Abstract

In this paper, the direct coupling between stir membrane extraction and infrared spectroscopy working under transmission mode is presented for the sensitive and selective determination of the total hydrocarbon index in waters. For this purpose, a new extraction unit was built using stainless steel in order to maximize the adsorption of the target analytes in the 40-μm-thick polytetrafluoroethylene membrane. The method allows the determination of hydrocarbons in the presence of grease, using hexadecane and stearic acid as model compounds, respectively. The proposal is optimized in depth, taking into account the main experimental variables such as membrane thickness, extraction time, and stirring and sample volume. Later on, the method was characterized on the basis of its linearity, precision, and limits of detection. The combination allows the determination of the hydrocarbon index with a limit of detection of 18 μg L−1, the precision being (expressed as relative standard deviation) better than 4.3%. The analytical method provides a high sample throughput since some extractions can be performed in parallel, the relative standard deviation between devices being better than 8%. The proposed analytical method is finally compared in terms of analytical figures with counterpart ASTM method, recently presented.

Stir membrane extraction using infrared-transparent materials is a useful tool for the determination of the hydrocarbon index in water samples. The hydrocarbons are isolated and preconcentrated in a polymeric membrane which is later on monitored by infrared spectroscopy. This approach allows the determination of the hydrocarbon index with a limit of detection of 18 μgL-1 and precision better than 4.3%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The development of simple methods that allow rapid decision making with the use of less resources and human efforts is a clear trend in analytical sciences [1]. In this context, infrared spectroscopy (IR) can be considered a rapid instrumental technique that provides useful qualitative information which permits the characterization of new materials and substances according to their spectra [2]. The lack of sensitivity and selectivity, taking into account the large number of substances that may absorb IR radiation, are the main limitations when the technique is employed for qualitative and quantitative purposes. In these cases, the extraction/isolation of the target analytes and even their preconcentration is crucial for the development of competitive analytical methodologies.

Liquid–liquid extraction has been extensively used for the improvement of sensitivity and selectivity in infrared determinations [3, 4]. However, this extraction technique presents some shortcomings, such as high consumption of organic solvents that limit its applicability. Liquid-phase microextraction emerging in the mid–late 1990s as an alternative to the conventional approach and its combination with infrared spectroscopy, both in attenuated total reflection (ATR) [5] and diffuse reflectance [6] modes, has been successfully accomplished.

Solid-phase extraction (SPE) has also been employed for the isolation/preconcentration of target analytes before IR determination [7–9]. In most of these methodologies, the IR spectra recording is performed in the eluent, and therefore an appropriate organic solvent (usually halogenated hydrocarbons) is necessary to elute the retained analytes. However, the analytes can be also monitored in the sorbent surface [10–12], improving the sensitivity of the determination since no elution is required. The evolution of SPE towards miniaturization has been also reflected in IR detection. In this sense, solid-phase microextraction (SPME) has been successfully employed for chemical agent identification [13] and also for the IR determination of nitroaromatic compounds in waters [14]. Moreover, IR can also be useful from a theoretical point of view since it permits the monitoring of the adsorption process as well as the calculation of partitioning of target solutes between a thin film of adsorbent and a donor solution [15].

Taking into account that both SPE and SPME are surface-dependent processes, the extraction capabilities dramatically depend on the extractant geometry. In this context, polymeric membranes are promising materials thanks to their enhanced sample/adsorbent contact surface. Furthermore, the large number of commercially available membranes (with diverse polarity and porosity) makes them a versatile tool for the extraction of analytes of different nature. After the extraction, membranes can be chemically eluted or directly monitored by using a spectroscopic technique. In this sense, IR has been employed using appropriate membrane for the determination of nitrate [16], benzene, toluene, ethylbenzenes, and xylene [17], and also oil and grease [18, 19].

