Abstract

A method for the determination of polycyclic aromatic hydrocarbons (PAHs) in liquid pyrolysate of biomass (bio-oil) was developed with attention to greenness along with accuracy. Bio-oil obtained from preparative pyrolysis at 500 °C of poplar wood as representative biomass matrix was dissolved into acetonitrile (ACN). An aliquot of the ACN solution (0.1 mg bio-oil) was added with water (20% v/v) and spiked with perdeuterated standards, then PAHs were extracted with n-hexane and separated from phenolic interferents by silica gel solid-phase extraction (SPE). All 16 priority PAHs were detected at concentrations between 7.7 µg g−1 (naphthalene) and 0.1 µg g−1 (benz[a]anthracene) with RSD in the 6–23% range. Recovery of perdeuterated acenaphthene, phenanthrene and chrysene was 84, 93 and 90%, respectively. Results obtained from the analysis of bio-oil were used to evaluate the performance of analytical pyrolysis conducted with a heated platinum filament in off-line configuration. Two sampling procedures were compared: (1) sorption onto silica gel followed by elution with n-hexane (Py-SPE), (2) dynamic solid-phase micro-extraction followed by fibre cleanup with aqueous ammonia (Py-SPME). Emission levels of priority PAHs could be determined by Py-SPE with RSD in the 13–45% range, while Py-SPME was unsatisfactory for quantitation. Emission levels determined by Py-SPE fell in the 6.4–0.1 µg g−1 range slightly higher than those calculated from bio-oil analysis. Both Py methods were adequate for screening purposes to assess the effect of catalysts on PAH formation. In particular, they agreed to show that the content of PAHs expected in bio-oil increased dramatically when pyrolysis was conducted over HZSM-5 zeolite.

PAHs in the pyrolysate of poplar wood: novel procedures of bio-oil analysis and analytical pyrolysis of biomass

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polycyclic aromatic hydrocarbons (PAHs) are recognised as toxic and ubiquitous pyrolysis products of vegetable biomass [1]. Understanding the pyrolytic formation of PAHs is important for assessing technological problems, health hazards and environmental impacts related to the utilisation of vegetable biomass for energetic purposes, such as combustion and pyrolysis. In the case of pyrolysis, formed PAHs end up into bio-oil, a candidate liquid biofuel for power plants and transportation, adversely affecting its toxicity with implications during storage, handling and transportation [2, 3]. Whereas there are plenty of studies regarding the analysis of PAHs emitted during biomass combustion due to the importance of this source in the global and local environment, fewer works have been published dealing with the quantitative determination of PAHs in bio-oil [3–8]. In these studies, GC-MS was the technique of choice due to its selectivity and sensitivity. However, direct GC-MS analysis of bio-oil is inadequate for quantitation because PAHs occur at trace levels into a very complex mixture consisting of hundreds of organic compounds ranging in polarity from formic acid to aliphatic hydrocarbons. Although direct analysis was reported after dilution with dichloromethane [8], thermal degradation products from main biomass constituents (lignin, cellulose and hemicelluloses) strongly interfere with PAH detection so that sample pre-treatment was mandatory. Moreover, published analytical procedures were not fully validated and made use of a relatively large amount of sample and laborious work-up often with toxic solvents (e.g. benzene) or corrosive chemicals (e.g. NaOH).

Obviously, analysis of bio-oil produced by bench-scale reactors as well as in pilot or demonstration plants is necessary to obtain accurate data on the levels of PAHs. In addition, fast screening methods can be usefully adopted to investigate the influence of such different factors as process conditions, biomass feedstock and the effect of catalysts preliminary to scale-up. Analytical and microscale pyrolysis combined with GC separation and/or MS detection where heating was induced by a platinum filament [9–11] or a laser beam [12, 13] along with small reactors heated by furnace [14–16] have been successfully applied to study the effect of various parameters on PAHs formation from biomass constituents. These studies have shown that PAH production tends to increase with increasing temperature and residence time [14, 15], and is generally highest for cellulose even at relatively low temperatures from the decomposition of char, while lignin mostly degrades to benzene derivatives [12, 14].

