Abstract

A molecularly imprinted polymer with trinitrotoluene as the template molecule was synthesized and used as the novel coating for solid-phase microextraction of the nitroaromatic explosive 2,4,6-trinitrotoluene for its selective determination. The fiber was characterized in terms of coating thickness, morphology, intra- and inter-batch repeatability and extraction efficiency. An average thickness of 50 ± 4 μm with a uniform distribution of the coating was obtained. Good performances of the developed procedure in term of both intra-batch and inter-batch repeatability with relative standard deviations <8% were obtained. Finally, detection and quantitation limits in the low nanogram per kilogram levels were achieved proving the superior extraction capability of the developed coating, obtaining gas chromatography-mass spectrometry responses about two times higher than those achieved using commercial devices.

Preparation of a MIP-based fiber for the solid-phase microextraction of 2,4,6-trinitrotoluene

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sampling and sample treatment play fundamental roles in the field of residue analysis of compounds of forensic concern at trace and sub-trace levels in complex matrices. The need for analytical tools able to detect explosives is currently emerging both in the gas phase in the online monitoring of critical areas and in solutions collected on scenarios in which explosions occurred. A fundamental item is also the need of reliable analytical methods, aimed at achieving information useful for the investigation to be used on behalf of forensic technicians in charge of the investigations. In addition, it has to be considered that the need for a rapid prosecution of the investigation and the necessity of avoiding the alteration and tampering of the exhibit impose the use of rapid and in situ techniques. Although several “ready-to-use kits” for the determination of explosives are commercially available, the major drawback relies on the reduced sensitivity with respect to laboratory assays. In this context, a problem of great importance is the development of innovative materials for sample preparation to be used in conjunction with reliable and effective separation techniques, with the aim of enhancing selectivity and method performance.

As for sample preparation, solid-phase microextraction (SPME) is one of the most widely used extraction/preconcentration techniques [1]. It has been successfully used for the pre-concentration of explosives from different matrices [2–4]. Although the recognized advantages of this technique rely on its simple use, as well as on the possibility of sample clean-up and pre-concentration, the major drawback is related to the lack of selectivity. Recently, great attention has been paid to the development of novel materials able to selectively interact with target analytes or specific classes of compounds [5–8]. In this field, molecular imprinting technique (MIP) is a powerful tool for the preparation of recognition materials characterized by high selectivity and chemical stability. MIPs are biomimetic polymers imprinted with a template molecule for the purpose of retaining a memory of that specific analyte. After polymerization, the template is removed providing selective cavities that are specific both to the shape and to the functionality of the template. Many applications of MIPs rely both on mass sensing, MIPs being used with quartz crystal microbalance systems [9, 10], and on their use as SPME coatings. In fact, many MIPs-based fibers have been prepared and used for the selective determination of tetracyclines [11], β-blockers [12], pesticides [13–16], ascorbic acid [17], bisphenol A [18], and anabolic steroids [19] in different matrices. Despite the efforts in the development of novel SPME fibers, to our knowledge, no MIP-based SPME coatings have been developed for the selective determination of explosives. In this context, the aim of this study was the development of a MIP-based SPME fiber for the detection of 2,4,6-trinitrotoluene (TNT) at low concentration levels. The MIP was obtained by a very simple thermal polymerization procedure using methacrylic acid as monomer, ethylene glycol dimethacrylate as crosslinker and 2,2′-azobisisobutyronitrile as radical initiator.

The fibers were characterized in terms of coating thickness, intra- and inter-batch repeatability, extraction efficiency and tested for the extraction of some nitroaromatic explosives in rubble samples.

Experimental

Chemicals

Methacrylic acid (MAA, 99% purity), ethylene glycol dimethacrylate (EGDMA, 98% purity), 2,2′-azobisisobutyronitrile (AIBN, 98% purity), 2-nitrotoluene (2-NT, ≥99% purity), 2,6-dinitrotoluene (2,6-DNT, 99% purity), 2,4,6-trinitrotoluene (stock solution of 1,000 mg/L in acetonitrile, 98% purity) and ethanol (99.5% purity) were from Sigma-Aldrich (Milan, Italy). Silica-fused and PDMS/DVB 65-μm fibers were purchased from Supelco (Bellefonte, PA, USA).

All the solutions were prepared in acetonitrile at the concentration of 1,000 mg/L and stored at 4 °C until analysis. Working solutions were always prepared by proper dilution from the stock solutions.

