Abstract

Five ionic liquid-modified porous polymers with different imidazolium-based functional groups were obtained. A molecular imprinting technique was introduced to form the ordered functional groups in the porous structure. The adsorption isotherm was applied to investigate the interactions between the polymers and target compounds: cryptotanshinone; tanshinone I; tanshinone IIA. Thorough comparison revealed that the polymer with a carboxyl group possessed the highest reorganization of the three compounds. After that, the obtained polymer was applied as the sorbent in the solid-phase extraction process to separate the target compounds from methanol extract. The loading volume of extract solution on the sorbent was determined by adsorption isotherm equation and practical test. Under optimized washing and elution conditions, 0.35 mg/g of cryptotanshinone, 0.33 mg/g of tanshinone I, and 0.27 mg/g of tanshinone IIA from plant were obtained by quantitative HPLC analysis. Moreover, six commercial functional drinks containing tanshinones were purified and analyzed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Solid-phase extraction (SPE) is one of the most convenient and high-performance technologies for separation of bioactive compounds from plants [1]. It can help minimize the use of organic solvents which are regulated as priority pollutants [2]. The selection of the sorbent is a key point in SPE [3] because it can control analytical parameters such as adsorbed amount, selectivity and affinity [4, 5]. Molecular imprinted polymers (MIPs) are a rapidly developing sorbent with specific molecular-recognition properties for SPE (MISPE) [6, 7]. Because of the special structure and chemical functionality of the imprinted polymer, the MIP has a specific selectivity for compounds possessing similar structures and functional groups to the template.

In order to increase the efficiency of MISPE, two main methods are employed. One is increasing the surface area of polymer. Higher surface area can contain more functional groups, thus the interaction between polymer and bioactive compounds will be increased accordingly. Porous polymers with large surface areas and special porous structures have thus been introduced [8].

The other method is modification of functional groups on polymers. When the modifiers have specific functional groups that can form strong interaction with bioactive compounds, they can be introduced to replace the non-specific or less bioconjugation groups [9]. Ionic liquids (ILs) as an excellent functional chemical [10, 11] received a lot of attentions in the fields of analytical chemistry [12], sample preparation [13], organic synthesis [14–17], liquid-phase extraction [18, 19], chromatographic separations [20], even in polymer synthesis process as porogen [21, 22]. The characteristics, such as hydrophobicity, miscibility with several inorganic/organic solvents, π–π interactions between analyte and functional groups of the ionic liquids, are widely applied [23]. Some reports have examined the application of obtained ionic liquid-modified materials to separate familiar organic compounds [24, 25] and to extract bioactive components from natural plants [26, 27]. However, the recognition of these materials is generally not high [28].

In this research, porous polymer was prepared firstly and then five imidazoles with different functional groups (imidazole, methylimidazole, carboxyl-imidazole, amino-imidazole, and cyano-imidazole) were used as surface modifiers to form IL structures. Also, according to the non-covalent interactions between template and IL groups, the surface imprinted structure was finalized.

Tanshinones, including cryptotanshinone, tanshinone I, and tanshinone IIA were used as analysts in this research. These analytes are the major active constituents in Salvia miltiorrhiza Bunge (SMB), a well-known traditional medicinal herb used for the treatment of various diseases [29, 30] with exhibited anti-cancer effects [31, 32]. Several extraction processes [33–35] and purification materials [36] have been reported; still, there remains no selectivity of the target compounds. In this case, the molecular imprinted ionic liquid-modified porous polymers with large surface area, numbers of functional groups and high selectivity of target compounds was applied in SPE cartridge to separate the tanshinones from SMB extract and functional drinks.

