Abstract

Changes in free amino acids content and its potential racemization in ready-to-eat foods treated with E-beam irradiation between 1 and 8 kGy for sanitation purposes were studied. A simple heart cut two-dimensional high performance liquid chromatographic method (LC–LC) for the simultaneous enantiomeric determination of three pairs of amino acids used as markers (tyrosine, phenylalanine, and tryptophan) is presented. The proposed method involves the use of two chromatographs in an LC–LC achiral–chiral coupling. Amino acids and their decomposition products were firstly separated in a primary column (C18) using a mixture of ammonium acetate buffer (20 mM, pH 6) (94%) and methanol (6%) as the mobile phase. Then, a portion of each peak was transferred by heart cutting through a switching valve to a teicoplanin-chiral column. Methanol (90%)/water (10%) was used as the mobile phase. Ultraviolet detection was at 260 nm. Detection limits were between 0.16 and 3 mg L−1 for each enantiomer. Recoveries were in the range 79–98%. The LC–LC method combined with the proposed sample extraction procedure is suitable for complex samples; it involves an online cleanup, and it prevents degradation of protein, racemization of L-enantiomers, and degradation of tryptophan. Under these conditions, D-amino acids were not found in any of the analyzed samples at detection levels of the proposed method.

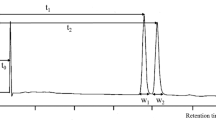

Two-dimensional direct chiral liquid chromatograms of tyrosine, phenilalanine and tryptophan

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Changes in the world population habits have produced an increase in the manufacture of a great variety of ready-to-eat (RTE) foods of both vegetable and animal origin. Consumption of RTE is becoming more and more frequent, and the food industry provides a vast variety of products, including pre-packed and precooked foods in individual or family-size packages with very different presentations. Preparation of these products involves processing operations and further manipulations such as cutting, slicing, dosing, and packing, in which a variety of pathogenic microorganisms from the environment, mechanical equipment, tools used, handlers, etc., can reach the food, thus increasing contamination risks; therefore, it is necessary to eliminate this potential contamination in order to enhance RTE shelf life and ensure that they are microbiologically safe [1].

E-beam irradiation involves direct exposure of the RTE foods to E-beam rays. It is a very effective process in killing many of the common microbial pathogens including Escherichia coli O157:H7, Listeria monocytogenes, Salmonella spp., and Vibrio spp., among others, that are significant contributors to foodborne illness [1–3]. The major advantage of E-beam irradiation is that RTE can be processed after sealing in its final packaging form, minimizing the possibility of recontamination following this treatment [4]. Application of ionizing radiation to RTE was approved at the beginning of the 1980s. Several extensive exams of toxicological and other data by regulatory and health organizations, including Health Canada (2003), Food and Drug Administration (1986), Codex Alimentarius Commission (CAC, 1983), European Commission’s Scientific Committee on Food (2003), and Word Health Organization (1981), have determined that food irradiated up to 10 kGy is safe. More recently, the CAC (2003) slightly revised its General Standard for Irradiated Foods, stating that the maximum absorbed dose delivered to a food should not exceed 10 kGy, except when necessary to achieve a legal technological purpose [5].

However, according to some authors, this treatment may produce changes in food sensory properties that negatively affect consumer acceptance (color and appearance [6], or aroma and flavor [7, 8]) or promote the formation of secondary chemical compounds [9] due to the linkage breakages of the excited molecules or ions and their reactions with neighboring molecules, giving rise to a reaction cascade. The overall process is known as “radiolysis”. The major components of foods, such as proteins, as well as minor components such as free amino acids, can be chemically altered to some extent after irradiation [4]. Some authors suggest that amino acids do not seem to be altered significantly by ionizing radiation [10, 11] but, on the other hand, free amino acids may be sensitive to radiation [12], and some of them can be used as markers to detect irradiated foods. In food containing phenylalanine, the formation of o-, m-, and p-tyrosine is observed, their yield being proportional to the absorbed radiation dose [13]. Tryptophan (Trp) is one of the most reactive amino acids and, due to its importance as an essential amino acid, the effect of irradiation on it has been investigated intensively. The OH-Trp isomers 4, 5, 6, and 7-OH-Trp have been suggested to be formed in irradiated food with high protein content [14, 15].

On the other hand, free amino acids enantiomers could be sensitive to potential racemization in several processes; for instance, the presence of D-amino acids in foods is related with some treatments such as extrusion, heating [16], and some biological processes including bacterial and yeast action or ripening [17, 18]. The D-amino acids ratio (D/L) in foodstuffs is an indicator of the quality and nutritional value; an increase of their levels means a decrease in the food quality. Consequently, there is a continuous need to investigate the effect of the ionizing irradiation on the racemization of the free amino acids in E-beam irradiated foodstuffs [19].

