Abstract

Compound-specific stable-isotope analysis (CSIA) has greatly facilitated assessment of sources and transformation processes of organic pollutants. Multielement isotope analysis is one of the most promising applications of CSIA because it even enables distinction of different transformation pathways. This review introduces the essential features of continuous-flow isotope-ratio mass spectrometry (IRMS) and highlights current challenges in environmental analysis as exemplified for the isotopes of nitrogen, hydrogen, chlorine, and oxygen. Strategies and recent advances to enable isotopic measurements of polar contaminants, for example pesticides or pharmaceuticals, are discussed with special emphasis on possible solutions for analysis of low concentrations of contaminants in environmental matrices. Finally, we discuss different levels of calibration and referencing and point out the urgent need for compound-specific isotope standards for gas chromatography–isotope-ratio mass spectrometry (GC–IRMS) of organic pollutants.

Compound-specific isotope analysis of environmental contaminants: chromatographic separation is followed by online conversion to a suitable measurement gas (M) and subsequent isotope ratio mass spectrometry. Current challenges in the field concern the analysis of multiple elements (C, H, N, O, Cl) in polar compounds, at low concentrations and in the presence of matrix interferences. An urgent need exists for contaminant-specific reference materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Compound-specific stable isotope analysis (CSIA) has made it possible to separate organic analytes from complex mixtures and to determine their individual stable isotope ratios at natural isotopic abundances. This breakthrough has been accomplished by direct coupling of gas chromatography (GC) or liquid chromatography (LC) to isotope-ratio mass spectrometers (IRMS [1]; Fig. 1).

Upper panel: the principle of compound-specific isotope analysis by chromatography–IRMS. Compound mixtures are separated by chromatography. The continuous carrier flow with the baseline-separated analyte peaks is directed into a chemical conversion interface. Individual analytes are converted into a measurement gas M that is suitable for isotope analysis. Peaks of M are transferred in a He carrier stream into the isotope-ratio mass spectrometer. Lower panel: instrumentation for carbon-isotope analysis by GC–IRMS

A first part of this review focuses on several instrumental challenges that had to be overcome in comparison with traditional isotope analysis:

-

1.

chemical conversion is accomplished in a helium carrier flow in miniature reactors;

-

2.

instead of repeated application of analyte gas, transient peaks are recorded; and

-

3.

the principle of identical treatment of sample and reference material had to be compromised [2].

It is discussed how these critical features of continuous-flow IRMS introduce new sources of uncertainty compared to traditional isotope analysis.

In a second part we briefly highlight the historical development of continuous-flow isotope analysis and CSIA.

In a third part the recent development of CSIA applications for transformation reactions of organic groundwater pollutants is summarized. This overview is not meant to be exhaustive. It partially refers to other review articles and highlights the following current research needs:

-

1.

multielement isotope analysis: the need to isotopically characterize as many elements in a compound as possible (part 4 of this review);

-

2.

analysis of polar molecules: the need for derivatization in GC–IRMS or for LC-based methods (part 5);

-

3.

analysis of small concentrations in environmental matrices: the need for enrichment and high chromatographic resolution (part 6);

-

4.

long-term and interlaboratory consistency: not only should isotope values be unambiguously attributed to specific target compounds [3], they must also be reproducible and consistent when measured at different times, in different laboratories, and when extending measurements over larger isotopic ranges (part 7 of this review). We discuss why some differences in instrument-generated values do not necessarily correspond to differences in absolute ratios, stress the importance of appropriate isotopic calibration, consider what can be learnt from well-established procedures for “traditional” isotope analysis, and point out an urgent need for reference materials for compound-specific isotope analysis of organic contaminants.

Part 1: Critical features of continuous-flow IRMS

Dedicated isotope mass spectrometers ([4]) are needed to measure subtle changes in isotope ratios (typically only a few ppm) at the low natural abundance at which some of these isotopes occur (Table 1). The ion sources and fixed detector cups of stable isotope mass spectrometers cannot directly utilize organic molecules but instead rely on gases derived from their combustion or pyrolysis, for example CO2 for 13 C/12 C, N2 for 15 N/14 N, H2 for 2H/1H, and CO for 18O/16O analysis.

Chemical conversion “on the fly”

Traditional “offline” methods accomplish such conversion in sealed quartz tubes, metal tubes, and specialized vacuum lines in which organic samples are chemically converted for an extended period of time in the presence of oxidizing or reducing agents [7], followed by gas separation and quantitative collection of pure analyte gases for mass spectrometry. Approaches relying on offline sample preparation are labour-intensive, slow, and typically require large sample sizes, but can achieve high accuracy. Modern continuous flow, or “online” methods, in contrast, are relatively fast, economical, and enable analysis of small samples (nmol quantities) [1]. They couple:

-

1.

chromatographic GC or LC separation;

-

2.

combustion or high-temperature reductive conversion of separated organic compounds into CO2, N2, H2 and CO; and

-

3.

final isotopic measurement by mass spectrometers “on the fly” (Fig. 1).

For oxidative GC–IRMS, the combustion interface typically consists of a few oxidized copper and/or nickel metal wires threaded through a narrow ceramic reactor tube. Such a miniature setup is needed to maintain the peak separation which is a prerequisite of compound-specific isotope analysis. Complete conversion and the absence of isotope fractionation, however, are quite a challenge under continuous flow conditions. Isotopic integrity of the conversion process must be carefully tested and verified for each target compound, because different organic structures may result in different conversion efficiency.

Chromatographic performance

In contrast to dual-inlet IRMS, in which sample gas can be injected several times, in continuous-flow IRMS analyte peaks are typically measured only once per analysis, i.e. in the sequence of elution from the chromatographic column. Each eluting peak of an organic compound passes through the chemical conversion interface before the resulting peak of CO2, etc., is swept with helium carrier gas into the ion source of a mass spectrometer. Owing to partitioning isotope effects, the isotopic composition will change slightly from front to tail of each peak (“isotope swing”), and non-symmetric peak shape may further complicate isotope evaluations. Accurate results therefore critically depend on chromatographic performance, peak separation from interfering components, and correct integration of the entire peak (typically conducted by automated integration through the IRMS software). Offline analysis, in contrast, generates ample CO2 and other gaseous analytes in closed containers from where they can be repeatedly introduced into the dual inlet system of an IRMS and measured directly against reference gases, for example CO2, from international carbonate measurement standards. Continuous-flow isotope analysis has, therefore, not only less favourable counting statistics, but is also much more prone to errors and critically depends on chromatographic performance.

Standardization and referencing

The “principle of identical treatment of sample and reference material” is the basis for eliminating systematic isotopic bias and achieving accurate calibration of isotopic data [2]. By individually adjusting the gas pressures of sample and standard gas to constant and equal values during offline measurements, the signal amplitudes can be adjusted to identical height, eliminating amount-dependent effects. In commercial continuous-flow IRMS, in contrast, CO2 monitoring gas bypasses the chromatographic system so that errors from chromatography or incomplete combustion are not accounted for, and the amplitudes of sample and reference gas are typically not the same. Such “monitoring gases” are useful to monitor the performance of the mass spectrometer and also to enable crude isotopic calibration of analyte peaks, but they cannot be used to achieve a reliable isotopic calibration on the basis of the “principle of identical treatment of sample and reference material”. The use of a single monitoring gas for calibration also precludes any two-point calibration approach based on two isotopically different reference materials [8, 9]. This contrasts strongly with traditional isotope analysis in which such two-point calibrations are routinely applied because mass spectrometers express slightly different, time-variable scaling factors (i.e. slopes) that result in compression of instrument scales compared with isotopic reference scales [10, 11].

As a consequence of these effects (counting statistics, chemical conversion, transient peaks of varying height) the precision of online GC–IRMS or LC–IRMS is about an order of magnitude smaller than for offline, dual-inlet IRMS. In addition, isotopic calibration of online techniques is particularly important as discussed in detail in the section “The need for contaminant-specific isotope reference materials”. (Part 7) These drawbacks are outweighed, however, by the possibility of measuring small environmental samples and the wealth of information that becomes accessible when analyzing individual molecular organic substances rather than bulk samples, for example soil or sediment.

Part 2: Historic development

The development of on-line continuous flow methods is fairly recent and has its origin in metabolic studies, biogeochemistry, and the petroleum and flavour/fragrance industries [12].