Experimental

Chemicals

2,2′-Azobisisobutyronitrile (AIBN) was from Junsei Chemical Co. (Tokyo, Japan). 3-Aminopropyl bromide hydrobromide (97%), 4-(chloromethyl)styrene (90%), divinylbenzene (50%), and polyvinylpyrrolidone (PVP, K 30), imidazole (98%), 1-methylimidazole (99%), 1-imidazoleacetic acid (98%), 1-(3-aminopropyl)imidazole (97%), 1-(2-cyanoethyl)-2-methylimidazole (98%), and 9, 10-phenanthrenequinone (99%) were purchased from Tokyo Chemical Industry Co. Ltd. (Tokyo, Japan). Cryptotanshinone, tanshinone I, and tanshinone IIA were purchased from the National Institute for the Control of Pharmaceutical and Biological Products (Beijing, China). Methanol, ethanol, and other organic solvents were obtained from DUKSAN PURE CHEMICALS Co., Ltd. (Ansan, Korea). Distilled water was filtered using a vacuum pump (Division of Millipore, USA) and a filter (HA-0.45, Division of Millipore, USA) before use. All other solvents used in the experiment were HPLC or analytical grade. All the samples were filtered by using a filter (MFS-25, 0.2 μm TF, WHATMAN, USA) before injection into the HPLC system.

HPLC analysis and characteristic analysis

Chromatography was performed with a Waters 600s multisolvent delivery system, a Waters 616 liquid chromatography, and a Waters 2487 variable wavelength, dual-channel UV detector (Waters Associates, Milford, MA, USA). A syringe with 25 μL injection volume and 20 μL sample loop were used. The HPLC analysis was performed with a commercial C18 column (4.6 × 250 mm, 5 μm) purchased from RStech Co. (Daejeon, Korea). The mobile phase was methanol/water (78:22, v/v, containing 0.5% acetic acid). The flow rate, UV wavelength, and injection volume were 0.5 mL/min, 254 nm and 5 μL, respectively.

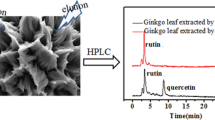

FT-IR data were obtained by a Vertex 80V (Bruker, Billerica, MA, USA) in the range of 400–4,000 cm−1 with a scan rate of 20 scans/min. KBr pellet was used for analysis. Field emission-scanning electron microscope (FE-SEM) data were obtained by an S-4200 instrument (Hitachi, Ontario, Canada) of 15 kV magnification (pixel size, 0.5 nm). And the BET surface area (0.03 g of polymer in N2 atm at −195.85 °C) was measured by ASAP2010 (Micromeritics, Norcross, GA, USA).

Preparation of molecularly imprinted ionic liquid-modified porous polymers

After dissolving 0.48 g of PVP in 100.0 mL of ethanol in a 250.0-mL flask, 5.65 mL of 4-(chloromethyl)styrene (monomer), 16.2 mL of divinylbenzene (crosslinker), 5.0 mL of heptanes (porogen), and 0.22 g of AIBN (initiator) was added under a nitrogen atmosphere and rapid stirring. The emulsion solution was then heated to 70 °C for 24 h polymerization. After complete polymerization, the obtained blank polymer was filtrated and washed with ethanol three times to remove any coagulated and soluble impurities.

The carbonyl groups in the 9,10-phenanthrenequinone and the tanshinones have the same arrangement, with similar chemical structures (Fig. 1). 9,10-Phenanthrenequinone was used as the template. Blank polymer (2.0 g), template (2.0 mmol) and different ionic liquid modifiers (2.0 mmol) were added to 35.0 mL of ethanol. After 12 h reflux, the obtained modified polymers (Fig. 2; imidazole polymer (PIm and MI-PIm); methylimidazole polymer (PImM and MI-PImM); carboxyl-imidazole polymer (PImCOOH and MI-PImCOOH); amino-imidazole polymer (PImNH2 and MI-PImNH2); cyano-imidazole polymer (PImCN and MI-PImCN)) were cooled to room temperature. After washing with toluene, ethanol, and methanol sequentially, the polymers were oven-dried for further experiments.

Adsorption isotherm application

A mass of 0.05 g silica, C18, amino-silica from commercial SPE cartridge and all polymers were respectively stirred with 1.0 mL of tanshinones standard solutions at five different concentrations (ranging 0.49 to 83.5 × 10−4 mg/mL) in vials under room temperature. Until the concentrations of unadsorbed tanshinones in solutions no longer decreased, the equilibrium adsorptions were obtained. The amounts of adsorbed tanshinones on polymers were calculated by subtraction. For comparison, 0.05 g of were stirred with tanshinones standard solutions under the same conditions.

