (RSD) and the total combined uncertainty (TCU) of LC-MS measurements were comparable for both methods, indicating that TCU was independent of measurement sensitivity.

Comparability of the quantitative measurements

Table 5 summarizes the outcome of the laboratory intercomparison, giving the average values obtained from three biological replicates analyzed in each of the two participating laboratories and the corresponding biological repeatability precision (RSD). Moreover, the total combined uncertainty of the quantitative results for each metabolite obtained in each laboratory was estimated, including uncertainty contributions from sample preparation. Equation 5 gives the simplified model used in this total combined uncertainty calculation. C1, C2, and C3 correspond to single concentration values obtained for biological replicates, which are associated with the experimentally assessed repeatability precision. Moreover, an additional factor K sp was introduced accounting for all uncertainties from sample preparation. Accordingly, the K sp value was 1, with the uncertainty derived from sampling and sample preparation procedures. In order to assess this uncertainty, additional experiments were carried out using 15 yeast cell pellets (biological replicates) spiked with the U13C internal standard. For all metabolites, the monoisotopic U12C and U13C signals were measured with the analytical tool set offered by laboratory 1. The recovery of the applied sample preparation was calculated using the U13C/U12C ratio [14], compensating for volume losses. Hence, this experimentally obtained repeatability precision of the metabolite recovery resembled the standard uncertainty of the sample preparation (K sp) in the uncertainty model for laboratory 1. This approach was not valid for laboratory 2 as the volume and metabolite losses during sample preparation were not compensated by an internal standard in this case. Here, the standard uncertainty of the sample preparation and, hence, the uncertainty associated with K sp in the model was deduced from the standard uncertainty (N = 15) of the monoisotopic U12C signals. Values for u(K sp) of each metabolite are shown in Table 5.

Accordingly, as can be readily observed in Table 5, TCU values for the results obtained by immediate internal standardization were generally lower compared to the ones obtained with internal standardization prior to LC-MS analysis, especially highly abundant compounds. Hence, not surprisingly, this once again confirms the importance of immediate internal standardization in the field of quantitative metabolite profiling. Moreover, the laboratory intercomparison was successful as most of the investigated metabolites showed concentration levels agreeing within their total combined uncertainty. Hence, interlaboratory reproducibility could be achieved for the first time for metabolite profiling in yeast. At the same time, the agreement implied that accurate quantification was given for those metabolites. It has to be mentioned that for all compounds, the experimentally assessed repeatability was less than than the calculated TCU, implying that the applied model considers all contributions of the total combined uncertainty. However, it has to be kept in mind that in this uncertainty calculation, sample storage uncertainty was not considered as the study was very tightly organized with minimized time spans between sample preparation and measurement (1 day). This becomes evident only in the case of methionine, known to be a highly unstable compound prone to oxidative degradation. The instability of methionine during sample and standard storage has been comprehensively examined [27, 28]. It was suggested that methionine reacted with the polystyrene and polypropylene surface inside the storage vessel [27]. Accordingly, the results obtained in the two laboratories displayed huge differences: 7.1 μM μmol gCDW−1 in the case of laboratory 1 and 0.42 μmol gCDW−1 in the case of laboratory 2. Finally, the intercomparison showed that sample shipment is feasible for most of the studied compounds. This situation could be significantly improved in future laboratory intercomparison studies if immediate internal standardization upon extraction was implemented.

Conclusion

In general, it is agreed that such a complex task as quantification metabolite profiling in yeast will not provide total combined uncertainties comparable to other quantitative methods using isotope dilution strategies. The interlaboratory comparison performed here demonstrated that the accurate assessment of metabolic amino acids and organic acids in yeast was feasible. From the obtained results, it can be concluded that, in order to increase the quality of interlaboratory comparison, immediate internal standardization should be applied in all participating laboratories. In several previous studies on the primary metabolome, a minimum twofold difference between the metabolite levels was considered as biologically significant [29–31]. Considering the overall aim of quantitative metabolic profiling, which was to expose those metabolites that show significant biological difference, it could be concluded that the implemented methodological tool sets in both laboratories were fit for the purpose.