Isotope-ratio mass spectrometry (IRMS)

First applications of stable isotope ratio measurements started in the late 1930s when Nier and Gulbransen observed that carbon in nature varies in isotope composition [13]. Soon thereafter, natural variations in stable isotope ratios were attributed to isotope fractionation processes, and it was recognized that they could be utilized as tracers to follow complex geochemical and biological processes and to reconstruct climate change [14, 15]. Alfred Nier and co-workers developed the fundamental design of isotope-ratio mass spectrometers. McKinney and co-workers introduced the dual inlet system, which enables repeated and direct comparison of analyte and reference gas [16]. Subsequent developments included multiple Faraday collector cups which enable continuous recording of all isotope masses at the same time, better amplification electronics, and differential pumping systems [4].

The delta notation

To harmonize reports of experimental data, the so-called δ notation was introduced [16]:

as the relative difference between the isotope ratio of a sample R(h E/ l E) comp (e.g., R(13 C/12 C)) and of an internationally accepted reference standard R(h E/l E) std (e.g., VPDB with R(13 C/12 C) = 0.0111802 [2]). We note that a factor of 1000 in the definition of the δ notation, as it has been traditionally used, was dropped in a recent revision of values and their proper expression [17]. The delta convention has the advantages that:

-

1.

differences between samples are far easier to determine than the absolute isotope abundance of a substance [18]; and

-

2.

internationally accepted stable isotope reference materials (i.e. measurement standards) can serve as anchor points to define isotopic scales and to ensure interlaboratory compatibility.

Positive δ values express enrichment, and negative values express depletion of the heavier isotope in a sample relative to the reference material.

Gas chromatography–IRMS (GC–IRMS)

In the mid to late 1970s, Sano et al. and Matthews and Hayes coupled the first on-line combustion interfaces between a capillary GC and a conventional single-collector sector-field mass spectrometer [19, 20]. In 1984, Barrie et al. adapted the setup to a dual collector isotope-ratio mass spectrometer [21, 22] with the purpose of establishing authenticity control of flavour compounds and ethanol [23]. In 1988, the first commercial GC–IRMS instrumentation was introduced at the 11th International Mass Spectrometry Conference in Bordeaux [23]. GC–IRMS determination of nitrogen isotope ratios was introduced in the early 1990s [24] by Preston and Slater [25] and Merritt and Hayes [26]. In 1994, Brand et al. introduced a GC–IRMS system for CSIA of oxygen, which has been commercially available since 1996 [24, 27]. Burgoyne and Hayes and Hilkert et al. spearheaded CSIA for hydrogen, which was commercialized in 1998 [28, 29].

Elemental analyzer–IRMS (EA–IRMS)

Continuous-flow IRMS has not only brought a breakthrough in compound-specific analysis, but has also greatly facilitated “bulk stable isotope ratio analysis” (BSIA) [2, 30] of organic composite samples by elemental-analyser–IRMS (EA–IRMS). In 1983, Preston and Owens reported the coupling of an automatic nitrogen analyser (ANA) with an IRMS [31]. Since then, BSIA with elemental analyzers (EA) or high-temperature conversion have found a huge number of applications that exceed the number of CSIA applications by far [30]. The role of EA–IRMS measurements in producing internal laboratory standards normalized against internationally accepted reference material for CSIA is taken up later in the section “The need for contaminant-specific isotope reference materials” (Part 7).

Liquid chromatography–IRMS (LC–IRMS)

Several attempts have been made over the last decades to couple LC with IRMS, including a chemical reaction interface [32] and a moving wire [33-35]. The first commercially available instrument was introduced in 2004 and is based on wet chemical oxidation [36]. It enables only carbon-isotope analysis. The section “Isotope analysis of polar compounds: complementary strategies” (Part 5) includes a more detailed discussion of LC–IRMS.

Part 3: CSIA to assess organic contaminants in the environment

A field which has been particularly stimulated by the advent of CSIA is the assessment of the sources of organic contaminants and their transformation reactions in the environment. It was only in the late 1990s that the first studies on degradation of groundwater pollutants were published [37-39]. Since then, the field has rapidly grown resulting in numerous articles, review articles [40-45], textbooks [46, 47], guidelines for environmental consultants [48-50], and focus issues [51].

Elucidation of contaminant sources

A prerequisite for source apportionment studies (“environmental forensics”) is that analytes from different sources are of consistently different isotopic composition and that the latter remains stable over the relevant spatial and time scales. Stable isotope information may help:

-

1.

to differentiate among different potential polluters on a local scale;

-

2.

to attribute specific emission sources on a regional scale; and

-

3.

to quantify volatile organic compounds and greenhouse gases on a global scale [52, 53].

Much environmental forensic work has been devoted to hydrocarbons such as alkanes and polycyclic aromatic hydrocarbons (PAHs). PAHs can be formed by either petrogenic or pyrogenic processes. Pyrogenic PAHs are typically less depleted in 13 C than their petrogenic counterparts, and this may be used for a differentiation of sources, mostly in combination with other indicators (i.e. molecular ratios of alkylated homologues to parent PAHs, other molecular indices, ratios of low molecular weight to high molecular weight compounds) and chemometric data analysis [54, 55]. For chlorinated hydrocarbons there have been few comprehensive studies at contaminated sites with affected groundwater [56, 57]. Environmental forensic studies would certainly benefit from dual isotope investigations. However, few examples have hitherto been reported, mainly on combined carbon and hydrogen isotope analysis [58, 59].

Detection and quantification of biodegradation

In addition to source apportionment, CSIA provides the unique possibility of identifying and quantifying transformation processes in the environment. During many abiotic and biotic reactions, light isotopes are transferred preferentially from the reactant to the product pool (normal isotope fractionation), whereas, more rarely, the opposite is observed (i.e. inverse isotope fractionation). During normal isotope fractionation, the residual reactant becomes increasingly enriched in the heavy isotope as the reaction proceeds, a trend that can usually be described by the Rayleigh equation [60] for an element E:

where (h E/l E) 0 is the average (“bulk”) isotope ratio of element E in the substrate, irrespective of its position, (h E/l E) is the isotope ratio reached once degradation has proceeded to a residual fraction of the substrate f, α E is the isotope fractionation factor and ε E is the isotope enrichment factor which reflects the extent of isotope fractionation per increment of transformation. By use of Eq. 2, isotope fractionation factors have been determined from laboratory isotope data for numerous compounds and transformation processes [43, 49, 61]. Initially, studies focused mainly on volatile petroleum and chlorinated hydrocarbons, because of their widespread occurrence in the environment and because they can be extracted easily from water for GC–IRMS analysis. More recently, isotope fractionation factors have become available for a wider range of contaminants including pesticides [62-65], anilines [66], and explosives [67-69]. Overall, most studies have reported isotope fractionation factors for C; data for other elements (H, N, Cl, O, S) are less frequent in this field.

Observable isotope fractionation depends on position-specific isotope effects

Although isotope fractionation factors are an important basis for evaluation of field data, they do not directly correspond to isotope effects in reacting bonds: isotope fractionation factors reflect the average behaviour of isotopes in a molecule. In contrast, the kinetic isotope effect (KIE) corresponds to the different reaction rates at the site of the reaction because of the presence of the heavy isotope as defined by:

where l k and h k are the rate constants for molecules with a light and heavy isotope, respectively, at the site of the reaction [70]. A mathematical approach was developed to relate fractionation factors to kinetic isotope effects [43], by taking into account that heavy isotopes may be present at positions that do not participate in the reaction and that multiple reacting positions may occur in a molecule but only one of these reacts [43]. For typical isotope effects in the reacting bond (i.e. primary isotope effects) the following approximate equation can be obtained:

where n is the number of atoms of element E in a molecule (more details are given elsewhere [43]). Equation 4 shows that for a given KIE of element E, an increase in n (e.g., the number of atoms of E within an organic reactant), reduces the observable isotope fractionation, which leads to an upper limit of the number of atoms of E for which isotope fractionation can still be measured. For carbon and hydrogen, this limit is directly related to the molecular size, whereas for other elements (N, O, S, or Cl, of which frequently only one or two atoms are present per molecule) isotope fractionation may still be detectable even in larger compounds. Thus, isotope analysis of elements other than carbon holds significant promise for enhanced assessment of contaminant degradation.

Field applications

An increasing number of field and theoretical studies have explored the use of CSIA to evaluate reactive processes on the field scale [42, 46, 49]. Typical insights obtained from CSIA field studies include:

-

1.

evidence for biotic and abiotic degradation of contaminants compared with their concentration decline due to other reasons (phase-transfer processes, dilution, or hydrodynamic dispersion);

-

2.

information regarding the pathways of degradation; and

-

3.

quantitative estimates of the extent and rates of (bio)transformation [71].

Such estimates of (bio)degradation B can be obtained according to:

where R 0 and R are the isotope ratios of element E in the compound at the source and at a specific location in the field respectively, and f is the fraction of the remaining contaminant at the given location [41].

