Abstract

In this review the focus is on application of porous monoliths to miniaturized extraction of biological analysis, with emphasis on porous monolithic materials and different miniaturized extraction formats. The general approaches used to synthesize organic polymer and silica monolithic materials are highlighted, and their properties and applicability are described and compared. Several extraction formats, including in-tube microextraction, chip-based microextraction, tip-based microextraction, among others, are reviewed in depth.

A visual model of the miniaturized extraction based on porous monoliths

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the development of human society, environmentally and biologically favorable analytical methods have been demanded. Sample pretreatment has been regarded as a bottleneck in modern analysis and many efforts have been devoted to developing methods for general or specific purposes [1]. Recent years have witnessed great progress in sorbent-phase sample pretreatment technology [1, 2]. In achieving the properties desired for ideal sample pretreatment methods, i.e. simple, affordable and economical, and automation to some degree, miniaturization has been a key factor [3, 4].

Miniaturized sorbent-phase extraction is the most useful, reliable, and practical miniaturized extraction technique in the modern-day laboratory [4]. Solid-phase microextraction (SPME) is a typical successful miniaturized sorbent-phase extraction technique, which has the merits of high sensitivity, low sample requirement, low solvent consumption, simplicity, and easy automation. Since its invention in 1990, SPME has been extensively used in a wide range of fields, covering food, biological, environmental, forensic, etc. [5]. To enhance extraction efficiency and ease, and to automate the operation, there are variations of miniaturized sorbent-phase extraction besides SPME, for example in-tube microextraction, chip-based microextraction, tip-based microextraction, among others [2–4].

The essential parts of miniaturized sorbent-phase extraction are the extraction phase and the extraction configuration, which determine the extraction efficiency and thus the sensitivity and precision of the analysis. Hitherto, advances in sorbent-phase extraction have been closely related to what we have achieved with the sorbent material. In this sense, one needs to have a way of fabricating materials with suitable configurations and characteristics for the technique of choice, while enhancing the performance of the technique. In essence, the design and fabrication of advanced materials coupled with good understanding of their behavior is of paramount importance in the development of both material science and analytical techniques [6].

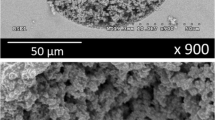

In recent years, advances in monolithic materials with novel and interesting properties, achieved by varying their chemical composition, configuration, and functionality, have attracted much attention, because of their potential for interesting applications, broad applicability, and tunable properties according to the needs of the applications [7–13]. Monolithic materials have been used as alternative stationary phases for high-performance liquid chromatography (HPLC) and capillary electrochromatography (CEC) [10], immobilized enzymatic reactors [11], and extraction sorbents [12, 13]. The monolith is generally formed in situ from reactant solution, and can conform to any shape or confined geometry with frit-free construction, which guarantees convenience of operation. The prevalence of monolithic materials may be partly because of the ease and simplicity of preparation and the availability of various precursors and chemistries. Most interesting, monolithic materials have a binary porous structure, mesopores and macropores. The presence of micron-size macropores ensures fast dynamic transport and low backpressure in applications; mesopores contribute to sufficient surface area (several to several hundred m2 g−1) and thus high loading capacity. Additionally, many of these materials have been demonstrated to be biocompatible. These features are especially desired when dealing with biological samples, which are notoriously difficult to handle, largely because of their complex constitution, intractable nature, and high viscosity. Hence, monolithic materials as extraction sorbents are particularly attractive for biological analysis.

Svec et al. have highlighted the preparation, characterization, and extraction applications of monolithic materials [7, 9, 13]. Porous monoliths for diverse extraction applications have been discussed in detail by Potter and Hilder [12]. In this review, applications in biological analysis, in particular, are discussed from the perspective of monolithic materials and operational formats.

Porous monoliths for miniaturized extraction

Basically, monolithic materials are divided into two groups: organic polymer-based and silica-based. The former has been known for almost five decades, and has been widely used in different areas, whereas the latter has become popular only recently. As far as sample pretreatment is concerned, much attention has been paid to organic polymer monoliths; silica monoliths have been more or less neglected. The popularity of organic polymer monoliths in sample pretreatment may be ascribed to their facile preparation and less likelihood of shrinkage during post-treatment processes [7, 9, 12, 13].

Organic polymer monoliths

The synthesis of organic polymer monoliths requires only one-step polymerization and simple post-treatment procedures, providing a tunable porous structure with tailored functional groups [8]. Generally, the pre-polymerization mixture consists of the monomers, crosslinkers, porogenic solvents, and initiators, in an appropriate ratio, which is sonicated and/or purged with oxygen-free nitrogen. The oxygen-free pre-polymerization mixture is then introduced into a mould, for example capillary, chip, syringe, etc., with the desired configuration. The mould may require proper pretreatment. For example, fused silica capillaries are commonly activated by treatment with a methanolic solution of 3-(trimethoxysilyl)propyl methacrylate (TMSPM) before introduction of the pre-polymerization mixture. By reaction between the methoxy groups in TMSPM and silanol groups on the fused silica capillary, the ethylene moieties are successfully attached to the capillary wall, and participate in the subsequent polymerization to achieve bonding of the monolithic materials to the capillary. This step is crucial to obtaining a stable monolithic bed in the mould. Polymerization is initiated by heating, use of UV radiation, or, less often, microwave [14] or γ-ray [15] radiation, in the presence of initiators. After reaction for the prescribed time at an appropriate temperature, the resulting material is washed with copious amounts of organic solvents to remove the unreacted components and porogenic solvents.

Organic polymer monoliths are generally highly biocompatible and pH-stable, which make them suitable for use with biological samples such as urine or serum. However, in most cases, they suffer from shrinkage or swelling when exposed to organic solvents, leading to poor mechanical stability. For extraction, methacrylate-based monoliths are the most popular. Roberts et al. have reported the versatility of polymethacrylate monoliths for purification of biomolecules [16]. Table 1 lists the organic polymer monoliths most often used for extraction applications, including the synthetic conditions.

Poly(methacrylic acid–ethylene dimethacrylate) (poly(MAA-EDMA)) is a polymeric sorbent with polar groups, carboxyl groups, and a hydrophobic framework. It is commonly prepared from methacrylic acid (MAA) and ethylene dimethacrylate (EDMA) in toluene and dodecanol as binary porogenic solvents. With azobisisobutyronitrile (AIBN) as initiator, polymerization proceeds to form a monolith. The monolith enables highly efficient extraction of basic analytes and is a very suitable biocompatible sorbent for biological samples, with satisfactory re-usability. Hitherto, it has been the most preferred monolithic matrix for extraction purposes [17–40].

By using glycidyl methacrylate (GMA), EDMA, AIBN, and cyclohexanol and dodecanol as monomer, crosslinker, initiator, and porogenic solvents, respectively, poly(GMA-EDMA) monolith was obtained [41–48]. Because of the presence of epoxide groups, this material is easily derivatized for extensive applications. For instance, hydroxyl groups were generated by flushing the poly(GMA-EDMA) monolith with 0.1 mol L−1 sulfuric acid solution, which led to the opening of the epoxide rings [41]. As a result, neutral analytes were extracted on to the monolith by dipole–dipole and hydrophobic interactions. Affinity sorbents based on poly(GMA-EDMA), with immunoglobulin G (IgG) and anti-ochratoxin A antibody immobilization, were also achieved [42, 43]. Metal affinity sorbents for extraction of peptides have also been described [46, 47].

