Abstract

Immobilized enzyme reactors (IMERs) produced by the covalent attachment of ribonuclease A to macroporous methacrylate-based monolithic supports using different experimental approaches are discussed and compared. Enzyme immobilization was carried out by direct covalent binding, as well as through attachment via a polymer spacer. The kinetic properties of an IMER operating in either recirculation mode or zonal elution mode were studied. Additionally, the effect of flow rate on the bioconversion efficiency of each IMER sample was examined.

Enzyme immobilization via aldehyde-bearing macromolecular spacer on the surface of epoxy-containing monoliths

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Enzyme immobilization is one of the leading methods employed in biotechnology and bioengineering because of the low cost-to-benefit ratios of real-world processes based on such biocatalytic systems. Attaching enzymes to a solid permeable support results in new advanced properties, such as significant stabilization of the protein macromolecule due to the restrictions on its spatial mobility and conformational rearrangements. In turn, this fixed conformation of the enzyme maintains its efficiency (catalytic activity) over a long period of time, as structural changes that could result in reduced efficiency are hindered.

Immobilization of enzymes on a solid support has several well-known advantages: long-term reusability, easy removal of products from the reaction mixture, better control and rapid termination of catalyzed reactions at crucial moments, lack of contamination with residual enzyme, and enhanced enzyme stability (for example, when it is attached via multiple covalent bonds) [1]. In addition, immobilization of enzymes protects their specific activities from inactivating processes.

Major enzyme immobilization methods include attachment to a surface of a natural or synthetic support (adsorption, chemical binding), entrapment in a polymeric structure (gel, membrane capsule, hollow fiber), as well as crosslinking the enzyme macromolecules with bi- or polyfunctional agents [2]. Among these methods, the covalent binding of enzyme to a support has been the most extensively studied [3]. Immobilization of the protein to a matrix by chemical binding is characterized by high efficiency and bond strength. The effect of the immobilization on enzyme activity is variable; it is influenced by changes in the structure of the enzyme macromolecule and its conformation as well as limitations of the diffusion of the substrate when attempting to access the enzyme’s active site.

Older flow-through enzyme reactor models utilized a column packed with porous beads modified with enzyme, and the substrate molecule usually had to diffuse into the pores of the packing material in order to interact with the active site of the biocatalyst. On the other hand, macroporous monolithic sorbents, which are characterized by extremely high permeability to liquid flow and are widely used in modern liquid chromatography, provide excellent conditions for all processes based on interphase mass exchange, even when large bioobjects are involved [4, 5]. Monolithic supports are characterized by high mechanical and chemical stability, good mass transfer properties, sufficiently high surface area, and a relatively small pressure drop due to their bimodal porous structure [6]. In addition, this class of materials possesses important advantages such as simplicity of preparation and ease of operation.

Considering the mentioned above advantages of monoliths, they have also become popular for preparing flow-through immobilized enzyme reactors (IMERs) [7]. Currently, most published works describing examples of the preparation and application of IMERs relate to the field of proteomics. Bioreactors constructed using monolithic supports allow enzymatically catalyzed reactions to be performed within a few minutes and facilitate the integration of the bioreactor into instrumentation that enables the online analysis of protein digestion products. Due to high scientific interest in this field, many reviews of it have been published recently [7, 8]. Proteomics aside, reports on the development and study of IMERs for pharmaceutical [1, 9, 10], biodiesel, or oligosaccharide [11–13] production, for biosensing [14], as well as for removing some sample biocontaminants [15] can be found in the current literature. However, the fundamental aspects of the application of monolithic materials as highly permeable solid phases for flow-through enzyme reactors are still to be investigated thoroughly.

Recently, we studied the effect of introduction of a spacer to distance the enzyme molecules from the surface on the properties of an IMER operating in recirculation mode [16]. For this purpose, α-chymotrypsin was immobilized via water-soluble, biocompatible, aldehyde-bearing, macromolecular spacers onto the surfaces of short monolithic columns (CIM epoxy disks). It was established that immobilization of the enzyme via a copolymer based on 2-deoxy-N-methacryloylamido-D-glucose positively influences the activity of the bound enzyme. The specific activity of the resulting IMER was close to that of soluble α-chymotrypsin and approximately threefold higher than that found for the enzyme immobilized the enzyme immobilized directly on the surface of the monolithic support.

In the present work, we discuss the preparation and characterization of ribonuclease-based IMERs, as well as results from investigations of their kinetic properties and a comparison of the properties of IMERs with different designs (disk or column) operated in different ways (in either recirculation mode or zonal elution mode). Ribonuclease A (RNase) is a member of a class of nucleases that catalyzes the degradation of RNA under physiological conditions [17]. Benčina et al. reported that ribonuclease A immobilized on polymethacrylate monoliths (CIM disks) can be used to remove RNA contaminants from DNA and protein samples [18]—a vital task in gene therapy and DNA vaccine production.

