Abstract

A novel and efficient surfactant-assisted dispersive liquid–liquid microextraction combined with high-performance liquid chromatography–photodiode array detection was developed for the determination of phenylurea herbicides in water samples. Based on this procedure, which is a dispersive-solvent-free technique, the extractant is dispersed in the aqueous sample using methyltrialkylammonium chloride. Compared with the conventional dispersive liquid–liquid microextraction, the new extraction method has many advantages such as higher extraction efficiency, low cost, reduced environmental hazards, and consumption of less extracting solvent. A few microliters of chloroform containing an appropriate amount of methyltrialkylammonium chloride (mixture of C8–C10) was used to extract the analytes from water samples. The main parameters relevant to the extraction process (namely, type of surfactant, selection of extractant solvent, extractant volume, surfactant concentration, ionic strength, and extraction time) were investigated. The performed analytical procedure showed limits of detection ranging from 2.3 to 18 ng/L, and precision ranges from 0.6% to 2.0% (as intra-day relative standard deviation, RSD) and from 1.3% to 8.3% (as inter-day RSD) depending on the analyte. The method showed good linearity between 0.04 and 40 µg/L with squared correlation coefficients better than 0.9920. This newly established approach was successfully applied to spiked real water samples.

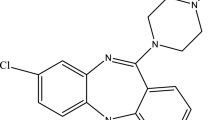

Schematic representation of the surfactant assisted dispersive liquid-liquid microextraction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The traditional liquid–liquid extraction (LLE) method has been in use for years as a basic and powerful method for sample preparation. However, it is time consuming, uses a large volume of expensive and hazardous organic solvents, and employs multistep procedures associated with the high risk of analyte losses. Nowadays, attention is focused on techniques that are environmentally friendly and reduce the cost of analysis by reduction or complete elimination of organic solvents [1].

Solid-phase extraction (SPE), which was developed as a complement to or replacement for LLE, is one of the sampling techniques most commonly used in many areas of chemistry including environmental, pharmaceutical, clinical, food, and industrial chemistry [2, 3]. SPE has several advantages over LLE. The main advantages are minimal consumption of harmful solvents, ease of automation, and shorter processing time. Although SPE uses much less solvent than LLE does, it is still in the milliliter range and normally an extra step is required to concentrate the extract down to a small volume.

Interest in microextraction techniques in analytical chemistry has been first reported in 1990 by Arthur and Pawliszyn when they introduced solid-phase microextraction (SPME) [4]. SPME is a solvent-free, simple, and fast extraction method. It has, in general, higher detection limits than SPE because the extraction is not exhaustive with a narrower application range due to the difficulties encountered when analyzing hydrophilic and non-volatile compounds [5, 6]. The major drawback of this procedure is its high cost, sample carry-over, fiber fragility, and limited lifetime of the fiber.

In recent years, a number of solvent microextraction approaches have been developed that include single-drop microextraction [7–9] and liquid-phase microextraction (LPME) [10–12]. These methods, which have been developed as alternatives to SPME, avoid some of the problems associated with SPME. They have, however, their own disadvantages such as instability of the solvent drop, formation of air bubbles in the hollow-fiber LPME, time-consuming extraction procedure, failure in most cases to easily attain equilibrium even after a long time, and low precision [7–12].

Surfactants have been widely used in extraction processes and separation sciences [10, 13–20]. In order to enhance efficiency of LPME techniques, surfactant is added into the aqueous donor phase solution [14, 15]. Also, to increase the extraction of hydrophilic drugs, carrier-mediated LPME has been reported. In this technique, ionic surfactants (as carrier) are added to the sample solution [10, 16] or are dissolved in the impregnation solvent in the pore of hollow fiber [17, 18]. In 2006, Assadi and Coworkers developed a novel LPME technique called dispersive liquid–liquid microextraction (DLLME) [21]. In this method, an appropriate mixture of extraction and disperser solvents is rapidly injected into the aqueous sample by a syringe to form a cloudy solution. The analyte in the sample is extracted into the fine droplets of the extraction solvent. After extraction, phase separation is performed by centrifugation, and the enriched analyte in the sedimented phase is determined by chromatography or spectrometry methods. The advantages of this novel method include very short extraction time, ease of operation, low cost, and high enrichment factors. Since its introduction, DLLME has been successfully applied for the determination of trace organic pollutants and metal ions in different media [22–25].

