Abstract

Sedimentation field-flow fractionation–inductively coupled plasma–mass spectrometry (SdFFF-ICP-MS) was successfully applied to investigate particle size distribution of titanium dioxide (TiO2) in sunscreen samples after hexane extraction to remove organic components from the samples. Three brands of sunscreen products of various sun protection factor (SPF) value were used as samples. Different particle size distribution profiles were observed for sunscreen samples of various brands and SPF values; however, the particle size distributions of titanium dioxide in most sunscreen samples investigated in this work were larger than 100 nm. The titanium dioxide concentrations were higher for the products of higher SPF values. By comparing the results obtained from online SdFFF-ICP-MS and those from the off-line ICP-MS determination of titanium after acid digestion, ICP-MS was found to effectively atomize and ionize the titanium dioxide particle without the need for acid digestion of the samples. Therefore, the online coupling between SdFFF and ICP-MS could be effectively used to provide quantitative information of titanium dioxide concentrations across particle size distribution profiles.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

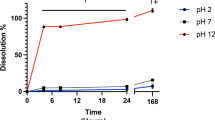

Ultraviolet (UV) radiation including UV-A (320–400 nm) and UV-B (290–320 nm) can cause skin cancer and other harmful effects to humans [1–4]. To avoid unwanted skin effects from the sun it is necessary to use sunscreen filters. Titanium dioxide (TiO2), which is a physical UV filter, can reflect and scatter UV radiation very efficiently [5], and it is, therefore, often used to formulate sunscreen products with a high sun protection factor (SPF) value [6]. According to the European legislation, titanium dioxide is the only inorganic UV filter permitted to be used in sunscreen products with the maximum allowable concentration of 25% (w/w) [7]. The radiation reflection and scattering efficiencies of titanium dioxide depend on its concentration and particle size, with a particle size of approximately 60–120 nm the most effective in UV reflection and scattering ability [5]. Therefore, the analysis of sunscreen cosmetics in terms of the concentration and particle size of titanium dioxide should be considered.

Although the official methods for determining titanium dioxide particles in sunscreen cosmetics, either in terms of quantitative element content or the particle size distribution, have never been documented, several analytical techniques have been reported for determination of titanium dioxide in sunscreen. These techniques include the classical volumetric method [8], atomic absorption spectrometry [9], inductively coupled plasma optical emission spectrometry [8, 10], and X-ray fluorescence spectrometry [11, 12]. For particle size characterization, flow field-flow fractionation (FlFFF) has been reported for titanium dioxide particles in a commercial sunscreen product [13] and titanium dioxide nanoparticles imprinted for tyrosine [14].

Field-flow fractionation (FFF) is a flow-assisted technique for size characterization of particles in the nanometer to sub-micrometer scale. The fractionated particles can be further characterized by various detection methods [15, 16]. The principle [16, 17] and applications [18, 19] of FFF have been described elsewhere. Depending on the type and the particle size of samples, various types of external field forces may be applied. These external fields give rise to an assortment of FFF sub-techniques, including gravitational, sedimentation, flow, electrical, and thermal FFF. Sedimentation FFF (SdFFF) and FlFFF are most commonly used. As the particle size of titanium dioxide in sunscreen products is in the sub-micrometer size range, SdFFF may be used [18]. Previous works indicated that sedimentation FFF was successfully used to separate titanium dioxide microparticles [18–20].

An online coupling between SdFFF and inductively coupled plasma–mass spectrometry (SdFFF-ICP-MS) was proposed to provide the quantitative information of titanium dioxide concentrations across particle size distribution profiles of the sunscreen samples. The necessity for sample preparation before SdFFF particle size characterization was evaluated. Various initial field strengths were employed in SdFFF fractionation to check for the reliability of the resulting particle size distribution information. The ability of ICP-MS as an online detector for the fractionated titanium dioxide particles was examined. The developed SdFFF-ICP-MS method was applied to investigate size distribution of titanium dioxide particles in various sunscreen products of various SPF values.