Poly(acrylamide–vinylpyridine-N,N′-methylene bisacrylamide) (Poly(AA-VP-Bis)) is synthesized by copolymerization of acrylamide (AA), 4-vinylpyridine (4-VP), and N,N′-methylene bisacrylamide (Bis) (the crosslinker), with dimethyl sulfoxide (DMSO) and dodecanol as the porogenic solvents. Poly(AA-VP-Bis) has multiple interactions with analytes, including anion-exchange, hydrophobic, and π–π interactions. It has been shown to be effective for extraction of phenols and other acidic species [49–52]. Because several functional groups are present on the poly(AA-VP-Bis) monolith, it has been used to prepare molecularly imprinted polymer (MIP) extraction columns, with guanosine as molecular template [53, 54].

Apart from the above most commonly used organic polymer monoliths, others, prepared by changing the monomers or crosslinkers, have been reported for some applications, as listed in Table 1 [17–70].

Silica monoliths

Silica monoliths can circumvent some disadvantages associated with organic polymer monoliths, for example possible swelling and decomposition under the action of organic solvents and/or high temperature. They therefore have huge potential for application under extreme conditions. Another favorable feature of silica monoliths is their active surface, which can be easily derivatized. This implies that greater diversity of desirable functional groups can be obtained by surface modification, leading to additional efficient, selective, and thus sensitive extraction. They have recently been attracting much attention in sample pretreatment [9, 12, 13].

Silica monoliths are normally prepared via a sol–gel method with phase separation. This mainly includes hydrolysis, condensation, and polycondensation of silica precursors. Typically, tetraethoxysilane (TEOS) or tetramethylorthosilicate (TMOS) is distributed in a suitable solvent in the presence of a porogen (e.g. poly(ethylene glycol) (PEG)), followed by the addition of a catalyst, acid or base, or a binary catalyst, acid and base in sequence. After reaction for the prescribed time, the resulting gel-like product is washed with copious amounts of solvents to remove unreacted precursor, porogen, and catalyst, followed by the proper post treatment. Bare silica monoliths are directly used for purification and enrichment of deoxyribonucleic acid (DNA), ribonucleic acid (RNA), proteins, etc.

The silica surface may be subsequently modified by silanization to anchor functional groups via siloxane bonds. Shintani et al. first used C18 bonded monolithic silica microcolumns, for preconcentration before capillary LC [71]. However, the chemical bonding reactions should be carried out under rigorously anhydrous conditions with functional silanes individually, which may lead to problems in reproducibility [72]. Another disadvantage of this approach is that the hydrolytic stability of the Si–O–Si–C linkage in the bonded stationary phases may be insufficient, especially under moderately acidic or slightly alkaline conditions. In addition, the organic coverage is relatively limited after use of conventional chemical bonding methods [73]. These disadvantages can lead to the exposure of a substantial number of silanols on the surface of the material; these are believed to be primarily responsible for the residual adsorption phenomena that plagues silica-based extraction phases [74].

The preparation and functionalization of silica monoliths can be combined in a single step by adding functional monomers to the silica precursor mixture for generation of the desired surface. This is regarded as a more straightforward and broadly applicable synthetic route. The monolith prepared in this way is commonly called an organic–inorganic hybrid silica monolith. In this way, a more hydrolytically stable bonded phase is obtained by silica–carbon (Si–C) or silica–nitrogen (Si–NH–C) bond attachment, rather than Si–O–Si–C linkage. Research in which hybrid silica monoliths have been applied to miniaturized extraction has been widely reported [75–78].

Shrinkage, however, cannot be completely avoided when preparing silica monoliths, and is most serious for large-diameter monoliths. Possibly for this reason, most applications of silica monoliths for sample pretreatment are on the micro scale, for example in-capillary microextraction or chip-based microextraction. Although monoliths in smaller devices still tend to shrink to some extent during post-treatment procedures, the shrinkage may be minimized or prevented by covalent attachment of the monoliths to the capillary or tubing walls. Hence, they are directly synthesized in situ, which may ensure reliable and reproducible performance of the material for sample pretreatment.

Application formats

In-tube microextraction

The original SPME format is based on an extraction fiber coated with a sorbent phase. It suffers from fragility and low extraction capacity. It has been successfully connected online with GC analysis. For online HPLC, however, it is not very popular because of the inconvenient interfacing. This has prompted the emergence of other microextraction formats, of which in-tube microextraction is typical.

Unlike fiber-based SPME, the sorbent phase of in-tube microextraction is coated on a capillary/tube interior wall or is contained in a capillary/tube as packed particles or monolithic materials. This format increases the range of available coatings and conveniently realizes the integration of extraction (online or offline) with separation and detection, especially successful coupling of SPME with HPLC. The initial work on this was reported by Eisert et al. in 1997 [79]. Recently, several reviews have highlighted its diverse applications [80, 81].

In early work on this method, the extractant phase was based on coating of the capillary wall. However, such coatings suffer from low sample loading, which limits the sensitivity of the method to some extent. To address this problem, a capillary tube packed with particles was proposed as an alternative [82]; frits were required to hold the particles in situ. However, the preparation of frits is normally tedious and hard to control. Compared with the two forms of sorbents (coatings or particles) mentioned above, monolithic materials have satisfactory phase ratios, ensuring high sample loading, and are always prepared in situ without the need for frits. Additionally, because of their special bimodal structures, monolithic materials result in convective mass transfer other than diffusive mass transfer during the extraction process, which is a desirable feature for fast extraction. Hence, monolithic materials are much more attractive. The preliminary work associated with monolithic materials for in-tube microextraction was presented by Shintani et al. in 2003 [71]. From then on, monolithic materials with different functional groups have been evaluated for a variety of applications in biological analysis in this mode of microextraction [17–43, 46–48, 51–58, 60, 68, 77, 78, 83–93].

In-tube microextraction based on organic polymer monoliths

Feng’s group has contributed much to the application of diverse monolithic materials for in-tube microextraction. They reported the first use of a poly(MAA-EDMA) monolithic capillary [36] as an in-tube microextraction medium, which has been extensively explored. Owing to the presence of carboxyl groups and a hydrophobic backbone, it is effective for basic/neutral analytes via ion-exchange and/or hydrophobic interactions from different sample matrices, for example urine, blood, serum, etc. Because of its excellent biocompatibility, only simple sample pretreatment before extraction was required, for example dilution, centrifugation, or filtration. To promote extraction or facilitate detection, derivatization of analytes may be required. In most cases, pre-extraction derivatization was performed. For example, catechols and 5-hydroxyindoleamines were derivatized via a two-step reaction, using benzylamine and 1,2-diphenylethylenediamine as derivatization reagents under weakly alkaline conditions. The benzoxazole derivatives obtained were extracted and analyzed by HPLC–fluorescence (FL) [19]. For 5-hydroxymethylfurfural, derivatization with 2,4-dinitrophenylhydrazine was performed before extraction and HPLC–UV analysis [20]. Nitric oxide was derivatized with a fluorescent probe, 1,3,5,7-tetramethyl-8-(3′,4′-diaminophenyl)-difluoroboradiaza-s-indacene, to enable extraction and FL detection. With HPLC–FL analysis, up to 10−13 mol L−1 nitric oxide could be detected in blood, tissue, and hydrophytes [24–26].