One of the main disadvantages associated with DLLME, however, is that it uses relatively high volumes (in the mL range) of a polar solvent such as methanol or acetonitrile to disperse the extraction solvent into the aqueous sample. The use of a disperser organic solvent results in lower extraction efficiency due to increased solubility of the analytes in solution. Additionally, utilization of relatively high volumes of a harmful solvent is environmentally unfriendly. In 2009, a DLLME method with little solvent consumption was developed to reduce the negative effect of disperser solvent [25]. In addition, in a novel microextraction technique (ultrasound-assisted emulsification microextraction (USAEME)) [19], a few microliter volume of water-immiscible extraction solvent is dispersed into sample aqueous solution by ultrasound-assisted emulsification without using any dispersive solvent. The ultrasound-assisted emulsification is usually carried out either at 25 °C for 10 min [19, 20] or at 35 °C for 5 min [19]. To diminish emulsification time and enhance extraction efficiency, the use of a surfactant as emulsifier in USAEME has been reported [20]. In this method, surfactant is added into the aqueous solution to accelerate the formation of fine droplets of the extraction solvent in an aqueous sample solution under ultrasound radiations [20].

In the novel DLLME technique developed here (i.e., surfactant-assisted dispersive liquid–liquid microextraction (SADLLME)), to avoid the use of a disperser organic solvent, a surfactant is used to emulsify water-immiscible organic solvent into the aqueous sample solution. A few microliters of an organic solvent containing an appropriate amount of methyltrialkylammonium chloride (mixture of C8–C10) (Aliquat 336) was used to extract the analytes from water samples. Seven phenylurea herbicides (tebuthiuron, fluometuron, diuron, propanil, siduron, linuron, and diflubenzuron) were used as model compounds. The analytes were determined by liquid chromatography–photodiode array detection. The parameters affecting extraction efficiency were also studied and optimized. The analytical performance and possible application of the method in real water sample analysis was investigated.

Experimental

Chemicals and reagents

Tebuthiuron, fluometuron, diuron, propanil, siduron, linuron, and diflubenzuron were purchased from Fluka (Buchs, Switzerland). A stock standard solution of the analytes (500 mg/L) was prepared in acetonitrile and stored at −4 °C.

An intermediary standard solution at a concentration of 2 mg/L was prepared by diluting the standard solution in methanol. More diluted working solutions were prepared daily by diluting the intermediary standard solution with HPLC water.

HPLC-grade methanol, acetonitrile, and CHCl3 (99%) were purchased from Caledon Laboratories (Georgetown, ON, Canada). CS2 (99%), CCl4 (99%), CH2Cl2 (99%), C2Cl3F3 (98%), HPLC-grade water, methyltrialkylammonium chloride (mixture of C8–C10) (Aliquat 336), trioctyl phosphine oxide (TOPO), oleic acid, and diphenylamine (as the internal standard (IS)) were obtained from Merck (Darmstadt, Germany). Other reagents and solvents were also obtained from Merck.

HPLC analysis

A Hewlett-Packard 1090-II liquid chromatograph (now Agilent, Palo Alto, CA, USA) equipped with a UV–Vis diode array detector was used. The system was equipped with a Rheodyne 7125i injector with a 20-μL loop. Separations were carried out at room temperature on a 5-μm, 125 × 4 mm I.D. C18 reversed-phase column (LiChrospher 100 RP-18) preceded by a guard column (10 × 4 mm, 5 μm) of the same packing material from Merck (Darmstadt, Germany).

Gradient elution was accomplished by using acetonitrile (solvent A) and a 12 mM phosphate buffer solution at pH 2.5 (solvent B). The gradient contained the following steps: 0–2 min isocratic 20% A; 2–24 min linear gradient from 20% A to 50% A; 24–26 min isocratic 50% A; 26–28 min linear gradient from 50% A to 70% A; 28–32 min linear gradient from 70% A to 90% A. The mobile phase was constantly degassed using helium sparging and used at a flow-rate of 1.0 mL/min. The detections were performed at 245 nm for diuron and propanil at 250 nm for tebuthiuron, fluomethuron, siduron, diflubenzuron, and linuron and at 280 nm for diphenylamine.