Recently, a new micro-SPE methodology based on the use of polymeric membrane has been reported. In this methodology, the so-called stir membrane extraction, the excellent extraction capabilities of polymeric membranes, and the well-known beneficial effect of stirring were exploited [20]. For this purpose, a novel unit was designed in order to allow the stirring of the membrane during the extraction procedure. Besides its simplicity and versatility, the proposal allows the rapid extraction and preconcentration of the analytes from the sample matrix. In this paper, the combined use of stir membrane extraction and infrared spectroscopy is proposed for the determination of the hydrocarbon index in waters. The main novelty of the approach is the in-membrane monitoring of the extraction unit. It requires the use of a thin membrane (40 μm) which permits the transmission of the infrared beam. The material of the membrane should present a negligible absorption in the infrared region selected for analyte determination. Polytetrafluoroethylene (PTFE) was proven to be the most appropriate membrane for the model analytical problem selected.

Experimental

Reagents and samples

All reagents were of analytical grade or better. Mineral oil standards type A and type B, which consist of mixtures of hydrocarbons in the diesel oil and lubricating oil range, respectively, were purchased from Fluka (Buchs, Switzerland). These environmental standards are used for hydrocarbon index determination according to EN ISO 9377-2 to provide a mixture of hydrocarbons within the range C10 and C40. Besides an individual aliphatic hydrocarbon, hexadecane (also from Fluka) was employed for optimization purposes. Stock standard solutions of 1/1 (v/v) diesel oil/lubricating oil and hexadecane were prepared in methanol of HPLC-grade at a concentration of 6 g L−1 and stored at 4 °C. Working solutions were prepared by dilution of the stocks in deionized water or methanol as required. Methanol at a final concentration of 10% (v/v) was added to standards and spiked water samples in order to stabilize the hydrocarbons in the aqueous media.

PTFE membranes (40 μm in thickness and 4.7 cm in diameter), which were purchased from Pall Corporation (NY, USA), were directly coupled to the stir membrane extraction system without any pretreatment.

Fourier transform infrared instrument

All experiments were carried out on a Bruker (Karlsruhe, Germany) Equinox 55 spectrometer equipped with a mercury cadmium telluride detector. Spectra were collected between 4,000 and 700 cm−1 at a 4-cm−1 resolution with 32 co-added scans and a scanning velocity of 60 kHz. Data collection and processing were done using OPUS software (Bruker, Ettlingen, Germany) 6.5 version. Measurements were performed in the transmission mode using the appropriate sampling accessory of the Fourier transform IR (FT-IR) spectrometer. The spectra were integrated between 3,000 and 2,800 cm−1, and the spectrum area was used as analytical signal. No pretreatment of the spectra was required.

Stir membrane system and instrumental coupling

The extraction unit, which is described elsewhere [20], is presented in Fig. 1a. It was custom-built from two main cylindrical concentric parts and made of stainless steel in order to prevent potential adsorption of the target analytes. The PTFE membrane was placed in the upper part of the internal cylinder, and the unit was sealed by displacing the external part through the internal one. Then an iron wire (1.4 cm) was introduced through prepierced orifices to allow the magnetic stirring of the device. In this configuration, the effective surface of the exposed membrane was 226 mm2 (113 mm2 each face). The dimensions of this design allow its direct coupling with the transmission sampling accessory of the FT-IR spectrometer as it can be seen in Fig. 1b.

Experimental procedure

The proposed extraction procedure is as follows: 10 mL of the aqueous standard or sample (containing also 10% (v/v) of methanol) was added to a 25-mL extraction vial and placed in a magnetic stirrer. Later on, the stir membrane unit is introduced in the vial and stirred at 500 rpm for 30 min, the extraction of the analytes being performed. Once finished, the extraction unit is withdrawn from the solution by means of tweezers and located in the transmission accessory of the FT-IR spectrometer to accomplish the in-surface determination of the total hydrocarbon index. The membrane is completely dry when it is taken out from the solution, and therefore no interference from water and methanol is observed.

After each extraction, the membrane is cleaned by immersion in methanol and continuous stirring for 10 min.

Results and discussion

The determination of hydrocarbons in waters is a relevant analytical problem which requires simple and sensitive enough analytical procedures. Most of the available standard methods consist in either gravimetric or infrared approaches. Infrared detection is an awesome alternative of choice when the total hydrocarbon index is determined, taking into account the spectral characteristics of the target compounds. However, the limited sensitivity of the technique requires a previous extraction and preconcentration of the analytes which are frequently performed by means of a liquid–liquid extraction. Due to their spectral suitability, halogenated solvents such as carbon tetrachloride or trichlorofluoroethane are preferred for these extractions.