Procedure of SPE

The SMB samples obtained from local market were oven-dried and 0.5 g of the sliced powder was extracted using 50.0 mL of methanol for 4 h. Then the concentration of obtained extract was detected by HPLC. A mass of 0.05 g of different polymers were packed into 3.0 mL of empty polypropylene cartridges (Ø 0.9 cm, Alltech, Deerfield, IL, USA) and preconditioned with 5.0 mL of acetone and methanol. After loading, washing and eluting the extract in SPE cartridges with different solvents, the filtrates were dried and reconstituted in 0.1 mL of mobile phase for further HPLC analysis.

Analysis of commercial drinks

Korean Red Ginseng, Hong Seng Yuan, Hwalsam, Hwalsam Dulcis Gold (Lotte Chilsung Beverage Co., LTD, Seoul, Korea), Red Ginseng and Honey Drink, and Red Ginseng Gold (Kwang Dong Pharmaceutical CO., LTD, Seoul, Korea) are six commercial functional drinks which contain the extract from SMB. A volume of 5.0 mL of each sample was mixed with 2.0 mL of acetonitrile, and after the denatured protein was removed by filter (0.45 μm), the liquids were prepared for further SPE experiments.

Results and discussion

Performance evaluation

Figure 3 shows FT-IR results for all MIPs. The appearance of a peak at 1,593 cm−1 is attributed to the imidazole group [37, 38] immobilized on polymers; 2,880–3,000 cm−1 was the range for the C–H group. Thus, in the spectra, the band adsorbances of MI-PImM, bearing one more methyl group, was higher than MI-PIm [39, 40]. In previous research, the peaks at 1,680 cm−1 and 3,402 cm−1 were proven to be the –COOH and –NH2 groups, respectively [41, 42]; 2,251 cm−1 is the assignment of –C≡N group in FT-IR [43], but the extremely small peak in the spectra of MI-PImCN revealed that immobilization efficiency of the ImCN group on polymer was quite low.

SEM image of MI-PImCOOH in Fig. 4 shows that the special porous structure was formed and the surface area (44.23 m2/g for blank polymer, 30.52 m2/g for PImCOOH, 42.89 m2/g for MI-PImCOOH) was determined by BET. The porous structure of the blank polymer exhibited a large surface area. After modification, the pores of the PImCOOH were blocked by disorganized functional groups. Thus, the BET surface area was lower than the blank polymer. When template was introduced into the modification, the structure of the functional groups was arranged in a new order. Hence, the surface area of MI-PImCOOH increased.

Adsorption isotherm

First of all, the calibration curves were constructed using the chromatographic peak areas measured at seven increasing concentrations, ranging from 0.042 × 10−3 to 16.70 × 10−3 mg/mL. Good linearity was obtained and the linear correlation equations were y = 5.0 × 107 x − 891 (r 2 = 0.999) for cryptotanshinone, y = 1.0 × 108 x − 92 (r 2 = 0.999) for tanshinone I, and y = 2.0 × 108 x − 1,517 (r 2 = 0.999) for tanshinone IIA (y is peak area and x is the concentration of target compounds).

Adsorption isotherm as a power tool was introduced to investigate the interactions between target compounds and sorbents. The adsorbed amounts (Q) of tanshinones on all the sorbents were determined as follows:

where Q (mg/g) is the adsorbed amount, C 0 (mg/mL) is the initiator concentration, C (mg/mL) is the unabsorbed concentration, V (mL) is the volume of the sample solvent, and m (g) is the mass of the sorbent.