The advantages gained from interpretation of isotope fractionation have led to a large number of hydrogeological CSIA applications. The CSIA-based approach has found acceptance as a tool for delineating natural attenuation in groundwater systems [49, 72-76]. Field studies have been reported for a number of pollutants and compound classes, for example chlorinated aliphatic, olefinic, and aromatic compounds [39, 73, 77], monoaromatic compounds [78-81], polyaromatic compounds [82], ethers [72, 83], or triazine rings [84] (overviews are available elsewhere [44, 61]). However, considering the large number of environmentally relevant (micro)pollutants, the potential of CSIA investigations is far from being explored. There is a need to establish adequate analytical procedures to address further important target compounds such as pharmaceuticals, pesticides, etc.

Within little more than a decade, the field has moved from being a purely scientific discipline to a widely accepted method used in routine analysis [48, 49]. This development has an important consequence—the demand for isotope measurements is expected to increase and more laboratories may specialize in CSIA. This increases the requirement that identical values are obtained on different instruments and in different laboratories.

Deciphering transformation pathways from multiple element isotope fractionation analysis

A challenge when investigating the fate of organic contaminants in the environment is that they can be degraded by several processes, for example aerobic and anaerobic biodegradation or abiotic and biotic transformation. In such cases it is difficult to identify the predominant process and to choose the correct enrichment factor (ε in Eq. 5). In addition, isotope fractionation may be smaller than expected if the isotopically sensitive step is accompanied by other steps, for example formation of a substrate–enzyme complex, and if these steps become (partially) rate-limiting [43]. If such a “masking” of the KIE occurs, the interpretation of isotope enrichment factors in terms of KIEs may no longer be unique.

However, reaction mechanisms may still be identified if multiple isotopes are analyzed. Different reaction mechanisms often involve bonds containing different elements. Reaction mechanisms can therefore be differentiated by considering the relative isotope fractionation for different elements, typically using dual (or two-dimensional) isotope plots that have different slopes for different reaction mechanisms. This approach has been successfully applied to an increasing range of compounds, as summarized in Elsner [44].

The example of isoproturon in Fig. 2 illustrates two cases in which:

-

1.

different bonds are involved in the reaction (hydroxylation versus hydrolysis); and

-

2.

the same bond is involved, but is cleaved in different ways (i.e. hydrolysis by two different mechanisms).

Carbon, hydrogen and nitrogen isotope fractionation during biotransformation and abiotic hydrolysis of isoproturon [65]. In each panel, data points to the left represent samples taken at the beginning of the degradation whereas points to the right are from the end of the respective experiments. Dual element isotope fractionation of hydrogen and carbon enables C–H bond cleavage to be distinguished from hydrolysis (left panel). Nitrogen and carbon-isotope analysis even reveals the chemical nature of biotic versus abiotic hydrolysis of isoproturon (right panel). Δ2H indicates changes compared with the initial value (“Delta over baseline”)

Multi-isotope analysis, therefore, holds strong promise for elucidation of the mechanisms of reaction of groundwater contaminants. For many compounds and reactions, however, data on multiple elements are still lacking, especially for reactions involving N, Cl, O, and S atoms.

Part 4: Analyzing multiple elements: compound-specific hydrogen, nitrogen, chlorine and oxygen isotope analysis

Most laboratories specializing in GC–IRMS focus on carbon isotope measurements. However, as discussed above, valuable information can be obtained from isotope measurements of other elements. Besides carbon, those most commonly encountered in organic contaminants are hydrogen, oxygen, nitrogen, and chlorine.

Hydrogen isotope analysis

Hydrogen isotope analysis poses several unique challenges:

-

1.

The mean natural abundance of 2H of only 0.0156 atom % of all hydrogen is low compared with 1.1 % for 13 C, which makes it more difficult to generate a sufficiently strong deuterium-containing ion current in the mass spectrometer;

-

2.

Hydrogen-bearing organic molecules must be converted quantitatively into hydrogen gas. To this end, Hayes and coworkers pioneered online pyrolysis in carbon-lined non-porous alumina tube reactors, without involvement of metal reductants [28].

-

3.

Optimum temperature and flow conditions are critical in the pyrolysis process. Increased porosity of alumina tubes causes significant loss in signal yield above 1470 °C, whereas temperatures below 1440 °C or carrier flow rates above 1.5 mL min−1 may result in incomplete conversion [24, 28, 29, 85].

-

4.

Some isobaric interferences during the ionization process are critical and must be accounted for. The triatomic ion \( ^1{\text{H}}_3^{+} \) is formed in the ion source and interferes with [2H1H]+ (m/z 3) leading to overestimation of the isotope ratio 2H/1H [2, 4]. Because its formation is amount-dependent, it can be corrected according to:

$$ \left[ {^1{\text{H}}_3^{ + }} \right]\infty \left[ {^1{\text{H}}_2^{ + }} \right] \cdot \left[ {^1{{\text{H}}_2}} \right] = K \cdot {\left[ {^1{{\text{H}}_2}} \right]^2} $$(6)where K is the “H3-factor”, expressed in ppm nA–1 [85].

-

5.

Nitrogen from pyrolysis of N-rich organic compounds must be chromatographically separated from H2 before mass spectrometric analysis to avoid interference [86].

-

6.

Compounds containing chlorine (e.g., trichloroethylene) or fluorine presently cannot be analyzed because their pyrolysis forms HCl or HF inside the oven. [24]. Fused silica columns may be destroyed, the IRMS source can be corroded, and incomplete conversion leads to fractionation and inaccurate hydrogen isotope measurements.

Therefore, although hydrogen isotope analysis is instrumentally well established, in everyday practice measurements are often difficult. The numerous potential sources of bias highlight the importance of careful calibration and referencing to ensure interlaboratory compatibility. However, few compound-specific isotope standards are yet available.

Nitrogen isotope analysis

Despite the availability of commercial instrumentation [1, 26, 27, 34, 87], nitrogen isotope analysis of organic micropollutants is still far less common than measurements of carbon isotope ratios. Challenges arise from properties of the targeted analytes and from instrumental procedures. N-containing compounds must be converted to N2 for analysis in the IRMS. As sketched in Fig. 3, the latter is achieved in two consecutive reactions—initial combustion of organic N to N2 (in a miniature oxidation reactor tube containing CuO/NiO/Pt wire) and subsequent reduction of traces of nitrogen oxides to N2 (in a miniature reduction reactor tube containing Cu wire) (Fig. 3).

This approach is prone to a series of potential problems [27]:

-

1.

Organic molecules typically contain fewer nitrogen than carbon atoms.

-

2.

The abundance of 15 N in total nitrogen is approximately a factor of three smaller than for 13 C.

-

3.

Two N atoms are required to generate one N2 analyte molecule compared with only one C in CO2.

-

4.

The ionization efficiency of N2 in the ion source of the IRMS is only approximately 70% that of CO2. Taken together, the amount of sample theoretically necessary for nitrogen isotope analysis is approximately fifty times higher than that for carbon if the same precision is required. This leads to smaller peak amplitudes despite greater substance loads on the gas chromatographic column; the greater loads lead to deterioration of chromatographic performance.

-

5.

At the same time, nitrogen-containing compounds are typically more “sticky” (i.e. more polar and less volatile) increasing the potential of sorption by active sites and leading to adverse effects on peak separation and chromatographic performance.

-

6.

Ambient air contains more nitrogen than CO2 increasing the sensitivity to leaks in the system and impurities in the carrier gas.

-

7.

Nitrogen isotope measurements are affected by isobaric interferences from CO+ formed from CO2 in the ion source of the IRMS, so CO2 must be routinely scavenged by cryogenic trapping. However, CO may also originate from incomplete combustion. Oxidation reactor tubes in nitrogen isotope analysis therefore must be operated in a delicate balance. On the one hand, they must release sufficient oxygen to ensure complete combustion to CO2. On the other hand, any excess oxygen would rapidly deactivate the reduction reactor leading to a breakthrough of nitrogen oxides. The problem of correct reactor conditioning has been alleviated by the introduction of new commercial “GC-Isolink” reactors (ceramic tubes filled with a Ni-tube and NiO/CuO wire; Thermo Scientific) which combine oxidation and reduction in one unit.

The fact that nitrogen isotope analysis requires two separate complete conversion processes (oxidation and reduction), together with the potential for poor chromatographic performance, makes the method particularly vulnerable to systematic bias. Neither IAEA nor NIST currently offer well-calibrated N-containing organic compounds that could serve as N-isotopic reference material in GC–IRMS analysis.