In our work, two kinds of monolithic materials—CIM-epoxy disks and polymethacrylate-based columns made in the lab—were used as stationary phases. The IMERs were prepared in two ways: by the direct covalent binding of RNase onto the surface of the monolithic disk, or by reaction functional groups of the enzyme with active groups of a macromolecular spacer introduced into the sorbent structure beforehand. A quantitative comparison of the efficiency of the RNase bound using each method and operated in different modes was performed. The kinetic studies were carried out using a specific low-molecular mass substrate, cytidin-2′,3′-cyclic monophosphate. The highly permeable ribonuclease-based reactors obtained were tested at different speeds of substrate solution flow to examine the dependence of the enzymatic activity on this important IMER parameter.

Materials and methods

Reagents and materials

Ribonuclease A (RNase A, EC 3.1.27.5) from bovine pancreas, cytidin-2′,3′-cyclic monophosphate (CCM), cytidin-2′(3′)-monophosphate, sodium borohydride, and periodic acid were purchased from Sigma (Taufkirchen, Germany). Glycidyl methacrylate (GMA, 97 % pure), glycerol dimethacrylate (GDMA, 85 % pure), ethylene dimethacrylate (EDMA, 98 % pure), azobisisobutyronitrile (AIBN, 98 % pure), dodecanol (99 % pure), and cyclohexanol were purchased from Sigma–Aldrich Russia (Moscow, Russia). Analytical-grade sodium dihydrogen phosphate dihydrate, disodium hydrogen phosphate dodecahydrate, sodium tetraborate decahydrate, tris(hydroxymethyl)aminomethane, ethylenediaminetetraacetic acid disodium salt (EDTA), sodium chloride, sodium hydroxide, as well as 25 % aqueous ammonium solution and hydrochloric acid were purchased from Vecton Ltd. (St. Petersburg, Russia). The buffer solution was prepared by dissolving salts in distilled water and filtering through a 0.45 μm membrane Millipore filter.

The water-soluble polymer of 2-deoxy-N-methacryloylamido-D-glucose (pMAG), MW 25,000, was synthesized by radical polymerization, characterized, and then oxidized to generate reactive aldehyde groups (Fig. 1) using a previously developed protocol [19]. The oxidized pMAG (ox-pMAG) contained 28 mol% aldehyde groups.

CIM-epoxy disks (12 × 3 mm, monolith volume 0.34 mL) and appropriate CIM housing were obtained from BIA Separations (Ljubljana, Slovenia). Stainless steel tubes 50 mm in length and 4.6 mm i.d. from Supelco (Bellefonte, PA, USA) were used as molds for the synthesis of monolithic columns.

Instrumentation

The experiments performed in recirculation mode were carried out using a low-pressure chromatographic system including a Masterflex Console Drive Easy-Load II model 77201–60 pump (Cole-Parmer Instrument Company, Vernon Hills, IL, USA) and a 2138 Uvicord S UV detector (Pharmicia LKB, Uppsala, Sweden). In zonal elution mode, a Shimadzu chromatographic system (Columbia, MD, USA) consisting of an LC-10 AD VP pump, an SPD-10AV VP spectrophotomeric detector and an SCL-10A VP system controller was used. The absorbances of the analyzed solutions were measured with a UVmini-1240 UV–Vis spectrometer (Shimadzu, Kyoto, Japan).

Methods

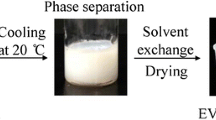

Synthesis and characterization of polymethacrylate monolithic rods (columns)

Three kinds of polymer monolithic supports with close porous characteristic were synthesized in a column mold using a thermo-initiated polymerization procedure: (I) poly(glycidyl methacrylate-co-ethylene glycol dimethacrylate) (GMA-EDMA); (II) poly(glycidyl methacrylate-co-2-hydroxyethyl methacrylate-co-ethylene glycol dimethacrylate) (GMA-HEMA-EDMA); and (III) poly(glycidyl methacrylate-co-glycerol dimethacrylate) (GMA-GDMA). A polymerization mixture containing the monomers, porogens, and AIBN as the initiator was used in the synthesis. The selected component ratios in the reaction phase were 60:40 vol% for functional monomer:crosslinker and 40:60 vol% for monomers:porogens. The concentration of initiator was 1.0 % of the mass of monomers. To optimize the porogenic solvent composition, mixtures with different combinations and ratios of dodecanol, cyclohexanol, and toluene were tested. All solutions were purged with nitrogen for 5 min before polymerization. The mixture was then placed into the stainless steel tubing and incubated in water maintained (using a thermostat) at 70 °C. The optimal experimental conditions for achieving close columns characteristics can be found in Table 1.

After the polymerization process had completed, the ready-to-use monolithic columns were installed into the chromatographic system and washed with ethanol, ethanol:water (1:1, vol), and then with water for 3 h at a flow rate of 0.5 mL min−1.

The characteristics of the monolithic columns obtained (permeability, mean pore size, as well as porosity) were calculated from their flow-through properties. According to theory [20], the permeability (B) for flow-through monoliths can be calculated using an equation based on Poiseuille–Darcy’s law:

where F is the flow rate through the monolithic phase (m3 s−1), η is the viscosity of the mobile phase (Pa s); L is the effective length of the monolith (m); r is the inner radius of the monolith (m), and ΔP is the pressure drop in the monolith (Pа).