Experimental

Chemicals and samples

Polystyrene latex standards having diameters of 0.35, 0.53, and 0.72 μm from Postnova Analytik (Landsberg, Germany) were used for SdFFF calibration. A carrier liquid was 0.02% (v/v) FL-70 detergent (Fisher Scientific, PA, USA) containing 0.02% (w/v) NaN3 (Merck, Darmstadt, Germany) to prevent bacterial growth. FL-70 is a mixture of anionic and non-ionic compounds containing the following active components: oleic acid, sodium carbonate, tergitol, tetrasodium EDTA, polyethylene glycol, and triethanolamine [21].

Three brands of commercial sunscreen cream products of various SPF values (0 and 50 SPF for brand A; 0, 15, and 30 SPF for brand B; and 0 and 15 SPF for brand C) were purchased from a local supermarket. Hexane, which was employed to remove some organic components, was purchased from Labscan (Bangkok, Thailand). Ti elemental standard solution of 100 μg mL−1 (AccuStandard, New Haven, CT, USA) was used to prepare the ICP-MS calibration solution.

Preparation of sunscreen sample

Sunscreen cream products (0.01 g) of various brands and SPF values were weighed and diluted in 1 mL of deionized water to obtain the sunscreen sample of 1% (w/v). Before injection into SdFFF, a 50-μL volume of 1% (w/v) of sunscreen cream sample in deionized water was mixed thoroughly by vortex.

Preparation of defatted sunscreen sample

To defat or remove some organic components from sunscreen cream products, 1 mL of hexane was applied to soak 0.01 g of sunscreen cream samples for 12 h at room temperature. Hexane containing organic components was removed and the defatted part was diluted with deionized water to 1% (w/v). To study particle size distribution in sunscreen cream samples, a 50-μL volume of 1% (w/v) of defatted sunscreen cream sample in deionized water was mixed thoroughly by vortex before SdFFF analysis.

Acid digestion of sunscreen sample

Sunscreen cream products (0.05 g) were weighed and digested at approximately 350 °C with 10 mL of H2SO4 in the presence of 4 g of (NH4)SO4. Then, 25 mL of HCl and 30 mL of deionized water were added to the mixture and heated until the clear solution was obtained. Subsequently, the digested solution was diluted with deionized water before ICP-MS determination of Ti concentration.

Instrumentation

The SdFFF system (Model S-101 Particle/Colloid Fractionator, Postnova Analytik, Landsberg, Germany) was used in this study. The SdFFF channel was 89.5 cm long, 2.0 cm wide, and 0.0254 cm thick, with a rotor radius of 15.1 cm. The channel volume was calculated to be 4.45 mL. The carrier solution was introduced into the SdFFF channel by an HPLC pump (model PN1122, Postnova Analytik). A UV detector (model UV2075, Jasco, Essex, UK) was set at 254 nm to monitor light attenuation of the eluted particles. Samples of 50 μL were injected into SdFFF via a Rheodyne injector.

An ICP-MS instrument (model Sciex/ELAN 6000, Perkin Elmer, CT, USA) was used as an element detector sequentially after the UV absorption detector. Owing to the similarity of the SdFFF channel and ICP-MS sample flow rates typically used for analysis, the ICP-MS cross-flow nebulizer was connected directly to the UV detector outlet with a 30-cm length of poly(tetrafluoroethylene) tubing (0.58 mm id). The operating conditions of SdFFF and ICP-MS measurements are summarized in Table 1.

Data treatment

Raw fractograms were translated into size distribution profiles using the Postnova FFF Analysis software version 2.0 (Postnova Analytik, Landsberg, Germany). Peak evaluation, baseline adjustment, and integration were performed using PeakFit™ (SPSS, IL, USA).