Nevertheless, δ 15N-values have been measured with good precision for compounds such as triazine and phenylurea herbicides [62, 88, 89], nitroaromatic compounds [90, 91], and substituted anilines [66] in water samples, by using different enrichment procedures (solid phase (micro)extraction, solvent extraction, etc.) to compensate for the poor sensitivity of CSIA of nitrogen. Because of these restrictions and the limited amount of contaminants studied so far, broadly accepted estimates of total uncertainties are lacking but are higher (~ ± 1‰) than those for carbon (±0.5‰).

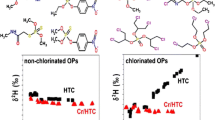

Chlorine isotope analysis

Although highly desired for numerous chlorinated environmental contaminants, compound-specific chlorine isotope analysis has long been elusive owing to the difficulty of creating a simple chlorine-containing gas in a continuous He carrier flow. Offline chlorine isotope analysis traditionally relies on either conversion to chloromethane (for dual inlet-IRMS analysis [92-94]) or caesium chloride (for thermal ion mass spectrometry analysis [95, 96]). In a recent development, several innovative solutions for GC coupling have been proposed, each based on a different strategy (Fig. 4).

-

1.

Production and measurement of chlorine ions are possible by use of an inductively coupled plasma combined with a multi-collector MS measuring the 37Cl/35Cl ratio (“GC–MC–ICPMS method”) [97]. This method has the advantage that it is very precise (1σ = 0.06‰) and universally applicable, but it suffers from high instrument costs, low ionization efficiency to Cl+, and interference of ArH+ ions from the inductively coupled plasma. The required sample size for a precise isotope analysis is therefore relatively high (several μmol Cl).

-

2.

Online high temperature conversion (HTC) converts organic Cl into gaseous HCl under H2 gas flow, which is followed by MS measurement of the H37Cl/H35Cl ratio (“GC–HTCMS method”, Fig. 4 lower panel) [98]. This method holds great promise, because it is also universal with regard to target compounds, and it successfully performs isotope measurements by online conversion to a chlorine-containing gas. However, analysis has so far been realized only on a quadrupole MS instrument with precision of approximately 1σ = 0.5–1‰. It remains to be investigated whether the method can be adapted to high-precision IRMS.

-

3.

Alternatively, target molecules are not converted. Instead the GC effluent is transferred directly to a high-precision IRMS (Fig. 4 upper panel) [99] or a quadrupole MS [100-102]. Instead of species that contain only one chlorine atom (e.g., 37Cl/35Cl or H37Cl/H35Cl), isotopologues containing multiple chlorine substituents are analyzed, for example C2H 372 Cl35Cl/C2H 352 Cl2. Evaluations either involve molecular ions [101, 102], fragment ions [6, 99], or a weighted combination of both [100]. The applicability of the isotopologue approach has been theoretically validated [103] and practically investigated [102]. When the GC is coupled to an IRMS, the approach is highly precise (1σ ≈ 0.1‰), but only applicable to masses of target compounds for which the IRMS has a dedicated cup configuration. Conversely, it is universal with regard to target compounds, but less precise (1σ ≈ 0.5‰) when coupled to a quadrupole MS.

Currently, the development of compound-specific chlorine isotope analysis is at a stage at which different approaches have been proposed, but it is unclear how their precision and trueness compare in real-world applications. A recent method comparison in an interlaboratory study [6] has taken a step toward such a validation for trichloroethylene as example and has shown that precise and consistent isotope values can be obtained by different laboratories by use of GC–IRMS or GC–quadrupole MS. At the same time, the study emphasizes the need for method calibration with at least two different isotope standards which are chemically identical to the compound to be analyzed, yet sufficiently different in 37Cl abundance (see Part 7).

Oxygen isotope analysis

For oxygen isotope analysis a commercially available analytical solution is available—pyrolytic conversion to CO [27]. Such analysis may be useful if oxygen resides in molecular positions where it does not exchange with water and therefore maintains its diagnostic isotopic fingerprint (e.g., in ether bridges as opposed to carboxyl groups). Indeed, compound-specific oxygen isotope analysis has been established for, and has delivered valuable information for, fragrance compounds [104, 105]. In contrast, we are not aware of any applications of oxygen GC–IRMS for environmental contaminants. A particular challenge is posed by compounds that contain both oxygen and nitrogen, because of isobaric interferences of CO and N2, so that they must be separated before mass spectrometric analysis. There is an evident research need to further explore the potential of this method for organic pollutants.

Part 5: Isotope analysis of polar compounds: complementary strategies

Many environmental contaminants, for example pesticides but also steroids and pharmaceuticals, contain carboxyl, alcohol, or amino groups. In many cases these functional groups substantially reduce their volatility, so the compounds tend to decompose when injected on to gas chromatographic columns. Therefore, such substances are not directly amenable to gas chromatographic separation. Different strategies have been developed for isotope analysis of such compounds, most importantly derivatization before GC–IRMS, or analysis by LC–IRMS.

Derivatization

Derivatization typically introduces atoms which reduce the polarity and alter the chemistry of functional group(s) leading to better thermal stability and improved chromatographic separation. The disadvantages, however, are:

-

1.

the introduced atoms have their own isotopic signature from a foreign source;

-

2.

isotope effects during derivatization need to be taken into account; and

-

3.

even if foreign signature and isotope effects are tightly controlled, the additional atoms “dilute” isotope changes in the target compound by contributing to n in Eq. 4. Moreover,

-

4.

derivatives should be stable, and they should not contain elements that jeopardize chemical conversion for isotope analysis.

Different cases can be distinguished.

-

1.

Elements are analyzed (e.g., N, Cl) of which no additional atoms are introduced during derivatization. Aspects (1) and (2), above, are therefore not of concern, and even isotope effects in the analyte’s structure do not matter if the analyte is derivatized quantitatively. Good results can therefore be obtained with a variety of derivatization agents [106].

-

2.

Additional atoms of the element (e.g., C, H) are introduced by derivatization. In this case the following aspects are crucial relating to the difficulties (1–3) listed above [107]:

(i) The isotope signature of the foreign source must be known.

(ii) The chemical derivatization reaction(s) must be complete in order to avoid kinetic isotope fractionation in the structure of the target analyte. At the same time, a kinetic isotope effect in the added group(s) must be avoided, or at least kept constant by using a standardized derivatization procedure. Such kinetic isotope fractionation may occur, because the derivatization agent must be added in excess, precluding its own complete conversion.

(iii) Derivatization should introduce as few additional atoms as possible. A variety of derivatization strategies have been tested for GC–IRMS and are discussed below according to their ability to fulfil these criteria.

Chemical modification without addition of protecting groups

The approach is elegant for carbon or hydrogen GC–IRMS, because it does not introduce extraneous carbon sources. However, it is restricted to specific compounds and is, therefore, not universally applicable. Examples for chemical modifications are decarboxylation [108, 109], reduction of fatty acid esters to alcohols [110], reduction of organometal(loid) oxides to the corresponding hydrides [111], intramolecular esterification [112], or selective fragmentation [89]. Besides enabling carbon-isotope analysis, the latter approach has been shown to facilitate isotope analysis of nitrogen and hydrogen also [65, 89].

Silylation

Trialkysilyl protection groups are easily introduced and are universally applicable to many functional target groups (–OH, –NH2, –COOH), for example in amino acids [106], steroids [113], and fatty acids [114]. A bond is formed to a silicon (Si) rather than carbon atom so that derivatization results in very little carbon or hydrogen isotope fractionation. However, silylation introduces many foreign atoms and derivatized compounds have a limited storage lifetime. It is suspected that silicon carbide is formed in the reductive high-temperature conversion oven [115] leading to incomplete combustion [22, 116]; this reduces precision [116] and precludes hydrogen isotope analysis [117].

Acetylation

Acetylation is suitable for derivatization of hydroxyl and amino groups, and is frequently used for steroids [118], carbohydrates [119], and amino acids [120]. Reactions are usually performed with excess acid (e.g., acetic acid) or an anhydride mixed with pyridine [121] or n-methylimidazole [119] as promoters. Two foreign carbon atoms are introduced, and a strong isotope effect occurs in the protecting acyl group. This requires precise control of the carbon source and of reaction conditions. To achieve quantitative conversion, use of trifluoroacetate [122] is frequently advantageous. However, the concomitant formation of hydrogen fluoride generates CuF2 and NiF2 in the combustion oven, irreversibly poisons platinum [1], and precludes hydrogen isotope analysis.