The permeability of a monolith with channels of diameter d can be estimated from the following equation [20]:

where ε is the sorbent porosity, determined from a relation between the elution volume of the unretained component and the volume of the monolith [21]:

where V e is the elution volume (m3), V c is the elution volume without the column (system volume) (m3), and V m is the monolith volume (m3).

The permeabilities of the synthesized monoliths were calculated using water as the flowing liquid and Eq. 1. To determine the porosity, a 0.1 g L−1 solution of the low molecular mass compound uracil dissolved in a mobile phase consisting of acetonitrile and water (1:1) was passed through a column. The detection of the elution zone was achieved at a wavelength of 254 nm. Porosity was calculated using Eq. 3. The mean pore diameter was estimated by substituting the established values of permeability and porosity into Eq. 2.

Direct immobilization of ribonuclease A

Before immobilization, the CIM-epoxy disk was washed with 20 % ethanol and then with water and finally equilibrated with 0.1 M sodium borate buffer, pH 9.4 (immobilization buffer). The procedures used to immobilize the RNase onto the disks and columns were similar. RNase was dissolved in immobilization buffer at a concentration of 5 mg mL−1. 1.5 mL of RNase solution were pumped through the disk at a flow rate of 0.5 mL min−1 to fill the void space of the monolith. The loaded monolith was incubated for 21 h at 22 °C. After immobilization was complete, the RNase-modified disk was installed into the chromatographic system and washed with 10 mL of immobilization buffer, then with 3 mL of 2 M NaCl, and finally distilled water up to the baseline to remove unbound protein. For the monolithic columns made in the lab, the solution volumes were increased 2.5-fold compared to those used for the disks.

The amount of RNase covalently coupled to the support (q) was calculated as mg protein per disk/column in the following manner: q RNase = (amount of protein in initial solution) – (amount of protein in the same solution after immobilization) – (amount of protein in the washout). To determine the unreacted fraction of the enzyme, the enzyme solution was quantified with the Lowry assay [22] using an RNase A calibration curve constructed beforehand.

The immobilized enzyme reactors obtained were equilibrated with 0.01 M sodium phosphate buffer (pH 7.0) containing 0.15 M NaCl (0.01 M PBS) and stored at 4 °C.

Immobilization of ribonuclease A through a polymer spacer (ox-pMAG)

Figure 2 shows the experimental approach developed for the immobilization of RNase on the surfaces of GMA monoliths using an intermediate polymer spacer (ox-pMAG). Prior to the binding of the aldehyde-bearing spacer, the epoxy groups of the monolithic material were converted into amino groups. To perform this reaction, a large excess of 25 % aqueous ammonium solution was pumped through the monolithic disk/column. The loaded monolithic columns were then incubated for 5 h at 40 °C; after that, the functionalized monoliths were equilibrated with distilled water, and then with 0.01 M PBS.

Scheme for the immobilization of RNase via an aldehyde-bearing macromolecular spacer on the surfaces of epoxy-bearing monoliths: (a) amination of epoxy groups of GMA-containing polymer monoliths; (b) the covalent binding of aldehyde-bearing macromolecular spacer; (c) enzyme immobilization through Schiff base linkages; (d) reduction of unreacted aldehyde groups and imine bonds by sodium borohydride; (e) the end-capping of the residual aldehyde groups with lysine and the reduction of the formed imine bonds; (f) the end-capping of residual aldehyde groups with hexylamine, followed by the same reduction step

The solution of the polymer spacer was prepared by dissolving ox-pMAG in 0.01 M PBS, pH 7.0, until a concentration of 0.65 mg mL−1 was obtained for the immobilization of RNase on the disks and 0.45 mg mL−1 for the preparation of the column IMER. The porous space in the amino-bearing disk or column was filled by pumping in 1.5 or 4.0 mL of polymer solution, respectively. After that, the loaded disk/column was incubated for 1.5 h at 22 °C. The activated sorbent was rinsed with 0.01 M PBS for 10 min at a flow rate of 0.5 mL min−1.

To immobilize RNase A, the ox-pMAG-bearing monolithic disk or column was equilibrated with 0.01 M sodium borate buffer (pH 8.4) and then the porous space of the sorbent was filled by pumping in 1 or 3 mL of enzyme solution, respectively. RNase was dissolved in 0.01 M sodium borate buffer (pH 8.4) at a concentration of 5 mg mL−1 for immobilization on the disks and 4 mg mL−1 for the preparation of the column IMER. The monoliths loaded with RNase were left to react for 1.5 h at 22 °C. The washing procedures, as well as the calculation of the amount of RNase A coupled to the support, were performed in the same way as described above (see the section “Direct immobilization of ribonuclease A”). In the final step, imine bonds (Schiff bases) were reduced using 2 mg mL−1 aqueous sodium borohydride solution for 1 h at 22 °C.