Extraction procedure

For the SADLLME, an aliquot of 5.0 mL of an aqueous solution containing the analytes was placed in an 8-mL glass test tube with a conical bottom. CHCl3 (73 μL) containing 5% (w/v) Aliquat 336 was injected into the sample solution using a 100-μL GC syringe, and the mixture was then gently shaken for 30 s until a cloudy solution was formed in the test tube. The cloudy solution contained very fine droplets of CHCl3 dispersed in the aqueous sample, and the analytes were extracted into the fine droplets. After centrifugation of the mixture at 3,800 rpm for 6 min, the extraction phase was settled at the bottom of the conical test tube (about 40 μL). The deposited phase was transferred to another test tube with a conical bottom using a 50-μL HPLC syringe. The extracted phase was evaporated to a volume of about 4 μL with a gentle stream of nitrogen gas (∼2-min evaporation time). The residue was dissolved in 21 μL of water–methanol mixture (1:1) containing 1 mg/L IS, and a 20-μL aliquot was injected into the HPLC system for analysis.

Real samples

River water sample was taken from the Zayandeh-rood River (Isfahan, Iran). Groundwater was collected from an area around the city of Isfahan. Tap water was collected from IUT Campus. To eliminate particulate matter, the water samples were filtered through a 0.45-μm nylon membrane filter (Millipore, Bedford, MA, USA).

Calculations

The enrichment factor (EF) was measured as the ratio between the analyte concentration in the settled phase (C set) and the analyte concentration before extraction (C o) in the aqueous sample:

Absolute recovery (R%) was defined as the percentage of the total analyte (n 0), which was extracted into the settled phase (n set).

where V set and V aq are the volumes of the sedimented organic solvent and the aqueous sample solution, respectively. The relative recovery (RR%) is calculated from the following equation:

where C found, C real, and C added are analyte concentration after addition of a known amount of the standard solution into the real sample, analyte concentration in the real sample, and concentration of a known amount of the standard solution spiked to the real sample, respectively.

Results and discussion

In the conventional DLLME method, a volume of about 0.5–3 mL of the disperser solvent (e.g., methanol, acetonitrile, or acetone), which is miscible with the organic solvent, is used to disperse a non-polar extraction solvent in an aqueous sample. The addition of this relatively large volume of the organic solvent, which is miscible with water, leads to the reduced extraction efficiency of the method due to an increase in the solubility of the analytes in the sample solution.

In ultrasound-assisted surfactant-enhanced emulsification microextraction [20], as previously described, to enhance the dispersion of extraction solvent in the aqueous sample, the surfactant is added into to aqueous phase. The solvent is emulsified in the presence of ultrasonic radiation (3-min sonication time). In comparison with USAEME [19], the addition of surfactant accelerates the formation of fine droplets of the extraction solvent in aqueous sample, hence decreasing the extraction time.

In this study, the surfactant was added to the water-immiscible extraction solvent. Following the addition of the extraction solvent to the aqueous phase, the solvent was dispersed in the solution, and a stable emulsion system was formed, without the aid of ultrasound irradiation. Due to the formation of very fine solvent droplets, the surface area among the extraction solvent and the aqueous phase is essentially large. Therefore, as it will be seen later, quick equilibrium (less than 0.5 min) was achieved due to the fast transition of analytes from aqueous phase to extraction solvent.

Method optimization

The effects of all such parameters as the kind and volume of extraction solvent, the type of surfactant, the surfactant concentration in extraction solvent, salt addition, and extraction time that could probably influence the performance of extraction needed to be investigated and optimized in order to achieve high extraction efficiency of phenylurea herbicides from water samples. Sample pH is another important parameter in the DLLME procedure. Adjustment of the pH of the sample can improve the sensitivity of the method for acidic and basic analytes. However, many authors have found that sample pH has no influence on the extraction efficiency of phenylurea pesticides [26–29]. This is because the phenylurea compounds are nearly neutral. Therefore, solution pH was not investigated in this study.

In this study, seven compounds were selected as representatives of phenylurea herbicides to determine their behavior under the extraction conditions. All the determinations were based on the ratio of the analyte peak area to the internal standard, averaged from three replicate measurements.

Selection of the surfactant

Three types of surfactant, namely the cationic (Aliquat 336), the anionic (oleic acid), and the non-ionic (TOPO), were investigated. To study the effect of surfactant type, extraction solvent (chloroform) containing 5% (w/v) each surfactant was added into the 5 mL of water sample spiked with 30 μg/L of the studied compounds. In these experiments, the sedimented phase volume was 20 μL. As a result, among the three surfactants investigated, Aliquat 336 and oleic acid give highest and lowest extraction recovery for the analytes respectively.