The development of new and simple approaches which minimize or even avoid the use of halogenated solvents is desirable, taking into account their environmental and toxicity problems. In fact, a new ASTM method [21] (D7575-10) for the determination of oil and grease has been recently presented. The method is based on the extraction of both types of compounds with an appropriate membrane and its subsequent infrared determination. In this case, the sample is filtered through the membrane using a syringe.

The combination of the stir membrane extraction and FT-IR detection can be an alternative of choice to this approach, taking into account its extraction capabilities in terms of sensitivity. Moreover, stir membrane extraction can be beneficial when complex samples (containing particles) are analyzed since the membrane clogging is avoided.

Selection of the membrane for analyte extraction

The nature of the membrane is a crucial issue in the developed methodology. On the one hand, the membrane should interact with the target analytes in order to achieve their quantitative isolation and effective preconcentration from the sample matrix. On the other hand, it should not absorb all the photons coming from the interferometer, allowing the interaction between the IR radiation and the analytes.

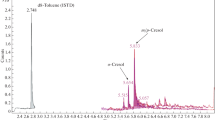

Fluoropolymers are a good alternative of choice for the extraction and preconcentration of hydrophobic analytes from aqueous samples. In this sense, PTFE also presents a simple IR spectrum with a wide spectroscopic window which can be exploited for the determination of hydrocarbons. Figure 2 shows the FT-IR spectra (in the transmission mode) of the PTFE membrane and hexadecane, the last one being selected as model hydrocarbon for optimization purposes. Since the PTFE does not present intense absorption bands in the range from 3,000 to 2,800 cm−1, it allows the determination of hydrocarbons based on their stretching bands.

On the other hand, the thickness of the membrane plays a key role in the determination of hydrocarbons. This aspect is clearly presented in Fig. 3, where the single beams obtained for different membrane thickness are presented. As can be seen, values higher than 93 μm do not permit the transmission of the infrared beam for the interferometer to the detector since a flat line is observed. Taking into account that the thickness of the membrane also affects its mechanical stability, membranes of 40 μm were employed for further studies.

Optimization of the extraction procedure

For simplicity, the optimization of the whole procedure was developed using hexadecane as model analyte. The involved variables were optimized following a one-at-a-time optimization approach using the spectra area between 3,000 and 2,800 cm−1.

The stability and homogeneity of the samples, which are limited by the hydrophobic nature of the target analytes, play a crucial role in the developed methodology. The stability of the hydrocarbons can be improved by adding to the raw sample an appropriate amount of organic solvent, such as methanol. For this purpose, the effect of the concentration of methanol in both method sensitivity and the precision of the measurements was deeply studied. The obtained results, which are presented in Fig. 4, indicate an evident improvement of the precision with increasing methanol content although the extraction rate decreases. The optimum percentage of methanol (10% v/v) was selected as compromise between sensitivity and precision. In this sense, after sampling, the corresponding volume of methanol was added to the sample in order to stabilize the analytes until their analysis.

In general, a process occurring under the influence of diffusional contributions is characterized by an increase of the extraction rate with increase in the stirring velocity and/or the extraction time. Therefore, the effect of both operational variables on the analytes extraction was quantitatively studied. First of all, the stirring velocity was evaluated in the range from 0 to 1,100 rpm, each point being measured in triplicate. The extraction increases up to 250 rpm, remaining almost constant for higher velocities. For this reason, a stirring rate of 500 rpm (located in the asymptotic region of the response curve) was selected as optimum for further studies.

As it is the case with other solid-phase microextraction approaches, the proposed extraction technique is time dependent. Extraction time was evaluated in the range 0–60 min at two different concentrations levels, namely 50 and 5 mg L−1. In the case of 50 mg L−1, the extraction increased with the extraction time, two different zones being observable (see Fig. 5a). From 0 to 30 min, the extraction markedly increases with extraction time, while from 30 to 60 min the increase is less pronounced probably due to the saturation of the membrane with the target analytes. On the contrary, when the analyte was prepared at a lower concentration (5 mg L−1), the extraction linearly increases with time from 0 to 60 min (see Fig. 5b). For further studies, the extraction time was fixed at 30 min since it provides a high extraction level as well as acceptable sample throughput (taking into account that various extractions can be performed in parallel).