Results and discussion

The need for sample preparation before particle size characterization of titanium dioxide in cosmetics by using SdFFF

By knowing the exact geometry of the SdFFF channel, the field, flow rate, and the density difference between particle and carrier liquid, diameter of the separated particle can be calculated directly from the experimental retention time [22]. The average density of titanium dioxide particles was 4.05 g mL−1 [23], and therefore, the density difference between the particles and the carrier liquid (Δρ) was 3.05 g mL−1. To apply SdFFF for particle size characterization of titanium dioxide in sunscreen samples, various experimental conditions were examined to demonstrate the reproducibility and reliability of SdFFF for particle size characterization of titanium dioxide in sunscreen products. Various initial field strengths (500, 600, and 800 rpm) were applied to fractionate titanium dioxide particles in a 30 SPF sunscreen as illustrated in Fig. 1. Fractograms of 1% (w/v) 30 SPF sunscreen (brand B) showed two separated peaks at different retention times. With higher field strength, the peaks shifted towards longer retention times (Fig. 1a). Nonetheless, the particle size distributions obtained from various experimental conditions did not agree well with each other, indicating the erroneous results in particle size determination by the SdFFF technique. This error might be due to the fact that the cosmetic sample contains not only the titanium dioxide particles, but also some other types of particles. Alternatively, it might be due to the fact that the titanium dioxide particles were coated by some organic components in the sunscreen sample, which could make the approximation of the particles density of 4.05 g mL−1 to be incorrect.

Effect of field strength on fractionation of 30 SPF sunscreen (brand B). a Raw fractograms and b particle size distributions of 30 SPF sunscreen (brand B) obtained from various initial fields as 500 (diamond), 600 (square), and 800 rpm (triangle). The SdFFF operating condition was as follows: initial field hold time 8 min, field decay parameter −64, final field 50 rpm, and Δρ = 3.05 g mL−1. The channel flow rate was constant at 1 mL min−1

Therefore, it was necessary to carry out sample preparation before introduction of sunscreen samples into SdFFF channel. To remove the organic components from the titanium dioxide particles, hexane extraction was performed [13]. Hexane removes the organic compounds contained in the sunscreen products, which could cause some interaction between organic component and SdFFF channel, and affected on particle size fractionation of sunscreen sample. With hexane removal of organic components from the sunscreen samples, the resulting samples were called “defatted sunscreen samples.” Various initial field strengths (400, 500, and 600 rpm) were applied to fractionate titanium dioxide particles in the defatted sunscreen as illustrated in Fig. 2a with the resulting particle size distributions shown in Fig. 2b. The particle size distributions in Fig. 2b obtained from various experimental conditions were all similar showing the particle size range of 0.1–0.6 μm with the peak maximum at around 0.52 μm. This suggests that the particle size determination of titanium dioxide in sunscreen products is possible with SdFFF with the necessity of sample preparation before analysis, and hexane extraction is considered effective for such purpose. The initial field strength of 400 rpm was selected for further use as it was sufficient to separate the particles from the void fraction with minimized analysis time.

Effect of field strength on fractionation of the defatted 30 SPF sunscreen (brand B). a Raw fractograms and b particle size distributions of 30 SPF sunscreen (brand B) obtained from various initial fields as 400 (diamond), 500 (square), and 600 rpm (triangle). The SdFFF operating condition was as follows: initial field hold time 8 min, field decay parameter −64, final field 50 rpm, and Δρ = 3.05 g mL−1. The channel flow rate was constant at 1 mL min−1

Particle size distribution of titanium dioxide in sunscreen products of various brands and SPF values