Methylation

Methylation has the advantage that only one extraneous carbon atom is introduced. Because this occurs by an SN2 reaction, isotope effects are large [123] and control over reaction conditions is mandatory. Although, in principle, –OH, –NH2, and –COOH functionality may be methylated, in many cases it takes diazomethane (CH2N2) to accomplish this task. Unfortunately, this reagent is so highly reactive that control over carbon source or reaction conditions is impossible and it is, therefore, not suitable for isotope analysis at natural isotope ratio abundance. In contrast, derivatization with catalytic boron trifluoride (BF3) in methanol is well established for isotope analysis of organic acids, most prominently for derivatizing n-alkanoic acids as fatty acid methyl esters (FAME) [1], but cannot be used for alcohol or amino groups. Recent results with trimethyl sulfonium hydroxide (TMSH) suggest a promising alternative. Clean automated derivatization was accomplished under controlled conditions in a temperature programmable injector in which reproducible carbon isotope values were obtained with TMSH in 250-fold excess of the target analyze. This approach enabled compound-specific isotope analysis for the anionic pesticide species chlorophenoxy acids and bentazone [124].

As shown by these examples, derivatization before isotope analysis is challenging for several reasons, and method development is still in progress for environmental contaminants. Even when choosing the best strategy, derivatization changes the original isotope value of a target compound if additional pertinent atoms are introduced during derivatization. To obtain the correct value, isotopic control over the source of the extraneous atom(s) and the isotope effect associated with the derivatization reaction are, therefore, mandatory. Unfortunately, only very few isotopically characterized derivatization reagents are yet available [24].

Liquid chromatography–IRMS (LC–IRMS)

An alternative to derivatization of polar compounds is high-pressure liquid chromatography in combination with IRMS (LC–IRMS or HPLC–IRMS) [125]. After chromatographic separation, target analytes in the eluent are converted to CO2 by wet chemical combustion by concentrated sodium peroxodisulfate (Na2S2O8) in the presence of phosphoric acid [36, 126]. The acidification supports the formation of CO2 and the high ionic strength enhances transfer of the CO2 into the gas phase, which occurs through an exchange membrane into a He counterflow leading to the IRMS [36]. A schematic diagram of a wet chemical combustion interface as realized in the LC-IsoLink (Thermo Fisher Scientific, Bremen, Germany) is shown in Fig. 5.

LC–IRMS isotope analysis is currently possible for carbon only, because selective conversion of nitrogen-containing compounds to N2 remains elusive under these conditions. Also, chromatographic separations must be conducted in the absence of organic solvents or modifiers, or the CO2 analyte peak would be dwarfed by the background of the eluent. Thus, stationary phases must be compatible with pure aqueous mobile phases and loss of carbon because of phase bleeding should be minimized. Common columns for ion chromatography fulfil these requirements [127, 128] whereas the development of suitable reversed-phase columns remains a challenge. In addition, increasing the temperature of the mobile and stationary phase may modulate the solubility and, therefore, the retention of compounds. The static permittivity of water decreases with temperature, rendering its eluent strength similar to that of a methanol–water mixture [129]. Consequently, temperature gradients can replace organic solvent gradients. As a first example Godin et al. used temperatures up to 170 °C to separate hydrosoluble fatty acids and phenolic acids via a very hydrophobic porous graphitic carbon column [130]. Because commercially available columns often do not support these temperatures [130], Zhang et al. investigated four different stationary phases and showed that under isothermal and temperature gradient conditions, column bleed had no effect on the precision and accuracy of δ 13C values [131]. These results are promising for compound-specific isotope analysis of polar organic contaminants by high-temperature LC–IRMS.

Derivatization–GC–IRMS and (high temperature) LC–IRMS are therefore two complementary strategies for CSIA of polar organic environmental pollutants. LC–IRMS facilitates carbon-isotope analysis without introduction of extraneous carbon atoms, whereas GC–IRMS enables in addition N and H isotope analysis, accomplishes higher peak resolution, and is more sensitive. Further advances in both methods can be expected to close the gap for heteroatom-containing polar compounds such as pesticides and pharmaceuticals.

Part 6: Analysis of low compound concentrations in the presence of complex matrices

An intrinsic challenge of isotope analysis is that all isotopes must be analyzed with high precision, whereas conventional concentration analysis typically measures only the most abundant isotope. In addition, the minor isotope must be quantified with a precision of 10−4 h E/l E, which is quite different from the detection limit in conventional concentration analysis, defined as 2–3 times the standard deviation of the baseline. For example, only one percent of all carbon is 13 C. The required signal strength for precise compound-specific carbon isotope analysis is therefore approximately two orders of magnitude larger than for conventional analysis of compound concentrations. The problem is even worse for nitrogen and hydrogen. A second difficulty is that conversion of the chemical before IRMS transforms all compounds into the same chemical form (e.g., CO2 for carbon-isotope analysis). If a target analyte peak overlaps with an interfering matrix component, it is no longer possible to distinguish whether the CO2 stems from the analyte or the matrix so that bias is introduced into isotope analysis. Both aspects are of particular concern for analysis of contaminants in environmental samples, because these pollutants occur in small concentrations and in the presence of interfering matrix components. Preconcentration, purification and high chromatographic performance are, therefore, of particular importance. A common concern to all preconcentration methods is the possibility of systematic isotope fractionation during sorption, desorption, and phase transfer [132]. Before analysis of samples, methods must therefore be carefully validated with isotope standards.

Preconcentration methods

Purge and trap (P&T)

For volatile groundwater contaminants, for example gasoline components and chlorinated hydrocarbons, purge and trap (P&T) methods have been successfully established in recent years. A gas stream sparges compounds out of the aqueous sample, and subsequently they are sorbed by a trap. Before measurement, the compounds are released by heating and are carried in a He stream into the injection port of a gas chromatograph. Reliable isotope values in the low ppb concentration range have been obtained for numerous volatile groundwater contaminants [133-137]. Larger amounts of water samples (up to 100 mL) can be extracted in an automated process, and interfering non-volatile matrix components are left behind leading to “clean” chromatograms.

Solid-phase microextraction (SPME)

An alternative to P&T is solid-phase microextraction (SPME) before GC–IRMS [90, 133, 138]. Organic compounds are sorbed by the polymer coating of a miniature fibre that is either directly immersed in the aqueous sample (direct immersion SPME) or exposed to its headspace (headspace SPME). The fibre is subsequently introduced into the hot injector of a gas chromatograph where the compounds are released onto the gas chromatographic column. SPME does not enable isotope analysis at the same low concentrations as P&T, but has the advantage that it is applicable also to less volatile target compounds in direct immersion mode, because the preconcentration step relies on kinetically controlled sorption rather than volatilization.

Solid-phase extraction (SPE)

For compounds of low volatility that occur in even lower concentrations such as pesticides or pharmaceuticals, solid-phase extraction (SPE) of aqueous samples followed by elution with an organic solvent offers the highest preconcentration factors. However, interfering matrix components are frequently also extracted so that it might be necessary to apply further purification of extracts to remove interfering matrix components, e.g. by silica cleanup [139] or preparative HPLC [140], similar to soil and sediment analysis. For subsequent quantitative transfer onto the GC column on-column injection is an expedient option, since the losses that are associated with split injection are avoided [133].

Two-dimensional gas chromatography

Strategies to separate target compounds from interfering components and to accomplish isotope analysis at low concentrations have also extended to the setup of GC–IRMS systems. Two-dimensional (2D) gas chromatography is an expedient option, because parts of a chromatogram may be cut out and released on to a second GC column where analytes are separated according to different compound properties. 2D-GC–IRMS has been realized in two different manners.

Heart-cut two-dimensional gas chromatography

In heart-cut 2D-GC–IRMS with moving capillary stream switching (MCSS) [141, 142] only a part (the heart cut) of the first chromatogram is released onto the second column, whereas the rest is lost. This method is commercially available and it is powerful if only selected target compounds are of interest and if it is convenient to blend out the rest.

Comprehensive two-dimensional gas chromatography

In comprehensive two-dimensional gas chromatography–IRMS (GC × GC–IRMS) the effluent from a first GC column (0.25 mm inner diameter) is “sliced” by freezing in a cryogenic modulator. Each fraction is immediately released by flash heating on to a second GC column of thinner inner diameter (0.1 mm inner diameter) on which peak separation in the second dimension is accomplished. This method has the advantage that the full chromatogram can be obtained in 2D resolution and no part is cut out. However, it is not easily implemented in commercial GC–IRMS systems for the following reasons.

Low flow rates are necessary for the narrow GC columns of the second dimension for which commercial combustion reactor tubes are too wide. Recently, Tobias and Brenna resolved this issue by construction of customized microreactors [143].

Slices of peaks end up in several fractions of the second dimension. An algorithm has therefore been developed to reconstruct isotope ratios of target compounds from the slices of several fractions [144].

Although it seems that these solutions are still not readily implemented in conventional GC–IRMS systems, the system is a promising approach for better sensitivity and higher resolution in future analysis of environmental samples.