Finally, the effect of the sample volume on the analyte extraction was evaluated in the range of 5–25 mL. The analytical signal for hexadecane increased in the interval 5–10 mL and decreased over this volume. This effect can be ascribed to the location of the extraction unit into the extraction vial as well as the lower density of hydrocarbons compared with water. When an aliquot of 10 mL of sample is employed, the vortex is created exactly over the membrane favoring the analyte extraction. Therefore, this volume was selected as the optimum volume.

Selectivity of the stir membrane extraction

Finally, the extractability of grease was evaluated using stearic acid as model analyte. For this purpose, an aqueous standard containing this compound at a final concentration of 50 mg/L was analyzed by the proposed method, negligible signal being obtained. Figure 6 shows the spectra for the extraction of (a) an aqueous standard of hexadecane (at a final concentration of 50 mg/L) and (b) an aqueous standard containing hexadecane and stearic acid (both at a final concentration of 50 mg/L). As can be seen, the signals are comparable, which indicates that the presence of grease does not affect to the extraction of hydrocarbons by the proposed method.

Spectra obtained for the extraction of an (A) aqueous standard of hexadecane (at a final concentration of 50 mg/L) and (B) an aqueous standard containing hexadecane and stearic acid (both at a final concentration of 50 mg/L). Hexadecane and stearic acid are selected as model hydrocarbon and grease, respectively

Analytical features

Once optimized, the method was quantitatively evaluated. There is a lack of agreement regarding how to perform the calibration for “oil-in-water” analysis. Some methods, based on infrared measurement of the organic extracts, use an octane–cetane–benzene (OCB) (2,2,4-trimethylpentane-iso-octane-), hexadecane (cetane), and benzene mixture as standard, where the total hydrocarbon content is presented as an OCB value. Other methodologies use “diesel standard” and “lubricating oil” for the determination of hydrocarbons in water. It is clear that hexadecane cannot be used as reference standard, a more appropriate standard being necessary. In this article, mineral oil standards type A and type B, which consist of mixtures of hydrocarbons in the diesel oil and lubricating oil range, respectively, were used for calibration. These environmental standards are used for hydrocarbon index determination according to EN ISO 9377-2 to provide a mixture of hydrocarbons within the range C10 and C40.

The calibration model for the total response of hydrocarbons in the range studied (C10–C40) was constructed by analyzing 13 working standards of 1/1 (v/v) diesel oil/lubricating oils at different concentrations (between 0.001 and 180 mg L−1) in aqueous solution containing a 10% of methanol. Two different linear ranges appeared. The first one, obtained for low concentrations (up to 0.75 mg L−1), seemed to be very sensitive. In the second linear range obtained for higher concentrations, the calibration slope was substantially lower (see Table 1). This peculiar behavior can be ascribed to the foundation of the extraction. In this sense, adsorption presents some disadvantages over absorption such as limited extraction capacity, incomplete desorption (due to the very strong interaction of analyte/adsorbent), and displacement effects, among others. The limited extraction capacity may be responsible for these double linear ranges. In fact, at high concentrations, the membrane is near saturation and, therefore, the adsorption is restricted.

The method detection limit, defined by the US EPA, was used to estimate the minimum detectable concentration for the hydrocarbons, which was found to be 18 μg L−1. This value was concordant with the one obtained using a signal-to-noise ratio of 3.

The repeatability of the method was evaluated at 60 mg L−1 and 60 μg L−1 in quintuplicate, the results expressed as relative standard deviation being 3.4% and 4.5%, respectively. The reproducibility between devices is a key aspect in making possible the transference of the new extraction approach to other laboratories. For this reason, five independent devices were quantitatively evaluated by extracting aqueous standards (60 mg L−1 of hydrocarbons) by the proposed method. The results show a good reproducibility (under 8% of relative standard deviation (RSD)) between extraction devices.