One of the objectives of this study was to develop a simple and well-characterised procedure to analyse PAHs in liquid oil derived from biomass pyrolysis. While developing the method, attention was paid toward sustainability and safety issues (green analytical chemistry) [17–19]. In particular, solvent choice is fundamental and to this purpose there are guides based on life cycle assessments [20] and safety issues [21]. Regarding screening methods, a quantitative evaluation of analytical pyrolysis in the off-line configuration was the second objective of this study. Two different techniques of sampling were tested, for the sake of simplicity abbreviated as Py-SPE (from solid-phase extraction) and Py-SPME (from solid-phase micro-extraction). In the former case, pyrolysis products were trapped onto a sorbent and subsequently solvent-eluted; in the latter case, pyrolysate was sampled by means of a SPME micro-fibre. Poplar was selected as representative woody biomass owing to its importance as potential feedstock for renewable energy.

Experimental

Analysis of bio-oil

Bio-oil was obtained from batch pyrolysis of milled poplar wood at 500 °C for 10 min under nitrogen (Alphagaz from Air Liquide, purity >99.999%, C n H m ≤ 0.5 ppm) employing a quartz reactor described in detail elsewhere [22]. The overall yield was 33.0%. Bio-oil was dissolved into acetonitrile (ACN) and after elimination of the solvent by rotary evaporation, the resulting bio-oil sample with a water content of 5.2% w/w (determined by Karl–Fischer titration [2]) was used to prepare a stock solution at 20.0% (w/v) concentration in ACN. An aliquot of 0.5 ml of the stock solution (0.1 g bio-oil) was diluted with 0.5 ml ACN, spiked with 0.1 ml of surrogate PAH mix (Supelco for EPA 525 containing acenaphthene-d 10, phenanthrene-d 10 and chrysene-d 12 5 μg ml−1 each in acetonitrile) and mixed with 0.25 ml deionised water. This solution was extracted twice with 5 ml hexane (LLE, liquid–liquid extraction by means of a separator funnel). Hexane solutions were collected, concentrated under a gentle nitrogen stream and loaded onto a silica gel cartridge (6 ml, 1 g DSC-Si Supelco washed with ethyl acetate, dried and conditioned with 5 ml n-hexane). PAHs were eluted with 10 ml hexane. This solution was preconcentrated, spiked with 0.1 ml of 4.7 mg l−1 2-bromonaphthalene solution in ACN, further blown down to 10–50 µl and subjected to GC-MS analysis.

Variations from this procedure while developing the method are discussed in the “Results and discussion” section.

Analytical pyrolysis

The apparatus employed in off-line pyrolysis was a pyrolysis chamber fitted for a pyroprobe model 1000 (CDS Analytical Inc.) equipped with a resistively heated platinum filament (Fig. 1). A sample holder quartz tube containing an exactly weighed amount of milled poplar wood (about 8–10 mg) or poplar wood mixed with HZSM-5 zeolite (15 mg, 1/20 weight ratio; zeolite (PQ Corporation) was pretreated at 550 °C for 6 h) was introduced into the platinum coil and the probe was in turn inserted into the pyrolysis chamber. The apparatus was fluxed with a nitrogen stream at 200 ml min−1 prior to pyrolysis. Two sampling procedures were utilised: Py-SPE and Py-SPME (Fig. 1).

Py-SPE

The exit of the pyrolysis chamber was connected to a glass tube containing 100 mg of silica gel, withdrawn from a DSC-Si SPE cartridge, packed with glass wool and conditioned with n-hexane. The selected quantity of sorbent was sufficient to trap evolved PAHs quantitatively as determined by breakthrough experiments with a second layer of silica. Samples were pyrolysed at 625 °C set temperature (corresponding to a maximum temperature of 500 °C as measured with a thermocouple) for 100 s at the maximum heating rate (20 °C ms−1). After pyrolysis, the apparatus was vertically positioned, spiked with 100 μl of surrogate PAH mix solution and rinsed with 6 ml of n-hexane. The solvent was left to flow through the silica cartridge into the collecting vial. The obtained solution was then blown down to 10–50 μl under nitrogen and analysed by GC-MS. Emission levels (μg PAH g−1 pyrolysed biomass) were determined by internal calibration.

Py-SPME

In the Py-SPME procedure, a carboxen/polydimethylsiloxane (CAR/PDMS) 75 µm fibre (Supelco) was placed at the exit of the pyrolysis chamber as described in detail in a previous work [23]. Samples were pyrolysed at 700 °C set temperature for 100 s at the maximum heating rate of 20 °C m s−1. After pyrolysis, the fibre was immersed into 5 ml of 10% ammonia aqueous solution under magnetic stirring for 15 min. The fibre was gently dried under nitrogen flow for a few seconds and then subjected to GC-MS analysis. Peak areas of PAHs normalised to the amount of pyrolysed biomass exhibited a high variability (RSD 30–70% three replicates), therefore emission levels were not determined.