Part 7: The need for contaminant-specific isotope reference materials

Because chromatography and chemical conversion may involve analyte-structure-dependent isotope fractionation, the accuracy of isotope measurements must, ideally, be validated for each target compound by use of chemically identical isotope reference materials with known isotopic compositions. In practice, lack of suitable reference materials forces the scientific community to address such issues of quality assurance on a laboratory-by-laboratory basis. Guidelines for referencing and calibration are missing, and round-robin tests, or even proficiency tests for GC–IRMS, are rare. Considering that contaminant-specific isotope assessments are widely accepted and involve a steadily increasing number of laboratories, there is an obvious need for quality assurance: it must be ensured that reproducible and consistent results are obtained between laboratories and over time. In this section, different levels of calibration and referencing, and the urgent need for contaminant-specific isotope standards, are discussed.

The role of a monitoring gas

In GC–IRMS and EA–IRMS measurements “monitoring gas” peaks (i.e. of CO2, N2 or H2) are typically introduced at the beginning and end of each chromatographic run. They are useful for monitoring the performance of chemical conversion process and the mass spectrometer and also to provide a crude isotopic calibration of analyte peaks. Many studies report excellent accuracy of automatically generated results, meaning that GC–IRMS instrument values based on automated monitoring gas calibration coincide with those from offline analysis or EA–IRMS, for which reported standard deviations are typically ±0.3‰ for carbon and ±1‰ for nitrogen [24, 49, 145]. Although such results may seem to suggest that complete oxidative or reductive conversion of analytes and accurate isotope results are the norm, this cannot be taken for granted in analysis of new target compounds by GC–IRMS. Monitoring gas peaks bypass the GC and the interface and, therefore, cannot be used to monitor possible isotopic fractionation during chromatographic separation and chemical conversion. They cannot be used to achieve reliable isotopic calibration based on the “principle of identical treatment of sample and reference material”. Isotope values that are solely based on monitoring gas calibration should therefore never be trusted at face value.

Offset correction with a single compound-specific in-house standard

It is common practice in most laboratories to have an inventory of compound-specific in-house standards. Economically priced target compounds with environmental relevance are often rare, however, and isotope values of different products may hardly vary (e.g., carbon isotope values typically cluster in the range of C3 plants). Frequently only one compound-specific in-house standard is therefore available per target analyte. Target analytes are typically purchased in high purity, and are characterized by either dual-inlet (i.e. off-line) IRMS or EA–IRMS. If uncorrected GC–IRMS measurements reproduce the in-house target value within the analytical uncertainty of GC–IRMS (for carbon-isotope analysis typically 2σ = 0.5‰) this is sometimes taken as evidence that there is no systematic bias and that GC–IRMS analysis is accurate. However, use of a single in-house standard can only show that no significant fractionation occurs during gas chromatography and chemical conversion (i.e., that there is no systematic offset for GC–IRMS analysis compared with independent characterization of the same in-house standard). In contrast, no claim can be made about samples with isotope values differing from that of the standard, because nothing is known about how isotope values reported by the instrument change when moving along the delta scale (discussion below and Fig. 6).

Examples of one-point calibrations (upper panels) and two-point calibrations (lower panels) in two interlaboratory comparison studies. Left: analysis of hydrogen gas samples by dual inlet IRMS on 40 different instruments [146]. Right: analysis of trichloroethene (TCE) samples by direct GC–IRMS or GC–qMS (i.e., no chemical conversion) on eight different instruments [6]

Calibration with two isotopically contrasting in-house standards

Differences between the attenuation of mass spectrometers along isotopic scales (“scale compression”) can be taken into account by using more than one standard, thus correcting for slightly different, time-variable, attenuation (i.e. slopes) of mass spectrometers that typically result in compression of isotopic reference scales [10, 11].

The examples in Fig. 6 are a telling illustration that one-point calibration can only correct samples for which values are similar to those of the standard, whereas a two-point calibration is necessary to obtain reliable values over a greater range of δ values. They show that measurement bias is exacerbated with increasing distance between the δ values of sample and standard.

Bias can result from a variety of sources which may have their origin either inside or outside the mass spectrometer. MS-specific sources include ionization differences in ion sources and individual electronic amplifier characteristics resulting in incompatible slopes of isotopic scales among mass spectrometers [10, 147]. Sources outside the MS include, for example, conversion effects when using water reduction in high-temperature reactions [148]. Coplen et al. [149] reported that isotopic analyses in different laboratories often differ by ten times the reported total uncertainty of their measurements. Two or more isotopically different reference materials should therefore be sufficiently diverse to isotopically bracket all sample measurements. Routine two-point calibrations are already mandatory for inorganic isotopic measurements of hydrogen, carbon, nitrogen, and oxygen [8, 149]. Detailed guidelines for two-point calibration procedures for measurement of hydrogen, carbon, and oxygen stable isotopes ratios have been published [11, 148-150]. Currently, however, two-point calibrations are rare in compound-specific isotope analysis of organic contaminants.

Calibration with international measurement standards and external reference materials

Although in-house standards can ensure the reproducibility of measurements over time in a given laboratory, for interlaboratory comparisons external reference materials are crucial. “Traditional” isotope analysis has established careful use of international reference materials. For example, the International Atomic Energy Agency in Vienna (IAEA) and the US National Institute of Standards and Technology (NIST) are globally distributing isotopically distinct waters, carbonates, ammonium sulfates, and other inorganic and some organic stable isotope measurement standards that can serve for calibration along established δ scales [8]. In many cases, the chemical type of reference material is available in at least two isotopic varieties for two-point or multiple-point normalizations in order to compensate for instrument-specific attenuation of instrument δ scales (e.g., “Vienna Standard Mean Ocean Water 2” (VSMOW2) with δ 2H = 0.0‰ and δ 18O = 0.00‰, and “Standard Light Antarctic Precipitation 2” (SLAP2) with δ 2H = −427.5‰ and δ 18O = −55.50‰; http://www-naweb.iaea.org/NAALIHL/docs/ref_mat/InfoSheet-VSMOW2-SLAP2.pdf).

Missing organic reference materials for CSIA

Unfortunately, modern continuous flow GC–IRMS and LC–IRMS methods are analytically restricted to reference materials that are physically and chemically similar to the unknown analytes, because of the need for chromatographic mobility. For example, waters and ammonium salts cannot be injected into a GC. Likewise, carbonates cannot be used in GC and LC methods in the same way as organic materials are combusted to generate CO2 analyte gas. A first attempt to prepare common solutions of a variety of isotopically characterized organic compounds that can jointly serve as an isotopic equivalent of a Grob test [151] has failed, because two or more of the chemical components were reacting with each other. As a consequence, mixtures had a short shelf life, even when refrigerated, and suffered rapid isotope fractionation. Organic stable isotope reference materials should therefore be chosen carefully to maximize chemical stability and isotopic long-term integrity, which excludes many compounds of environmental interest. The development of suitable international organic stable isotopic reference materials for continuous-flow methods has not kept pace with the growing importance of GC and LC. The IAEA and NIST do not offer any organic reference materials for GC–IRMS, even though the technique has been available for up to 20 years.

Outlook: first initiatives and next steps

In the absence of suitable organic reference materials from the IAEA and NIST, the scientific community has usually been forced to work with temporary laboratory reference materials and/or routinely violate the principle of identical treatment. Some laboratories have taken the initiative in the development of organic reference materials [152, 153]. Indiana University has been offering dozens of pure organic reference materials (http://mypage.iu.edu/~aschimme/hc.html) and in 2011, with a supporting grant from the US National Science Foundation, started a group effort with ten other laboratories to jointly develop certified compound-specific organic reference materials (δ 2H, δ 13C, and δ 15N of, e.g., n-alkanes, n-alkanoic acid methyl esters, and amino acids) that will subsequently be distributed internationally by the IAEA and other agencies.

Unfortunately, many organic contaminants are flammable and/or toxic. It seems unlikely that the IAEA or NIST will globally distribute any reference materials that are believed to be hazardous and would require sophisticated packaging and elaborate shipping declarations. The development and distribution of hazardous reference materials will probably remain dependent on volunteering academic institutions and private organizations.

The future development of specific reference materials for organic contaminants can, therefore, not rely on large organizations, for example IAEA and NIST, but will need to be organized at the grass-roots level, including the development of organic standard materials for additional elements of environmental interest (e.g., δ 32S, δ 37Cl, and δ 81Br). Interested users should propose specific compounds to laboratories that have a track record in the development of reference materials. Professional organizations with special expertise in scientific sub-fields (e.g., groundwater hydrology) can promote the development of compound-specific isotope reference materials that will bring the community closer to:

-

1.

adherence to the principle of identical treatment of sample and reference material; and

-

2.

reproducible isotopic data based on two-point calibrations.