Several analytical methods have been used for the quantitative determination of L- and D-amino acids, including capillary electrophoresis [20] and enzymatic assays [21]. Nowadays, chromatographic and electromigration methods seem to be the most popular techniques applied in this field. High performance liquid chromatography (HPLC) is generally preferred over gas chromatography [22] for chiral analysis of nonvolatile compounds, because HPLC can be used without derivatization. Chiral HPLC analysis of amino acids can be carried out either by indirect methods using numerous derivatization reagents [23] such as o-phthaldialdehyde and the chiral reagent N-acetyl-L-cysteine, or by direct methods using several chiral stationary phases such as covalently immobilized quinine t-butylcarbamate chiral stationary phases [24], quinine and quinidine carbamates immobilized onto porous silica [25], as well as chiral stationary phases based on immobilized network polymers derived from L-tartaric acid [26], crown ether stationary phases [27], or Pirkle type enantioselective columns [28]. The use of direct analysis methods prevents the possibility of racemization that some author gives to the derivatization process [23, 29]. Macrocyclic antibiotics [30], in particular teicoplanin, teicoplanin aglicon, vancomycin, and ristocetin A, have been extensively used as chiral stationary phases for amino acids [31–33]. These chiral stationary phases have demonstrated broad selectivity in reversed phase, normal phase, polar ionic, and polar organic mode. Since these phases contain peptide, carbohydrate, and other ionizable groups, the enantioselectivity appears to be different in the above chromatographic modes, resulting very useful in a wide variety of separations. Reversed phase conditions seem to favor inclusion and hydrogen bonding, and changes in pH produce cationic or anionic interactions [34].

A common problem of these chiral stationary phases is the intrinsically limited chemical selectivity and efficiency. This means that complex mixtures of diverse pairs of enantiomers cannot be analyzed in one run due to peak overlapping [35]. Moreover, some drawbacks still remain when the analyte is present in more complex samples containing other chiral or achiral compounds as well as endogenous matter which can co-elute with the enantiomer peaks. These problems could be overcome by heart cut two-dimensional HPLC, where two columns are linked via a switching valve in such a manner that fractions of each racemic flowing through the primary column (a nonenantioselective one that provides chemoselectivity) can be directed into a second column (an enantioselective one) in which further enantiomeric resolution can be obtained [36]. The advantages of this technique include orthogonal selectivity, because two different columns are used, as well as an online cleanup of the sample. The achiral–chiral coupling in the case of chiral analysis [28, 35, 37] is particularly advantageous because it allows a simultaneous analysis of the racemate and its enantiomers. Moreover, the commercially available chiral stationary phases work satisfactory in very restricted conditions, which require extremely clean samples to preserve their integrity; therefore, the transference of only a portion of the racemic peak into the chiral column assures clean extracts, avoiding previous cleanup steps, preventing the degradation of the chiral stationary phases, maintaining the column performance for longer times, and yielding simpler analysis in a shorter time [36].

In this paper, we report the development of a simple and easy to perform heart cut two-dimensional high performance liquid chromatography–ultraviolet (LC–LC–UV) method based on the use of a reverse-phase octadecyl silane column switched to a commercial teicoplanin-chiral column for the achiral and chiral analysis of three amino acids: tryptophan, tyrosine, and phenylalanine and their decomposition products in commercial RTE foods with the aim to evaluate both potential changes on free amino acids and its racemization in samples treated with an electron beam (accelerated electrons) at different irradiation doses for sanitation purposes [1–3]. These amino acids were selected as markers since they have been found to be sensitive to radiation [13–15] and they can be often found easily in foodstuffs, and also, they absorb in UV. The proposed method also involves the optimization of the chromatographic conditions and a fast and very simple sample preparation procedure.

Experimental

Chemical and materials

All reagents and solvents were of analytical grade, and purified water from a Milli-Q system was used in all procedures (Millipore, Bedford, MA, USA). Methanol, gradient HPLC quality was supplied by Scharlau (Barcelona, Spain). Chemicals including ammonium acetate, sodium hydroxide, and hydrochloric acid were purchased from Panreac (Barcelona, Spain). Glacial acetic acid (99.5%) was from Carlo Erba (Milan, Italy), L-ascorbic acid was from Sigma-Aldrich (St. Louis, MO, USA), and triethylamine acetate (purity > 99.5%) was from Sigma-Aldrich.