GC-MS

Analyses were performed in splitless mode at 280 °C in the injection port of an Agilent 6850 gas chromatograph connected to an Agilent HP 5975 quadrupole mass spectrometer. Analytes were separated by a HP-5MS fused-silica capillary column (stationary phase poly[5% diphenyl/95% dimethyl] siloxane, 30 m, 0.25 mm i.d., 0.25 µm film thickness) using helium as carrier gas. GC conditions were 20 °C min−1 from 50 to 100 °C, 5 °C min−1 from 100 °C to 300 °C and then 300 °C for 7.5 min. Mass spectra were recorded under electron ionisation (70 eV) within three m/z ranges: (1) m/z 127–241 from 0 to 35 min (10 scan/s), (2) m/z 251-253 from 35 to 40 min (10 scan/s). (3) m/z 276-278 from 40 to 50 min (15 scan/s). A wider mass range was adopted in step (1) in order to identify alkylated PAHs. In the case of Py-SPME, mass spectra were recorded in the m/z 35–450 interval.

Peak areas were integrated in the extracted mass chromatograms. Calibrations were performed in the 0.014–5.0 mg l−1 interval (R 2 in the 0.999–0.985 range) by serial dilutions of the 10 μg ml−1 PAH calibration mix (Supelco). Each calibration solution contained perdeuterated PAHs utilised to calculate PAH concentrations in bio-oil and PAH emission levels from Py-SPE. From the lowest limits in the calibration curves, LOQ was estimated to fall in the 1–4 10−3 µg g−1 interval in the analysis of bio-oil and 1–4 10−2 µg g−1 in Py-SPE. Acenaphthene-d 10 was utilised to quantify naphthalene, acenaphthylene, acenaphthene and fluorene; phenanthrene-d 10 to quantify phenanthrene, anthracene, fluoranthene and pyrene; chrysene-d 12 to quantify the remaining PAHs. Recovery of surrogated PAHs were determined with respect to the internal standard 2-bromonaphthalene. Mean values and RSD were calculated from replicate runs of the overall procedure. Absence of PAH contamination was ensured by procedural blanks of “wet” and Py-SPE analyses.

Results and discussion

Analysis of bio-oil

Solubilisation of bio-oil into a suitable solvent was the first important step to obtain a homogeneous and representative test solution. Acetonitrile (ACN) was a powerful solvent to this purpose, due to its capacity to dissolve solutes ranging in polarity from water to aromatic hydrocarbons. Once bio-oil was dissolved into ACN, PAHs could be extracted by liquid–liquid extraction (LLE) with an immiscible solvent like n-hexane. In terms of greenness, ACN was not considered an ideal solvent [20], thus we kept its utilisation at lowest. Hexane was not replaced by heptane, which was considered safer [21], in order to avoid loss of PAHs in pre-concentration steps. Cyclohexane could be utilised as an alternative to hexane [3].

A main drawback of LLE was the concurrent partitioning of volatile carboxylic acids (e.g. acetic acid) and lignin phenols into hexane. Therefore, during method development, the hexane solution was washed with an alkaline aqueous solution in accordance to other studies [3, 4]. However, washing with aqueous KOH (1.0 M, 2 ml) greatly reduced but did not completely eliminate lignin phenols. Hence, SPE cleanup with silica gel was applied in order to separate oxygenated aromatics along with aliphatic hydrocarbons from PAHs. SPE was preferred over column chromatography adopted in previous studies [3–5] in order to reduce solvent utilisation and labour time. Hexane washing (5 ml) followed by dichloromethane/hexane 1/1 (5 ml) elution was selected in a preliminary stage in order to separate aliphatic from aromatic hydrocarbons and phenols from PAHs [4]. Recoveries of surrogate PAHs resulting from this initial procedure, reported in Table 1, were unsatisfactory. The need to increase recovery prompted us to improve the accuracy of the procedure meanwhile taking into consideration aspects related to greenness.

First of all, the content of water was a critical factor in LLE. A model experiment was performed by equilibrating at room temperature a standard solution of PAHs (5 mg l−1 in 2.0 ml hexane) with 2.0 ml ACN containing increasing amount of water. GC-MS analyses of the hexane/ACN mixture showed that the level of PAHs partitioning into hexane ranged from 18% (dibenzo[a,h]anthracene) to 55% (acenaphthene). When water was added into the system (0.1 ml) more PAHs partitioned into hexane (e.g. 27% and 69% for dibenzo[a,h]anthracene and acenaphthene, respectively). Partitioning of PAHs into hexane increased with increasing content of water reaching the highest levels at 20% v/v of water into ACN (range from 70%, benz[a]anthracene, to 100%, acenaphthene).