In the preparation of the disk-shaped IMER, different ways to quench the residual aldehyde groups on the polymer spacer were studied. In particular, the remaining aldehyde groups were blocked with hydrophilic (lysine) or hydrophobic (hexylamine) compounds. In both cases, the blocking agents were dissolved in 0.01 M sodium borate buffer (pH 8.4) at concentration of 1 mg·mL−1 and pumped through the disks (1.5 mL each). The reaction proceeded for 1 h at 22 °C. After that, the IMERs obtained were washed with distilled water and treated with sodium borohydride solution as described above.

The immobilized enzyme reactors were equilibrated with 0.01 M sodium phosphate buffer (pH 7.0) containing 0.15 M NaCl (0.01 M PBS) and stored at 4 °C.

Determination of kinetic parameters

The measurements of the kinetic parameters of RNase immobilized on surfaces of monolithic materials were carried out using two experimental methods: substrate recirculation mode for the disk IMERs, and zonal elution mode for the polymethacrylate monolithic columns made in the lab.

In both cases, the rate of hydrolysis was calculated according to the increase in absorbance of the products during the initial step in the reaction (linear part of the kinetic curve). The apparent values of the Michaelis constant (К M) and the maximum velocity of the enzymatically catalyzed reaction (V max) were calculated using a graphical method based on plotting the dependence of the velocity of hydrolysis (V) on the substrate concentration ([S]) (Michaelis–Menten plot) and its subsequent linearization in coordinates of [S]/V − [S] (Hanes plot).

The rate of the enzymatic reaction V (μmol L−1 min−1) was calculated as

where t r is the reaction time (min) and [P] is the concentration of the product (μmol L−1) calculated from experimental data using equation:

where ΔA n is the increase in absorbance after the enzymatic reaction related to product formation, ε n is the extinction coefficient of the reaction product, l is the spectrophotometer cuvette thickness.

For flow-through systems, the reaction time is defined by the residence time of the product inside the sorbent layer, and depends on the flow rate in the column. According to the protocol provided by Benčina et al. [23] for zonal and frontal elution modes, the reaction time (t r) coincides with the residence time (t res), and can be calculated from the flow rate and pore volume of the monolith using the following equation:

where V b is the pore volume of the monolith (bed volume, in mL), and Φ is the flow rate (mL min−1).

In our case, Eq. 6 was used to calculate the residence time in the zonal elution experiments. For bioreactors functioning in recirculation mode, the reaction time was determined as follows:

where N is the number of cycles during recirculation.

If the values of V max and the reaction volume are known, the active units of the immobilized enzyme or the enzyme activity (U) is calculated as follows:

where U is the activity of the enzyme (μmol min−1), and φ is the reaction volume (L).

Another kinetic parameter, the turnover number of the enzyme (k 3), was found as follows [24]:

where [E] is the enzyme concentration (mol L−1).

The specific activity (A sp) of the immobilized RNase A was determined by dividing the immobilized enzyme activity (U) by the amount of immobilized enzyme:

where A sp is the specific activity (μmol min−1 mg−1), and m is the amount of enzyme (mg).

In all experiments, the temperature was constant and equal to 22 °C. The kinetic study was performed using the specific substrate cytidin-2′,3′-cyclic monophosphate and the optimized (for the RNase activity assay) mobile phase 10 mM Tris–HCl, pH 7.5, containing 2 mM EDTA and 0.1 M NaCl (operating buffer). The absorbence measurements were carried out offline using a UV spectrophotometer at 288 nm. To calculate the concentration of the product, an extinction coefficient of cytidin-2′(3′)-monophosphate at 288 nm of 2960 M−1 cm−1 was used. OriginPro 8.1 software was applied for graph plotting.

- Recirculation mode::

-

3.4 mL of substrate solution in the operating buffer was recirculated through the disk IMER for 45 min at different flow rates (0.5, 1.0, or 2.0 mL min−1). The substrate concentrations were varied from 0.17 to 1.93 mM.

- Zonal elution mode::

-

100 μL of substrate solution in the operating buffer was injected into the column IMER. The substrate concentration was varied from 0.06 to 1.7 mM. The substrate hydrolysis reaction was performed at flow rates of 0.3, 0.5, and 1.0 mL min−1.

The correlations between the flow rate and the linear flow velocity for disk and column bioreactors are presented in Table 2.

Results and discussion

IMER preparation

CIM-disk-based IMERs

It is well known that immobilization leads to significant stabilization of the enzyme macromolecule. At the same time, the covalent binding associated with the immobilization often leads to a decrease in enzymatic activity. Along with the effects of surface structure and diffusion limitations, the microenvironment of the immobilized enzyme (as defined by the support’s properties) strongly influences its characteristics. Choosing the optimal method and conditions for covalent enzyme immobilization seems to be extremely important. The effect of the solid matrix on enzyme activity and biomolecule flexibility (which is important as it facilitates accessibility to the active center of the biomolecule) can be minimized by introducing a spacer that distances the enzyme from the surface of the solid phase.

In our study, RNase was immobilized on GMA-EDMA monolithic disks in two ways: the direct, one-step reaction of amino groups on the enzyme with the original epoxy groups of the solid matrix; or the covalent attachment of the enzyme to an aldehyde-bearing spacer that was introduced into the solid matrix beforehand (i.e., immobilization through a spacer). Direct protein immobilization via the epoxy groups of monoliths based on the GMA-EDMA copolymer is the most commonly applied method [13, 15, 25–27]. This approach provides highly stable covalent bonds that prevent enzyme leakage.