The following amino acids whose structure is shown in Fig. 1, D- and L-tyrosine (Tyr), D- and L-phenylalanine (Phe), and D-and L-tryptophan (Trp), were supplied by Sigma-Aldrich. According to the manufacturer, the chemical purity was higher than 98%. Decomposition products of these amino acids: m-tyrosine, o-tyrosine, and 5-OH-tryptophan, were purchased from Sigma-Aldrich too. Analyte stock solutions were prepared by dissolving 0.1 g of each amino acid in 100 mL of water (1,000 mg L−1) and were stored in the dark at 4 °C. In the case of tyrosine solutions, a small amount of NaOH 1 M was added to achieve its complete dissolution. Fresh working standard solutions were also prepared daily by suitable dilution of the stock solutions, in order to prevent the influence of the possible analyte degradation on the results. L-ascorbic acid solutions were prepared by dissolving 176 mg of substance in 10 mL of water (100 mM) and were also stored in the dark at 4 °C. Working solutions were prepared daily by dilution of this solution to prevent the oxidation and formation of dehydroascorbic acid.

Solvents to prepare mobile phases were filtered through Teknokroma nylon membrane filters (Barcelona, Spain) with 0.45 μm pore size in a Visiprep vacuum manifold system (Supelco, Bellfonte, PA, USA), and sample extracts were also filtered using nylon membrane filters (25 mm, 0.45 μm, and 0.20 μm pore size) from Teknokroma.

Samples

The following RTE foodstuffs were studied: cooked ham (low fat content), minced meat (beef meat), dry cured Iberian ham, smoked salmon, and soft cheese. These samples were purchased in a local supermarket of Madrid.

LC–LC instrumentation and other equipments

Two analytical HPLC systems were used to carry out the separations in one- or two-dimensions mode.

The achiral chromatographic separation of the racemates and their decomposition products was carried out in an HPLC chromatograph (system A) consisting of a C18-ATLANTIS column, 150 × 4.60 mm, 5 μm (primary column; Waters, Milford, MA, USA) with a 20 × 4.4-mm (40 μm ID) SUPERCOSIL-C18 Pelliguard pre-column (Supelco, Bellfonte, PA, USA) both thermostated at 20 °C in a column oven Jasco CO-2067 (Jasco, Tokyo, Japan) with a temperature control range from 10–80 °C. An injection valve with a 20-μL sample loop (Rheodyne, Cotati, CA, USA), a one-channel pump Varian Pro Star Solvent Module (Varian, PA, USA), and a Waters Variable Wavelength 481 detector (Waters Corporation, Milford, MA, USA) both interfaced to a computer that contains the CromaNec XP Integration Software (Madrid, Spain), Windows XP for chromatographic data processing.

Chiral separation of the enantiomers was carried out in an HPLC chromatograph (system B) that includes a four-channel gradient pump Jasco PV-2089 Plus Solvent Module (Jasco, Tokyo, Japan). The injector employed was a manual Rheodyne valve, model 7010, with a 20-μL sample loop (Rheodyne, Cotati, CA, USA). A Jasco programmable variable wavelength UV-2075 Plus detector (Jasco, Tokyo, Japan) was used, and all components were interfaced to a PC data station with the Borwing Workstation Software (version 1.50) for Windows (Jasco). A teicoplanin Chirobiotic-T column, 150 × 21 mm, 5 μm (secondary column), was used for the chiral separation (Supelco, Bellfonte, PA, USA). Mobile phase was thermostated in a P-Selecta Presciterm Bath (Barcelona, Spain) at 20 °C.

The LC–LC method system was linked by means of a switching Lab Pro Rheodyne six port valve (Rheodyne, Cotati, CA, USA; Fig. 2).

Free amino acids extraction was carried out by means of a P-Selecta (Barcelona, Spain) ultrasonic bath for shaking and a Meditronic P-Selecta (Barcelona, Spain) centrifuge.

Procedures

Sample irradiation treatment

RTE foods were sliced (2–3 mm thickness) with an electric machine with the exception of beef meat which was chopped. Meat portions of about 50 g were mixed with 0.5 g of NaCl. The final meat mixture was prepared as a steak of 1 cm thickness. After these previous operations, all the samples were then vacuum-packaged in laminated film bags of low gas permeability. Then, they were transported in insulated polystyrene boxes and irradiated under an electron-beam radiation source, which operated at 10 MeV, in the IONMED irradiation sterilization plant (Tarancón, Spain); doses between 1 and 8 kGy were applied to the slices included in each bag. The dose absorbed by samples was checked by determining the absorbance of cellulose triacetate dosimeters (ASTM 2000) simultaneously irradiated with samples. The product temperature increase during E-beam irradiation was less than 2 °C. Vacuum bags containing non-irradiated samples, as well as those containing samples treated with ionizing radiation, were stored at −20 °C and thawed at 4 °C for 24 h before applying the extraction and purification procedures described below.