Because of porous structure, under the same initiator concentration (0.0017 mg/mL), even blank polymer (range 1.83 to 9.46 × 10−3 mg/g) had much higher adsorbed amount than silica (ranging 0.06 to 0.51 × 10−3 mg/g), amino-silica (range 0.19 to 1.58 × 10−3 mg/g), and C18 (ranging 0.34 to 3.91 × 10−3 mg/g). Then, effects of different functional groups were evaluated. In Fig. 5, the functionalized imprinted polymers had higher absorbed amounts than non-imprinted polymers, and the order of adsorbed amounts on imprinted polymers were MI-PImCOOH > MI-PIm > MI-PImCN > MI-PImNH2 > blank polymer > MI-PImM.

The strength of interaction between functional groups and target compounds affects the adsorbed amount on sorbent. In MI-PImM, there were only weak π–π and hydrophobic interactions between methyl imidazolium groups and tanshinones. Also, the pore size was decreased when the polymer was modified with ionic liquid groups. Hence, it has the lowest adsorbed ability. For MI-PImNH2 and MI-PImCN, they not only had hydrophobic interactions with tanshinones, but also exhibited hydrogen-bonding and dipole–dipole interactions, respectively. However, the long carbon chain decreased the pore size obviously and prevented the interactions between imidazolium groups and tanshinones. Therefore, the MI-PImNH2 and MI-PImCN presented low adsorbed abilities. Hydrogen-bonding interaction existed in both MI-PIm and PImCOOH. For MI-PIm, the large pore size can retain large amount of tanshinones. For PImCOOH, in previous research, the –COOH group had a stronger hydrogen-bonding interaction with the carbonyl group [44]. Also, tanshinones possess greater stability under acid environment [45, 46]. In this case, PImCOOH has the highest adsorbed amount as well as the best selectivity.

The experimental data of MI-PImCOOH was fitted to the following adsorption isotherm equations:

Where, C E (mg/mL) in the three equations is the equilibrium concentration of the solute in the liquid phase. a, b, d, e, f, and g are the parameters. These adsorption isotherm equations are the linear (2), Langmuir (3) and Freundlich (4) equations, respectively. According to the regression coefficient (r 2 ≥ 0.999), the Langmuir equation was evidently better than the others in this experiment, and Q = 71.25C E/(1 + 0.34C E) for CT, Q = 8.98C E/(1-0.12C E) for TI, Q = 79.02C E/(1 + 0.032C E) for TIIA were obtained. Further comparison of the adsorbed amounts of tanshinones on PImCOOH and MI-PImCOOH was evaluated by t test [47], and it reveals that the adsorbed amounts on functionalized imprinted polymer were much higher than non-imprinted polymer (Table 1).

Applications of the porous polymer

Isolation of three tanshinones from the SMB extract

Based on the adsorbed amount obtained from Langmuir equations, the theoretically adsorbed amount (Q T) of the SPE cartridges can be calculated when C E was considered as the concentration of tanshinones in the methanol extract solvent (0.0035 mg/mL of CT, 0.0033 mg/mL of TI and 0.0027 mg/mL of TIIA); 0.05 g of sorbent was packed into SPE cartridge, so according to the equations:

the theoretical loading volume (V T) was 3.56, 0.45, 3.95 mL for CT, TI, and TIIA, respectively. Then, the maximum loading volume of the SPE cartridge (0.4 mL) was determined by a practical test, which proved less than the theoretical V T. As such, 0.4 mL was selected as the loading volume.

It is important to apply a washing step immediately after the extract from the natural plant was loaded onto the sorbent, as it could obviously reduce the matrix interferences in separation of the analyte.

First, the same volume of water, methanol, acetone, n-hexane and dichloromethane were used. Water can remove interference without target compounds. However, large amounts of target compounds were washed out by using n-hexane and dichloromethane, so these two solvents were eliminated in washing stage. Although interference can be removed by methanol and acetone, small amounts of target compounds were still washed out. To solve these problems, mixtures of water/acetone and water/methanol were used to reduce removal efficiency. Acetone was eliminated because the target compounds were washed out at any percentage. Moreover, different components of methanol in water were used and the volume of washing solvent was increased to remove most of the interference. With the component of the methanol increasing, the volume of water/methanol was decreased, and only 4.0 mL of water/methanol (30:70, v/v) could be achieved (Fig. 6a). It was thus selected as the optimized washing condition.