Polymer monoliths based on other matrices were also explored. Detailed examples are listed in Table 2.

To expand the extraction ability, monoliths have sometimes been used after derivatization. For example, by opening the epoxide rings of the poly(GMA-EDMA) material, a monolith enriched with diol moieties was obtained; this was used for extraction of clenbuterol from urine, with a limit of detection (LOD) of 2.3 ng mL−1 [41].

To enhance extraction selectivity, MIP or affinity monoliths were evaluated. MIP monolithic materials based on poly(AA-VP-Bis) were prepared, using guanosine as the template, for detection of 8-hydroxy-2′-deoxyguanosine (8-OhdG) [53, 54]. LOD of 2.6 and 3.2 nmol L−1 were obtained for CE–electrochemical detection (ED) and HPLC–UV analysis, respectively. An ion-imprinted polymer based on a poly(HEMA–EDMA) matrix was obtained by using N-methacryloyl-l-cysteine methyl ester-Fe3+ as the template [58]. It was shown to enable effective analysis of Fe3+ in human plasma. An immunoextraction sorbent phase based on poly(2-vinyl-4,4-dimethylazlactone (VDA)-HEMA-EDMA) was obtained by immobilizing antitestosterone polyclonal antibody on to the monolithic material via reaction with VDA [57]. Testosterone was thus detected by laser-induced fluorescence (LIF) with an LOD <70 nmol L−1. Other affinity monoliths based on poly(GMA-EDMA), for example monoliths containing immobilized anti-ochratoxin A antibodies [42] and monoclonal antifluorescein isothiocyanate antibodies (FITC) [43], were prepared for high-sensitivity preconcentration and isolation of ochratoxin A and fluorescein, respectively.

Wen et al. described the preparation of TMSPM monolith by a photoinitiation process. After modification with TMOS to generate the silica surface, it was used to purify DNA from human whole blood, because of the combination of interactions such as electrostatic forces, DNA dehydration, and intermolecular hydrogen-bonding forces [86].

In-tube microextraction based on silica monoliths

Compared with polymer monolithic materials, silica monoliths have been less used in in-tube microextraction. Octadecyl (C18) monoliths have been used to preconcentrate proteins and flavins [87–89]. A hybrid silica monolith containing mercapto groups was derivatized to yield sulfonic acid groups for cation-exchange extraction of anesthetics from human urine [78]. Combined with CE–UV analysis, LODs between 6.6 and 36.7 μg L−1 were achieved. Electrostatic interaction between the phosphate groups of DNA and the calcium ions of hydroxyapatite monolith resulted in high-capacity recovery of DNA from Bacillus subtilis (B. subtilis) crude lysate [85]. In addition, by use of Coulombic force, DNA extraction was achieved by means of an amino-silica hybrid monolith [77].

Interfacing with different instruments

The original fiber-based SPME has the merit of being easily connected to GC injection whereas in-tube microextraction is advantageous for interfacing with HPLC. Based on the diversity of monolithic matrices, in-tube microextraction has been coupled online or offline with a variety of instruments, predominantly HPLC, for determination of a wide range of analytes in biological matrices. Much work has been devoted to this aspect of interfacing between in-tube microextraction and different instruments [94].

Typically, a syringe pump is normally used to assist the offline extraction procedures. To connect the syringe needle and extraction tube, a delicate interface is required. Zhang et al. [28] proposed a novel extraction technique, named “polymer monolith microextraction” (PMME). As shown in Fig. 1, the extraction device consists of a plastic syringe barrel (1 mL), a polymer monolithic capillary (20 mm, 0.53 mm i.d.), and a plastic pinhead connecting the former two components seamlessly. Sorption of the analytes was achieved by injecting the sample via the monolithic capillary tube with a programmable syringe pump. For the desorption step, an aliquot of an appropriate solution was injected to pass through the monolithic capillary tube and collected in a vial for subsequent analysis. Obviously, this device is convenient for operation and requires a simple instrument and manipulation, which adds a bonus for sampling in the field. Poly(MAA-EDMA) and poly(AA-VP-Bis) have subsequently been successfully incorporated into this device. Recently, a boronate affinity monolith based on poly(AAPBA-EDMA) was used as the sorbent for PMME. It was demonstrated to have good selective extractability towards glycol-containing compounds [93]. Use of PMME for a variety of analyses also seems highly feasible. Apart from HPLC hyphenation, its hyphenation to GC [21], CE/CEC [17, 27, 28, 30, 33], inductively coupled plasma–mass spectrometry (ICP–MS) [52], and MALDI-TOF MS [93] have been reported.

On-line, in-tube microextraction–HPLC was easily realized by using two six-port valves and two pumps, as depicted in Fig. 2. The monolithic capillary was placed on valve B in the position where the sample loop was originally positioned. High method precision was ensured by controlling the valve-switching time interval accurately to condition the extraction column, load sample solution, wash the column, and elute analytes for the final instrumental analysis. With this automatic design, on-line interfacing in-tube microextraction with HPLC has been achieved [18, 31, 32, 34–37].

Similarly, successful hyphenation of in-tube microextraction and pressure-assisted capillary electrochromatography (pCEC) has been achieved by installing a poly(MAA-EDMA) monolithic capillary on the six-port valve in a CEC system. The device designed was appropriate for on-line, in-tube microextraction coupled to pCEC or micro-HPLC [23].

In-line capillary extraction has emphasized the use of CE instrumentation for extraction, irrespective of whether or not electrophoretic separation is involved. Because the sorbent phase is contained in the capillary, from this point, it is a special mode of in-tube microextraction. There are two ways of connecting the monolithic capillary to electrophoretic systems. A segment of monolithic capillary was connected to two other fused-silica capillaries by use of PRFE sleeves and glued with epoxy resin [47, 83]. Alternatively, the capillary containing monolithic material in part of its length was used directly as the extractor, which may avoid the extra connection [39, 40, 46, 48, 68, 90–92].

Sample loading and washing were manipulated by pressure and/or voltage, which could be achieved by use of the CE instrument. However, in this mode of in-line extraction, CE separation was not that convincing, because of the difficulty of matching the elution solution with subsequent CE separation. In some cases, although a potential was applied, only one analyte was involved and no actual separation occurred [47, 48, 90]. For several analytes, separation took place after in-line preconcentration [39, 40, 68, 91, 92]. In specific cases, the CE instrument was used only as a tool for sample loading, washing, elution, and online detection by pressure [86].