Free amino acids extraction

Sample treatment was made based on the methods developed by Lang et al. [38] and Gil-Díaz et al. [19]. Briefly, two slices of each food selected were finely crushed using a knife. Intermixing was accomplished by the sampling tabling method. For extraction of free amino acids, 2 g of the homogenized sample (1 g in the case of the dry cured Iberian ham) were weighed and transferred into a 30-mL centrifuge tube, adding 2 mL of 1 mM ascorbic acid. The tube was shaken in an ultrasonic bath for 30 min, keeping the temperature below 35 °C. Then, the mixture was centrifuged at 4,000 rpm for 15 min. The supernatant liquid was transferred to a 5-mL glass flask. The residue was extracted two times more using portions of 2 and 1 mL of ascorbic acid following the same steps. The final combined extract was adjusted to pH 6 and filtered through a 0.45-μm nylon membrane filter (in the case of soft cheese, two consecutive filtrates, first through a 0.45-μm and then through a 0.20-μm nylon membrane filter, were necessary).

Aliquots of 1 mL were used for the analysis by adding 60 μL of methanol. Five replicates were performed for each sample. In all cases, volumes of 20 μL of these solutions were injected into the LC–LC system.

Achiral racemic separation of free amino acids

Achiral racemic separations of solutions containing 10 mg L−1 of tyrosine, phenylalanine and tryptophan racemate mixtures and its decomposition products o-tyrosine, m-tyrosine, and 5-OH-tryptophan were carried out in system A by injecting 20 μL of sample on the primary column. An isocratic mobile phase containing 94% ammonium acetate buffer (20 mM, pH 6) and 6% methanol at a flow rate of 1.0 mL min−1 was used.

Direct chiral HPLC determination of free amino acids

The enantiomers of each racemic were separated in system B using the secondary column. A volume of 20 μL of standard solutions containing 10 mg L−1 of the L-enantiomer and 5 mg L−1 of the D-enantiomer was injected into the HPLC system. An isocratic mobile phase containing 10% of water and 90% methanol at a flow rate of 0.5 mL min−1 was used.

The UV detection wavelength in both achiral and chiral analysis was made at 260 nm.

Chiral enantiomers separation by “heart cut” LC–LC

A volume of 20 μL of standard mixture containing 20 mg L−1 of each amino acid enantiomer and 20 mg L−1 of their decomposition products was injected into the primary column in system A, which has been previously conditioned with the above-mentioned mobile phase, keeping the switching valve in position 1. When tyrosine begins to be eluted from the primary column, a portion of this peak is transferred to the secondary column (system B) by changing the switching valve to position 2 for 2 s. Afterwards, the valve is switched back to its initial position, allowing the system to be ready for the subsequent transference. This process is repeated for the rest of the transferences. Table 1 summarizes the overall LC–LC procedure, showing the switch valve positions for each operation.

Results and discussions

One-dimensional direct chiral liquid chromatography method for standards

To evaluate the separation quality in this study, enantioselectivity factor was used. In chiral HPLC, values of α ≥ 1.1 mean that enantioselectivity is considered to exist. Several preliminary experiments to establish best conditions for the enantiomeric separation of tyrosine, phenylalanine, and tryptophan on the teicoplanin-chiral column were carried out, including the evaluation of the nature and organic modifier proportion effect and the pH buffer nature and its concentration effect. These studies showed that using methanol as organic modifier, around 20% in aqueous solutions of ammonium acetate 20 mM at pH 7, or triethylamine acetate 0.1% at pH 4, or water allowed to obtain enantioselectivity values above 1.1; therefore, a systematic study was carried out using this modifier. For all the amino acids, a multilevel design was used to optimize the factors that can affect both enantioselectivity and enantiomeric resolution, and six experiments were carried out. Two levels for the methanol and three levels for the buffer nature were studied. The two factors considered were buffer nature (ammonium acetate 20 mM pH 7, triethylamine acetate 0.1% at pH 4, and no adjust of pH using water) and organic modifier ratio (90% and 100%, ratios in which enantiomeric resolution is higher). Finally, a mixed mode was used; an intermediate situation between reversed phase and polar ionic mode, which provided high enantioselectivity values for the three amino acids containing 10% of water and 90% of methanol, was selected as a compromise. Under these conditions, for the tyrosine, the first enantiomer eluted at a retention time of 1.87 min and the second one eluted at 2.83 min; the selectivity obtained was 1.95 (R s = 2.84). For phenylalanine, retention times for the enantiomers were 2.02 and 3.09 min, respectively; the selectivity obtained was 1.94 (R s = 2.68). Finally, for tryptophan, the first enantiomer eluted at a retention time of 2.15 min and the second one eluted at 3.34 min; the selectivity factor obtained was 1.91 (R s = 2.79). Figure 3 shows chromatograms obtained in the optimum conditions established for the three amino acids.