In contrast to direct coupling, RNase immobilization through a polymer spacer (ox-pMAG) includes several steps (Fig. 2): amination of the epoxy groups of the monolithic material, covalent binding of the aldehyde-bearing spacer, and then enzyme immobilization with the formation of imine bonds (Schiff base linkages). In a final polishing step, the reduction of unreacted aldehyde groups and unstable imine bonds using sodium borohydride is strongly recommended. This procedure was recently developed for α-chymotrypsin IMER preparation, where the covalent binding of the enzyme was performed through another aldehyde-bearing spacer [16]. In that study, the macromolecular spacer selected for investigation was the hydrophilic polymer of 2-deoxy-N-methacrylamido-D-glucose (pMAG) with an MW 25,000. This polymer is a water-soluble and biocompatible compound [17] for which aldehyde groups can be generated by periodate oxidation. The high reactivity of these aldehyde groups allows fast covalent binding of amino-bearing ligands (e.g., enzymes) under mild conditions, with water as the only side product. The structure of the applied polymer, as well as reaction schemes for its synthesis and activation, are presented in Fig. 1.

To accurately compare the properties of the various IMERs, the amount of enzyme attached to the monolithic support must be the same in each case. In contrast to the well-known procedure of direct protein immobilization, when the RNase was immobilized through the macromolecular spacer, it was necessary to optimize the amounts of the reagents used. It was established that the concentrations of ox-pMAG and enzyme that were needed to achieve an RNase immobilization capacity close to that obtained with direct attachment were 0.65 and 5.0 mg mL−1, respectively. In our case, the RNase immobilization capacities for both methods of IMER preparation were close to 0.9 mg per disk.

To study the effect of the microenvironment, two bioreactors were prepared. In the first, the residual aldehyde groups of the polymer spacer were end-capped with a charged hydrophilic agent (lysine); in the second, these groups were quenched using a hydrophobic substance (hexylamine) (Fig. 2). The amount of RNase coupled using each approache can be found in Table 3.

Column synthesis and IMER preparation

To obtain polymethacrylate monolithic columns with different hydrophobic/hydrophilic properties and desirable porous characteristics that allow the immobilization of sufficient amounts of enzyme, the synthetic conditions for several GMA-containing polymer monoliths were optimized. Three types of polymer monoliths were prepared: columns based on GMA-EDMA, GMA-HEMA-EDMA and GMA-GDMA copolymers.

It is well known that the larger the average pore size, the better the interphase mass exchange. In our case, this means that sufficient free space is available for the enzyme to assume its favored conformation, allowing effective interaction of the enzyme’s active site with the corresponding substrate. However, increasing the pore size leads to a decrease in the specific surface area, which, in turn, leads to a reduction in the amount of immobilized enzyme. To reduce the effect of the monolith pore structure on the properties of the IMER, the experimental conditions for synthesis were varied with the aim of achieving similar pore characteristics (such as porosity and pore size) in the various monoliths.

The columns developed here were tested for their flow resistance, as determined from plots of the back pressure at different flow rates. For all of the columns, the plots were linear across a wide range of flow velocities, confirming the structural rigidity and lack of incompressibility of the prepared monoliths (see the “Electronic supplementary material,” ESM, Fig. 1). Basing on the hydrodynamic properties of the synthesized monolithic columns, the pore characteristics of the sorbents (permeability, mean pore size, and porosity) were calculated (see the “Experimental” section). As it seen from Table 1, all of the monolithic columns possessed practically the same values of permeability and mean pore size, and quite similar values of porosity.

The immobilization of RNase on the surfaces of the columns made in the lab was achieved in the same way as for the disks. However, because the bed volumes of the monolithic columns are about 2.5 times higher than those of the disks, the amount of directly bound RNase was proportionally higher: 2.2–2.4 mg of enzyme per column (Table 4). When immobilization was realized through a macromolecular spacer, the concentrations of ox-pMAG and RNase were reduced to 0.45 and 4.0 mg mL, respectively, to keep the immobilization capacity close to that attained using direct immobilization. The amounts of RNase coupled by the different approaches can be found in Table 4.

Kinetic study

Recirculation mode

In this approach, the IMER functioned as a cyclic system where the substrate solution recirculated through the disk with bound enzyme for a fixed time at a chosen flow rate (see the ESM, Fig. 2a). This approach allowed the product to accumulate in the reaction medium.

To compare the properties of the prepared RNase disk-based IMERs, the hydrolytic conversion of cytidin-2′,3′-cyclic monophosphate as a specific substrate was performed. The apparent Michaelis constant (K M) and immobilized enzyme activity (U) as well as the indirectly established catalytic constant (k 3) were estimated using the Michaelis–Menten kinetic theory. k 3, also called the turnover number of the enzyme, can be calculated from the maximum product concentration obtained under saturating substrate conditions per time and per enzyme unit. The kinetic parameters were determined at a fixed flow rate of 2 mL min−1 (3 cm min−1).

