Abstract

In the present paper, we report on the development of a straightforward reversed-phase liquid chromatography–electrospray ionization–tandem mass spectrometry method for the determination of the most abundant fatty acids; α-tocopherol and cephalosporin P1 in fermentation broths. Using this method, fatty acids could be successfully determined in extracts of fermentation broths from penicillin and cephalosporin production without prior derivatization. Matrix effects were investigated in detail, and various kinds of calibrations (i.e., by use of neat standard solutions as well as by matrix-matched calibration employing standard addition each with and without internal standards) were comparatively assessed. The optimized and validated method was employed for the analysis of extracts of fermentation broths and nutrition media.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Metabolomics is an emerging field in systems biology [1]. It is also gaining increasing popularity in biotechnology as a tool to advance the understanding of metabolic pathways occurring for instance during fermentation processes [2, 3]. In this context, metabolic profiling studies have been implemented, in which arrays of analysis methods measure concentrations of various groups of metabolites [3]. Among them, analysis of free fatty acids is an integral part of any extended metabolic profiling study, particularly in lipidomics [4].

In living cells, fatty acids are stored in form of triglycerides and, if required, are catabolized to acetylcoenzyme A in the course of β-oxidation in order to serve as energy provider. In the form of phospholipids, they build up cell membranes. In industrial fermentation processes, oils are frequently used as ingredients of nutrition media to partly replace the more expensive glucose, and by this way, fatty acids are introduced as energy source.

Gas chromatography (GC) is the most widely used separation technique for the analysis of fatty acids because of its high specificity, sensitivity, and good reproducibility [5]. Separation of fatty acids by GC requires prior derivatization to increase compound volatility and thermal stability. Most often, this is accomplished by esterification resulting in methyl [6], or trimethylsilyl and pentafluorobenzyl esters [7, 8]. Commonly employed detectors are flame ionization detectors and in metabolomics-related studies, primarily mass spectrometers. Thus, GC–mass spectrometry (MS) has become the method of first choice for metabolic studies of free fatty acids [5, 9, 10].

Relatively, high-performance liquid chromatography–tandem mass spectrometry (HPLC-MS/MS) is rarely employed in metabolomics for the analysis of free fatty acids, although it circumvents derivatization steps. Nevertheless, a number of applications have been reported in other context, where analysis of free fatty acids was successfully achieved by LC-MS [7, 11–16].

Lack of sensitivity for cis/trans isomers in the analysis of unsaturated fatty acids has been alleviated by silver ion chromatography, which allows their separation. This methodology, however, was most often employed with the intention to fractionate complex mixtures, which were then further analyzed employing GC-MS [17, 18].

One of the major problems of LC-MS/MS of fatty acids is their non-ideal fragmentation behavior. Under low-energy collision-induced dissociation conditions, fragmentation hardly occurs. Most prominent losses originate from elimination of water (∆m −18) as well as loss of CO2 (∆m −44) from the carboxylic acid group. Fatty acids exhibiting double bonds show to some extent structure specific fragmentation but the intensities are rather weak for the purpose of multiple reaction monitoring (MRM) measurements furnishing poor sensitivity. Recently, Zehethofer et al. [19] determined fatty acids in plasma using postcolumn infusion of a barium ion solution, thereby enhancing detection sensitivity of fatty acids by the formation of positively charged adduct ions and at the same time promoting fragmentation reactions. Other cationizing agents, including alkaline and alkaline earth metals or copper ions, also proved to be suitable to improve detection sensitivity of fatty acids in the MRM mode [20, 21]. Another strategy to improve ionization efficiency of fatty acids constitutes specific derivatization. For example, an easily ionizable group may be introduced by derivatization [22], which unfortunately necessitates additional sample preparation steps. Even higher signal intensities could be obtained by the incorporation of permanently positively charged groups like quaternary amines, e.g., trimethylaminoethyl ester moiety [23–25].

Along with fatty acids, fat-soluble vitamins such as in particular α-tocopherol (vitamin E) and its analogs (β-, γ-, and δ-) might be simultaneously analyzed by HPLC-MS/MS as they are of similar physico-chemical characteristics and of relevance in metabolomics studies of fermentation processes as well.

They are typically separated not only on RP stationary phases like C18 [26–28] but also on C30 stationary phases under strong elution conditions using acetone [29].

Again MS detection may be problematic. Regarding MS detection of α-tocopherol, it was reported that its complexation with silver ions, achieved by postcolumn infusion of AgClO4 solution, affected fragmentation, as additional fragments appeared [29].

The goal of the present work was to develop a LC–electrospray ionization (ESI)–MS/MS analysis method allowing simultaneous monitoring of various lipophilic metabolites and nutritional compounds in fermentation broths from production of β-lactam antibiotics including fatty acids, cephalosporin P1, and α-tocopherol. This method is supposed to complement our LC-MS-based metabolic profiling platform, which comprises a small array of hydrophilic interaction chromatography (HILIC)–MS/MS and reversed-phase liquid chromatography (RPLC)–MS/MS methods for the quantitative analysis of extracellular metabolites (including amino acids, organic acids, water-soluble vitamins, and secondary metabolites, i.e., β-lactams) [30] as well as intracellular metabolites (such as nuclobases, nucleosides, nucleotides and other phosphorylated compounds, sugars, and sugar acids) [31].