Since phenylurea herbicides have no acidic and basic functional groups, they are nonionizable and form no ion-pair complex with any of the surfactants. Therefore, the enhancement of extraction efficiency was not due to the formation of ion pairs. It is possible that the analytes interact with the surfactants through non-ionic intermolecular forces such as dispersion and polar interactions [18]. In the previous reports [17, 18, 30], Aliquat 336 has been applied for the extraction of both dissociate and associated forms of analytes. According to the results, Aliquat 336 was selected as the best surfactant.

Selection of the extraction solvent

The selection of a suitable extraction solvent is critical for the DLLME process. In the selection of the extraction solvent, certain properties of the solvent that need to be considered are: (1) higher density than that of water, (2) good chromatographic behavior, (3) ability to extract analytes of interest, and (4) low solubility in water. Based on these requirements, five different extraction solvents including CCl4 (density, 1.59 g/mL), CS2 (density, 1.26 g/mL), CH2Cl2 (density, 1.33 g/mL), CHCl3 (density, 1.48 g/mL), and C2Cl3F3 (density, 1.58 g/mL) were selected. In order to pick up a constant volume of the deposited phase (20 μL), different volumes of the extraction solvents (35, 30, 100, 50, and 39 μL) of C2Cl3F3, CCl4, CH2Cl2, CHCl3, and CS2 containing 5% w/v Aliquat 336 were used, respectively. The average peak area (triplicate) and the standard deviation for the different extraction solvents are depicted in Fig. 1. As can be seen in Fig. 1, the extraction efficiencies using CHCl3 obtained for all the analytes were higher than those with other solvents. Therefore, CHCl3 was selected as the extraction solvent for the purposes of this study.

Effect of surfactant concentration in extraction solvent

Variations in Aliquat 336 concentration (as the disperser) cause changes in the volume of the sedimented organic solvent. To avoid this and also to achieve a constant volume of the sedimented organic solvent, chloroform volumes containing various amounts of Aliquat 336 were studied. Constant experimental conditions were used that included the use of different chloroform volumes (i.e., 55, 55, 54, and 52 μL) containing 1.0%, 2.0%, 5.0%, and 10.0% (w/v) Aliquat 336, respectively. In this step, the volume of the sedimented phase was kept constant (20 μL). The effect of Aliquat 336 concentration on extraction efficiency is shown in Fig. 2 As can be seen, extraction efficiency for tebuthiuron was slightly reduced with increasing surfactant concentration up to 2%, beyond which it remained constant. Extraction efficiency for fluometuron, diuron, and linuron were almost constant with increasing surfactant concentration. For other compounds, extraction efficiency appeared to reach its maximum at 5% concentration of the surfactant. So, the 5% w/v was selected as the optimum concentration of Aliquat 336.

Effect of extraction solvent volume

A volume range (42–105 μL) of the extraction solvent containing 5% (w/v) Aliquat 336 was used to estimate the influence of different volumes of the extractant on extraction recovery. Figure 3 shows the curves for sedimented phase volume versus volume of the extraction solvent. As can be seen, increasing the extraction solvent volume from 42 to 105 μL caused a corresponding increase in the volume of the sedimented phase (9.0–70 μL). Figure 4 displays the effect of chloroform volume on the extraction efficiency of phenylurea herbicides. The maximum response was obtained when 73 μL CHCl3 was used. Using 105 μL CHCl3, however, did not cause any significant changes in extraction efficiency. Based on these results, 73 μL of CHCl3 was chosen for further experiments.

Effect of salt concentration

In DLLME experiments, the extraction of the analytes can be enhanced or retarded by adding salts [24, 31] depending on the nature of the analytes. To investigate the influence of ionic strength on the performance of DLLME, various concentrations of NaCl (0–0.33 g/mL) were studied. Increasing the ionic strength of the sample from 0 to 0.33 g/mL increased the volume of the deposited organic solvent due to the decrease occurring in the solubility of the extraction solvent in aqueous phase. The results showed a slight decrease in the extraction efficiency with increase in NaCl concentration for the selected phenylurea herbicides. Hence, no salt was added in the following experiments.