Chiral two-dimensional “heart cut” LC–LC method for standards

Chromatograms in Fig. 3 demonstrate how similar retention times are for the enantiomers of the tree amino acids, thus showing high enantioselectivity but low chemical selectivity. To overcome this problem of the chiral column, two-dimensional HPLC was tried.

For this purpose, two chromatographs were interconnected by means of a switching valve, according to the scheme in Fig. 2 and descriptions given in “Chiral enantiomers separation by “heart cut” LC–LC” section. To get the simultaneous chiral separation of the three amino acids in the same sample, the following chemical and operational parameters were optimized: mobile phase compatibility between the primary and the secondary column, separation time between peaks in the primary column, and transference time from the primary column to the secondary column [39].

Regarding the mobile phase compatibility, several mobile phases were tested. Experiments were carried out in order to establish the best conditions for the achiral separation of tyrosine and their decomposition products m-tyrosine, o-tyrosine, phenylalanine, tryptophan, and its radiation product 5-OH-tryptophan on the primary column, including the evaluation of the nature of the organic modifier effect and the buffer nature, pH, and its concentration effect. The best results were obtained using methanol as organic modifier, acetate buffer at low concentrations, and a pH value close to the isoelectric point of the amino acids studied. Results obtained showed that mobile phases containing methanol as organic component and ammonium acetate buffer (20 mM/pH 6) as aqueous component displayed no incompatibilities with the mobile phase used in the secondary column. To allow the complete elution of the enantiomers of each amino acid studied and the stabilization of the chiral column before the next transference from the primary column, a reasonable separation between peaks in this column was required, so different ratios of methanol/ammonium acetate buffer (20 mM/pH 6) as mobile phase in the primary column were tested; the range of values studied was 5–90% for the organic component. From this study, it was concluded that the best conditions were 6% methanol/94% ammonium acetate buffer (20 mM/pH 6). Under these conditions, tyrosine eluted at a retention time of 4.13 min, while their decomposition products m-tyrosine and o-tyrosine eluted at a retention times of 5.35 and 6.93 min, respectively. Phenylalanine eluted at 7.76 min and tryptophan and its radiation product 5-OH-tryptophan eluted at 16.66 and 8.71 min, respectively. To optimize transference time, different elution volumes from the primary column were transferred into the secondary column by switching the valve applying different transference times, starting from 1 s and ending with 7 s for the three amino acid racemics. High transference times generated a great system peak that overlapped with the peak corresponding to the L-amino acid, giving a value of enantiomeric ratio (ER1/2), different to the expected one, so transference time was optimized by plotting the ER1/2 versus transference time and fitting the curve to a Gaussian function (Fig. 4). The maximum of this Gaussian was taken as the optimum transference time, which was 2 s for each amino acid.

Figure 5 shows the two-dimensional separation of a mixture containing both the three amino acids and their decomposition products. The selectivity obtained was 1.92 (R s = 2.94) for tyrosine, 1.19 (R s = 3.03) for phenylalanine, and 1.10 (R s = 2.64) for tryptophan. Good enantiomeric separation was obtained (Fig. 5b), concluding that the change from one-dimensional to two-dimensional mode does not practically affect the enantiomeric resolution of the three amino acids selected. Reversed phase used in the primary column is absolutely compatible with mixed mode used in the secondary column; therefore, brand-broadening is practically negligible. Eluent strength is weaker in the first dimension than in the second one, which means that the resolution should be independent on the injection volume as long as column overloading does not occur [35].

Heart cut two-dimensional high performance liquid chromatograms from achiral–chiral coupling. a Achiral separation of 20 mg L−1 of each amino acid enantiomer and 20 mg L−1 of m-tyrosine, o-tyrosine, and 5-OH-triptophan. b Chiral separation: (1) enantiomeric separation of L- and D-tyrosine, (2) enantiomeric separation of L-and D-phenylalanine, and (3) enantiomeric separation of L- and D-tryptophan. Chromatographic conditions specified in “Achiral racemic separation of free amino acids” section and “Direct chiral HPLC determination of free amino acids” section

Analytical characteristics for standards

Detection limits were calculated by injecting solutions containing progressively smaller amounts of the three racemics until the response obtained in the secondary column had a peak height only three times larger than the average height of noise around the respective enantiomer. The reproducibility of the method was evaluated in day and intraday in terms of the ER1/2. It was calculated from 20 mg L−1 of each enantiomer standard and three replicates. The analytical characteristics of the method for standard are shown in Table 2. As could be expected, the LC–LC method is less sensitive than the one-dimensional one, because only a portion of the peak is transferred each time, and additional dilution effect has occurred. However, cleaner chromatograms and a higher precision can be expected.