A straightforward RPLC-ESI-MS/MS method was developed and validated, enabling quantitative analysis of most relevant fatty acids without derivatization or postcolumn addition of complexing agents. “Pseudo-molecular” MRM transitions of most analytes were measured to alleviate the problem of limited sensitivity. Furthermore, much emphasis was put on the evaluation of calibration efforts and strategies to deal with matrix effects in the complex sample matrices. Different calibration approaches were comparatively examined and evaluated with regard to their possible routine application. An extension of the method, which additionally allows determination of less hydrophilic β-lactam derivatives (penicillin V and degradation products), is suggested in the Electronic supplementary materials. It was the aim to elucidate what can be accomplished by HPLC-MS/MS for direct analysis of free fatty acids in fermentation broths in case of lack of GC-MS, while it is not our intention to propose this method as replacement of GC-MS if such instrumentation is available.

Experimental

Chemicals and reagents

Standards of myristic acid 99.0%, tridecanoic acid 98.0%, pentadecanoic acid 99.0%, and heneicosanoic acid 99.0% were supplied from Sigma-Aldrich (Vienna, Austria). Arachidonic acid 98.5%, nonanoic acid 99.5%, heptadecanoic acid 99.0%, linolenic acid 98.5%, linoleic acid 99.0%, and (+)-α tocopherol 99.0% were from Fluka (Sigma-Aldrich). Uniformly 13C-labeled palmitic acid (99 atom% 13C) and stearic acid (99 atom% 13C) were purchased from Sigma-Aldrich. Lauric acid 99.6%, palmitic acid 99.3%, stearic acid 99.9%, oleic acid 99.4%, and cephalosporin P1 93.8% were provided by Sandoz (Kundl, Austria). For LC-MS/MS analysis, Chromasolv Plus ultra pure water from Sigma-Aldrich, HPLC grade acetonitrile (ACN) from VWR (Leuven, Belgium), HPLC grade isopropanol (IPA), and ethylacetate (EtOAc) from Roth (Karlsruhe, Germany) were used. Acetic acid 99.8% and ammonium hydroxide solution (NH4OH) 25.0% in water were obtained from Fluka (Sigma-Aldrich).

Methanolic extracts of fermentation broths stemming from the production of β-lactam antibiotics as well as various nutrition media were provided by Sandoz.

LC-MS/MS instrumentation

Experiments were performed on an Agilent 1200 HPLC system (Agilent, Waldbronn, Germany) coupled to a Q-Trap 4000 (Applied Biosystems/MDS Sciex, ON, Canada). The HPLC system was equipped with a thermostatted autosampler, which allowed cooling of the samples to 5 °C, a binary pump, and a column thermostat. A turboionspray (TIS) source was used as ESI interface. Data were processed using the Analyst 1.4.1. software.

Optimization of MS parameters

Detection was carried out in the MRM mode with positive and negative polarity depending on the solute (see Table 1).

Compound-dependent fragmentation parameters were optimized using the quantitative optimization tool of the Analyst software. For this purpose, standard solutions were prepared with concentrations ranging from 0.5 to 5.0 mg/L in a mixture of ACN and buffer (20 mM acetic acid adjusted to pH 5.0 with ammonium hydroxide solution; 50:50; v/v) and then introduced into the MS by continuous infusion using a syringe pump. The flow rate was set to 30 µL/min. The resultant optimized MS parameters for the target solutes are summarized in Table 1. Further, MS parameters were optimized by performing LC-MS/MS runs applying different TIS temperatures (550, 600, and 650 °C) and TIS voltages (4,300 and 4,000 V).

Optimization of chromatographic conditions

A mixed standard solution of eight fatty acids (Table 1) was analyzed using two stationary phases, namely Synergi Fusion-RP 80 (150 × 3.0 mm ID; 4 µm particles) from Phenomenex (Aschaffenburg, Germany) and X-Bridge C18 (150 × 3.0 mm ID; 3.5 µm particles) from Waters (Vienna, Austria) using a mobile phase pH of 5.0. Additionally the X-Bridge C18 stationary phase was also tested at a buffer pH of 9.5. Both columns were equipped with dedicated precolumns (Synergi Fusion-RP 5 µm, 4.0 × 3.0 mm ID and X-Bridge™ C18 3.5 µm, 10 × 2.1 mm ID, respectively).

Mobile phase conditions were as follows: Eluent (A) contained 10% (v/v) buffer in H2O and eluent (B) 10% (v/v) buffer in ACN, whereupon the buffer consisted of 50 mM acetic acid. The pH was adjusted with ammonium hydroxide solution to 5.0 and 9.5, respectively. Solutes were eluted by linear mobile phase gradients starting from either 50% or 70% (B) and increasing to 100% (B) in 20 min, followed by 5 min hold at 100% (B), at a flow rate of 0.3 mL/min. Finally, mobile phase conditions were changed within 1 min to gradient starting conditions, and the stationary phase was allowed to reequilibrate for 13 min.

Final LC-MS/MS method

The set of analytes comprised besides the eight mentioned fatty acids also α-tocopherol and cephalosporin P1 (see Table 1). Finally, optimized mobile phase conditions were as follows: eluent (A) contained 5% (v/v) buffer in water and eluent (B) 5% (v/v) buffer in 55% (v/v) ACN and 40% (v/v) IPA. The employed buffer consisted of 100 mM acetic acid adjusted to pH 5.0 with ammonium hydroxide solution.