MIP preparation

MIP was prepared from a reagent mixture composed of 7.5 μL of MAA, 166 μL of EGDMA, 5 mg of TNT and 3.75 mg of AIBN. The molar ratio TNT/MAA/EGDMA/AIBN was 1:4:40:1. The mixture was uniformly dispersed by sonication and deareated with nitrogen for 10 min before polymerization. The obtained mixture was used to dip SPME supports or casted on glass slides before thermal polymerization. The polymerization was carried out in a sealed flask saturated with nitrogen, put into an oven, and maintained at 70 °C for 6 h.

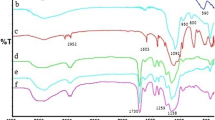

Finally, the template molecule was removed by soaking the MIP under sonication in 4 mL ethanol for 90 min. The extraction time was evaluated on the basis of gas chromatography-mass spectrometry (GC-MS) analyses of the extracted ethanolic solutions after 30, 60 and 90 min. The polymer was then washed using fresh ethanol and separated by centrifugation.

Not imprinted polymeric materials (NIPs) were also prepared according to the above procedure except for the addition of the template. For further experiments, NIP was also subjected to the same extraction treatment.

Fiber preparation and characterization

The polymer casted on glass slides was finely ground, and the obtained powder was used to coat the silica support of SPME fibers by using an ASM 030 109620 epoxy resin glue (Elantas Italia, Parma, Italy). The coating was obtained by vertically dipping the silica supports into the glue and subsequently in the MIP powder for three times. NIP-based fibers were prepared in the same way.

Prior to use, the fibers were maintained at room temperature for 12 h. Four fibers were prepared both for MIPs and for NIPs.

Thermogravimetric analysis (TGA) was performed using a TGA 7 instrument (Perkin-Elmer, Waltham, MA, USA) over the 30–400 °C temperature range (heating rate, 50 °C/min) under inert nitrogen atmosphere. Coating thickness and surface morphology were investigated by using scanning electron microscopy (SEM) with a Leica 430i instrument (Leica, Solms, Germany).

SPME analysis

The MIP-based SPME fiber was suspended in the headspace of a 20-mL vial containing 5 g of rubble spiked with appropriate amounts of the investigated analyte. The extraction was performed at the temperature of 60 °C for 40 min. Desorption was carried out at the temperature of 250 °C for 2 min. The same procedure was applied using the NIP-based and the PDMS/DVB fibers.

GC-MS analysis

A HP 6890 Series Plus gas chromatograph (Agilent Technologies, Milan, Italy) equipped with MSD 5973 mass spectrometer (Agilent Technologies) was used for GC-MS analysis. Helium was used as the carrier gas at a constant flow rate of 1 ml/min; the gas chromatograph was operated in splitless mode with the PTV injector (Agilent Technologies) maintained at the temperature of 250 °C and equipped with a PTV multi-baffled liner (I.D. 1.5 mm, Agilent Technologies). Chromatographic separation was performed on a 30 m × 0.25 mm, d f 0.25 μm Factor Four-5MS capillary column (Varian, Turin, Italy). The following gas chromatography (GC) oven temperature program was applied—50 °C for 2 min, 10 °C/min to 230 °C, 230 °C for 1 min.

Transfer line and source were maintained at the temperature of 280 °C and 150 °C, respectively. Preliminarily, full-scan EI data were acquired to determine appropriate masses for selected-ion monitoring mode under the following conditions—ionization energy, 70 eV; mass range, 35–250 amu; scan time, 3 scan/s. The mass spectrometer was finally operated in time-scheduled selected-ion monitoring mode by applying a delay time of 5 min and by recording the current of the following ions—m/z 65, 92, and 120 for 2-NT from 5 to 11 min; m/z 89, 148, and 165 for 2,6-DNT from 11 to 14.5 min; and m/z 89, 193, and 210 for TNT from 14.5 to 21 min. The corresponding ion ratios were used for confirmation purposes. A dwell time of 100 ms was used for all the ions. All the analyses were performed by setting the electron multiplier voltage at 2,000 V.

Signal acquisition and data processing were performed using the HP Chemstation (Agilent Technologies).

Validation

Method validation was carried out according to Eurachem guidelines [20] using uncontaminated rubble as blank matrix. Detection (LOD) and quantitation (LOQ) limits were calculated by constructing a proper calibration curve following the approach already used in previous works [21, 22].