Michaelis–Menten curves were therefore constructed and linearized in Hanes coordinates for all of the CIM-based IMERs (see Fig. 3). In contrast to Lineweaver–Burke and Eadie–Hofstee plots, where errors in the determination of the rate of the enzymatic reaction at low substrate concentrations are greatly magnified, in a Hanes plot the impact of this error is negligible [28].

a–b Michaelis–Menten (a) and Hanes (b) plots constructed for the enzymatic conversion of cytidin-2′,3′-cyclic monophosphate by RNase immobilized on CIM-epoxy disks using direct covalent attachment (a), through the macromolecular spacer ox-pMAG (b), through the macromolecular spacer ox-pMAG with lysine end-capping (c), and through the macromolecular spacer ox-pMAG with hexylamine end-capping (d). The flow rate was 2 mL min−1

The effect of the enzyme coupling method on the apparent kinetic parameters for RNase immobilized on monolithic GMA-EDMA disks is presented in Table 3. The calculated values of K M determined for CCM hydrolysis were found to be in the range 1.3–7.5 mM, depending on the immobilization method. This thermodynamic parameter indicates the strength of the enzyme–substrate complex. The values of K M for RNase immobilized using the ox-pMAG spacer and the direct coupling procedure were 1.6 mM and 1.3 mM, respectively, thus demonstrating that only minor changes occurred upon immobilization. RNase that was covalently attached via the introduction of the ox-pMAG spacer followed by an end-capping reaction with lysine or hexylamine exhibited the increase of K M up to 7.5 and 3.3, respectively. According to Michaelis–Menten kinetics, a high K M value indicates that the rate of the re-dissociation process (the breakdown of the ES complex) dominates over the association step (ES complex formation). In contrast, a low K M indicates that the substrate has a high affinity for the active site of the enzyme. In our case, the observed restrictions can be attributed to a reduction in the amount of specific interactions between the immobilized enzyme and the substrate due to its probable nonspecific binding to lysine/hexylamine residues via electrostatic and hydrophobic bonds, respectively. The increase in K M can also be explained by limited enzyme–substrate interactions due to the surrounding lysine/hexylamine microenvironment.

At the same time, RNase bound to the chemically modified support exhibited higher activity than enzyme directly bound to the surface. As seen in Table 3, the lowest specific activity, 0.52 μmol mg−1 min−1, was noted for RNase immobilized using the direct coupling procedure. The introduction of the polymer spacer ox-pMAG led to a 1.8-fold increase in the specific activity of the bound RNase, corresponding to 0.95 μmol mg−1 min−1. In contrast to RNase immobilized via the spacer, introduction of end-capping agents created a microenvironment for the attached enzyme that provoked a significant reduction in its specific activity, down to 0.71 when lysine end-capping was performed, and down to 0.61 μmol mg−1 min−1 when hexylamine was used. In any case, these values were still higher than the activity found for directly immobilized RNase. Thus, when operated in the recirculation mode, the IMER prepared by introducing a macromolecular spacer between the support and enzyme was found to be favorable. In this case, the high specific activity of the RNase immobilized via the ox-pMAG spacer can be related to the reduced effect of the solid matrix and the easier access of the substrate to the active site of the enzyme.

The calculated values of k 3 for immobilized RNase show the same tendency as the activity values, and were found to be in the range 0.12–0.25 s−1 depending on the immobilization approach employed. As seen from Table 3, the highest value of k 3, 0.25 s−1, was obtained for RNase immobilized through the ox-pMAG spacer. In most cases, the larger value the of k 3, the greater the degree of catalysis. Usually, a decrease in the turnover number of the immobilized enzyme is related to restricted intrapore diffusion, which slows the enzyme kinetics [29]. Although this factor is not relevant for monoliths, there could still be restricted accessibility of the substrate to the active site [18] when a particular microenvironment is present around the immobilized enzyme.

The efficiency of enzyme catalysis can also be expressed in terms of k 3/K M [28]. This ratio is often taken as a measure of substrate specificity. When the product formation reaction dominates over ES complex breakdown, the catalytic process occurs extremely rapidly, and the efficiency of the enzyme depends on its ability to bind the substrate. In our case, the highest values of k 3/K M, 0.16 and 0.09 s−1 mM−1, were seen for RNase immobilized through the ox-pMAG spacer as well as for that obtained in the direct coupling procedure, thus demonstrating the high catalytic efficiency of the bound enzyme. The introduction of charged and hydrophobic end-capping agents led to a decrease in k 3/K M to 0.02 when lysine was used and to 0.04 when hexylamine was applied. Presumably, limitations on the ability of the immobilized enzyme to bind the substrate due to additional nonspecific interactions caused this loss of affinity.

Zonal elution mode

In contrast to recirculation, the zonal elution operative method involves the application of a small, fixed amount of substrate solution to a column with immobilized enzyme, and is usually employed as an analytical tool [30] (see the ESM, Fig. 2b).