The effect of extraction time

The effect of extraction time (interval time after shaking a mixture of the surfactant and the extraction solvent in the aqueous sample and prior to centrifugation onset) on the performance of SADLLME is considered to be a major parameter that must be investigated and evaluated. This parameter was studied over the range of 0.5–5 min under constant experimental conditions. The extraction time profiles show that peak area variations versus extraction time were not significant. It is because after the formation of the cloudy solution, the surface area between the extraction solvent and the aqueous sample became significantly large. So, the transfer of the analytes from the aqueous sample to the extraction solvent took place very quickly. The equilibrium state subsequently obtained correspondingly fast and the extraction time was rather short. The most time-consuming step in this method was the centrifugation of the cloudy solution on the basis of the extraction procedure, which took about 6 min. The method can, therefore, be considered as very rapid, which is the most distinct benefit of the DLLME technique over other microextraction methods [21, 32].

Method validation

The following optimum conditions were selected: 5.0 mL of the sample solution, 73 μL CHCl3 as the extraction solvent containing 5% (w/v) Aliquat 336, and 6.0 min centrifugation at 3,800 rpm at room temperature, without any salt addition. Under these conditions, precision, linear range, limit of detection, recovery, and the enrichment factor of the proposed method were investigated. The results are presented in Table 1.

The calibration curve was linear in the range 0.1–40 μg/L for tebuthiuron, fluometuron, propanil, diuron, and linuron; 0.04–0.4 and 0.4–40 μg/L for siduron; and 0.04–20 μg/L for diflubenzuron. The values of the squared correlation coefficient (r 2) ranged from 0.9920 to 1.000. The intra-day precision of the method was evaluated by analyzing three spiked HPLC-grade water samples (1 μg/L). The relative standard deviations (RSDs) were in the range of 0.6–2.0% for all the analytes used. The inter-day precision of the method was determined by performing three consecutive extractions each day over a period of three working days. The inter-day RSDs varied between 1.3% and 8.3%. Limits of detection (LODs), based on three times of standard deviation of blank to slope of calibration curve (3S b/m), were between 2.3 and 18 ng/L.

The enrichment factors were obtained by three replicate extractions of water samples spiked with 1 μg/L of the analytes. The results indicate that enrichment factors varied from 128 to 198. Based on Eq. 2, absolute recoveries for the water sample spiked with 1 μg/L were estimated at about 64 to 99.

At present, the proposed method yields a very low detection limit (2.3 to 18 ng/L) compared with the records reported in previous studies of DLLME, SPE, and SPME combined with GC-MS, LC-MS, LC-fluorescence, and LC-UV for the analysis of phenylureas in water samples (Table 2). These low detection limits are probably due to high enrichment factors obtained by the method. Satisfactory inter- and intra-day precisions and high extraction recovery within a very short time are among its other advantages. The proposed method also yields better values for the enrichment factor than other methods do, especially for polar compounds.

Real water analysis

In order to determine possible matrix effects and investigate the suitability of the proposed SADLLME method for real water analysis, experiments were carried out with tap, ground, and river (Zayandeh-rood) water samples spiked at concentration levels between 0.1 and 1 μg/L with the standard solution of the studied compounds. The results showed that the waters analyzed were either free of phenylurea herbicides or had concentrations below detection limits. A good linear relationship was observed between the spiked amounts and peak areas of the analytes in real samples (r 2 > 0.99). Recoveries and precision levels were obtained as listed in Table 3. As can be seen in the table, the relative recoveries, which are defined in Eq. 3, ranged from 91% to 104%. RSDs (n = 3) ranged from 1.0% to 8.6% for a spiked concentration level of about 1 μg/L. This means that the matrices of the real water samples had no plain effects on the recovery or extraction efficiency of the analytes from real water samples. Figure 5 shows a chromatogram of the spiked Zayandeh-rood river water sample obtained after SADLLME.

Conclusion

A novel, simple, and disperser-solvent-free method based on SADLLME combined with HPLC-DAD was developed for the analysis of phenylurea herbicides in water samples. The technique exhibited excellent results for real water samples with many advantages such as very high extraction efficiency and recovery, low cost, low matrix effects, and minimum extractant solvent consumption (without the use of dispersive solvent), all of which agree with green chemistry criteria. The surfactant used for the proposed method is environmentally friendly and cost effective to such an extent that the amounts used for effective extraction schemes are minimal compared with the amounts of organic solvents used in conventional DLLME.