Linearity was evaluated over one order of magnitude by analyzing blank matrices properly spiked with the investigated compound. Homoscedasticity was verified by applying the Bartlett test. Lack-of-fit and Mandel’s fitting tests were also performed to check the goodness of fit and linearity [23]. The significance of the intercept (significance level 5%) was established running a t test. For each batch of MIP-based SPME fibers, precision was calculated in terms of intra-day repeatability and between-day precision on two concentration levels.

Trueness was evaluated in terms of recovery by spiking blank rubble with TNT at the concentrations of 300 and 1,500 ng/kg. Recovery (R%) was calculated as percent ratio found added to the amount as follows:

where \( \overline {{c_{\text{obs}}}} \) is the mean concentration of the fortified sample, c spike is the spiked concentration. All the measurements were replicated three times.

Real samples analysis

Two rubble samples taken from post-blast scenarios were provided by Raggruppamento Carabinieri Investigazioni Scientifiche of Parma. Five grams of each sample were weighted into 20-mL vials and submitted to headspace SPME analysis at 60 °C for 40 min. Desorption was then carried out at the temperature of 250 °C for 2 min.

Results and discussion

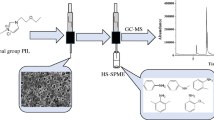

The molecular imprinting technique allows the formation of specific recognition sites in macromolecules. In the polymerization process, the monomers self-organize around the template and the functional groups responsible for specific interactions are held in a highly cross-linked structure. The main advantage of the non-covalent imprinting applied in this study is the reversibility of bonds between polymer and template. In fact, non-covalent imprinting ensures complete removal of the analyte and enables the formation of cavities specific for the target molecule in terms of spatial and electronic affinity. A schematic representation of the polymerization and extraction processes is depicted in Fig. 1.

Preparation of the MIP coating

The formulation of the MIP developed in this work was based on our previous studies focused on the preparation of polymers imprinted with atrazine [24] and cyanuric acid [25].

It is known that monomer, crosslinker and component proportions play important roles in MIP synthesis. Our preliminary experiments, performed in order to obtain the MIP-based fibers via dip-coating, were based on the use of a solution containing TNT/MAA/EGDMA/AIBN 1:5:22:1 in which the SPME silica supports were dipped for 5, 15, and 30 min. The fibers were then heated at 70 °C for 6 h to perform the polymerization step. Since a very scarce adhesion of the coating on the silica support was observed, a change in the ratio among the components of the mixture (TNT/MAA/EGDMA/AIBN 1:4:40:1) was performed in order to increase the viscosity of the solution. However, as shown in Fig. 2a, no satisfactory results were obtained. On the basis of the obtained results, a different approach based on a complete dipping of the fibers into the MIP solution also during the polymerization step was devised. Unfortunately, the major drawback of this procedure was related to the very rapid thickening of the MIP on the SPME silica support. The polymerization proved to be a very fast process and cannot be maintained under control, thus requiring the use of a different strategy.

A two-step approach consisting into the polymerization followed by the adhesion of the MIP powder on the SPME fiber was thus carried out. By finely grounding the MIP powder, the applied procedure allowed to obtain a homogeneous coating characterized by an enhanced surface area available for the interaction with the analyte.

Another important aspect that deserves emphasis is that the procedure we developed provides dramatically reduced production times, compared with other MIPs for explosives. The rapidity and simplicity of our procedure does not involve only the polymerization time, but mostly the extraction of the template. In fact, the use of ethanol as solvent able to establish hydrogen-bond was chosen in order to perform a template extraction suiting the “competition” properties of such solvent that can establish this kind of interaction with –COOH groups of the polymer, thus inducing the displacement of TNT. In literature are also reported examples of removing processes [26] combining the use of ethanol with a Soxhlet extraction. In another study, a MIP used in the development of an electrochemical sensor for TNT [27] required a polymerization time of 24 h and a removal of the template by Soxhlet extraction for 48 h. In this work, we were able to perform the polymer preparation, the extraction of the template and the deposition on the SPME fiber in less than 8 h and at room temperature.

Characterization of the MIP-based SPME fibers

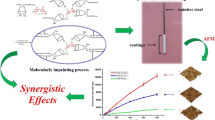

The morphology of the obtained coating was investigated by SEM under different magnifications. The average thickness (n = 4) was found to be 50 ± 4 μm with a uniform distribution along the entire silica support (Fig. 2b).