To establish the limit of detection of the system as the smallest amount of D-enantiomer that could be detected, some mixtures of amino acids with various ratios of L- and D-enantiomer were injected into the primary column and transferred onto the secondary column. The enantiomeric excess (% e.e) [40] was calculated for each fraction from peak areas of the two enantiomers in the second-dimension chromatograms by means of Eq. 1:

Experiments were carried out by triplicate, and the standard deviations (SD) were calculated. For the tyrosine, the maximum detectable % e.e (referred to the L-amino acid) was 91.1% (SD = 0.9%), for phenylalanine, it was 88.2% (SD = 0.3%), and for tryptophan, it was 98.5% (SD = 0.2%).

Determination of the content and potential racemization of free amino acids in non-irradiated and irradiated RTE food samples by “heart cut” LC–LC

The simultaneous analysis of the content and possible racemization of free amino acids as well as their decomposition products in non-irradiated and irradiated RTE food samples were studied by the optimized LC–LC method.

The primary column allowed establishing the free amino acid content at each level of radiation and the evaluation of the potential formation of the decomposition products of these amino acids. Smoked salmon, soft cheese, and dry cured Iberian ham presented the highest amount of free amino acid due to smoking [41] and curing process [42]. Table 3 shows the results obtained. It was observed that irradiation caused changes in amino acids content. In order to detect possible significant differences between mean concentrations of each amino acid from one level of radiation to another, they were compared by means of analysis of variance (ANOVA) test. Table 4 shows the results of the F ratios and P values obtained in these ANOVA tests. In most cases, significant differences at the 95% confidence level were found between one level of radiation and another. Multiple range tests allowed determining between which levels of radiation significant differences occurred.

Regarding cooked ham in Tyr and Trp, differences between non-irradiated sample and irradiated samples were observed from a radiation dose of 4 kGy. For dry cured Iberian ham, multiple range test showed significant differences for Trp and Tyr up to 4 kGy and for Phe, above 6 kGy. In minced meat, free amino acids were only affected above 4 kGy radiation dose. Phe and Trp were modified at any irradiation level in the case of soft cheese, and changes in Tyr content were observed up to 2 kGy. In smoked salmon, Tyr was modified at levels of 2 kGy, while Trp was modified up to 4 kGy, and Phe only at the highest irradiation dose applied representative means plot obtained from cooked ham and smoked salmon are shown in Fig. 6.

The results obtained could be in agreement with those obtained by some authors who have reported that in irradiated meat, chicken [43], and fish [12], amino acids such as tyrosine or tryptophan can produce biogenic amines by decarboxilation, which are very important from the toxicity point of view and as quality control indices for food spoilage. This fact may be the reason for the pronounced decrease of tyrosine and tryptophan in smoked salmon. The decrease of phenylalanine levels and increase of tyrosine levels observed in all the RTE food samples studied could be explained as a consequence of the formation of o- and m-tyrosine as well as the decrease of tryptophan levels observed in irradiated food with high protein content such as minced meat could be explained by the formations of the OH-Trp isomers 4, 6, 5, and 7-OH-Trp reported by some other authors too [13–15]. Tyrosine and tryptophan decomposition products were not observed either in minced meat or in smoked salmon nor dry cured Iberian ham. On the other hand, small amounts of m- and o-tyrosine and 5-OH-tryptophan were observed in soft cheese. Regarding cooked ham, only o-tyrosine was detected.

Taking into account other previous studies, irradiation does not seem to produce special nutrition problems at doses up to 8 kGy because losses in the amino acid content can be comparable to those obtained in a cooking treatment [44].

The second dimension with the teicoplanin-chiral columns allowed to evaluate the potential racemization of the free amino acids. Regarding D-amino acids, none was detected, neither in non-irradiated nor in irradiated RTE food samples at detection levels of the proposed method. Representative LC–LC chromatograms of non-irradiated and irradiated RTE food samples with different content of endogenous matter are shown in Fig. 7. Therefore, E-beam irradiations of RTE foodstuffs at 1–8 kGy do not seem to produce the racemization of L-amino acids. The results are also in agreement with those reported also by other authors [19] who did not find racemization of amino acid caused by ionizing irradiation.