Chip-based microextraction

Nowadays, a hot topic for total genetic analysis is development of a completely integrated microfluidic system, also called “lab-on-a-chip”. Such a microsystem should be able to handle multiple procedures for miniaturized genetic analysis, including nucleic acid purification, polymerase chain reaction (PCR), and electrophoretic separation. This represents a trend in biological analysis towards reducing time, size, cost, and contamination, especially considering the limited amount of samples. The challenges in this technology are design of the chip and incorporation of proper materials for diverse purposes. Ro et al. highlighted the use of monolithic media in microfluidic devices for proteomics [95]. Currently, most research on microfluidic devices has focused on biological analysis.

The isolation of DNA from biological samples is the first step in a variety of bioanalytical techniques. The use of monoliths in a microfluidic device ensures large surface area, which can provide abundant interaction sites for DNA extraction [96]. Examples of DNA extraction/clean-up on silica monoliths or silica functionalized polymer monoliths can be found in Refs. [97–102]. Landers’s group contributed much on chip microextraction of DNAs [97, 98]. A silica monolith was used for purification of DNA from human blood, spinal fluid, and bacteria [97]. The efficiency of extraction of DNA by a chip incorporating a silica monolith was reported to be higher than 85%, whereas that for a chip incorporating silica beads was approximately 70%. In their continuous efforts to achieve DNA extraction, they proposed use of a two-stage, dual-phase chip for the extraction of whole blood DNA [98]. Initial protein-capture precolumns based on four parallel chambers packed with C18 beads were used to remove undesired interferences from the whole blood; the second monolithic DNA extraction channel, based on a TMOS-modified TMSPM monolith, was used to recover target DNA. With this design, high extraction efficiency (69 ± 1%) was achieved.

Shaw et al. proposed introducing poly-A carrier RNA to the chaotropic salt solution, to enhance the efficiency of extraction of DNA. Five times the amount of DNA (25 ng) was recovered compared with the amount (5 ng) without RNA addition. This pronounced enhancement was obviously attributed to addition of carrier RNA to the binding solution. In their explanation, RNA was supposed to interact with adsorption sites on the silica monolith, which may irreversibly bind nucleic acids. As a result, DNA was largely released [99] and thus the extraction efficiency was increased. Later, the same authors reported novel manual loading of DNA samples by use of a pipette to simplify the chip interfacing and reduce contamination. The subsequent elution and washing steps were performed in an orthogonal direction to sample loading [100]. In a recent report, a functionalized silica monolith, for example an aminosilica monolith prepared by reaction of TEOS and N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, was evaluated for extraction of genomic DNA from the whole blood of crucian carp with an extraction efficiency of 52% [101].

Besides the use of silica monoliths, silica particle-incorporated polymer monoliths have also been reported for DNA/RNA purification. This strategy exploits the easy preparation of polymeric monoliths with no shrinkage and the surface property of silica for extraction. A silica particle-impregnated poly(BMA-EDMA) monolith was reported to lyze and extract DNA from bacteria; this was demonstrated to enable better recovery of DNA at low concentration than a commercial kit [63, 64]. The same silica particle-imported polymer monolith was also used to isolate viral RNA from influenza A virus-infected mammalian cells [103]. The available silica surface area was found to determine the recovery of the method.

Although silica or silica-related materials are prevalently used for capture of biological molecules, a few examples of the use of polymer monoliths have been reported. Online purification of fluorescein-labeled peptides and bovine serum albumin (BSA) tryptic digest was achieved by use of a polymethacrylate monolith, with 150-fold sensitivity enhancement [104]. Moschou et al. designed microfluidic compact discs with a poly(HEMA-EDMA) monolith as the protein purification sorbent. This integration enabled both protein purification and fractionation [59]. Robotti et al. reported a preliminary study on use of the poly(methystyrene–bisvinylphenyl ethane) monolith as the enrichment sorbent on the Agilent HPLC-Chip–MS system. Five selected components of a BSA digest were well concentrated on the proposed polymer monolith [105]. Li and Lee proposed a poly(GMA-trimethylolpropane trimethacrylate) monolith modified with Cibacron-blue-3G-A to capture lysozyme and human albumin [106]. A tetrapeptide was recovered on the poly(BMA-EDMA) monolith largely by hydrophobic adsorption [67]. Quaternary ammonium groups attached to a poly(HMA-META-EDMA) (META, [2-(methacryloyloxy)ethyl]trimethylammonium chloride) monolith had ion-exchange capacity for the probe analyte, Coumarin 519 [67].

It is noteworthy that preconcentration and separation can be achieved in a microfluidic system without any extra connection. A simple tee-type manifold chip was used to achieve this purpose [107]. One axis was used for concentration, and was directly connected to the sample waste reservoir, and the other orthogonal axis was used for separation; this has advantages over in-line capillary extraction. An acrylate-based monolith has been developed to concentrate both neutral (polycyclic aromatic hydrocarbons) and ionized compounds (tris(2,2′- (bipyridyl)dichlororuthenium(II)) via hydrophobic and ionic interactions, respectively [107].

In an effort to enhance extraction selectivity, a poly(GMA-EDMA) monolith was first prepared in situ within the microchannels by photopolymerization. Afterwards, amine groups were introduced to the monolith by reacting ethylenediamine with epoxy groups on the GMA; amine groups subsequently reacted with a heterobifunctional cross linker, sulfo-SMCC. In this way, anti-FITC could be linked to the derivatized monolith. The affinity monolith had high selectivity for fluorescently tagged amino acids. Twenty-fold enrichment and 91% recovery were obtained [44]. In addition, anti-FITC was immobilized on the poly(GMA-EDMA) monolith simply by flushing the material using an appropriate solution [45]. By using this chip, immunoaffinity extraction and electrophoretic separation of FITC-tagged human serum albumin were demonstrated.

There is no doubt that chip-based microextraction is widely employed for purification and enrichment of biological molecules, because of the small amount of sample solution required. Nevertheless, applications of this technology to small molecules are also promising. Esterified C18 silica monolith has been used for enrichment of dobutamine hydrochloride from serum, with an enrichment factor up to 77.2 [108]. Poly(BMA-EDMA) has been effectively used to purify isoniazid in plasma [65]. Yang et al. integrated a microchip containing poly(MMA-EDMA) monolith with an ion-trap mass spectrometer by use of a modified commercial interfacing system [109, 110]. It was demonstrated to be effective for purification of imipramine from urine, with a high enrichment factor up to 208-fold [109]. Additionally, poly(BMA-EDMA) has been used to clean and preconcentrate imipramine from human urine and P450 drug metabolism incubation mixture. A linear range of 0.025–10 μg mL−1 was achieved for human urine, with R 2 of 0.9995 [66].