References

Buchholz A, Hurlebaus J, Wandrey C, Takors R (2002) Metabolomics: quantification of intracellular metabolite dynamics. Biomol Eng 19:5–15

Theodoridis G, Gika H, Want E, Wilson I (2012) Liquid chromatography–mass spectrometry based global metabolite profiling: a review. Anal Chem Acta 711:7–16

Wu L, Mashego MR, van Dam JC, Proell AM, Vinke JL, Ras C, van Winden WA, van Gulik WM, Heijnen JJ (2005) Quantitative analysis of the microbial metabolome by isotope dilution mass spectrometry using uniformly 13C-labeled cell extracts as internal standards. Anal Biochem 336:164–171

Soga T, Ueno Y, Naraoka H, Ohashi Y, Tomita M, Nishioka T (2002) Simultaneous determination of anionic intermediates for Bacillus subtilis metabolic pathways by capillary electrophoresis electrospray ionization mass spectrometry. Anal Chem 74:2233–2239

Sato S, Yanagisawa S (2010) Capillary electrophoresis–electrospray ionization–mass spectrometry using fused-silica capillaries to profile anionic metabolites. Metabolomics 6:529–540

Antonio C, Larson T, Gilday A, Graham I, Bergstrom E, Thomas-Oates J (2008) Hydrophilic interaction chromatography/electrospray mass spectrometry analysis of carbohydrate-related metabolites from Arabidopsis thaliana leaf tissue. Rapid Commun Mass Spectrom 22:1399–1407

Lu W, Clasquin M, Melamud E, Amador-Noguez D, Caudy A, Rabinowitz J (2010) Metabolomic analysis via reversed-phase ion-pairing liquid chromatography coupled to a stand alone orbitrap mass spectrometer. Anal Chem 82:3212–3221

Luo B, Groenke K, Takors R, Wandrey C, Oldiges M (2007) Simultaneous determination of multiple intracellular metabolites in glycolysis, pentose phosphate pathway and tricarboxylic acid cycle by liquid chromatography–mass spectrometry. J Chromatogr A 1147:153–164

Vielhauer O, Zakhartsev M, Horn T, Takors R, Reuss M (2011) Simplified absolute metabolite quantification by gas chromatography–isotope dilution mass spectrometry on the basis of commercially available source material. J Chromatogr B 879:3859–3870

Kanani H, Chrysanthopoulos PK, Klapa MI (2008) Standardizing GC-MS metabolomics. J Chromatogr B 871:191–201

Canelas AB, Pierick A, Ras C, Seifar CR, van Dam J, van Gulik W, Heijnen J (2009) Quantitative evaluation of intercellular metabolite extraction techniques for yeast metabolomics. Anal Chem 81:7379–7389

Carnicer M, Canelas AB, Ten Pierick A, Zeng Z, van Dam J, Albiol J, Ferrer P, Heijnen JJ, van Gulik W (2012) Development of quantitative metabolomics for Pichia pastoris. Metabolomics 8:284–298

Canelas AB, Ras C, Pierick A, Dam JC, Heijnen JJ, Gulik WM (2008) Leakage-free rapid quenching technique for yeast metabolomics. Metabolomics 4:226–239

Neubauer S, Haberhauer-Troyer C, Klavins K, Russmayer H, Steiger M, Gasser B, Sauer MG, Mattanovich D, Hann S, Koellensperger G (2012) U13C cell extract of Pichia pastoris—a powerful tool for evaluation of sample preparation in metabolomics. J Sep Sci 35:3091–3105

Cipollina C, ten Pierick A, Canelas AB, Seifar RM, van Maris AJ, van Dam JC, Heijnen JJ (2009) A comprehensive method for the quantification of the non-oxidative pentose phosphate pathway intermediates in Saccharomyces cerevisiae by GC-IDMS. J Chromatogr B 877:3231–3236

Taymaz-Nikerel H, de Mey M, Ras C, ten Pierick A, Seifar RM, van Dam JC, Heijnen JJ, van Gulik WM (2009) Development and application of a differential method for reliable metabolome analysis in Escherichia coli. Anal Biochem 386:9–19

Hintikka L, Kuuranne T, Leinonen A, Thevis M, Schänzer W, Halket J, Cowan D, Grosse J, Hemmersbach P, Nielen M, Kostiainen R (2008) Liquid chromatographic–mass spectrometric analysis of glucuronide–conjugated anabolic steroid metabolites: method validation and interlaboratory comparison. J Mass Spectrom 43:965–973

Farre M, Petrovic M, Gros M, Kosjek T, Martinez E, Heath E, Osvald P, Loos R, Le Menach K, Budzinski H, De Alencastro F, Muller J, Knepper T, Fink G, Ternes TA, Zuccato E, Kormali P, Gans O, Rodil R, Quintana JB, Pastori F, Gentili A, Barcelo D (2008) First interlaboratory exercise on non-steroidal anti-inflammatory drugs analysis in environmental samples. Talanta 76:580–590