References

Chen Y, Guo Z, Wang X, Qiu C (2008) J Chromatogr A 1184:191–219

Poole CF (2003) Trends Anal Chem 22:362–373

Simpson NJK (2000) Solid phase extraction, principles, techniques, and applications. Marcel Dekker, New York

Arthur CL, Pawliszyn J (1990) Anal Chem 62:2145–2148

Prosen H, Zupančič-Kralj L (1999) Trends Anal Chem 18:272–282

Pawliszyn J (1999) Applications of solid phase microextraction. The Royal Society of Chemistry, UK

Psillakis P, Kalogerakis N (2002) Trends Anal Chem 21:54–64

Xu L, Basheer C, Lee HK (2007) J Chromatogr A 1152:184–192

Liu H, Dasgupta PK (1996) Anal Chem 68:1817–1821

Pedersen-Bjergaard S, Rasmussen KE (2008) J Chromatogr A 1184:132–142

Hyötyläinen T, Riekkola M-L (2008) Anal Chim Acta 614:27–37

Barri T, Jönsson J-Å (2008) J Chromatogr A 1186:16–38

Rubio S, Pérez-Bendito D (2003) Trends Anal Chem 22:471–485

Yazdi AS, Es’haghi Z (2005) J Chromatogr A 1094:1–8

Yazdi AS, Es’haghi Z (2006) J Anal Chem 61:787–793

Ho TS, Reubsaet JLE, Anthonsen HS, Pedersen-Bjergaard S, Rasmussen KE (2005) J Chromatogr A 1072:29–36

Shariati S, Yamini Y, Esrafili A (2009) J Chromatogr B 877:393–400

Zhang Z, Zhang C, Su X, Maa M, Chen B, Yao S (2008) Anal Chim Acta 621:185–192

Regueiro J, Llompart M, Garcia-Jares C, Garcia-Monteagudo JC, Cela R (2008) J Chromatogr A 1190:27–38

Wu Q, Chang Q, Wu C, Rao H, Zeng X, Wang C, Wang Z (2010) J Chromatogr A 1217:1773–1778

Rezaee M, Assadi Y, Milani Hosseini MR, Aghaee E, Ahmadi F, Berijani S (2006) J Chromatogr A 1116:1–9

Montes R, Rodríguez I, Ramil M, Rubí E, Cela R (2009) J Chromatogr A 1216:5459–5466

Wu Q, Zhou X, Li Y, Zang X, Wang C, Wang Z (2009) Anal Bioanal Chem 393:1755–1761

Chen H, Chen H, Ying J, Huang J, Liao L (2009) Anal Chim Acta 632:80–85

Tsai W-C, Huang S-D (2009) J Chromatogr A 1216:5171–5175

Mughari AR, Vázquez PP, Galera MM (2007) Anal Chim Acta 593:157–163

Chou T-Y, Lin S-L, Fuh M-R (2009) Talanta 80:493–498

Gou Y, Pawliszyn J (2000) Anal Chem 72:2774–2779

Gou Y, Eisert R, Pawliszyn J (2000) J Chromatog A 873:137–147

Yang S-T, White SA, Hsu S-T (1991) Ind Eng Chem Res 30:1335–1342

Li Y, Hu J, Liu X, Fu L, Zhang X, Wang X (2008) J Sep Sci 31:2371–2376

Berijani S, Assadi Y, Anbia M, Milani Hosseini MR, Aghaee E (2006) J Chromatogr A 1123:1–9

Carabias-Martínez R, Rodríguez-Gonzalo E, Herrero-Hernández E, Hernández-Méndez J (2004) Anal Chim Acta 517:71–79

De la Peña AM, Mahedero MC, Bautista-Sánchez A (2003) Talanta 60:279–285

Wu J, Tragas C, Lord H, Pawliszyn J (2002) J Chromatogr A 976:357–367

Saraji M, Tansazan N (2009) J Sep Sci 32:4186–4192

Acknowledgements

The authors are grateful for the financial support of this work from the Research Council of Isfahan University of Technology (IUT) and Center of Excellence in Sensor and Green Chemistry.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saraji, M., Bidgoli, A.A.H. Dispersive liquid–liquid microextraction using a surfactant as disperser agent. Anal Bioanal Chem 397, 3107–3115 (2010). https://doi.org/10.1007/s00216-010-3894-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-010-3894-2