Conclusions

This review shows how compound-specific isotope analysis enables the detection of changing isotope ratios in organic contaminants and how this information can be used to assess their degradation in the environment. Multielement isotope analysis and analysis of polar target contaminants holds great promise to better evaluate the fate of pollutants in the environment, yet face several challenges. Strategies to deal with low concentrations in the presence of environmental matrices have been discussed. Dedicated method development has helped to increase the number of accessible substances and isotopic elements in the portfolio of isotope methods.

At the same time, however, the discussion also made it clear that CSIA is a very delicate method, because the integrity of isotope measurements is highly dependent on critical factors which include chromatographic performance and adequate on-line conversion to analyte gases in dedicated interfaces for chemical conversion. Compared with carbon, these factors are even more critical for hydrogen, nitrogen, and chlorine isotope analysis. Considering that contaminant-specific isotope assessment is widely accepted and involves a steadily increasing number of laboratories, quality assurance will become even more important in the future: it must be ensured that reproducible and consistent results can be obtained between laboratories and over time. An urgent need exists for compound-specific isotope standards of environmental contaminants.

References

Meier-Augenstein W (2004) GC and IRMS technology for 13C and 15N analysis on organic compounds and related gases. Handbook of Stable Isotope Analytical Techniques 1:153–176

Werner RA, Brand WA (2001) Referencing strategies and techniques in stable isotope ratio analysis. Rapid Commun Mass Spectrom 15:501–519

Hall JA, Barth JAC, Kalin RM (1999) Routine analysis by high precision gas chromatography/mass selective detector/isotope-ratio mass spectrometry to 0.1 parts per mil. Rapid Commun Mass Spectrom 13(13):1231–1236

Brand WA (2004) Mass Spectrometer Hardware for Analyzing Stable Isotope Ratios. In: Groot PAd (ed) Handbook of Stable Isotope Analytical Techniques, Volume-I. Elsevier B.V., pp 835-857

Coplen TB, Bohlke JK, De Bievre P, Ding T, Holden NE, Hopple JA, Krouse HR, Lamberty A, Peiser HS, Revesz K, Rieder SE, Rosman KJR, Roth E, Taylor PDP, Vocke RD, Xiao YK (2002) Isotope-abundance variations of selected elements - (IUPAC Technical Report). Pure Appl Chem 74(10):1987–2017

Bernstein A, Shouakar-Stash O, Ebert K, Laskov C, Hunkeler D, Jeannottat S, Sakaguchi-Söder K, Laaks J, Jochmann MA, Cretnik S, Jager J, Haderlein SB, Schmidt TC, Aravena R, Elsner M (2011) Compound-Specific Chlorine Isotope Analysis: A Comparison of Gas Chromatography/Isotope Ratio Mass Spectrometry and Gas Chromatography/Quadrupole Mass Spectrometry Methods in an Interlaboratory Study. Anal Chem 83(20):7624–7634

de Groot PA (2009) Carbon: Organic materials. In: de Groot PA (ed) Handbook of Stable Isotope Analytical Techniques, Vol. 2 Elsevier, Amsterdam, pp 229-269

Gröning M (2009) International stable isotope reference materials. In: de Groot PA (ed) Handbook of Stable Isotope Analytical Techniques, Vol. 1 Elsevier, Amsterdam, pp 874-906

Coplen TB, Brand WA, Gehre M, Gröning M, Meijer HAJ, Toman B, Verkouteren RM (2006) New Guidelines for 13C Measurements. Anal Chem 78(7):2439–2441

Debajyoti P, Grzegorz S, István F (2007) Normalization of measured stable isotopic compositions to isotope reference scales – a review. Rapid Commun Mass Spectrom 21(18):3006–3014

Lin Y, Clayton RN, Gröning M (2010) Calibration of δ 17O and δ 18O of international measurement standards – VSMOW, VSMOW2, SLAP, and SLAP2. Rapid Commun Mass Spectrom 24(6):773–776

Lichtfouse E (2000) Compound-specific isotope analysis. Application to archaelogy, biomedical sciences, biosynthesis, environment, extraterrestrial chemistry, food science, forensic science, humic substances, microbiology, organic geochemistry, soil science and sport. Rapid Commun Mass Spectrom 14(15):1337–1344

Nier AO, Gulbransen EA (1939) Variations in the relative abundance of the carbon isotopes. J Am Chem Soc 61(3):697–698

Urey HC (1948) Oxygen isotopes in nature and in the laboratory. Science 108(2810):489–496

Bigeleisen J (1949) The Validity of the Use of Traces to Follow Chemical Reactions. Science 110(2844):14–16

McKinney CR, McCrea JM, Epstein S, Allen HA, Urey HC (1950) Improvements in mass spectrometers for the measurement of small differences in isotopic abundance ratios. Rev Sci Instrum 21:724–730

Coplen TB (2011) Guidelines and recommended terms for expression of stable-isotope-ratio and gas-ratio measurement results. Rapid Commun Mass Spectrom 25(17):2538–2560

Taylor PDP, De Bièvre P, Valkiers S (2004) The Nature and Role of Primary Certified Reference Materials: A Tool to Underpin Isotopic Measurement on a Global Scale. In: De Groot PA (ed) Handbook of Stable Isotope Analytical Techniques, vol 1. Elsevier, Amsterdam, pp 907–927

Sano M, Yotsui Y, Abe H, Sasaki S (1976) A new technique for the detection of metabolites labelled by the isotope 13C using mass fragmentography. Biomed Mass Spectrom 3(1):1–3

Matthews DE, Hayes JM (1978) Isotope-Ratio-Monitoring Gas Chromatography-Mass Spectrometry. Anal Chem 50(11):1465–1473

Barrie A, Bricout J, Koziet J (1984) Gas Chromatography - Stable Isotope Ratio Analysis at Natural Abundance Levels. Biomed Mass Spectrom 11(11):583–588

Meier-Augenstein W (1999) Applied gas chromatography coupled to isotope-ratio mass spectrometry. J Chromatogr A 842:351–371

Brand WA (1998) Isotope Ratio Mass Spectrometry: Precision from Transient Signals. In: Karjalainen EJ, Hesso AE, Jalonen JE, Karjalainen UP (eds) Advances in Mass Spectrometry, vol 14. Elsevier Science Publishers B. V, Amsterdam

Sessions AL (2006) Isotope-ratio detection for gas chromatography. J SepSci 29:1946–1961

Preston T, Slater C (1994) Mass-Spectrometric Analysis of Stable-Isotope-Labelled Amino-Acid Tracers. Proc Nutr Soc 53(2):363–372

Merritt DA, Hayes JM (1994) Nitrogen Isotopic Analyses by Isotope-Ratio-Monitoring Gas Chromatography / Mass Spectrometry. J Am Soc Mass Spectrom 5:387–397

Brand WA, Tegtmeyer AR, Hilkert A (1994) Compound-specific isotope analysis: extending toward 15N/14N and 18O/16O. Org Geochem 21(6–7):585–594

Burgoyne TW, Hayes JM (1998) Quantitative production of H-2 by pyrolysis of gas chromatographic effluents. Anal Chem 70(24):5136–5141

Hilkert AW, Douthitt CB, Schlüter HJ, Brand WA (1999) Isotope ratio monitoring gas chromatography/mass spectrometry of D/H by high temperature conversion isotope-ratio mass spectrometry. Rapid Commun Mass Spectrom 13(13):1226–1230

Platzner IT, Habfast K, Walder AJ, Goetz A (1997) Modern isotope-ratio mass spectrometry. J. Wiley, Chichester, New York, ISBN 0471974161, 9780471974161

Preston T, Owens NJP (1983) Interfacing and automatic elemental analyser with an isotope-ratio mass spectrometer: the potential for fully automated total nitrogen and nitrogen-15 analysis. Analyst 12:510–513

Abramson FP, Black GE, Lecchi P (2001) Application of high-performance liquid chromatography with isotope-ratio mass spectrometry for measuring low levels of enrichment of underivatized materials. J Chromatogr A 913(1–2):269–273

Caimi RJ, Brenna JT (1993) High-Precision Liquid Chromatography-Combustion Isotope Ratio Mass-Spectrometry. Anal Chem 65(23):3497–3500

Brand WA (1996) High precision isotope ratio monitoring techniques in mass spectrometry. J Mass Spectrom 31(3):225–235

Sessions AL, Sylva SP, Hayes JM (2005) Moving-wire device for carbon isotopic analyses of nanogram quantities of nonvolatile organic carbon. Anal Chem 77(20):6519–6527