Finally, the proposed methodology was evaluated by means of a recovery study. For this purpose, different samples (including river, tap, and well waters) spiked at a final concentration of 0.5 mg L−1 were analyzed by triplicate. The samples were previously analyzed, hydrocarbon not being found. The relative recovery values, which are summarized in Table 2, were in the range from 77% to 105%.

Conclusions

In this paper, the direct coupling between stir membrane extraction and infrared spectroscopy is proposed for the first time. In this coupling, the selection of the IR sampling technique plays a key role, with sensitivity connotations. Attenuated total reflection is a valuable alternative for infrared sampling which is characterized by its speed and simplicity, especially when solid materials are measured. However, ATR presents a lack of sensitivity compared to transmission modes due to the lower optical path. At the same time, the higher optical length can also be a limitation in transmission mode when membranes are employed, and the thickness of the membrane has to be controlled.

The coupling of stir membrane extraction (using thin membranes) and infrared spectroscopy (working in transmission mode) is a powerful tool for analytical purposes. In fact, the limit of detection is clearly improved compared to the new ASTM method [21] (18 μg L−1 vs 1 mg L−1) while the precision is comparable in both cases. The new approach also allows the determination of hydrocarbons in the presence of grease. Besides taking into consideration the good reproducibility between devices (RSD lower than 8%), the new method presents a good sample throughput since various extractions can be performed at the same time.

The proposed method provides a global hydrocarbon index, and therefore for individual and more accurate sample characterization, a chromatographic separation should be employed.

References

Baena JR, Valcarcel M (2003) Trends Anal Chem 22:641–646

Griffiths PR, De Haseth JA (2007) Fourier transform spectrometry. Wiley, Hoboken

Gallignani M, Ayala C, Brunetto MR, Burguera JL, Burguera M (2005) Talanta 68:470–479

Armenta S, Garrigues S, de la Guardia M (2007) Anal Bioanal Chem 387:2887–2894

Lucena R, Cárdenas S, Gallego M, Valcárcel M (2005) Anal Chem 77:7472–7477

Verma D, Verma SK, Deb MK (2009) Talanta 78:270–277

Garrigues S, Vidal MT, Galliganani M, de la Guardia M (1994) Analyst 119:659–664

Daghbouche Y, Garrigues S, de la Guardia M (1995) Anal Chim Acta 314:203–212

Daghbouche Y, Garrigues S, Vidal MT, de la Guardia M (1997) Anal Chem 69:1086–1091

Alcudia-León MC, Lucena R, Cardenas S, Varlcarcel M (2008) Anal Chem 80:1146–1151

Alcudia-León MC, Lucena R, Cardenas S, Varlcarcel M (2009) Anal Chem 81:1184–1190

Armenta S, Lendl L (2009) Vib Spectrosc 51:60–64

Bryant CK, LaPuma PT, Hook GL, Houser EJ (2007) Anal Chem 79:2334–2340

Stahl DC, Tilotta DC (2001) Environ Sci Technol 35:3507–3512

Freger V, Ben-David A (2005) Anal Chem 77:6019–6025

Linker R, Shaviv A (2006) Appl Spectrosc 60:1008–1012

Karlowatz M, Ktaft M, Mizaikoff B (2004) Anal Chem 76:2643–2648

Ferrer N, Romero MT (2002) Microchim Acta 140:35–39

Romero MT, Ferrer N (1999) Anal Chim Acta 395:77–84

Alcudia-León MC, Lucena R, Cardenas S, Varlcarcel M (2009) Anal Chem 81:8957–8961

ASTM (2010) Standard test method for the solvent-free membrane recoverable oil and grease by infrared determination. ASTM D7575-10. doi:10.1520/D7575-10

Acknowledgments

Financial support from the Spanish Ministry of Science and Innovation (Grant CTQ2007-60426) is gratefully acknowledged. M.C.A.-L. also wished to express her gratitude for the predoctoral grant award (ref AP2006-03573).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alcudia-León, M.C., Lendl, B., Lucena, R. et al. Sensitive in-surface infrared monitoring coupled to stir membrane extraction for the selective determination of total hydrocarbon index in waters. Anal Bioanal Chem 398, 1427–1433 (2010). https://doi.org/10.1007/s00216-010-4040-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-010-4040-x