The corresponding optimized gradient profile is as follows: 70% B to 100% (B) in 20 min with flow rate of 0.3 mL/min, then increase of flow rate to 0.5 mL/min within 1 min employing 100% (B) followed by hold at 100% (B) for 6 min at 0.5 mL/min and afterward re-equilibration with 70% (B) from 27 to 40 at 0.3 mL/min. The LC run was divided into three time periods corresponding to retention time windows of the analytes. Only MRM transitions of compounds that eluted within the respective time windows were measured (Table 1). Ion source parameters were adjusted as following: turboionspray voltage ±4,000 V, temperature 550 °C, curtain gas 10 psi, turbogas 50 psi, nebulizer gas 50 psi, cell entrance potential ±10 V. Collision gas pressure was set to high. DP and CE were adjusted according to the results of the fragmentation optimization experiments (see Table 1), and dwell time was set to 100 ms for each MRM transition.

The injector needle was washed after each sample injection by dipping into a vial containing EtOAc.

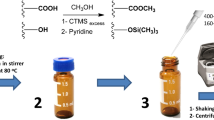

Preparation of solutions

To yield a concentration of 1.0 mg/mL, 0.8 to 1.0 mg of each compound was weighed into Eppendorf vials and diluted with EtOAc/IPA (50:50, v/v). These individual standard solutions were used to prepare mixed stock solutions of spiking standards intended for standard addition (0.50, 0.75, 1.0, 2.5, 5.0, 7.5, 10.0, and 20.0 mg/L) and internal standards (1.0 and 5.0 mg/L, respectively). Cold methanolic sample extracts of fermentation broths and nutrition media were diluted 1:10 with the standard diluent water/ACN (80:20; v/v).

Each calibration sample for analysis was prepared by mixing of 100 µL 1:10 diluted sample (of extracts or nutrition media), 100 µL spiking solution, and 100 µL internal standard solution with 700 µL diluent.

Fifteen methanol extracts stemming from two different fermentation lots, one from penicillin synthesis the other one from cephalosporin synthesis, sampled at different time intervals of the fermentation process and eight different nutrition media were analyzed. Sample preparation included mixing of 100 µL internal standard and 100 µL of 1:10 diluted extracts which after addition of 800 µL diluent (water/ACN, 80:20, v/v) yielded a final dilution factor of 1:100.

Validation of the final LC-MS/MS method

Calibration

Four different approaches for calibration were evaluated: (A) calibration with neat standard solutions (matrix-free solutions of standard compounds in water/ACN, 80:20; v/v) with and without use of internal standards for peak area normalization and (B) matrix-matched calibration using standard addition, also performed with and without use of internal standards.

Fatty acids with uneven carbon number (nonanoic acid, tridecanoic acid, pentadecanoic acid, heptadecanoic acid, and heneicosanoic acid) as well as uniformly 13C-labeled palmitic acid and stearic acid were employed as internal standards.

Neat standard solutions of seven different concentrations (0.05, 0.075, 0.1, 0.5, 0.75, 1.0, 2.0, and 4.0 mg/L) in water/ACN (80:20; v/v) were employed for generation of calibration functions.

For matrix-matched calibration using standard addition, distinct amounts of standards were spiked to three extracts (extract 11, 16, and 4), stemming from two different fermentation lots (extracts 11 and 16 from penicillin production and extract 4 from cephalosporin production), and to two nutrition media (medium 10 and medium 16). The calibration set covered eight different concentration levels. The concentrations of the corresponding spiking standard solutions were 0, 0.5, 0.75, 1.0, 5.0, 7.5, 10.0, and 20.0 mg/L. Spiking solution (100 µL) was added to the 1:10 diluted extracts and nutrition media.

Calibration functions were constructed by (1) plotting peak area vs concentration and (2) by plotting the ratio of analyte peak and internal standard peak area (normalized area) vs concentration. Linear regression was performed using the Analyst software; 1/x 2 was introduced as weighting factor if accuracy of calibration functions in the low concentration range could be improved by that. The sum of relative errors served as goodness-of-fit parameter.

Calibration functions resulting from standard additions were corrected for the endogenic analyte concentrations in the sample.

Precision, accuracy, and LOQ

Method precisions and accuracies were determined by measuring quality control samples obtained by spiking a sample extract at three concentration levels (extract 11 spiked with concentrations of 0.075, 0.5, and 1.0 mg/L) in triplicate. Accuracies were calculated utilizing calibration functions constructed from different calibration procedures with and without internal standards.

To elucidate interday precisions and accuracies, calibrations were performed on three different days. Interday precisions and accuracies were determined for calibration via standard addition using extract 11. For that purpose, one quality control sample (extract 11 spiked with a concentration of 0.5 mg/L) was stored at 5 °C and analyzed at three different days in triplicate using freshly constructed calibration functions.