Then, pure methanol and acetone were used as elution solvents. However, target compounds with some residual interferences were simultaneously carried out by acetone. So methanol was selected and 2.0 mL could elute all the target compounds (Fig. 6b). Methanol/acetic acid (90:10, v/v) with a higher eluting strength was used to prove the elution efficiency; no target compounds remained on the sorbent after methanol eluting (Fig. 6c). Summarizing the above data, 2.0 mL of methanol was selected as the optimized elution condition. Finally, 0.35 mg/g of CT, 0.33 mg/g of TI and 0.27 mg/g of TIIA were obtained from the methanol extract.

Validation of proposed analytical method and recycling of porous polymer in SPE

The assays of repeatability were calculated from the relative standard deviation (RSD), determined by injecting standard solutions of tanshinones and extract sample after SPE process five times over a 5-day period. The RSDs of the precision tests were less than 2.76% for standard. Validation of analytical method for real sample and the recycling of polymer in the SPE cartridge were investigated simultaneously. The errors of detected concentrations of the tanshinones were less than 8.20%. This revealed that the sorbents possess stable characteristics.

Detection of commercial functional drinks

After removing protein in six SMB drinks by acetonitrile, the filtrated solutions were loaded, washed, and eluted in an SPE cartridge under optima conditions. Table 2 lists the concentrations of the three target compounds extracted.

Conclusions

In this study, an ionic liquid-modified molecular imprinted porous polymer with a large surface area, large amount of functional groups and high selectivity for target compounds was used in the SPE. The adsorption isotherm proved that the sorbent with MI-PImCOOH possessed the highest reorganization of the target compounds. Under optimized SPE conditions (0.4 mL of loading volume, 4.0 mL of water/methanol (30:70, v/v) as washing solvent and 2.0 mL of methanol as elution solvent), 0.35 mg/g of cryptotanshinone, 0.33 mg/g of tanshinone I, and 0.27 mg/g of tanshinone IIA were obtained from plant extract. The low deviation error, stable characteristics and application in commercial drink detection demonstrated the sorbent to be a viable alternative tool for further researches.

Abbreviations

- CT:

-

Cryptotanshinone

- PIm:

-

Imidazole polymer

- PImCN:

-

Cyano group-based imidazole polymer

- PImCOOH:

-

Carboxyl group-based imidazole polymer

- PImM:

-

Methylimidazole polymer

- PImNH2 :

-

Animo group-based imidazole polymer

- TI:

-

Tanshinone I

- TIIA:

-

Tanshinone IIA

References

Wells MJM, Yu LZ (2000) J Chromatogr A 885:237–250

Poole CF, Wilson ID (2000) J Chromatogr A 885:1

Li Z, Chang X, Zou X, Zhu X, Nie R, Hu Z, Li R (2009) Anal Chim Acta 632:272–277

Pyrzynska K, Trojanowicz M (1999) Crit Rev Anal Chem 29:313–321

Cai YQ, Jiang GB, Liu JF, Zhou QX (2003) Anal Chem 75:2517–2521

Qiao F, Sun H, Yan H, Row KH (2006) Chromatographia 64:625–634

Wang D, Hong SP, Row KH (2004) Korean J Chem Eng 21:853–857

Kawaguchi H (2000) Prog Polym Sci 25:1171–1210

Goddard JM, Hotchkiss JH (2007) Prog Polym Sci 32:698–725

Kim MJ, Choi MY, Lee JK, Ahn Y (2003) J Mol Catal B Enzym 26:115–118

Zhang DH, Bai S, Ren MY, Sun Y (2008) Food Chem 109:72–80

Pandey S (2006) Anal Chim Acta 556:38–45

Liu JF, Jiang GB, Jönsson JÅ (2005) TRAC Trends Anal Chem 24:20–27

Nara SJ, Harjani JR, Salunkhe MM (2001) J Org Chem 66:8616–8620

Potewar TM, Nadaf RN, Daniel T, Lahoti RJ, Srinivasan KV (2005) Synth Commun 35:231–241