However, the presence of water favoured the distribution of interfering lignin phenols into hexane that could not be totally eliminated by alkaline washing. Considering that the content of aliphatic hydrocarbons was rather low in poplar bio-oil, separation of phenols from PAHs was pursued in the SPE cleanup by searching for a mobile phase alternative to dichloromethane/hexane. According to the guide of solvent selection in laboratory practice, ethyl acetate might be a substitute of the more toxic dichloromethane in chromatography [21]. However, lignin phenols co-eluted with PAHs from silica gel when hexane/ethyl acetate mixtures were used as mobile phase. Therefore, PAHs were eluted by utilising a sufficiently large volume of pure hexane (at least 10 ml/g silica). In this way, interfering phenols were totally retained so that the alkaline washing step could be omitted. Table 1 shows that this final procedure resulted in a good recovery of surrogate PAHs, with mean values in the 84–93% range and RSD between 6% and 11% .

An example of GC-MS trace obtained with the optimised procedure is shown in Fig. 2b and compared with GC-MS of a standard PAH solution in Fig. 2a. TIC chromatograms were dominated by aromatic hydrocarbons, principally alkylated benzofurans (#11, 15), indenes (#12) and naphthalenes (#17 and 19). Among priority PAHs, naphthalene (#14) and fluorene (#39) were clearly revealed as rather intense peaks, while heavier PAHs could be detected in the mass chromatograms reported in the inset of Fig. 2b. Alkylated PAHs represented an important group of bio-oil constituents as evidenced in the mass chromatograms depicted in Fig. 3a. Their tentative identification, reported in Table 2, was based on published retention index [5, 24]. The pattern of alkylated PAHs was dominated by methylated naphthalenes and exhibited a distribution similar to that reported in the literature for bio-oil derived from woody biomass [5].

GC-MS profiles obtained from a standard solution of PAHs (5 mg l−1 each) and b analysis of bio-oil obtained from preparative pyrolysis of poplar wood at 500 °C. In the inset extracted mass chromatograms at selected ions. Peak numbers refer to Table 2. *Contaminants

Mass chromatograms at m/z 142, 156, 170, 180, 192, 206 obtained from a the analysis of poplar bio-oil, b Py-SPE and c Py-SPME of poplar wood. Peak numbers refer to Table 2

Concentrations of priority PAHs in poplar bio-oil are reported in Table 3. Repeatability is rather satisfactory with RSD in the 6–13% range for most of the PAHs. Typically, concentrations were lower than 10 mg kg−1, similar to what observed in other studies on bio-oils from woody biomass of different origins [2, 3, 5]. PAH composition in fuels is rather variable; but in general, PAH concentrations measured in bio-oil were within or below the values reported in literature for gasoline [25, 26] and diesel fuels [10, 26]. As far as benzo[a]pyrene (#60) is concerned, its concentration in poplar bio-oil was found to be 0.26 µg g−1, a value comparable to published data (0.03-1.9 mg kg−1 [2–4]). Thus, the levels of benzo[a]pyrene in bio-oil are higher than those reported for diesel fuel (<0.1 mg l−1) [10, 26] and comparable to those reported for gasoline (e.g. 0.2–1.8 mg l−1) [26, 27].

Emission levels of priority PAHs were calculated from the yield of bio-oil and reported in Table 3. These values were used to evaluate the ability of analytical pyrolysis to predict PAH emission as discussed in the next paragraph.

Py-SPE

In a previous study devoted to the determination of emission levels by analytical pyrolysis in the off-line configuration, PAHs evolved from pyrolysis of organic materials were trapped onto a non-polar sorbent (polystyrene/divinylbenzene XAD-2 resin) and eluted with dichloromethane [9]. However, the application of this procedure to biomass was inadequate due to the strong interference by lignin phenols. Therefore, we have adopted the SPE procedure described above for the analysis of bio-oil: PAHs were trapped onto silica gel and eluted with n-hexane. The resulting chromatograms (an example in Fig. 4a) were similar to those obtained from the analysis of bio-oil, featured by peaks associated to polyaromatic compounds, principally benzofurans, indenes and naphthalenes. The pattern of alkylated naphthalene, fluorene and phenanthrene from Py-SPE was also strongly similar to that found in bio-oil, as one can see by comparing Fig. 3a and b.