Representative heart cut two-dimensional high performance liquid chromatograms of: (1) non-irradiated soft cheese, (2) irradiated minced meat at a dose of 2 kGy, (3) irradiated dry cured Iberian ham at a dose of 8 kGy. a: Achiral separation. b: Chiral separation. Chromatographic conditions specified in “Achiral racemic separation of free amino acids” section and “Direct chiral HPLC determination of free amino acids” section

Recovery studies in the primary column

It has previously been reported that determination of tryptophan presents several analytical problems due to its labile nature in the presence of light and hydrogen ions. Tryptophan can not be determined by routine chromatography methods after acid hydrolysis with HCl 6 M as it is destroyed by oxidation [45]. Therefore, it is necessary to use other hydrolysis or extraction procedures to render tryptophan stable. The methods that have been recently investigated included soft acidic or alkaline hydrolysis, enzymatic methods, or extraction methods that use an antioxidant or buffer medium [46, 47]. Adding L-ascorbic acid as a protecting agent to the samples significantly improved the stability of amino acids, especially of the tryptophan. In order to validate the proposed method, recovery studies of amino acids from RTE food samples were performed.

Samples were spiked with L-amino acid solutions at three different concentration levels ranging from 5 to 25 mg L−1. The matrix effect was investigated comparing the slopes of the direct calibration curve for each amino acid with that obtained by the standard additions method in each RTE food by means of a Student’s t test comparison. This test showed that there was not a statistically significant difference between the slopes at the 95.0% confidence level so, no matrix effect was observed. Recoveries were determined subtracting the initial concentration of amino acids in the initial sample (only L-enantiomer was found) to the value obtained from the spiked sample using the direct calibration curve. Linearity was observed for tyrosine between 0.5–20 (r = 0.997) and 30–400 mg L−1 (r = 0.999). For phenylalanine, linearity was found between 0.5–20 (r = 0.997) and 30–400 mg L−1 (r = 0.999), while for tryptophan, it was found between 0.1–20 (r = 0.998) and 30–100 mg L−1 (r = 0.999).

The results from the analysis of spiked RTE food samples are presented in Table 5. As can be seen, the spiked recoveries determined, as the mean of three determinations for each spiked level, were between 79% and 98%, with relative SD between 1 and 5, demonstrating the suitable extraction efficiency and good recoveries especially for tryptophan.

Conclusions

The proposed LC–LC “heart cut” achiral–chiral method allowed the simultaneous determination of three amino acids and their decomposition products both racemates and enantiomers taken as markers in several RTE foodstuffs. The primary column assures clean extracts for further enantiomer separation avoiding previous cleanup steps allowing rapid and easy analysis and preventing damage to the chiral stationary phase. All these provide clean chromatograms and good precision. This method was applied to detect potential changes in free amino acids content as well as L-amino acid racemization and could be suitable for racemization control of amino acid after any other food treatment, being a practical alternative to other more expensive or complicated methods. The proposed extraction method is gentle enough to minimize losses and racemization of tryptophan while yielding good recoveries as well as it is easier than and faster than other procedures or hrydrolysis treatments. E-beam irradiation does not seem to produce special nutrition problems at doses up to 8 kGy, being losses in the amino acid content comparable to those obtained in a cooking treatment, and no racemization is detected.

Abbreviations

- aa:

-

Amino acid

- CSP:

-

Chiral stationary phase

- e.e:

-

Enantiomeric excess

- ER1/2 :

-

Enantiomeric ratio

- HPLC:

-

High performance liquid chromatography

- LC:

-

Liquid chromatography

- LC–LC:

-

Heart cut two-dimensional high performance liquid chromatography

- ODS:

-

Octadecyl silane

- SD:

-

Standard deviation

- TEAA:

-

Triethylamine acetate

References

Cabeza MC, Cambero I, De la Hoz L, Ordóñez JA (2007) Innov Food Sci Emerg Technol 8:209

Medina M, Cabeza MC, Bravo D, Cambero I, Montiel R, Ordoñez JA, Nuñez M, Hoz L (2009) Food Microbiol 26:224

Cabeza MC, de la Hoz L, Velasco R, Cambero MI, Ordoñez JA (2009) Meat Sci 83:320

Brennan JG (2006) Food processing handbook, 1st edn. WILEY-VCH Verlag Gmbh & Co. Kgaa, Weinheim, p 147

Smith JS, Pillai S (2004) Food Technol 58:48

Brewer S (2004) Meat Sci 68:1

Jo C, Ahn DU (2000) J Food Sci 65:612

Barba C, Calvo MM, Herraiz M, Santa-María G (2009) Food Chem 114:1517

Rosales-Conrado N, León González ME, Pérez Arribas LV, Polo Díez LM (2008) Anal Bioanal Chem 391:1433

Matloubi H, Aflaki F (2004) Hadjiezadegan 17:133

Byun M-W, Yook H-S, Kwon O-J, Kwang I-J (1997) Radiat Phys Chem 49:483

Erkan N, Özden Ö (2007) Radiat Phys Chem 76:1636

Krack C, Sontag G, Solar S (1999) Food Res Int 32:43

Van Wickern B, Moiler B, Simat T, Steinhart H (1997) J Chromatogr A 786:57

Kleeberg KK, Müller A, Simat TJ, Steinhart H (2003) Adv Exp Med Biol 527:677

Csapó J, Varga-Visi E, Lóki K, Albert C, Salamon S (2008) Amino Acids 34:287

Giufrrida A, Tabera L, González R, Cuciontta V, Cifuentes A (2008) J Chromatogr B 875:243