Pereira E, Rodrigues SM, Otero M, Válega M, Lopes CB, Pato P, Coelho JP, Lillebø AI, Duarte AC, Pardal MA, Rocha R (2008) Evaluation of an interlaboratory proficiency-testing exercise for total mercury in environmental samples of soils, sediments and fish tissue. Trends Anal Chem 27:959–970

Bordet F, Inthavong D, Fremy JM (2002) Interlaboratory study of a multiresidue gas chromatographic method for determination of organochlorine and pyrethroid pesticides and polychlorobiphenyls in milk, fish, eggs, and beef fat. J AOAC Int 85:1398–1409

Allwood JW, Erban A, Koning S, Dunn WB, Luedemann A, Lommen A, Kay L, Löscher R, Kopka J, Goodacre R (2009) Inter-laboratory reproducibility of fast gas chromatography–electron impact–time of flight mass spectrometry (GC-EI-TOF/MS) based plant metabolomics. Metabolomics 5:479–496

Williams BJ, Cameron CJ, Workman R, Broeckling CD, Sumner LW, Smith JT (2007) Amino acid profiling in plant cell cultures: an inter-laboratory comparison of CE-MS and GC-MS. Electrophoresis 28:1371–1379

U.S. Department of Health and Human Services, Food and Drug Administration (2001) Guidance for industry: bioanalytical method validation. http://www.fda.gov/downloads/Drugs/…/Guidances/ucm070107.pdf. Accessed 10 August 2012

Gika HG, Theodoridis GA, Vrhovsek U, Mattivi F (2012) Quantitative profiling of polar primary metabolites using hydrophilic interaction ultrahigh performance liquid chromatography–tandem mass spectrometry. J Chromatogr A 1259:121–127

ISO/GUM (1995) Guide to the expression of uncertainty in measurement. ISO/GUM, Geneva, Switzerland

Kragten J (1994) Calculating standard deviations and confidence intervals with a universally applicable spreadsheet technique. Analyst 119:2161–2165

Chace DH, Luo Z, Jesus V, Haynes CA, Hannon WH (2010) Potential loss of methionine following extended storage of newborn screening sample prepared for tandem mass spectrometry analysis. Clin Chim Acta 441:1284–1286

Hustad S, Eussen S, Midttun O, Ulvik A, Kant PM, Morkrid L, Gislefoss R, Ueland PM (2012) Kinetic modeling of storage effects on biomarkers related to B vitamin status and one-carbon metabolism. Clin Chem 58:402–410

Tian J, Shi C, Gao P, Yuan K, Yang D, Lu X, Xu G (2008) Phenotype differentiation of three E. coli strains by GC-FID and GC-MS based metabolomics. J Chromatogr B 871:220–226

Plassmeier J, Barsch A, Persicke M, Niehaus K, Kalinowski J (2007) Investigation of central carbon metabolism and the 2-methylcitrate cycle in Corynebacterium glutamicum by metabolic profiling using gas chromatography–mass spectrometry. J Biotechnol 130:354–363

Yang S, Sadilek M, Synovec RE, Lidstrom ME (2009) Liquid chromatography–tandem quadrupole mass spectrometry and comprehensive two-dimensional gas chromatography–time-of-flight mass spectrometry measurement of targeted metabolites of Methylobacterium extorquens AM1 grown on two different carbon sources. J Chromatogr A 1216:3280–3289

Acknowledgments

This work has been financially supported by the FHplus Program of the Austrian Research Promotion Agency FFG, Project METORGANIC. Furthermore, this work has been supported by the Federal Ministry of Economy, Family and Youth (BMWFJ), the Federal Ministry of Traffic, Innovation and Technology (bmvit), the Styrian Business Promotion Agency SFG, the Standortagentur Tirol, and ZIT—Technology Agency of the City of Vienna through the COMET-Funding Program managed by the Austrian Research Promotion Agency FFG. EQ BOKU VIBT GmbH is acknowledged for providing LC-MS/MS instrumentation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in the topical collection Metabolomics and Metabolite Profiling with guest editors Rainer Schuhmacher, Rudolf Krska, Roy Goodacre, and Wolfram Weckwerth.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 81 kb)

Rights and permissions

About this article

Cite this article

Klavins, K., Neubauer, S., Al Chalabi, A. et al. Interlaboratory comparison for quantitative primary metabolite profiling in Pichia pastoris . Anal Bioanal Chem 405, 5159–5169 (2013). https://doi.org/10.1007/s00216-013-6964-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-013-6964-4