Cole AC, Jensen JL, Ntai I, Tran KLT, Weaver KJ, Forbes DC, Davis JH (2002) J Am Chem Soc 124:5962–5963

Armstrong DW, He L, Liu YS (1999) Anal Chem 71:3873–3876

Liu J, Jiang G, Chi Y, Cai Y, Zhou Q, Hu JT (2003) Anal Chem 75:5870–5876

Khachatryan KS, Smirnova SV, Torocheshnikova II, Shvedene NV, Formanovsky AA, Pletnev IV (2005) Anal Bioanal Chem 381:464–470

Polyakova Y, Jin Y, Zheng J, Row KH (2006) J Liq Chromatogr Related Technol 29:1687–1701

Snedden P, Cooper AI, Scott K, Winterton N (2003) Macromolecules 36:4549–4556

He C, Long Y, Pan J, Li K, Liu F (2008) Talanta 74:1126–1131

Bi W, Tian M, Row KH (2010) J Sep Sci 33:1739–1745

Qiu H, Jiang Q, Wei Z, Wang X, Liu X, Jiang S (2007) J Chromatogr A 1163:63–69

Qiu H, Jiang S, Liu X (2006) J Chromatogr A 1103:265–270

Wang Y, Row KH (2009) J Indian Chem Soc 86:1082–1108

Tian M, Yan H, Row KH (2010) Anal Lett 43:110–118

Tian M, Bi W, Row KH (2009) J Sep Sci 32:4033–4403

Liu YR, Qua SX, Maitz MF, Tan R, Weng J (2007) J Ethnopharmacol 111:573–583

Zhang Y, Li X, Wang Z (2010) Food Chem Toxicol 48:2656–2662

Wan X, Wang Y, Row KH (2009) J Liq Chromatogr Related Technol 32:544–552

Yoon Y, Kim YO, Jeon WK, Park HJ, Sung HJ (1999) J Ethnopharmacol 68:121–127

Pan X, Niu G, Liu H (2001) J Chromatogr A 922:371–375

Dean JR, Liu B, Price R (1998) J Chromatogr A 799:343–348

Pan X, Niu G, Liu H (2002) Biochem Eng J 12:71–77

Yang Q, Zhang X, Li X, Tang W, Zhang J, Fang C, Zheng C (2007) Anal Chim Acta 589:231–238

Berthomieu C, Boussac A (1995) Biospectroscopy 1:187–206

Tian M, Yan H, Row KH (2009) J Chromatogr B 877:738–742

Yadav BS, Ali I, Kumar P, Yadav P (2007) Indian J Pure Appl Phys 45:979–983

Mary YS, Ushakumari L, Harikumar B, Varghese HT, Panicker CY (2009) J Iranian Chem Soc 6:138–144

Kamio K, Kamata K, Mima S, Kuroda T, Ookawara H, Moriya M, Hidaka H (1995) J Am Oil Chem Soc 72:805–809

Ramanathan T, Fisher FT, Ruoff RS, Brinson LC (2005) Chem Mater 17:1290–1295

Huang Y, He J (1989) Mol Cryst Liq Cryst 174:11–19

Sellergren B (2001) Molecularly imprinted polymers, man-made mimics of antibodies and their applications in analytical chemistry. Elsevier, Netherlands

Pan J, Zheng Q, Yang M (2009) Zhongchengyao 31:383–386

Hao H, Wang G, Cui N, Li J, Ding Z (2007) Biomed Chromatogr 21:1172–1179

Bugani S, Camaiti M, Morselli L (2008) Anal Bioanal Chem 391:1343–1350

Acknowledgment

This research was supported by Basic Science Research Program through the National Research Foundation of Korea funded by the Ministry of Education, Science and Technology (2010-0015731)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, M., Bi, W. & Row, K.H. Molecular imprinting in ionic liquid-modified porous polymer for recognitive separation of three tanshinones from Salvia miltiorrhiza Bunge. Anal Bioanal Chem 399, 2495–2502 (2011). https://doi.org/10.1007/s00216-010-4641-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-010-4641-4