Brückner H, Lagner M, Lüpke M, Westhauser T, Godel H (1995) J Chromatogr A 697:229

Gil-Díaz M, Santos-Delgado MJ, Rubio-Barroso S, Polo-Díez LM (2009) Meat Sci 82:24

Cavani L, Ciavatta C, Carlo G (2003) J Chromatogr A 985:463

D’Aniello A, Fiore MM, Fisher GH, Milone A, Seleni A, D’Aniello S, Perna AF, Ingrosso D (2000) FASEB J 14:699

Kreidler D, Czesla H, Schurig V (2008) J Chromatogr B 875:208

Ilisz I, Berkecz R, Peter A (2008) J Pharm Biomed 47:1

Oberleitner WR, Maier NM, Lindner W (2002) J Chromatogr A 960:97

Lämmerhoher M, Lindner W (1996) J Chromatogr A 741:33

Weng W, Wang QH, Yao BX, Zeng QL (2004) J Chromatogr A 1042:81

Stenberg M, Marco-Varga G, Öste R (2002) Food Chem 79:507

Miyoshi Y, Hamase H, Tojo Y, Mita M, Konno R, Zaitsu K (2009) J Chromatogr B 877:2506

Péter A, Török R, Wright K, Wakselman M, Mazaleyrat JP (2003) J Chromatogr A 1021:1

Hsiao Y-L, Chen S (2009) Chromatographia 70:1031

Boesten JMM, Berkheji M, Schoemaker HE, Hiemstra H, Duchateau ALL (2006) J Chromatogr A 1108:26

Poplewska I, Kramarz R, Patkwski W, Seidel Morgensterm A, Antos D (2008) J Chromatogr A 1192:130

Péter A, Töroka G, Armstrongh DW, Tóthc G, Tourwéd D (2000) J Chromatogr A 904:1

Xiao TL, Tesarova E, Anderson JL, Egger M, Armstrong DW (2006) J Sep Sci 29:429

Welsch T, Schmidtkunz C, Müller B, Meier F, Chlup M, Köhne A, Lämmerhofe M, Lindner W (2007) Anal Bioanal Chem 388:1717

Mondello L, Lewis AC, Bartle KD (2002) Multidimensional chromatography, 1st edn. Wiley, Chichester, p 109

Hamase H, Morikawa A, Ohgusua T, Lindner W, Zaitsu K (2007) J Chromatogr A 1143:105

Lang W, Masucci JA, Caldwell GW, Hageman W, Hall J, Jones WJ, Rafferty BM (2004) Anal Biochem 333:79

Guillén-Casla V, Pérez-Arribas LV, León-González ME, Polo-Díez LM (2008) J Agric Food Chem 56:2303

Ali I, Aboul-Enein HY (2004) Chiral pollutants: distribution, toxicity and analysis by chromatography and capillary electrophoresis, 1st edn. Wiley, Chichester, p 1

Hultmann L, Bencze Rora AM, Steinsland I, Skara T, Rustad T (2004) Food Chem 85:377

Ruiz J, García C, Díaz MC, Cava R, Tejeda JF, Ventanas J (1999) Food Res Int 32:643

Min JS, Lee SO, Jang A, Jo C, Lee M (2007) Poult Sci 86:2034

Lacroix M, Ouattara B (2000) Food Res Int 33:719

Csapó J, Varga-Visi É, Lóki K, Albert Cs (2006) Chromatogria 63:S101

Ravindran G, Bryden WL (2005) Food Chem 89:309

Stam P, Booger I, Plugge W, Duchateau ALL (2009) Chromatographia 69:1

Acknowledgements

The present work has received financial support from the project TEMINYSA/CM (S-0505/AGR-0314) funded by the Dirección General de Universidades e Investigación, Consejería de Educación, Comunidad de Madrid, and the CTQ2008-05263 proyect founded by the Ministerio de Ciencia e Innovación. Vanesa Guillén Casla also wishes to thank the Comunidad de Madrid for the support through a “Personal Investigador de Apoyo” grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guillén-Casla, V., León-González, M.E., Pérez-Arribas, L.V. et al. Direct chiral determination of free amino acid enantiomers by two-dimensional liquid chromatography: application to control transformations in E-beam irradiated foodstuffs. Anal Bioanal Chem 397, 63–75 (2010). https://doi.org/10.1007/s00216-009-3376-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-009-3376-6