The thermal stability of the fibers was proved until 300 °C obtaining a weight loss lower than 3% (Fig. 3). A further assessment was obtained by performing subsequent desorption steps in the injection port of the gas chromatograph. Under these conditions, a reduced bleeding was observed, thus confirming the suitability of the MIP-based fibers for GC applications. In addition, the reusability of the fiber was proved by sampling rubble spiked with 500 ng/kg of TNT and performing subsequent adsorption–desorption experiments. The obtained results showed the complete removal of TNT from the MIP fiber after the first GC-injection, thus confirming the suitability of the material for SPME analyses. The performance of the developed material was also evaluated in term of intra-batch repeatability by preparing different fibers from the same MIP and inter-batch repeatability by preparing different fibers from MIPs obtained at different time. Under these conditions, three fibers for each experiment were prepared and the obtained results were very satisfying taking into account that relative standard deviation (RSD) lower than 8% were always achieved.

Extraction performances of the MIP- and NIP-based fibers

Preliminary experiments were carried out on blank rubber spiked with TNT at the concentration of 1,500 ng/kg to study the effects of temperature and time on the SPME extraction of the analyte (Fig. 4). Extraction efficiency was found to increase in the 40–60 °C range, whereas a slight decrease was observed from 60 °C to 75 °C, probably as a consequence of the decrease of the fiber/sample distribution constant of the analyte with the rise of the temperature [1]. The effect of extraction time was evaluated in the 15–60-min range, obtaining an increase of the response up to 40 min. On the basis of these findings, an extraction time of 30 min and an extraction temperature of 60 °C were used for subsequent work.

Additional measurements were performed in order to compare the extraction performances of the MIP- and NIP-based fibers by analyzing a rubble blank matrix spiked with TNT at the concentration of 2 μg/kg. The results are shown in Table 1. As expected, the GC responses provided by the MIP-based fiber were higher by more than one order of magnitude than those of the NIP-coated one, thus confirming that fiber coating material synthesized in the absence of template possesses a low specificity. Similar results were obtained also when the NIP was subjected to the same treatment of the MIP powder. Taking into account that the sonication treatment applied to MIP for the extraction of the template could influence the microstructure of the polymer, further experiments were performed using a fiber coated with a sonicated NIP. The obtained results showed the existence of different performances between the MIP- and NIP-based fibers, thus confirming that the driving force of the selectivity can be ascribed to the imprinting effect. The extraction capabilities of the MIP-based coating were also compared with those of a PDMS/DVB fiber. As shown in Table 1, the obtained results were satisfactory achieving responses about two times higher than those obtained using the commercially available device. In addition, another important feature was the reduction of interference of background contaminants (Fig. 5) attributable to the selective interaction via H-bonding between TNT and the coating. As shown in Fig. 5, representing the GC-MS full-scan chromatograms of a rubble sample taken from a post-blast scenario, the use of the MIP-fiber allowed obtaining a noticeable reduction of interfering compounds with respect to the PDMS/DVB 65 μm fiber. In addition, as represented by the mass spectra depicted in the insets of each figure, the SPME analysis performed with the MIP fiber (Fig. 5a) allowed a certain identification of TNT (retention time (RT), 15.6 min). By contrast owing to the presence of interferences, the same results cannot be achieved with use of the commercial device (Fig. 5b).

Method validation

The validation parameters calculated for the developed method are as shown in Table 2. LOD and LOQ values in the low nanogram per kilogram levels were obtained. A good linearity was observed over one order of magnitude whereas method precision and trueness proved the reliability of the developed coating for the determination of TNT at trace levels in real samples.

Taking into account that the MIP-based fiber was developed for TNT extraction, method selectivity was also evaluated by using 2-nitrotoluene and 2,6-dinitrotoluene as model compounds. Although no experiments were performed by imprinting the polymer with 2-NT and 2,6-DNT, as shown in Fig. 6, the adsorption capabilities of the coating can be ascribed to the number of nitro-groups on the molecule. In fact, the lowest response was obtained for 2-NT whereas better results were achieved when 2,6-DNT was extracted. The observed behavior could be explained taking into account both the recognition capability of MIP on molecular size compared with template molecule and on the basis of multiple H bonding interactions with the nitro-compounds. This result also suggests that the developed MIP-based coating can selectively enrich TNT from its analogues. A further confirmation of the selectivity of the MIP-based fiber was assessed also by the comparison of GC-MS chromatograms acquired in the full-scan mode after the SPME analysis of a rubble sample taken from post-blast scenarios (Fig. 5). In fact, as shown in the figure, a more complex chromatogram characterized by the presence of a greater number of extracted compounds was obtained when the commercial PDMS/DVB fiber was used. Finally, the analysis of two soil samples taken from post-blast scenarios allowed determination of TNT at 9.6 ± 0.8 and 94.8 ± 2 μg/kg, respectively, thus proving the feasibility of the MIP-based strategy for TNT determination in real samples.