Limit of quantitation (LOQ) was determined using neat standard solutions and was considered as the concentration for which the ratio of signal/noise was greater than 10. For linoleic acid, oleic acid, palmitic acid, and stearic acid, LOQ was calculated from the standard deviation of the memory peak areas. Thus, standard deviations of peak areas of the respective compounds in blank runs were determined (n = 3). LOQ was then calculated for these compounds according to Eq. 1:

Results and discussion

Optimization of MS/MS parameters

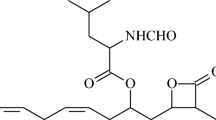

Optimization of the compound-specific fragmentation parameters was performed for each individual analyte using the quantitative optimization tool of the Analyst software. While cephalosporin P1 and arachidonic acid revealed characteristic fragmentations, other fatty acids and α-tocopherol were more or less resistant to strong specific fragmentation under the relatively soft ESI conditions. In fact, especially saturated fatty acids do not readily fragment. Thus, fragmentation completely failed for oleic acid and stearic acid, for which no detectable MRM transitions could be obtained. For this reason, “pseudo-MRM” transitions were optimized, where the pseudo-molecular ion was selected as precursor ion in Q1 and as product ion in Q3 as well, while MS parameters were optimized to avoid strong fragmentation in Q2. This allowed to detect these analytes with sufficient sensitivity as compared to regular MRM transitions with more specific, yet low, abundant fragments as product ions, however, at the expense of specificity.

Results of optimization of the fragmentation of α-tocopherol showed a noteworthy abnormality. α-Tocopherol, a phenolic compound, was detected in the positive mode. Typically positive ionization in the ESI process occurs by the formation of proton adducts. Thereby the molecular mass is increased by one mass unit. In case of α-tocopherol, which exhibits a molecular mass of 430.7 g/mol, higher signal intensities were obtained for m/z (mass/charge ratio) 430.5 (molecular ion) than for 431.5. This may indicate the formation of a radical cation. As a result, the transition 430.5 → 165, which might be employed as an alternative to the pseudo-MRM transition, yielded a more intense signal than the transition 431.5 → 165. This phenomenon was also observed by other groups [28, 32], which reported to find a constant ratio of m/z 430 to 431 using an APCI ion source.

Overall, reasonable intensities could be obtained with the selected optimized MS parameters, which are summarized in Table 1.

Optimization of chromatographic conditions

Fatty acids completely differ in their physico-chemical characteristics from other target analytes of the present extended metabolic profiling study, which mostly comprised rather small hydrophilic compounds like amino acids, organic acids, β-lactams, or vitamins [30]. Because of the wide range of polarities, it was not possible to find chromatographic conditions that were suitable for all compounds of interest. For this reason, analytes were separated into two groups: (1) metabolites and other polar compounds that can be retained on polar stationary phases in the HILIC mode, which are dealt with elsewhere [30], and (2) fatty acids and other hydrophobic compounds, which can be separated by RP chromatography, reported herein.

Concerning analysis of fatty acids, it was supposed that higher pH values of the mobile phase bring about increased deprotonation of fatty acids and thus would have a positive effect on ESI ionization efficiency [33]. Surprisingly, pK a values higher than 9 have been reported for long chain fatty acids [34]. For this reason, a buffer pH of 9.5 was tested initially (also due to the original idea of detecting α-tocopherol in negative ion mode) using X-Bridge C18, which is claimed to be stable in a pH range of 1–12. X-Bridge C18 of Waters is a hybrid organic–inorganic material that incorporates ethylene bridges into the siloxane matrix, which provide enhanced hydrolytic stability. Moreover mobile phase conditions with an intermediate buffer pH of 5.0 were also tested on X-Bridge C18 as well as on Synergi Fusion-RP 80.

In Fig. 1, total ion chromatograms (TIC) of standard solutions of fatty acids obtained on X-Bridge at a pH 9.5 and at a pH 5.0 are shown. As expected at pH 5.0, retention was markedly increased for all compounds in comparison to pH 9.5. Saturated fatty acids were relatively stronger affected by the pH switch than unsaturated ones, causing a change in the elution order. A possible explanation is that unsaturated fatty acids exhibit lower pK a values than saturated ones, when adsorbed to a surface [34]. Baseline separation of all fatty acids could be achieved at pH 9.5, whereas at pH 5.0, palmitic acid and oleic acid were not fully separated anymore, and stearic acid was not eluted within 30 min with the employed acetonitrile gradient (Fig. 1).

TIC of fatty acids on X-Bridge C18 obtained with eluents at pH 9.5 (a) and pH 5.0 (b). 1 Lauric acid, 2 myristic acid, 3 linolenic acid, 4 linoleic acid, 5 arachidonic acid, 6 palmitic acid, 7 oleic acid, and 8 stearic acid. Mobile phase conditions: (A) 10% (v/v) buffer in water, (B) 10% (v/v) buffer in ACN. Gradient elution from 50% (B) to 100% (B) in 20 min, then 5 min 100% (B), followed by re-equilibration with starting conditions for 13 min. Buffer: a 50 mM acetic acid adjusted with ammonium solution to pH 9.5 and b 50 mM acetic acid adjusted with ammonium solution to pH 5.0

Since X-Bridge C18 provided better peak efficiencies and selectivities for fatty acids than Synergi Fusion, this stationary phase was chosen for further method optimization.