Tip-based microextraction

Micropipette tip-based devices have been growing in popularity for purification, concentration, and selective isolation of proteins and peptides in the study of genomics, proteomics, and metabolomics. This format of microextraction is based on sorbent phase fixed in a pipette tip. The whole extraction process is achieved by repeated aspirating/dispensing cycles using a manual micropipettor. Compared with conventional SPE, the operation of tip extraction is easier and faster, suitable for inexpensive, and disposable usage. This kind of extraction tip is now available from several manufacturers, including ZipTip from Millipore (Bedford, MA, USA), Omix from Varian (Palo Alto, CA, USA), and NuTip and MonoTip C18 tip from GL Sciences (Tokyo, Japan). Blomberg has written a detailed review of the applications of bonded monoliths as the sorbents in polypropylene tips [111].

Because of the occurrence of shrinkage during silica monolith preparation, supersonication is used to assist the fixing of silica monoliths into the tips. Miyazaki and coworkers studied the performance of bare silica, and C18 and titania-coated silica monolithic tips for analysis of proteins [112]. Bare silica had good affinity for highly hydrophilic proteins whereas C18–silica monolith had good performance in the trapping of hydrophobic substances. Titania coated-silica monolith had highly selective affinity for phosphopeptides; combined with LC–MS analysis it was successfully used for detection of phosphopeptide from β-casein tryptic digestion. Using the same extraction tip, ten antihistamine drugs were purified from human plasma, with satisfactory recoveries between 73.8 and 105%. LODs achieved by GC–MS analysis were 0.2–0.5 ng mL−1 [113]. In a similar way, mequitazine was determined in human plasma [114], and methamphetamine and amphetamine in human whole blood and urine [115, 116]. The OMIX tip (C4) was used for desalting and cleanup in the analysis of lipids, proteins, and resins in paint [117, 118].

However, supersonication is not often available in routine laboratories, which may retard the development of this technology. As a solution, it is possible to prepare polymer monolith in situ in the plastic tip without any other extra force, because shrinkage is not serious in the preparation of polymer monoliths. Altun et al. carried out a series of experiments on the application of polymethacrylate monolithic tips to biological analysis [69, 119–122], especially emphasizing 96-tip arrays for high-throughput analysis. The tips were prepared as follows. The pipette tips were filled with the polymerization precursors to a specific height by capillary action and placed vertically inside the polymerization apparatus. With UV irradiation or heating, the polymer monoliths were formed inside the plastic tips. A robot operating in a 96-well format furnished with polymer monolithic tips could simultaneously handle 96 samples within 2 min [69]. Later, the same authors used benzophenone as photoinitiator to generate radicals at the surface of polypropylene tips by hydrogen abstraction. In this way, the poly(BMA-EDMA) monolith could be covalently attached to the pipette wall. This was used to detect ropivacaine in plasma samples in a 96-well plate format [119]. The applications of methacrylate monolithic tips have been extended to the extraction of pindolol and metoprolol [120] and local anesthetics [121] in human plasma.

Polydivinylbenzene (DVB) extraction tips embedded with zirconia or titania nanopowders were successfully prepared and used for the highly selective enrichment of phosphopeptides. The zirconia and titania particles embedded in the polymeric framework interacted with the target analytes. In this manner, two phosphorylated peptides of extracellular signal-regulated kinase could be identified by MALDI-MS–MS [123].

In order to increase the extent of through pores and facilitate the suction operation during extraction, Liang and Chen used an oil-in-water emulsion technique to prepare monolithic materials [124]. The emulsion pre-polymerization mixture consisted of ethanol, sodium dodecyl sulfate, 2,2-dimethoxy-2-phenylacetophenone, EDMA, and ammonium hydrogen carbonate, into which different beads, for example titania particles, MC20 (immobilized metal affinity chromatography, IMAC packing; Applied Biosystems, Foster City, CA, USA) and Waters Oasis HLB (St Quentin en Yvelines, France) were immobilized. Tryptic digests of ovalbumin, phosphopeptides, and estrogens were demonstrated to be successfully recovered from C18 beads, titania and IMAC packing, and Waters Oasis HLB immobilized monolithic tips, respectively.

Miscellaneous

Fibers

In an initial study, a codeine imprinted poly(MAA-EDMA) monolithic fiber was used, instead of the traditional coated silica fiber, directly as the extractant phase without any substrate for SPME analysis of codeine in various street-drug samples [38]. Similarly, Shi et al. proposed a carbon monolith as an alternative to the coated silica fiber [125]. Using phenols as the probe analytes, the carbon monolith had superior characteristics, for example faster extraction equilibrium and higher extraction capacity, to the commercial coated fibers (e.g. polydimethylsiloxane (PDMS), Carbowax–DVB and DVB–Carboxen–PDMS).

Recently, a novel hyphenated technique (molecularly imprinted micro-solid phase extraction fiber-MIP fiber sensor) was described by Prasad et al.. Adopting folic acid, 2,4,6-trisacrylamido-1,3,5-triazine, EDMA, and DMSO as template, monomer, cross-linker and porogen, respectively, a folic acid-imprinted monolith was obtained via free-radical thermal polymerization. This monolithic fiber was used for direct extraction of folic acid from human blood serum. The eluate was subjected to DPCSV measurement with another MIP–carbon composite fiber and an LOD as low as 0.0036 ng mL−1 was achieved [126].

Microextraction in a packed syringe (MEPS)

MEPS is a novel technique of miniaturized SPE, initially introduced by Abdel-Rehim [127]. In this device, a solid support is inserted directly into a syringe as a plug (with a filter at either end of the plug holding the solid phase), and fitted manually into the syringe. The plug is tightly fixed in the syringe to prevent its movement inside. This MEPS device was demonstrated to be easily connected on-line to GC and HPLC without any modification of the chromatograph. The authors claimed the packed syringe could be used more than 100 times with plasma samples, whereas a conventional SPE cartridge was used only once. In addition, compared with SPE or LLE, it is fully automated and takes only 1 min to process each sample. Compared with SPME, MEPS reduces not only sample preparation time but also sample volume (10–1000 μL). In addition, a much higher recovery (>50%) was obtained [127].

Poly(GMA-EDMA-BMA) was synthesized in situ in a syringe barrel which was to extract ropivacaine, and lidocaine and its metabolites from urine. Amongst three sorbents investigated (the other two were polystyrene and C8 beads), the monolithic materials had the lowest extraction efficiency and capacity. However, the authors still claimed the monolithic material was promising when handling plasma samples because of its low pressure drop, which may be suitable to deal with highly viscous samples [70].