Conclusions

A simple, rapid and low-cost procedure for the preparation of a TNT-imprinted polymer SPME fiber was developed, allowing achievement of good sensitivity and selectivity for the extraction of TNT from rubble samples. The obtained results in terms of extraction efficiency suggest that the developed MIP-based fiber is an attractive tool for determination of TNT at low nanogram per kilogram levels with negligible impurities interference, being suitable for the extraction of trace TNT in rubble samples taken from post-blast scenarios.

References

Pawliszyn J (1997) Solid phase microextraction. Wiley-VCH, New York

Monteil-Rivera F, Beaulieu C, Deschamps S, Paquet L, Hawari J (2004) J Chromatogr A 1048:213:221

Gaurav, Kaur V, Kumar A, Malik AK, Rai PK (2007) J Hazard Mater 147:691:697

Jonsson S, Gustavsson L, van Bavel B (2007) J Chromatogr A 1164: 65:73

Bianchi F, Mattarozzi M, Betti P, Bisceglie F, Careri M, Mangia A, Sidisky L, Ongarato S, Dalcanale E (2008) Anal Chem 80:6423–6430

Harvey SD (2008) J Chromatogr A 1213:110–117

Djozan D, Ebrahimi B (2008) Anal Chim Acta 616:152–159

Barahona F, Turiel E, Martin-Esteban A (2011) Anal Chim Acta 694:83–89

Pietrzyk A, Suriyanarayanan S, Kutner W, Chitta R, D’Souza F (2009) Anal Chem 81:2633–2643

Percival CJ, Stanley S, Braithwaite A, Newton MI, McHale G (2002) Analyst 127:1024–1026

Hu X, Pan J, Hu Y, Huo Y, Li G (2008) J Chromatogr A 1188:97–107

Hu X, Pan J, Hu Y, Li G (2009) J Chromatogr A 1216:190–197

Hu X, Hu Y, Li G (2007) J Chromatogr A 1147:1–9

Djozan D, Mahkam M, Ebrahimi B (2009) J Chromatogr A 1216:2211–2219

Hu X, Dai G, Huang J, Ye T, Fan H, Youwen T, Yu Y, Liang Y (2010) J Chromatogr A 1217:5875–5882

Zhou J, Chao M, Zhou S, Ma P, Chen F, Qi Y, Chen H (2010) J Chromatogr A 1217:7478–7483

Prasad BB, Tiwari K, Singh M, Sharma PS, Patel AK, Srivastava S (2008) J Chromatogr A 1198–1198:59–66

Tan F, Zhao H, Li X, Quan X, Chen J, Xiang X, Zhang X (2009) J Chromatogr A 1216:5647–5654

Qiu L, Liu W, Huang M, Zhang L (2010) J Chromatogr A 1217:7461–7470

The fitness for purpose of analytical methods: a laboratory guide to method validation and related topics, EURACHEM Guide, 1st English Edition 1.0-1998, LGC (Teddington) Ltd., http://www.eurachem.ul.pt/

Bianchi F, Careri M, Mangia A, Musci M (2006) J Chromatogr A 1102:268–272

Mattarozzi M, Giannetto M, Secchi A, Bianchi F (2009) J Chromatogr A 1216:3725–3730

Draper N, Smith H (1981) Applied regression analysis. Wiley, New York

D’Agostino G, Alberti G, Biesuz R, Pesavento M (2006) Biosens Bioelectron 22:145–152

Pesavento M, D’Agostino G, Biesuz R, Alberti G (2009) Electroanal 21:604–611

Schweiger B, Bahnweg L, Palm B, Steinfeld U (2009) World Acad Sci Eng Technol 54:633–638

Alizadeh T, Zare M, Ganjali MR, Norouzi P, Tavana B (2010) Biosens Bioelectron 25:1166–1172

Author information

Authors and Affiliations

Corresponding authors

Additional information

Published in the special issue Young Investigators in Analytical and Bioanalytical Science with guest editors S. Daunert, J. Bettmer, T. Hasegawa, Q. Wang, and Y. Wei.

Rights and permissions

About this article

Cite this article

Bianchi, F., Giannetto, M., Mori, G. et al. Solid-phase microextraction of 2,4,6-trinitrotoluene using a molecularly imprinted-based fiber. Anal Bioanal Chem 403, 2411–2418 (2012). https://doi.org/10.1007/s00216-012-5875-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-012-5875-0