Cephalosporin P1 and α-tocopherol, being also very apolar hydrophobic compounds, could be analyzed under RP conditions along with fatty acids. Cephalosporin P1 can be easily integrated in the aforementioned RP methods. However, α-tocopherol exhibited very strong interactions with the stationary phase. To decrease retention time, elution strength of the mobile phase had to be increased, which was achieved by partly substituting ACN by IPA in the organic phase. The effect of higher elution strength with a mixture of ACN/IPA/buffer (50/40/10, v/v/v) in channel B is confirmed by the chromatograms of lauric acid, linolenic acid, and linoleic acid presented in Fig. 2. Finally, we ended up with a reasonably fast LC method using X-Bridge and a mobile phase buffer pH of 5.0, as α-tocopherol could not be analyzed using a buffer at pH 9.5. A lower pH (<7.0) was also favorable in view of the possibility to include some β-lactam derivatives (see the Electronic supplementary materials), which are less stable at high pH values. Under such optimized conditions, compounds differing in their m/z by only two mass units such as oleic acid (m/z 281) and stearic acid (m/z 283) were readily separated, which was of importance in order to avoid interferences.

Overlaid extracted ion chromatograms of a lauric acid, b linolenic acid, and c linoleic acid in standard mixtures with a defined concentration of 1 mg/L employing different mobile phase conditions. The first eluting peak (1) corresponds to a buffer pH 9.5, the second one (2) to a buffer pH 5.0 containing 40% (v/v) IPA in the organic phase, and the third (3) to a buffer pH 5.0 containing solely ACN as organic modifier

The chromatograms of selected fatty acids at equal concentrations (1 mg/L) presented in Fig. 2 reveal that higher signal intensities were obtained at a pH of 5.0 and that signal intensities were further improved by addition of IPA revealing a positive effect on ionization efficiency of fatty acids. This stands in contrast to the assumption, which was stated before, that higher mobile phase pH would provide better ionization efficiency. Mobile phase conditions specified in Fig. 2b have been adopted as optimized conditions, and the corresponding chromatogram of all analytes is depicted in Fig. 3.

Chromatogram obtained employing the optimized RPLC-MS/MS method: overlaid MRM traces normalized to 100% of fatty acids (investigated analytes as well as internal standards), cephalosporin P1, and α-tocopherol. Experimental conditions: column: X-Bridge C18 from Waters (150 × 3.0 mm ID); eluent: channel A, 5% (v/v) buffer in water; channel B, 5% (v/v) buffer in 55% (v/v) ACN and 40% (v/v) IPA; buffer—100 mM acetic acid, adjusted to pH 5.0 with ammonia; gradient elution as specified in the “Experimental” section

Memory effects

In blank runs (injection of pure ACN) following injection of fatty acid standards or fatty acid containing samples, minor peaks could be found for nearly all fatty acids at their corresponding retention times. Excessive washing of column and injection needle minimized this disturbing phenomenon, yet could not completely eliminate it. So called “memory effects” could be found for nearly all fatty acids, except for arachidonic acid. For lauric acid, linolenic acid, and myristic acid, the effect was negligible and mostly much lower than the LOQ (i.e., S/N < 10:1). For linoleic acid, oleic acid, palmitic acid, and stearic acid, the effect was more pronounced and required to elevate the LOQs. Several experiments were carried out including flushing with 100% organic phase and injection of several 100 µL plaques of EtOAc to eliminate such memory effects without ground breaking success. These memory effects are supposed to have a noteworthy influence on furnished validation results especially for palmitic acid, oleic acid, and stearic acid at low concentrations. Precision and accuracy of these compounds were always worse compared to the results obtained for the other compounds and LOQ was thus much higher. LOQ of linoleic acid, oleic acid, palmitic acid, and stearic acid were therefore differently determined as given by Eq. 1. Above these obtained LOQs, the method showed to be suitable despite this memory effect because of a relatively constant background level of this memory effect for the individual fatty acids. It is also remarkable that memory effects were not observed when an isocratic elution mode was tested.

Validation of final LC-MS/MS method

Calibration, linearity, and LOQ

Calibration was performed by applying four different calibration protocols: calibration using neat standard solutions with and without internal standards and matrix-matched calibration via standard addition in extracts, again, with and without internal standards. Structural analogs of fatty acids with an uneven number of carbon atoms were employed as internal standards, as they were not expected to be present in the sample extracts of the fermentation broths. Moreover, they exhibit similar structures and retention times and were examined for their capability to correct for instrumental fluctuations and other disturbances. Additionally, uniformly 13C-labeled stearic and palmitic acid were tested as internal standards in comparison to corresponding non-isotope-labeled counterparts.

Linearity was evaluated by establishment of calibration functions obtained by analysis of neat standard solutions with and without peak area normalization and ranged over two orders of magnitude for linoleic, oleic, palmitic, stearic acid, and tocopherol and over three orders of magnitude for arachidonic acid, cephalosporin P1, lauric, linolenic, and myristic acid. The corresponding calibration curves exhibited correlation coefficients R 2 > 0.98. Weighted linear regression was performed using 1/x 2 as weighting factor, in case where accuracy could be improved this way.

Calibrants for matrix-matched calibration by standard addition were prepared by spiking distinct amounts of standard to three different fermentation extracts (extracts 11, 16, and 4) and two nutrition media (medium 10 and medium 16).

The correlation coefficient R 2 obtained with matrix-matched calibration was also >0.98 for the majority of analytes. For oleic acid, palmitic acid, and stearic acid, R 2 was somewhat lower especially using extract 4. This can be explained by high endogenic concentration levels of these analytes in the extract, which caused deviations in the low concentration range.