GC-MS profiles obtained from Py-SPE of a poplar wood and b poplar wood with zeolite HZSM-5 (1/20) at 500 °C. In the inset extracted mass chromatograms at selected ions. Peak numbers refer to Table 2. *Contaminants

Emission levels of priority PAHs are reported in Table 4. The precision of the method was fairly satisfactory (13–45% RSD) considering that the intrinsic variability of the pyrolytic process should be high when operating with a small quantity (<10 mg) of a heterogeneous sample such as woody biomass. Emission levels determined by Py-SPE (6–0.05 µg g−1 range) were fairly comparable to those calculated from the analysis of bio-oil (3–0.03 µg g−1 Table 3) with naphthalene and fluorene as the most abundant PAHs. The highest levels found in Py-SPE were probably determined by the different operating conditions between analytical and preparative pyrolysis (e.g. pyrolysis time, trapping of pyrolysis products, etc.).

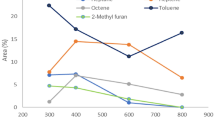

As far as catalytic pyrolysis is concerned, zeolite ZMS-5 is probably the most tested catalyst to improve fuel properties of bio-oil [5, 28, 29] and for this reason was selected in this study. It is known from analytical pyrolysis of biomass constituents that the presence of ZMS-5 increased noticeably the production of aromatic hydrocarbons; however, PAHs were not quantified [28, 29]. Accordingly, GC-MS profiles of the aromatic fraction resulting from Py-SPE of poplar wood were profoundly modified in the presence of HZMS-5 (Fig. 4b), naphthalenes became the dominant peaks and phenanthrene and anthracene (# 46 and 47) could be clearly revealed. Quantitative data reported in Table 4 show that the emission levels of PAHs markedly increased in the presence of HZMS-5 (e.g. naphthalene from 6 to 2,400 µg g−1, phenanthrene from 0.9 to 200 µg g−1 and benzo[a]pyrene from 0.1 to 6 µg g−1). This finding is in agreement with studies based on the analysis of bio-oil obtained from preparative pyrolysis of wood [5]. For instance, benzo[a]pyrene was reported to increase from undetectable levels in original bio-oil to 800 µg g−1 in HZSM-5 catalytically upgraded bio-oil [5]. In this respect, quantitative results from analytical pyrolysis with and without catalyst are consistent with literature data. It is worth underlying that the concentration of PAHs expected in bio-oil from uncatalysed pyrolysis was comparable to that found in diesel [10, 26] and gasoline [26, 27], but may exceed conventional transport fuels in bio-oil derived from pyrolysis with zeolite.

Py-SPME

Chromatograms obtained from Py-SPME of poplar wood (an example is shown in Fig. 5a) were characterised by peaks due to lignin phenols (# 10, 13, 16, 18, 21, 29, 33, 38, 41) that could not be eliminated after washing the fibre with ammonia solution. Prominent PAHs could be detected in the extracted mass chromatograms allowing a rough estimate of emission levels by external calibration. However, precision was rather low (RSD in the 30–70% range) and PAHs heavier than pyrene could not be detected. Main pyrolysis products probably saturated the fibre operating in the exposed mode [23] affecting the adsorption of PAHs. Although not suitable for PAH quantitation, Py-SPME could be proposed as a fast screening method to acquire a qualitative picture of the pyrolysate composition. As an example, the pattern of alkylated PAHs obtained by SPME sampling reported in Fig. 3c exhibited a strong resemblance with the distribution obtained from the analysis of bio-oil and Py-SPE. Likewise, the effect of zeolite on the pyrolysate composition determined by Py-SPME was in line with Py-SPE, as evidenced by comparing Figs. 5b and 4b. In the presence of zeolite the production of aromatic hydrocarbons augmented considerably, and chromatograms were featured by intense peaks due to naphthalene and its methylated forms. The absence of solvent in the Py-SPME procedure enabled the detection of volatile organic compounds, among them BTEX (benzene, toluene, ethylbenzene and xylenes) produced the most intense peaks.

GC-MS profiles obtained from Py-SPME of a poplar wood and b poplar wood with zeolite HZSM-5. Peak numbers refer to Table 2. *Contaminants

Conclusions

A simple method for the GC-MS analysis of PAHs in such a complex organic matrix as biomass liquid pyrolysate was developed and fully characterised. With respect to published methods, the one here proposed required minimal sample amount (100 mg), reduced work-up and waste generation, and avoided the use of corrosive alkaline solutions and aromatic or chlorinated solvents.