Krummen M, Hilkert AW, Juchelka D, Duhr A, Schluter HJ, Pesch R (2004) A new concept for isotope ratio monitoring liquid chromatography/mass spectrometry. Rapid Commun Mass Spectrom 18(19):2260–2266

Meckenstock RU, Morasch B, Warthmann R, Schink B, Annweiler E, Michaelis W, Richnow HH (1999) 13C/12C isotope fractionation of aromatic hydrocarbons during microbial degradation. Environ Microbiol 1(5):409–414

Sherwood Lollar B, Slater GF, Ahad J, Sleep B, Spivack J, Brennan M, MacKenzie P (1999) Contrasting carbon isotope fractionation during biodegradation of trichloroethylene and toluene: implications for intrinsic bioremediation. Org Geochem 30(8):813–820

Hunkeler D, Aravena R, Butler BJ (1999) Monitoring microbial dechlorination of tetrachloroethene (PCE) using compound-specific carbon isotope ratios: Microcosms and field experiments. Environ Sci Technol 33(16):2733–2738

Schmidt TC, Zwank L, Elsner M, Berg M, Meckenstock RU, Haderlein SB (2004) Compound-specific stable isotope analysis of organic contaminants in natural environments: a critical review of the state of the art, prospects, and future challenges. Anal Bioanal Chem 378(2):283–300

Meckenstock RU, Morasch B, Griebler C, Richnow HH (2004) Stable isotope fractionation analysis as a tool to monitor biodegradation in contaminated acquifers. J Contam Hydrol 75(3–4):215–255

Thullner M, Richnow H-H, Fischer A (2009) Characterization and quantification of in situ biodegradation of groundwater contaminants using stable isotope fractionation analysis: advantages and limitations. In: Gallo D, Mancini R (eds) Environmental and Regional Air Pollution. Nova Science Publishers

Elsner M, Zwank L, Hunkeler D, Schwarzenbach RP (2005) A new concept linking observable stable isotope fractionation to transformation pathways of organic pollutants. Environ Sci Technol 39(18):6896–6916

Elsner M (2010) Stable isotope fractionation to investigate natural transformation mechanisms of organic contaminants: principles, prospects and limitations. J Environ Monit 12(11):2005–2031

Hofstetter TB, Berg M (2011) Assessing transformation processes of organic contaminants by compound-specific stable isotope analysis. TrAC Trends Anal Chem 30(4):618–627

Aelion CM, Hohener P, Hunkeler D, Aravena R (eds) (2009) Environmental Isotopes in Bioremediation and Biodegradation. CRC Press,

Jochmann MA, Schmidt TC (2012) Compound-Specific Stable Isotope Analysis Royal Society of Chemistry

Wilson JT, Kaiser PM, Adair C (2005) Monitored Natural Attenuation of MTBE as a Risk Management Option at Leaking Underground Storage Tank Sites. EPA, Cincinnati, U.S

Hunkeler D, Meckenstock RU, Sherwood Lollar B, Schmidt TC, Wilson JT (2008) A Guide for Assessing Biodegradation and Source Identification of Organic Ground Water Contaminants using Compound Specific Isotope Analysis (CSIA) Office of Research and Development. US EPA, Oklahoma, USA

Eisenmann H, Fischer A (2010) Isotopenuntersuchungen in der Altlastenbewertung. In: Franzius V, Altenbockum M, Gerhold T (eds) Handbuch der Altlastensanierung und Flächenmanagement. Verlagsgruppe Hüthig Jehle Rehm, München

Hofstetter TB, Schwarzenbach RP, Bernasconi SM (2008) Assessing Transformation Processes of Organic Compounds Using Stable Isotope Fractionation. Environ Sci Technol 42(21):7737–7743

Brenninkmeijer CAM, Janssen C, Kaiser J, Röckmann T, Rhee TS, Assonov SS (2003) Isotope Effects Chem Atmospheric Trace Compd Chem Rev 103(12):5125–5162

Goldstein AH, Shaw S (2003) Istopes of volatile organic compounds: an emerging approach for studying atmospheric budgets and chemistry. Chem Rev 103:5025–5048

Boyd TJ, Osburn CL, Johnson KJ, Birgl KB, Coffin RB (2006) Compound-specific isotope analysis coupled with multivariate statistics to source-apportion hydrocarbon mixtures. Environ Sci Technol 40(6):1916–1924

Walker SE, Dickhut RM, Chisholm-Brause C, Sylva S, Reddy CM (2005) Molecular and isotopic identification of PAH sources in a highly industrialized urban estuary. Org Geochem 36(4):619–632

Hunkeler D, Chollet N, Pittet X, Aravena R, Cherry JA, Parker BL (2004) Effect of source variability and transport processes on carbon isotope ratios of TCE and PCE in two sandy aquifers. J Contam Hydrol 74(1–4):265–282

Blessing M, Schmidt TC, Dinkel R, Haderlein SB (2009) Delineation of Multiple Chlorinated Ethene Sources in an Industrialized Area: A Forensic Field Study Using Compound-Specific Isotope Analysis. Environ Sci Technol 43(8):2701–2707

Wang Y, Huang Y, Huckins JN, Petty JD (2004) Compound-Specific Carbon and Hydrogen Isotope Analysis of Sub-Parts per Billion Level Waterborne Petroleum Hydrocarbons. Environ Sci Technol 38(13):3689–3697

Mudge SM, Meier-Augenstein W, Eadsforth C, DeLeo P (2010) What contribution do detergent fatty alcohols make to sewage discharges and the marine environment? J Environ Monit 12(10):1846–1856

Rayleigh JWS (1896) Theoretical Considerations respecting the Separation of Gases by Diffusion and Similar Processes. Philos Mag 42:493–498

Hunkeler D, Morasch B (2010) Isotope Fractionation during Transformation Processes. In: Aelion CM, Höhener P, Hunkeler D, Aravena R (eds) Environmental isotopes in biodegradation and bioremediation. CRC Press. Taylor & Francis Group, Boca Raton, pp 79–128

Hartenbach AE, Hofstetter TB, Tentscher PR, Canonica S, Berg M, Schwarzenbach RP (2008) Carbon, hydrogen, and nitrogen isotope fractionation during light-induced transformations of atrazine. Environ Sci Technol 42(21):7751–7756

Meyer AH, Penning H, Elsner M (2009) C and N isotope fractionation suggests similar mechanisms of microbial atrazine transformation despite involvement of different Enzymes (AtzA and TrzN). Environ Sci Technol 43(21):8079–8085

Penning H, Cramer CJ, Elsner M (2008) Rate-Dependent Carbon and Nitrogen Kinetic Isotope Fractionation in Hydrolysis of Isoproturon. Environ Sci Technol 42(21):7764–7771

Penning H, Sorensen SR, Meyer AH, Aamand J, Elsner M (2010) C, N, and H Isotope Fractionation of the Herbicide Isoproturon Reflects Different Microbial Transformation Pathways. Environ Sci Technol 44(7):2372–2378

Skarpeli-Liati M, Jiskra M, Turgeon A, Garr AN, Arnold WA, Cramer CJ, Schwarzenbach RP, Hofstetter TB (2011) Using Nitrogen Isotope Fractionation to Assess the Oxidation of Substituted Anilines by Manganese Oxide. Environ Sci Technol 45(13):5596–5604

Hofstetter TB, Spain JC, Nishino SF, Bolotin J, Schwarzenbach RP (2008) Identifying Competing Aerobic Nitrobenzene Biodegradation Pathways by Compound-Specific Isotope Analysis. Environ Sci Technol 42(13):4764–4770

Hartenbach AE, Hofstetter TB, Aeschbacher M, Sander M, Kim D, Strathmann TJ, Arnold WA, Cramer CJ, Schwarzenbach RP (2008) Variability of Nitrogen Isotope Fractionation during the Reduction of Nitroaromatic Compounds with Dissolved Reductants. Environ Sci Technol 42(22):8352–8359

Bernstein A, Ronen Z, Adar E, Nativ R, Lowag H, Stichler W, Meckenstock RU (2008) Compound-Specific Isotope Analysis of RDX and Stable Isotope Fractionation during Aerobic and Anaerobic Biodegradation. Environ Sci Technol 42(21):7772–7777

Wolfsberg M, Van Hook WA, Paneth P (2010) Isotope Effects in the Chemical, Geological and Bio Sciences. Springer, Dordrecht, Heidelberg, London, New York

Hunkeler D, Aravena R (2010) Investigating the Origin and Fate of Organic Contaminants in Groundwater Using Stable Isotope Analysis. In: Aelion CM, Höhener P, Hunkeler D, Aravena R (eds) Environmental isotopes in biodegradation and bioremediation. CRC Press. Taylor & Francis Group, Boca Raton, pp 249–291