Detailed data of calibration functions established in the different matrices (extracts and media) can be found in the Electronic supplementary materials.

LOQ was defined as the concentration yielding a signal-to-noise ratio of 10:1 and was determined by dilution of neat standard solutions, except for linoleic, oleic, palmitic, and stearic acid. Since these compounds exhibited memory effects, a different strategy for the evaluation of LOQ was selected (see Eq. 1). As can be seen in Table 2, LOQs ranged between 0.005 and 0.05 mg/L for compounds without memory effects and between 0.03 and 0.137 mg/L for compounds exhibiting a memory effect.

Matrix effects

Matrix effects are one of the main reasons for the failure of quantitative HPLC-MS/MS bioassays [35, 36]. Constituents of the matrix may coelute with analytes of interest and may cause signal enhancement or more frequently suppression through modulation of ionization efficiencies in the ESI process. Absolute matrix effects refer to the situation that there are significant differences in signal intensities obtained in neat standard solutions and (after extraction) spiked blank samples. Moreover, the composition of various lots of biological samples may show strong variation. Thus, the type and extent of matrix effect in different lots of samples may not be uniform, which is referred to as relative matrix effects. Since quantitative results may be severely biased by matrix effects, it is necessary to investigate the possible influence of the matrix, especially when complex samples are analyzed without sample pretreatment like in the present metabolic profiling application.

There are several approaches to investigate matrix effects such as postextraction addition and postcolumn infusion experiments [37, 38]. Another one involves comparison of slopes of calibration functions obtained from calibration with neat standards with the slopes from matrix-matched calibration obtained by standard addition [38]. In Table 3, results of the evaluation of absolute and relative matrix effects by comparison of slopes of calibration functions, which were obtained without use of internal standards, is presented. The acceptance criterion for absolute matrix effects was established at 80–120% relative to slopes obtained in neat solutions. Except for palmitic and stearic acid, no strong absolute matrix effects were found in the investigated sample matrices. Furthermore, relative matrix effects (calculated as the relative standard deviation of the mean in six different matrices) were also found to be in an acceptable range as percent relative standard deviation (% RSD) values of slopes obtained in different matrices were consistently lower than the established acceptance criterion of 20%.

In Figure S1 of the Electronic supplementary materials, slopes of calibration functions obtained in various matrices without use of internal standards are plotted against each other. Significant deviations of data points from the 45° parity line (corresponding to equal slopes and thus equal sensitivities in neat standard solutions and in matrix) would indicate the presence of matrix effects. As illustrated in Figure S1 (see Electronic supplementary materials), slopes of most fatty acids lie within the acceptance interval of 80–120% relative to the slopes obtained in neat standard solutions, indicating absence of strong matrix effects, except for palmitic acid and stearic acid for which they were slightly outside the defined acceptance limits being tantamount with a non-negligible absolute matrix effect.

Precision and accuracy

Intra-assay precision was determined by repetitively (n = 3) analyzing spiked standards of one extract (extract 11) at three concentration levels (0.075, 0.5, and 1.0 mg/L). The % RSD of resultant concentrations calculated by corresponding calibration functions was always lower than 7% for analysis with internal standards (Table 2) and lower than 5% for analysis without internal standards.

Interday precision was determined for one spiking level (0.5 mg/L) using matrix-matched calibration in extract 11 with and without internal standards. Without use of internal standards, interday precision ranged within 20% and 30% for all analytes. Interday precision was improved when internal standards were employed and ranged between 3% and 16% RSD for all analytes, except for stearic acid for which it was 22% when heptadecanoic acid and 31% when the 13C-labeled internal standard was utilized for normalization (compare Table 2). On each day, new calibration curves were established using freshly prepared solutions.

Accuracies that were furnished by the different calibration protocols were determined with quality control samples prepared by spiking of extract 11 and are given as % recovery.

Detailed data of accuracies for these QC samples calculated with corrected matrix-matched calibration functions from extract 11 and other extracts/media are given in the Electronic supplementary materials.

From the data in the Electronic supplementary materials, it can be deduced that matrix-matched calibration was more accurate than calibration with neat standards. It is not surprising that the best results for accuracy were obtained with corrected matrix-matched calibration in extract 11 (i.e., corrected for its endogenous concentrations). Table 2 shows intraday accuracy of QC samples based on extract 11 spiked at three concentration levels and calculated with corrected matrix-matched calibration functions obtained by standard addition to the same extract 11. It is evident that the majority of accuracies were within 93% and 116% except for stearic acid for which accuracy at the highest level was 71%. Utilization of internal standards did not generally improve intra-assay accuracies, yet that for stearic acid at high levels could be increased to about 80%.

This method performance is quite acceptable and in agreement with common acceptance limits as proposed by bioanalytical method validation guidelines [39] and should be, in particular, adequate for process control in fermentations.

Calibration of stearic acid and palmitic acid was performed using two different types of internal standards, namely a structurally related compound heptadecanoic acid and uniformly 13C-labeled standards. No significant differences concerning accuracy could be determined for the two different internal standards which were more or less equivalent in terms of correcting for inaccuracies (compare Table 2).