Regarding the two sampling systems tested in off-line analytical pyrolysis, Py-SPE was more adequate for the quantitation of PAHs and the emission levels were comparable to those obtained from the analysis of bio-oil. From the qualitative point of view, the solventless and faster Py-SPME procedure provided a wider picture of the pyrolysate enabling the detection of volatile compounds, such as BTEX. Overall, analytical pyrolysis is suited as a screening technique on a quantitative base in those applications where significant rather than subtle variations of PAH emission have to be investigated. For instance, in the case of catalytic pyrolysis, the energetic value of bio-oil is improved by reducing the content of oxygen through the elimination of water or carbon dioxide from organic compounds through the action of active solids. Here, the activity of different catalysts towards the unwanted production of PAHs could be investigated by the Py-SPE procedure in order to predict the levels expected in biofuels.

References

Zhang Y, Tao S (2008) Atm Environ 43:812–819

Oasmaa A, Meier D (2005) J Anal Appl Pyrolysis 73:323–334

Cirad, Aston University, BFH, An assessment of bio-oil toxicity for safe handling and transportation, Final Technical Report, Part I, 2003 (available on-line at www.pyne.co.uk).

Pakdel H, Roy C (1991) Energ Fuel 5:427–436

Williams PT, Horne PA (1995) J Anal Appl Pyrolysis 31:15–37

Horne PA, Williams PT (1996) Fuel 75:1051–1059

Padban N, Odenbrand I (1999) Energ Fuel 13:1067–1073

Tsai WT, Mi HH, Chang YM, Yang SY, Chang JH (2007) Bioresour Technol 98:1133–1137

Fabbri D, Vassura I (2006) J Anal Appl Pyrolysis 75:150–158

Fabbri D, Bevoni V, Notari M, Rivetti F (2007) Fuel 86:690–697

Cai J, Wang S, Su Q (2008) Chromatographia 68:357–363

Herring AM, McKinnon JT, Gneshin KW, Pavelka R, Petrick DE, McCloskey BD, Filley J (2004) Fuel 83:1483–1494

Lee GJ, Shin EJ, Pavelka RA, Kirchner MS, Dounas-Frazer D, McCloskey BD, Petrick DE, McKinnon JT, Herring AM (2008) Energ Fuel 22:2816–2825

Sharma RK, Hajaligol MR (2003) J Anal Appl Pyrolysis 66:123–144

McGrath TE, Chan WE, Hajaligol MR (2003) J Anal Appl Pyrolysis 66:51–70

Garcia AN, Mar Esperanza M, Font R (2003) J Anal Appl Pyrolysis 68–69:577–598

Namiesnik J (2001) J Sep Sci 24:151–153

Keith LH, Gron LU, Young JL (2007) Chem Rev 107:2695–2708

Armenta S, Garrigues S, de la Guardia M (2008) TRAC, Trends Anal Chem 27:497–511

Capello C, Fisher U, Hungerbuhler K (2007) Green Chem 9:927–934

Alfonsi K, Colberg J, Dunn PJ, Fevig T, Jennings S, Johnson TA, Kleine HP, Knight C, Nagy MA, Perry DA, Mark S (2008) Green Chem 10:31–36

Fabbri D, Torri C, Mancini I (2007) Green Chem 9:1374–1379

Torri C, Fabbri D (2009) Microchem J 93(2009):133–139

Lee ML, Vassilaros DL, White CM, Novotny M (1979) Anal Chem 51:768–773

Perez Pavon JL, del Nogal Sanchez M, Fernandez Laespada ME, Moreno Cordero B (2008) J Chromatogr A 1202:196–202

Marr LC, Kirchstetter TW, Harley RA, Miguel AH, Hering SV, Hammond SK (1999) Environ Sci Technol 33:3091–3099

Zoccolillo L, Babi D, Felli M (2000) Chromatographia 52:373–376

Carlson TR, Vispute TP, Huber GW (2008) ChemSusChem 1:397–400

Carlson TR, Tompsett GA, Conner WC, Huber GW (2009) Top Catal 52:241–252

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fabbri, D., Adamiano, A. & Torri, C. GC-MS determination of polycyclic aromatic hydrocarbons evolved from pyrolysis of biomass. Anal Bioanal Chem 397, 309–317 (2010). https://doi.org/10.1007/s00216-010-3563-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-010-3563-5