With the selected SdFFF operating conditions, particle size distributions of titanium dioxide in the defatted sunscreen products of various brands and SPF values were investigated by using SdFFF-ICP-MS. With the UV detector, the particle size distributions of sunscreen samples are shown in Fig. 3. It can be seen that different brands of sunscreen products showed different particle size distribution patterns. For a particular brand of sunscreen products, the sample with higher SPF values showed larger particle size than that of the smaller SPF values. With the ICP-MS detector, the particle size distributions of titanium dioxide in sunscreen samples were obtained as illustrated in Fig. 4. For brand A, the signal of titanium was only slightly observed for sunscreen of 0 SPF value, whereas the distribution of titanium was found in the range of 0.1–0.5 μm for the sunscreen of 50 SPF value. For brand B, the distribution of titanium in sunscreen of various SPF values were different, but ranging between 0.1 and 0.4 μm. Titanium was found to present in a smaller particle size for the sunscreen of 15 SPF values as compared to that of 0 and 30 SPF values, suggesting that the manufacturer might have different strategies to formulate the products of different SPF values within the same brand. The manufacturer of brand B might not use the same titanium dioxide particle size for the products of different SPF values. For brand C, the distribution of titanium in sunscreen of 0 and 15 SPF values were found in the range of 0.2–0.6 μm. Higher titanium content was found in the product of higher SPF value.

Particle size distributions of titanium dioxide in defatted sunscreen samples. a Brand A, where diamond and square represent 0 and 50 SPF, respectively. b Brand B, where diamond, square, and triangle represent 0, 15, and 30 SPF, respectively. c Brand C, where diamond and square represent 0 and 15 SPF, respectively. Data were smoothed with Savitzsky–Golay function (PeakFit, SPSS, Chicago, IL, USA) with a smoothing level of 10%

Particle size distributions of titanium dioxide in all sunscreen samples investigated in this work were larger than 100 nm size range, except for the brand B of 15 SPF value. The particle size distributions of titanium dioxide in the defatted sunscreen samples (Fig. 4) were not well corresponded with the particle size distribution profiles (Fig. 3) except for the sunscreen brand A. For brand B, titanium (Fig. 4b) was found to associate with the small particle size range of the particles found in the defatted sunscreen samples (Fig. 3b). For brand C, titanium (Fig. 4c) was found to associate with the large particle size range of the particles found in the defatted sunscreen samples (Fig. 3c). These data suggest that the manufacturer of brand A might use titanium dioxide solely to adjust the SPF values of their products, whereas the manufacturers of brands B and C might adjust the SPF values of their products by adding both organic and inorganic components other than titanium dioxide as UV filters.

Titanium dioxide concentrations in sunscreen samples

Not only the particle size information, but it is also important to provide quantitative information on the titanium dioxide concentration in the sunscreen products, as its maximum allowable concentration in the sunscreen products has been declared by many countries such as European Union, Japan, and USA. In the European Union legislation, titanium dioxide is the only inorganic UV filter which is allowed at 25% maximum concentration [7]. The determination of titanium dioxide content (% w/w) in sunscreen products of various brands and SPF values was carried out using ICP-MS detection of titanium.

In this study, ICP-MS determination of titanium concentrations was performed with various approaches as follows: as an online detector for SdFFF, off-line detection of the collected fraction from SdFFF after acid digestion, and direct detection of the acid digested samples. The titanium dioxide concentrations in all sunscreen samples from various approaches are summarized in Table 2, which illustrates that the concentrations found from all approaches were similar. The closeness in the titanium dioxide concentrations obtained from the collected fraction from SdFFF after acid digestion with those directly determined after acid digestion of the samples indicates that titanium dioxide was not loss during the SdFFF fractionation of samples. The closeness in the titanium dioxide concentrations obtained from the online SdFFF-ICP-MS with those from the SdFFF fraction after acid digestion suggests that the ICP-MS could effectively atomize and ionize the titanium dioxide particle without the need for acid digestion. Therefore, the online coupling between SdFFF and ICP-MS could be effectively used to provide the quantitative information of titanium dioxide concentrations across particle size distribution profiles.

For all sunscreen samples in this study, the titanium dioxide contents were below the maximum allowable concentration (25%) as set by the European legislation. Different brands of sunscreen products showed different titanium dioxide contents. Nevertheless, higher titanium dioxide contents were observed for the sunscreen of the same brand but with increasing SPF values.