Figure S2 of the Electronic supplementary materials illustrates that in the course of the accuracy testing, the bias (averaged over three concentration levels) employing different calibration approaches (with and without internal standards, calibration in different matrices) were for all compounds, except for stearic acid, lower than the acceptance limit of 20% with and without use of internal standards.

Interday accuracies were determined for a QC sample prepared from extract 11 (intermediate level only), and for calculations, a corrected matrix-matched calibration function in the same extract 11 was utilized. Detailed results as obtained with and without internal standards are given in the Electronic supplementary materials. Briefly, without internal standards, accuracies scattered between 71% and 127% and could be significantly improved when internal standards were employed for data analysis, as expected. Table 2 depicts the values afforded with internal standards which ranged between 88% and 111%, which was considered to be quite tolerable. Instrumental fluctuations may be compensated for by use of internal standards as expected.

Interday precision and accuracy values for cephalosporin P1 and α-tocopherol were not considered because they were severely biased by their limited compound stabilities.

Discussion of method validation results

Calibrations were performed over a period of 4 days using neat standard solutions and matrix-matched calibration by standard addition in five different matrices.

Within one analysis sequence, slopes of calibration functions (in neat solution, in extracts 11, 4, and 16, and in media 10 and 16) showed quite good agreement for the different calibration approaches. Without use of internal standards, % RSD of slopes in the above mentioned distinct matrices was <9% for cephalosporin P1, lauric acid, linolenic acid, myristic acid, and arachidonic acid. For linoleic acid, oleic acid, palmitic acid, and stearic acid, significantly higher % RSD values were found (12.2–21.1%).

Using internal standards, % RSD values of slopes of the calibration functions were even lower and were <7% for lauric acid, linolenic acid, linoleic acid, myristic acid, and arachidonic acid. Concerning oleic acid, palmitic acid, and stearic acid, the slopes for calibration with neat standard solutions using internal standards were increased by a factor of 2, which may be attributed to an absolute matrix effect.

Comparing the slopes of calibration functions generated over a period of 14 days without use of internal standards, a significant decrease in steepness of slopes was recognized, whereas the slopes of calibration functions generated using internal standards agreed quite well (data not shown). An explanation may be a loss of detection sensitivity over time, which may have been caused by accumulation of impurities in the ESI sprayer or by contamination stemming from other sources. Internal standards can correct for such changes in detector sensitivity and can thus enable prolonged calibration intervals.

Concerning the situation within individual assays for oleic, palmitic, and stearic acid, calibration without internal standards often provided better results for accuracy and better agreement of slopes of calibration functions generated by spiking different matrices, probably because of accumulation of measurement uncertainties from two compounds, i.e., analyte and internal standard in case of use of internal standards. Nevertheless, for routine use, it is recommended to utilize some kind of internal standards and to regularly analyze quality standards between series of measurements, which should indicate changes in instrument sensitivity. These findings are no surprise; however, the current data allow to derive information on how to design the final method with regards to intervals between calibration runs, QC samples, and ESI sprayer cleaning as well as employment of which type of internal standard.

Validation results suggest that the structurally similar fatty acids with uneven carbon number are appropriate to be used as internal standards for fatty acids. Surprisingly it turned out that these structurally similar internal standards sometimes corrected even better for changes in experimental conditions for palmitic acid and stearic acid than expensive 13C-labeled internal standards.

Overall, it is stressed that matrix-matched calibration with averaged equations (from different lots of matrix) corrected for endogenous analyte concentrations is recommended for routine use. Matrix-to-matrix variations are averaged out, and the work load to do so is only slightly higher than with neat standard solutions.

Application of the developed method

Samples originating from two different fermentation batches of penicillin as well as cephalosporin synthesis were taken, and methanolic extracts of extracellular metabolites were prepared from these fermentation broths. Afterward, these sample extracts were analyzed, employing the presented method together with further samples stemming from different nutrition media. Linoleic, linolenic, oleic, palmitic, and stearic acid and cephalosporin P1 (data not shown) were successfully detected and quantified in extracts 4 and 11. The results are summarized in Table 4 and confirm the applicability of the developed assay for fatty acids in fermentation broths. A chromatogram of extract 11 spiked at the concentration of 0.05 mg/L is depicted in Fig. 4.

Conclusions

A RPLC-ESI-MS/MS method was developed for the quantitative analysis of free underivatized fatty acids and some other apolar compounds (α-tocopherol and cephalosporin P1) in extracts of fermentation broths and nutritional media. Although no sample clean up or other sample treatment was performed (except of 1:100 dilution of the methanolic extracts before injection), no strong matrix effects were detected except for stearic acid.

Comprehensive investigation of various approaches for calibration, including calibration using matrix-free standard solutions and calibration via standard addition in five different matrices, revealed that matrix-matched calibration combined with the use of internal standards performs best with regard to routine applications, as longer intervals for calibration can be tolerated. The use of structurally similar fatty acids with an uneven number of carbon atoms as internal standards for fatty acids proved to be a good alternative to expensive 13C or other isotopic-labeled standards.

Memory effects that appeared for most fatty acids could not be entirely eliminated. These memory effects seemed to be constant, and for the concentration range of interest in process control, in which extracellular compounds are analyzed, no intolerable negative influences on accuracy and precision were observed.