Stir-bar-sorptive extraction (SBSE)

Because the volume of extraction phase bound to SPME fibers is relatively small, the extraction capacity is commonly limited. This problem prompts the emergence of SBSE, whose original format is a magnetic stir bar coated with a sorbent layer. Compared with an SPME fiber, the sorbent phase on a stir bar is 50–250 times greater, resulting in a higher phase ratio and, hence, a higher extraction yield than that in fiber-based SPME. Magnetic stir bars coated with functional layers of thickness of 0.5 or 1 mm are commercially available (Twister; Gerstel, Müllheim a/d Ruhr, Germany). After extraction, thermal or solvent desorption is used to elute the analytes. The main difficulty in the extraction process is that it is hard to automate removal of the stir bar from the sample solution [128]. PDMS is currently the only commercially available coating for SBSE. Increased coating thickness may elevate the extraction capacity of SBSE sorbents. However, preparation of thick coatings is difficult. Additionally, the mass transfer rate of the analytes to the thick coatings is slow when conventional material is used. To solve the problem, monolithic material was proposed for coating stir bars. It can be synthesized within a desired mould to form a coating of desired thickness on stir bars. Owing to the interconnected porous structure of the monoliths, fast mass transfer can be guaranteed. For instance, poly(octyl methacrylate (MAOE)–EDMA) monolithic material was prepared in situ on a stir bar pretreated with 3-(trimethoxysilyl)propyl methacrylate. It was used for the identification of anabolic steroids in urine samples. Combined with HPLC–UV analysis, satisfactory LODs were obtained—62.3 pg mL−1 for estriol and 212 pg mL−1 for diethylstilbestrol [61]. Similarly, poly(MASE-EDMA) monolith was used as a stir bar coating for enrichment of steroid sex hormones from human urine. Low LODs between 0.062 and 0.38 ng mL−1 were obtained [62].

Microextraction based on a monolithic spin column

Four steps—preconditioning, loading, washing, and elution— are used for extraction using spin columns. The difference between spin columns and other microextraction formats is the mode of operation. Extraction is performed with the assistance of centrifugation. Preparation of a monolithic spin column is simple—the monolithic material is fixed inside the spin column by supersonic adhesion. The spin column is then installed in a siliconized microtube, and the four-step extraction procedure is performed by centrifugation at a prescribed rotation rate for a prescribed time. It was claimed by the authors that this approach afforded simple operation, needed only low eluent volume, reduced operator labor, ensured high sample throughput, and avoided solvent evaporation. A C18 monolith was used to concentrate amphetamines and methylenedioxyamphetamines from urine [129, 130], and dibucaine and naphazoline [131], amitraz and its metabolite [132], and nine cold medication compounds and the drug bromoisovaleryl urea in human serum [133]. Strong cation-exchange and anion-exchange spin columns were used for identification of basic drugs and acidic drugs, respectively, in human serum and urine [134].

Conclusion and outlook

This review has focused on the use of porous monoliths for miniaturized sample pretreatment, specifically covering biological applications. To conclude, porous monoliths have the following merits:

-

1.

They have a bicontinuous structure of interlaced through pores and skeleton, with the latter enriched with mesopores. This highly porous structure leads to large surface area, which can be derivatized with many functional moieties to enhance extraction capacity. Moreover, it enables a favorable mass transfer and low back pressure during extraction. As a result, less time is needed to condition the column, and a high flow rate may be applied to deliver sample solution and to elute analytes.

-

2.

Monolithic materials of diverse functionality are available. It is well known that silica is readily derivatized by silylation. The functional groups on silica monoliths may undergo further derivatization. Greater selectivity and sensitivity can thus be obtained. On the other hand, organic polymer materials have diverse properties because numerous monomers and crosslinkers are available for fabrication of the monoliths. In addition, they can also undergo derivatization to satisfy various applications.

-

3.

Online sample pretreatment involving monoliths is convenient. Unlike particle-packed columns, monolithic materials require no frits and are synthesized in situ. This affords convenience when connected to analytical instruments.

-

4.

Silica and organic polymer monolithic materials are complementary to each other. Silica has better resistance to organic solvents and elevated temperatures than organic polymers, whereas shrinkage, a drawback of silica monoliths, is not an obvious obstacle in the case of organic polymer materials.

-

5.

Biocompatibility of both silica and organic polymer materials is generally regarded as satisfactory. This is crucial when dealing with biological samples.

Monolithic materials represent useful approaches to fast, selective, sensitive, and automatic miniaturized extraction, particularly in biological analysis. The applications are expected to be further expanded in the future. With regard to inorganic species as target analytes, especially, few studies have been conducted. Nevertheless, monolithic materials do have shortcomings. Preparation is subject to many influential factors. So far, most monolithic materials have been home-made, so precision and accuracy among different laboratories are not guaranteed. More functional monolithic materials with more stringent analytical requirements may enable analysis of complex sample matrices. There is some way to go before monolithic materials are accepted as routine sorbent phases for sample preparation.

References

Smith RM (2003) J Chromatogr A 1000:3–27

Chen Y, Guo Z, Wang X, Qiu C (2008) J Chromatogr A 1184:191–219

Saito Y, Jinno K (2003) J Chromatogr A 1000:53–67

Cruz-Vera M, Lucena R, Cárdenas S, Valcárcel M (2009) Trends Anal Chem 28:1164–1173

Risticevic S, Niri VH, Vuckovic D, Pawliszyn J (2009) Anal Bioanal Chem 393:781–795

He L, Toh CS (2006) Anal Chim Acta 556:1–15

Svec F (2010) J Chromatogr A 1217:902–924

Buchmeiser MR (2007) Polymer 48:2187–2198

Svec F, Huber CG (2006) Anal Chem 78:2100–2107

Fernández M, Miguel HMG-S, Estela JM, Cerdá V (2009) Trends Anal Chem 28:336–346

Ma J, Zhang L, Liang Z, Zhang W, Zhang Y (2009) Anal Chim Acta 632:1–8

Potter OG, Hilder EF (2008) J Sep Sci 31:1881–1906

Svec F (2006) J Chromatogr B 841:52–64

Zhang YP, Ye XW, Tian MK, Qu LB, Choi SH, Gopalan AI, Lee KP (2008) J Chromatogr A 1188:43–49

Zhang YP, Fan LQ, Lee KP, Zhang YJ, Choi SH, Gong WJ (2007) Microchim Acta 158:353–360

Roberts MWH, Ongkudon CM, Forde GM, Danquah MK (2009) J Sep Sci 32:2485–2494

Wei F, Fan J, Zheng M-M, Feng Y-Q (2010) Electrophoresis 31:714–723

Zheng M-M, Zhang M-Y, Feng Y-Q (2009) J Sep Sci 32:1965–1974

Wu Y-B, Wu J-H, Shi Z-G, Feng Y-Q (2009) J Chromatogr B 877:1847–1855

Wu J-Y, Shi Z-G, Feng Y-Q (2009) J Agric Food Chem 57:3981–3988

Luo D, Chen F, Xiao K, Feng Y-Q (2009) Talanta 77:1701–1706

Zhang H-J, Huang J-F, Lin B, Feng Y-Q (2007) J Chromatogr A 1160:114–119

Lin B, Zheng M-M, Ng S-C, Feng Y-Q (2007) Electrophoresis 28:2771–2780

Huang K-J, Zhang M, Xie W-Z, Zhang H-S, Feng Y-Q, Wang H (2007) Anal Chim Acta 591:116–122

Huang K-J, Zhang M, Xie W-Z, Zhang H-S, Feng Y-Q, Wang H (2007) Anal Bioanal Chem 388:939–946

Huang K-J, Zhang M, Xie W-Z, Zhang H-S, Feng Y-Q, Wang H (2007) J Chromatogr B 854:135–142