Conclusions

SdFFF-ICP-MS was demonstrated feasible to provide quantitative information of titanium dioxide concentrations across particle size distribution profiles. Nonetheless, sample preparation was necessary prior to SdFFF particle size characterization. Various brands and SPF values of sunscreen products showed different particle size distributions and different titanium dioxide contents. The information obtained from SdFFF-ICP-MS can be useful for quality control of the finished sunscreen products.

References

De Fabo EC, Noonan EP (1983) J Exp Med 158:84–98

Heck DE, Vetrano AM, Mariano TM, Laskin JD (2003) J Biol Chem 278:22432–22436

Agar NS, Halliday GM, Barnetson RS, Ananthaswamy HN, Wheeler M, Jones AM (2004) Proc Natl Acad Sci USA 101:4954–4959

Krutmann J (2000) J Dermatol Sci 23:S22–S26

Popov AP, Lademann J, Priezzhev AV, Myllylä R (2005) J Biomed Opt 10:1–9

Anderson MW, Hewitt JP, Spruce SR (1997) In: Lowe NJ, Shaath NA, Pathak MA (eds) Broad-spectrum physical sunscreens: titanium dioxide and zinc dioxide. Marcel Dekker Inc., New York, pp 353–398

Salvador A, Chisvert A (2005) Anal Chim Acta 537:1–14

Kim YS, Kim BM, Park SC, Jeong HJ, Chang JS (2006) J Cosmet Sci 57:377–381

Mason JT (1980) J Pharm Sci 69:101–102

Salvador A, Pascual-Martí MC, Adell JR, Requeni A, March JG (2000) J Pharm Biomed Anal 22:301–306

Kawauchi A, Ishida M, Saitoh I (1996) Spectrosc Lett 29:345–366

Melquiades FL, Ferreira DD, Appoloni CR, Lpoes F, Lonni AG, Oliveira FM, Duarte JC (2008) Anal Chim Acta 613:I35–I43

Contado C, Pagnoni A (2008) Anal Chem 80:7594–7608

Zattoni A, Reschiglian P, Montalti M, Zaccheroni N, Prodi L, Picca RA, Malitesta C (2007) Inorg Chim Acta 360:1063–1071

Contado C, Blo G, Fagioli F, Dondi F, Beckett R (1997) Colloid Surf A 120:47–59

Saeseaw S, Shiowatana J, Siripinyanond A (2006) Anal Bioanal Chem 386:1681–1688

Saeseaw S, Shiowatana J, Siripinyanond A (2005) Food Res Int 34:777–786

Cardot PJP, Rasouli S, Blanchart P (2001) J Chromatogr A 905:163–173

Rasouli S, Blanchart P, Clédat D, Cardot PJP (2001) J Chromatogr A 923:119–126

Koliadima A, Gavril D, Karaiskakis G (1999) J Liq Chromatogr Relat Technol 22:2779–2793

Kirkland JJ, Rementer SW, Yau WW (1981) Anal Chem 53:1730–1736

(2006) In: Ó Neil MJ (ed) The Merck Index: an encyclopedia of chemicals, drugs, and biological, 14th ed. Merck Research Laboratories: Whitehouse Station, NJ

Acknowledgments

The Center for Innovation in Chemistry: Postgraduate Education and Research Program in Chemistry (PERCH-CIC), Commission on Higher Education, Ministry of Education is gratefully acknowledged for the studentship support for A. Samontha, the partial research support for A. Siripinyanond, and the purchase of the SdFFF equipment. Thanks are also due to the Thailand Research Fund for the research support for A. Siripinyanond. This paper was presented in part at the Pure and Applied Chemistry Conference 2010 (PACCON 2010), Ubonratchathani, Thailand, January 21–23, 2010, Oral Presentation Number ANC-OR-17.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Samontha, A., Shiowatana, J. & Siripinyanond, A. Particle size characterization of titanium dioxide in sunscreen products using sedimentation field-flow fractionation–inductively coupled plasma–mass spectrometry. Anal Bioanal Chem 399, 973–978 (2011). https://doi.org/10.1007/s00216-010-4298-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-010-4298-z