The present RPLC-ESI-MS/MS method may be not as powerful and robust as GC-MS implementing precolumn derivatization, yet may be regarded as a useful alternative if GC-MS equipment is not available. In our case, it complements our LC-MS-based metabolic profiling platform that consists of a small set of HILIC and RPLC-ESI-MS/MS methods and is assessed to be suitable in particular for process control of extracellular metabolites and nutrients, respectively.

References

Van der Greef J, Hankemeier T, McBurney RN (2006) Pharmacogenomics 7:1087–1094

Oldiges M, Luetz S, Pflug S, Schroer K, Stein N, Wiendahl C (2007) Appl Microbiol Biotechnol 76:495–511

van der Werf MJ, Overkamp KM, Muilwijk B, Coulier L, Hankemeier T (2007) Anal Biochem 370:17–25

Hu C, van der Heijden R, Wang M, van der Greef J, Hankemeier T, Xu G (2009) J Chromatogr B 877:2836–2846

Bicalho B, David F, Rumplel K, Kindt E, Sandra P (2008) J Chromatogr A 1211:120–128

Eder K (1995) J Chromatogr B 671:113–131

Sajiki J, Yonekubo J (2002) Anal Chim Acta 465:417–426

Lagerstedt SA, Hinrichs DR, Batt SM, Magera MJ, Rinaldo P, McConnell JP (2001) Mol Genet Metab 73:38–45

Yi LZ, Yuan DL, Che ZH, Liang YZ, Zhou ZG, Gao HY, Wang YM (2008) Metabolomics 4:30–38

Zheng X, Shen J, Liu Q, Wang S, Cheng Y, Qu H (2009) J Pharm Biomed Anal 49:481–486

Lacaze J-PCL, Stobo LA, Turrell EA, Quilliam MA (2007) J Chromatogr A 1145:51–57

Perret D, Gentili A, Marchese S, Sergi M, Caporossi L (2004) Rapid Commun Mass Spectrom 18:1989–1994

Pettinella C, Lee Seon H, Cipollone F, Blair Ian A (2007) J Chromatogr B 850:168–176

Rigol A, Latorre A, Lacorte S, Barcelo D (2003) J Mass Spectrom 38:417–426

Nagy K, Jakab A, Fekete J, Vekey K (2004) Anal Chem 76:1935–1941

Carrier A, Parent J (2001) J Liq Chromatogr 24:97–107

Nikolova-Damyanova B, Momchilova S (2002) J Liq Chromatogr 25:1947–1965

Ratnayake WMN (2004) J AOAC Int 87:523–539

Zehethofer N, Pinto DM, Volmer DA (2008) Rapid Commun Mass Spectrom 22:2125–2133

Hsu F-F, Turk J (1999) J Am Soc Mass Spectrom 10:600–612

Afonso C, Riu A, Xu Y, Fournier F, Tabet J-C (2005) J Mass Spectrom 40:342–349

Johnson DW (1999) Rapid Commun Mass Spectrom 13:2388–2393

Yang W-C, Adamec J, Regnier FE (2007) Anal Chem 79:5150–5157

Lamos SM, Shortreed MR, Frey BL, Belshaw PJ, Smith LM (2007) Anal Chem 79:5143–5149

Johnson DW (2000) Rapid Commun Mass Spectrom 14:2019–2024

Capote FP, Jimenez JR, Granados JMM, Luque de Castro MD (2007) Rapid Commun Mass Spectrom 21:1745–1754

Bustamante-Rangel M, Delgado-Zamarreno MM, Sanchez-Perez A, Carabias-Martinez R (2007) Anal Chim Acta 587:216–221

Lauridsen C, Leonard SW, Griffin DA, Liebler DC, McClure TD, Traber MG (2001) Anal Biochem 289:89–95

Rentel C, Strohschein S, Albert K, Bayer E (1998) Anal Chem 70:4394–4400

Schiesel S, Laemmerhofer M, Lindner W (2009) Anal Bioanal Chem (submitted)

Preinerstorfer B, Schiesel S, Laemmerhofer M, Lindner W (2009) J Chromatogr A. doi:10.1016/j.chroma.2009.11.051

Andreoli R, Manini P, Poli D, Bergamaschi E, Mutti A, Niessen WMA (2004) Anal Bioanal Chem 378:987–994

Jemal M, Schuster A, Whigan DB (2003) Rapid Commun Mass Spectrom 17:1723–1734

Kanicky JR, Shah DO (2002) J Colloid Interface Sci 256:201–207

Taylor PJ (2005) Clin Biochem 38:328–334

Maurer HH (2007) Anal Bioanal Chem 388:1315–1325

Careri M, Mangia A (2006) Anal Bioanal Chem 386:38–45

Matuszewski BK, Constanzer ML, Chavez-Eng CM (2003) Anal Chem 75:3019–3030

Food and Drug Administration (2001) Guidance for industry. Bioanalytical method validation. FDA, Silver Spring

Acknowledgments

Financial support by the Austrian Christian Doppler Research Society and the industry partner Sandoz (Kundl, Austria) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Schiesel, S., Lämmerhofer, M. & Lindner, W. Quantitative LC-ESI-MS/MS metabolic profiling method for fatty acids and lipophilic metabolites in fermentation broths from β-lactam antibiotics production. Anal Bioanal Chem 397, 147–160 (2010). https://doi.org/10.1007/s00216-009-3340-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-009-3340-5