Wei F, Zhang M, Feng Y-Q (2007) J Chromatogr B 850:38–44

Zhang M, Wei F, Zhang Y-F, Nie J, Feng Y-Q (2006) J Chromatogr A 1102:294–301

Zhang H-J, Huang J-F, Wang H, Feng Y-Q (2006) Anal Chim Acta 565:129–135

Wei F, Zhang M, Feng Y-Q (2006) Electrophoresis 27:1939–1948

Nie J, Zhao Q, Huang J, Xiang B, Feng Y-Q (2006) J Sep Sci 29:650–655

Wen Y, Fan Y, Zhang M, Feng Y-Q (2005) Anal Bioanal Chem 382:204–210

Wei F, Fan Y, Zhang M, Feng Y-Q (2005) Electrophoresis 26:3141–3150

Nie J, Zhang M, Fan Y, Wen Y, Xiang B, Feng Y-Q (2005) J Chromatogr B 828:62–69

Fan Y, Feng Y-Q, Zhang J-T, Da S-L, Zhang M (2005) J Chromatogr A 1074:9–16

Fan Y, Feng Y-Q, Da S-L, Shi Z-G (2004) Anal Chim Acta 523:251–258

Fan Y, Feng Y-Q, Da S-L, Gao X-P (2004) Analyst 129:1065–1069

Djozan D, Baheri T, Azar MHP, Mahkam M (2007) Mater Manuf Processes 22:758–763

Thabano JRE, Breadmore MC, Hutchinson JP, Johns C, Haddad PR (2009) J Chromatogr A 1216:4933–4940

Thabano JRE, Breadmore MC, Hutchinson JP, Johns C, Haddad PR (2007) J Chromatogr A 1175:117–126

Wen Y, Wang Y, Feng Y-Q (2007) J Sep Sci 30:2874–2880

Faure K, Delaunay N, Alloncle G, Cotte S, Rocca J-L (2007) J Chromatogr A 1149:145–150

Jiang T, Mallik R, Hage DS (2005) Anal Chem 77:2362–2372

Yang W, Sun X, Pan T, Woolley AT (2008) Electrophoresis 29:3429–3435

Sun X, Yang W, Pan T, Woolley AT (2008) Anal Chem 80:5126–5130

Zhang L, Zhang L, Zhang W, Zhang Y (2005) Electrophoresis 26:2172–2178

Vizioli NM, Rusell ML, Carbajal ML, Carducci CN, Grasselli M (2005) Electrophoresis 26:2942–2948

Armenta JM, Gu B, Humble PH, Thulin CD, Lee ML (2005) J Chromatogr A 1097:171–178

Fan Y, Zhang M, Feng YQ (2005) J Chromatogr A 1099:84–91

Fan Y, Zhang M, Da SL, Feng YQ (2005) Analyst 130:1065–1069

Zhang H-J, Li J-S, Wang H, Feng Y-Q (2006) Anal Bioanal Chem 386:2035–2042

Yin J, Hu B, He M, Zheng M, Feng Y-Q (2009) J Anal At Spectrom 24:76–82

Zhang SW, Zou CJ, Luo N, Weng QF, Cai LS, Wu CY, Xing J (2010) Chin Chem Lett 21:85–88

Zhang S-W, Xing J, Cai L-S, Wu C-Y (2009) Anal Bioanal Chem 395:479–487

Moravcová D, Kahle V, Rehulková H, Chmelík J, Rehulk P (2009) J Chromatogr A 1216:3629–3636

Iannacone JM, Ren S, Hatcher NG, Sweedler JV (2009) Anal Chem 81:5433–5438

Chen H-X, Huang T, Zhang X-X (2009) Talanta 78:259–264

Özkara S, Say R, Andac C, Denizli A (2008) Ind Eng Chem Res 47:7849–7856

Moschou EA, Nicholson AD, Jia G, Zoval JV, Madou MJ, Bachas LG, Daunert S (2006) Anal Bioanal Chem 385:596–605

Ma Q, Chen M, Shi Z-G, Feng Y-Q (2009) J Sep Sci 32:2592–2600

Huang X, Yuan D (2007) J Chromatogr A 1154:152–157

Huang X, Yuan D, Huang B (2008) Talanta 75:172–177

Kulinski MD, Mahalanabis M, Gillers S, Zhang JY, Singh S, Klapperich CM (2009) Biomed Microdevices 11:671–678

Bhattacharyya A, Klapperich CM (2006) Anal Chem 78:788–792

Xu Y, Xu P-Z, Cao Q, Lu Q, Wen Z-Y (2008) Chin J Anal Chem 36:1636–1640

Tan A, Benetton S, Henion JD (2003) Anal Chem 75:5504–5511

Yu C, Davey MH, Svec F, Fréchet JM (2001) J Anal Chem 73:5088–5096

Armenta JM, Gu B, Thulin CD, Lee ML (2007) J Chromatogr A 1148:115–122

Altun Z, Blomberg LG, Abdel-Rehim M (2006) J Liq Chromatogr R T 29:1477–1489

Altun Z, Blomberg LG, Jagerdeo E, Abdel-Rehim M (2006) J Liq Chromatogr Relat Technol 29:829–840

Shintani Y, Zhou X, Furuno M, Minakuchi H, Nakanishi K (2003) J Chromatogr A 985:351–357

Tanaka N, Kobayashi H, Ishizuka N, Minakuchi H, Nakanishi K, Hosoya K, Ikegami T (2002) J Chromatogr A 965:35–49

Sandoval E, Pesek J (1991) Anal Chem 63:2634–2641

Nawrocki J (1991) Chromatographia 31:177–192

Zheng M-M, Lin B, Feng Y-Q (2007) J Chromatogr A 1164:48–55

Zheng M-M, Ruan G-D, Feng Y-Q (2009) J Chromatogr A 1216:7739–7746

Yu S, Geng J, Zhou P, Wang J, Feng A, Chen X, Tong H, Hu J (2008) Anal Chim Acta 611:173–181

Xu L, Lee HK (2008) J Chromatogr A 1195:78–84

Eisert R, Pawliszyn J (1997) Anal Chem 69:3140–3147

Kataoka H, Ishizaki A, Nonaka Y, Saito K (2009) Anal Chim Acta 655:8–29

Hu B, Zheng F, He M, Zhang N (2009) Anal Chim Acta 650:23–32

Mullett WM, Levsen K, Lubda D, Pawliszyn J (2002) J Chromatogr A 963:325–334

Jarmalavičiene R, Szumski M, Kornyšova O, Kłodzińsk E, Westerlund D, Krawczyk S, Mickevičius D, Buszewski B, Maruška A (2008) Electrophoresis 29:1753–1760

Geiser L, Eeltink S, Svec F, Fréchet JMJ (2008) J Chromatogr A 1188:88–96

Yu S, Geng J, Zhou P, Wang J, Chen X, Hu J (2008) J Chromatogr A 1183:29–37

Wen J, Guillo C, Ferrance JP, Landers JP (2006) Anal Chem 78:1673–1681

Johannesson N, Pearce E, Dulay M, Zare RN, Bergquist J, Markides KE (2006) J Chromatogr B 842:70–74