It is known that the chemical nature of the solid support can influence the enzymatic catalysis [31, 32]. In this work, we examined the influence of three polymethacrylate monolithic materials with different hydrophilic/hydrophobic properties on the kinetic parameters of the immobilized RNase. These kinetic parameters were estimated using a Hanes plot. The kinetic parameters were determined at a fixed flow rate of 1 mL min−1 (10 cm min−1). The data obtained are presented in Table 4. The calculated values of K M determined for CCM hydrolysis catalyzed by RNase directly bound to the different monoliths were found to be in the range 0.5–1.8 mM, depending on the column type. The K M values estimated for CCM hydrolysis by enzyme directly bound to the monolithic support were one order of magnitude lower than those determined for the reaction where the enzyme was immobilized through the spacer. The lowest K M value was noted for the IMER based on the GMA-HEMA-EDMA copolymer. The value obtained was very close to that obtained for enzymatic catalysis in solution. According to data published by Benčina et al., the measured K M value for the same enzyme–substrate pair interacting in solution was 0.6 mM [18]. The U and A sp values slightly increased from 0.073 to 0.101 and from 0.032 to 0.049, respectively. However, in contrast to the recirculation mode, these changes are relatively minor. Thus, for the zonal elution mode, introducing a polymer spacer did not appear to be a useful approach.

Unlike K M, the activity and turnover number of the directly immobilized RNase were close to those obtained for hydrophilic IMERs, and slightly higher than those seen for the GMA-EDMA-based bioreactor. At the same time, the efficiency of enzyme catalysis was the greatest when the RNase was coupled to the surface of the GMA-HEMA-EDMA monolithic column; in this case, the k 3/K M value was twice as high as those seen for the two other IMERs.

Effect of the flow rate on the kinetic parameters and the efficiencies of the IMERs

The flow rate is one of the most important influences on the flow-through bioreactor performance. To examine the effect of the flow rate on the kinetic parameters and efficiency of the RNase IMERs developed here, we examined both disk and column heterogeneous biocatalysts that were prepared by direct immobilization and through the use of the aldehyde-bearing ox-pMAG spacer. In these experiments, the conversion of CCM substrate was investigated at different flow rates: 0.3, 0.5, and 1.0 mL min−1 for the column IMERs and 0.5, 1.0, and 2.0 mL min−1 for the disk IMERs. According to the data in Table 5, when the recirculation mode was applied, the values of K M, U, and k 3 increased with increasing flow rate. The dependence of the flow rate on the calculated specific activity of each RNase-IMER is shown in Fig. 4. The results obtained are in agreement with published data for enzyme bioreactors based on polymethacrylate and polyacrylamide macroporous monoliths [33–36]. The increase in enzymatic activity is presumably due to the increase in the mass transfer of the substrate to the fixed enzyme molecules and the reduction in the stagnant diffusive solvent layer at the monolith. In another words, when the flow rate is increased, the diffusivity of the substrate molecules in the mobile phase is enhanced under the convective mass transfer conditions achieved on monoliths. In turn, the increase in diffusivity with flow rate leads to a rise in the number of efficient contacts between the molecules of dissolved substrate and immobilized enzyme (enzyme–substrate complex formation). In fact, taking into account the microsecond timescales of most biocatalyzed reactions, the formation of the enzyme–substrate complex appears to be the rate-limiting step of this process.

However, since K M also increased with increasing flow rate, the efficiency of enzyme catalysis (the ratio k 3/K M) remained the same for the IMER operated in recirculation mode. For the column IMER operated in zonal elution mode, the specific activity also increased with increasing flow rate. For flow rates of 0.3 and 0.5 mL min−1, corresponding to 3 and 5 cm min−1, respectively, the catalytic efficiency was found to be practically the same (Table 6). However, at a flow rate of 1.0 mL min−1 (10 cm min−1), this ratio was considerably higher. This result is probably related to the peculiarities of the dynamic behavior of molecules at high flow rates. The established approach of using of high flow rates for the enzymatic hydrolysis of small substrates thus looks to be appropriate, considering the convective mechanism of interphase mass transfer in porous monolithic media.

Conclusions

The introduction of a polymeric long-chain spacer as an intermediate between the surface of the monolith and the biocatalytic molecule was proven to have a positive effect on ribonuclease IMERs operated in recirculation mode. In contrast to simple RNase immobilization via the macromolecular spacer, introducing end-capping agents modified the microenvironment of the attached enzyme, leading to a reduction in its specific activity. Among the RNase bioreactors operated in zonal elution mode, the best catalytic efficiency was observed for the IMER based on the hydrophilic material GMA-HEMA-EDMA. An examination of the effect of flow rate on bioconversion efficiency indicated that the specific activity of the enzyme increased as the flow rate increased in both modes of operation. At the same time, the catalytic efficiency observed for the column IMER was almost constant as the applied flow rate was increased up to 5 cm min−1, but the efficiency significantly increased at 10 cm min−1.

The monolithic enzyme bioreactors developed here will be studied to assess the degradation of polynucleotides (RNA), which is a very important consideration for the applications described above. Moreover, a solid-phase design would uniquely allow the conversion and separation steps to be combined into one chromatographic process, so we plan to explore and optimize that approach.