Nissum M, Schneider U, Kuhfuss S, Obermaier C, Wildgruber R, Posch A, Eckerskorn C (2004) Anal Chem 76:2040–2045

Jia L, Tanaka N, Terabe S (2004) J Chromatogr A 1053:71–78

Ramautara R, Ratnayake CK, Somsena GW, de Jong GJ (2009) Talanta 78:638–642

Schaller D, Hilder EF, Haddad PR (2006) Anal Chim Acta 556:104–111

Breadmore MC (2006) Anal Chim Acta 556:121–126

Chen M, Lu Y, Ma Q, Guo L, Feng Y-Q (2009) Analyst 134:2158–2164

Lord HL (2007) J Chromatogr A 1152:2–13

Ro KW, Nayak R, Knapp DR (2006) Electrophoresis 27:3547–3558

Wolfe KA, Breadmore MC, Ferrance JP, Power ME, Conroy JF, Norris PM, Landers JP (2002) Electrophoresis 23:727–733

Wu Q, Bienvenue JM, Hassan BJ, Kwok YC, Giordano BC, Norris PM, Landers JP, Ferrance JP (2006) Anal Chem 78:5704–5710

Wen J, Guillo C, Ferrance JP, Landers JP (2007) Anal Chem 79:6135–6142

Shaw KJ, Thain L, Docker PT, Dyer CE, Greenman J, Greenway GM, Haswell SJ (2009) Anal Chim Acta 652:231–233

Shaw KJ, Joyce DA, Docker PT, Dyer CE, Greenman J, Greenway GM, Haswell SJ (2009) Lab Chip 9:3430–3432

Liu L, Yu S, Yang S, Zhou P, Hu J, Zhang Y (2009) J Sep Sci 32:2752–2758

Oakley JA, Shaw KJ, Docker PT, Dyer CE, Greenman J, Greenway GM, Haswell SJ (2009) Lab Chip 9:1596–1600

Bhattacharyya A, Klapperich CM (2008) Sens Actuators B 129:693–698

Liu J, Chen C-F, Tsao C-W, Chang C-C, Chu C-C, DeVoe DL (2009) Anal Chem 81:2545–2554

Robotti KM, Yin H, Brennen R, Trojer L, Killeen K (2009) J Sep Sci 32:3379–3387

Li C, Lee KH (2004) Anal Biochem 333:381–388

Proczek G, Augustin V, Descroix S, Hennion M-C (2009) Electrophoresis 30:515–524

Xu Y, Zhang J, Zhang W-P, Zhang Z-F, Wen Z-Y (2008) Chem J Chin Univ 29:892–896

Yang Y, Li C, Lee KH, Craighead HG (2005) Electrophoresis 26:3622–3630

Yang Y, Li C, Kameoka J, Lee KH, Craighead HG (2005) Lab Chip 5:869–876

Blomberg LG (2009) Anal Bioanal Chem 393:797–807

Miyazaki S, Morisato K, Ishizuka N, Minakuchi H, Shintani Y, Furuno M, Nakanishim K (2004) J Chromatogr A 1043:19–25

Hasegawa C, Kumazawa T, Lee X-P, Fujishiro M, Kuriki A, Marumo A, Seno H, Sato K (2006) Rapid Commun Mass Spectrom 20:537–543

Kumazawa T, Hasegawa C, Lee X-P, Marumo A, Shimmen N, Ishii A, Seno H, Sato K (2006) Talanta 70:474–478

Hasegawa C, Kumazawa T, Lee X-P, Marumo A, Shinmen N, Seno H, Sato K (2007) Anal Bioanal Chem 389:563–570

Kumazawa T, Hasegawa C, Lee X-P, Hara K, Seno H, Suzuki O, Sato K (2007) J Pharm Biomed Anal 44:602–607

Bonaduce I, Cito M, Colombini MP (2009) J Chromatogr A 1216:5931–5939

Lluveras A, Bonaduce I, Andreotti A, Colombini MP (2010) Anal Chem 82:376–386

Altun Z, Hjelmström A, Abdel-Rehim M, Blomberg LG (2007) J Sep Sci 30:1964–1972

Abdel-Rehim M, Persson C, Altun Z, Blomberg L (2008) J Chromatogr A 1196–1197:23–27

Altun Z, Hjelmström A, Blomberg LG, Abdel-Rehim M (2008) J Liq Chromatogr Relat Technol 31:743–751

Altun Z, Skoglund C, Abdel-Rehim M (2010) J Chromatogr A 1217:2581–2588

Rainer M, Sonderegger H, Bakry R, Huck CW, Morandell S, Huber LA, Gjerde DT, Bonn GK (2008) Proteomics 8:4593–4602

Liang S-S, Chen S-H (2009) J Chromatogr A 1216:2282–2287

Shi Z-G, Chen F, Xing J, Feng Y-Q (2009) J Chromatogr A 1216:5333–5339

Prasad BB, Tiwari MP, Madhuri R, Sharma PS (2010) Anal Chim Acta 662:14–22

Abdel-Rehim M (2010) J Chromatogr A 1217:2569–2580

Prieto A, Basauri O, Rodil R, Usobiaga A, Fernández LA, Etxebarria N, Zuloaga O (2010) J Chromatogr A 1217:2642–2666

Namera A, Nakamoto A, Nishida M, Saito T, Kishiyama I, Miyazaki S, Yahata M, Yashiki M, Nagao M (2008) J Chromatogr A 1208:71–75

Nakamoto A, Nishida M, Saito T, Kishiyama I, Miyazaki S, Murakami K, Nagao M, Namura A (2010) Anal Chim Acta 661:42–46

Saito T, Morita S, Kishiyama I, Miyazaki S, Nakamoto A, Nishida M, Namera A, Nagao M, Inokuchi S (2008) J Chromatogr B 872:186–190

Saito T, Yamamoto R, Inoue S, Kishiyama I, Miyazaki S, Nakamoto A, Nishida M, Namera A, Inokuchi S (2008) J Chromatogr B 867:99–104

Saito T, Yamagiwa T, Kishiyama I, Miyazaki S, Nakamoto A, Nishida M, Namera A, Inokuchi S (2009) Chromatographia 70:519–526

Miyazaki S, Yamada T, Ohta S, Sarro T, Namera A, Ohira M (2010) Bunseki Kagaku 59:213–218

Acknowledgements

This work was partly supported by grants from the National Science Fund for Distinguished Young Scholars (no. 20625516), the National Key Technologies R&D Program (2006BAF07B03), and the Science Fund for Creative Research Groups (no. 20921062), NSFC.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in the special issue Analytical and Bioanalytical Science in China with Guest Editors Lihua Zhang, Qiankun Zhuang, and Yukui Zhang.

Rights and permissions

About this article

Cite this article

Xu, L., Shi, ZG. & Feng, YQ. Porous monoliths: sorbents for miniaturized extraction in biological analysis. Anal Bioanal Chem 399, 3345–3357 (2011). https://doi.org/10.1007/s00216-010-4190-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-010-4190-x