References

Mancini F, Naldi M, Cavrini V, Andrisano V (2007) J Chromatogr A 1175:217–226

Sheldon RA (2007) Adv Synth Catal 349:1289–1307

Battistel E, Bianchi D, Rialdi C (1991) Pure Appl Chem 63:1483–1490

Josić D, Buchacher A (2001) J Biochem Biophys Methods 49:153–174

Vlakh EG, Tennikova TB (2009) J Chromatogr A 1216:2637–2650

Vidič J, Podgornik A, Jančar J, Frankovič V, Kosir B, Lendero N, Cuček K, Krajnc M, Štrancar A (2007) J Chromatogr A 1144:63–71

Krenkova J, Svec F (2009) J Sep Sci 32:706–718

Ma J, Zhang L, Liang Z, Zhang W, Zhang Y (2007) J Sep Sci 30:3050–3059

Bartolini M, Cavrini V, Andrisano V (2004) J Chromatogr A 1031:27–34

Bartolini M, Greig NH, Yu QS, Andrizano V (2009) J Chromatogr A 1216:2730–2738

Kawakami K, Oda Y, Takahashi R (2011) Biotechnol Biofuels 4:42

Urban J, Svec F, Frechet JMJ (2012) Biotechnol Bioeng 109:371–380

Delattre C, Michaud P, Vijayalakshmi MA (2008) J Chromatogr B 861:203–208

Ozoner SK, Keskinler B, Erhan E (2011) Mat Sci Eng C 31:663–668

Benčina M, Benčina K, Štrancar A, Podgornik A (2005) J Chromatogr A 1065:83–91

Ponomareva EA, Kartuzova VE, Vlakh EG, Tennikova TB (2010) J Chromatogr B 878:567–574

Raines RT (1998) Chem Rev 98:1045–1065

Benčina M, Babic J, Podgornik A (2007) J Chromatogr A 1144:135–142

Korzhikov VA, Diederichs S, Nasarova OV, Vlakh EG, Kasper C, Panarin EF, Tennikova TB (2008) J Appl Polym Sci 108:2386–2397

Rodrigues A, Mata A, Zabka M, Pais L (2003) Chapter 15. In: Svec F, Tennikova TB, Deyl Z (eds) Monolithic materials: preparation, properties and applications. Elsevier, Amsterdam, pp 325–350

Tennikov MB, Gazdina NV, Tennikova TB, Svec F (1998) J Chromatogr A 798:55–64

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) J Biol Chem 193:265–275

Benčina M, Benčina K, Podgornik A, Štrancar A (2008) Methods Mol Biol 421:257–274

Stryer L (1996) Biochemistry. W.H. Freeman and Company, New York

Lim YP, Josic D, Callanan H, Brown J, Hixson DC (2005) J Chromatogr A 1065:39–43

Křenkova J, Bilkova Z, Foret F (2005) J Sep Sci 28:1675–1684

Platonova GA, Vlakh EG, Ivanova ND, Tennikova TB (2009) Russ J Appl Chem 82:2182–2186

Rogers A, Gibon Y (2009) Chapter 4. In: Schwender J (ed) Plant metabolic networks. Springer, Berlin, pp 71–103

Bailey JE, Ollis DF (1986) Biochemical engineering fundamentals. McGraw-Hill, New York

Hage DS (2005) Chapter 35. In: Cazes J (ed) Encyclopedia of chromatography. CRC, Boca Raton, pp 184–190

Temporini C, Perani E, Mancini F, Bartolini M, Calleri E, Lubda D, Felix G, Andrisano V, Massolini G (2006) J Chromatogr A 1120:121–131

Calleri E, Temporini C, Gasparrini F, Simone P, Villani C, Ciogli A, Massolini G (2011) J Chromatogr A 1218:8937–8945

Nicoli R, Gaud N, Stella C, Rudaz S, Veuthey JL (2008) J Pharm Biomed Anal 48:398–407

Petro M, Svec F, Fréchet JMJ (1996) Biotech Bioeng 49:355–363

Duan J, Liang Z, Yang C, Zhang J, Zhang L, Zhang W, Zhang Y (2006) Proteomics 6:412–419

Xie S, Svec F, Frechet JMJ (1999) Biotech Bioeng 62:30–35

Acknowledgments

This work was supported by the Russian Foundation of Basic Research (grant RFBR #11-03-00829-a) and the Russian Federal Program “Research and scientific-pedagogical personnel of innovative Russia in 2009–2013” (contract #14.740.11.0382). The authors are very grateful to BIA Separations Company (Ljubljana, Slovenia) for their kind donation of the CIM disks.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in the topical collection Monolithic Columns in Liquid Phase Separations with guest editor Luis A. Colon.

Electronic supplementary material

A'dditional figures (as noted in the text) are available on the journal website.

ESM 1

(PDF 102 kb)

Rights and permissions

About this article

Cite this article

Ponomareva, E.A., Volokitina, M.V., Vinokhodov, D.O. et al. Biocatalytic reactors based on ribonuclease A immobilized on macroporous monolithic supports. Anal Bioanal Chem 405, 2195–2206 (2013). https://doi.org/10.1007/s00216-012-6391-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-012-6391-y