Abstract

Four new ionic liquids (IL) were prepared and bonded onto 5-µm silica particles for use as adsorbent in solid-phase microextraction (SPME). Two ILs contained styrene units that allowed for polymerization and higher carbon content of the bonded silica particles. Two polymeric ILs differing by their anion were used to prepare two SPME fibers that were used in both headspace and immersion extractions and compared to commercial fibers. In both sets of experiments, ethyl acetate was used as an internal standard to take into account adsorbent volume differences between the fibers. The polymeric IL fibers are very efficient in headspace SPME for short-chain alcohols. Immersion SPME also can be used with the IL fibers for short-chain alcohols as well as for polar and basic amines that can be extracted at pH 11 without damage to the IL-bonded silica particles. The sensitivities of the two IL fibers differing by the anion were similar. Their efficacy compares favorably to that of commercial fibers for polar analytes. The mechanical strength and durability of the polymeric IL fibers were excellent.

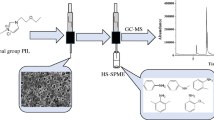

Chemistry of the polymerized ionic liquid absorbant and its morphology when bonded to the SPME fiber.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Solid-phase microextraction (SPME) was developed by Pawliszyn in the early 1990s as a simple and “green” technique for sample preparation without the use of any solvent [1–4]. SPME is simply performed by exposing a silica fiber covered by an adsorbing agent to the headspace (HS) volume of a vial or directly immersing it into the matrix of the liquid sample. A rapid preconcentration of analytes into the fiber surface is observed if the coating adsorbing agent is appropriate. The extracted agents are analyzed by simply placing the fiber into the injection port of a gas chromatograph (GC). The injector is heated at an elevated temperature that will cause the vaporization of the adsorbed analytes into the GC inlet and a classical GC chromatogram can be developed for full identification and quantitation of all extracted compounds.

The chemistry of the sorptive SPME coating layer plays a significant role in enhancing the extraction of specific classes of compounds and discriminating against others [5, 6]. The SPME extractant must primarily be thermally stable so as not to decompose during the GC injection process. Also, it must be mechanically strong to support agitation and manipulation. Finally, it must be able to withstand harsh chemical media when immersed in the sample solution including extreme pHs, high ionic strengths, and various organic solvent concentrations. Bare silica gel, polydimethylsiloxane (PDMS), divinylbenzene (PDMS–DVB), polyacrylate (PA), high-density polyoxyethylene (Carbowax) are used in commercially available SPME fibers [7, 8]. Since higher selectivity, as well as higher sensitivity, is needed as the technique gains widespread popularity, the quest for new coating adsorbents is the goal of numerous research teams [9–11].

Ionic liquids are a new class of non-molecular solvents with unique properties such as a very low volatility, often good thermal stability, electrical conductivity, good solvating properties, tunable polarity, and water or solvent solubility [12–17]. Ionic liquids are actually salts with a melting point close to or below room temperature. Their low volatility and unique solvating properties were soon considered as attractive properties that would make them very useful for use in separation techniques [18] and especially, possible candidates for new adsorbents for SPME fibers.

Considerable insights into solute-IL interactions and affinities were obtained during the development and evaluation of GC stationary phases made with ILs [19–22]. This experience was first used to develop microextractions on a single ionic liquid drop, i.e., without fiber support [23, 24]. Next ionic liquid coated fibers were prepared for a single determination of trace amount of polyaromatic hydrocarbons in water samples [25]. The contamination of the GC injection liner precluded the widespread use of this method. Polymerized ionic liquids were used to coat on the silica fiber and obtain thermally stable and reusable SPME fibers for esters [26] and amphetamine metabolite [27] determination.

Thus far, the reports on ionic liquid SPME fibers were successful with mixtures containing mainly hydrophobic and semi-polar compounds. It was found in GC analyses on ionic liquid stationary phase [20–22] and in ionic liquid-water liquid–liquid extractions [15] that alcohols had an unusually high affinity for ILs. In this work, attention will be given to the extraction of hydrophilic and polar compounds such as short-chain alcohols and amines. For this purpose, completely new and different ionic liquids were prepared and tested as new adsorbents for SPME. To reduce contamination and/or loss of adsorbent, the different ionic liquid derivatives were covalently bonded to silica microparticles that were subsequently used to prepare a porous and mechanically strong fiber coating. Both headspace and immersion techniques were tested to evaluate the capabilities of the newly developed bonded ionic liquid sorbents with a large variety of polar solutes.

Experimental

Materials and reagents

The reagents, imidazole, 1-methylimidazole, 1-hydroxyethyl imidazole, triethylene glycol, phosphorous tribromide, ethyl acetate, toluene, 4-chloromethyl styrene, tetrahydrofuran (THF), n-butanol, methylene chloride, chloroform, dioxane, butyric acid, phenol, dimethylamine, trimethylamine, pyridine, and aniline, were purchased from Sigma-Aldrich, Milwaukee, WI, USA. The common HPLC solvents: acetonitrile (ACN), isopropyl alcohol (IPA), ethanol, and methanol were OmniSolvTM solvents obtained from EMD Merck, Darmstadt, Germany. Kromasil spherical silica gel with 5 µm particle diameter, 10 nm pore size, and 310 m2 surface area was obtained from Supelco, Sigma-Aldrich.

The beverages tested were obtained from different local grocery stores. The standard reference material used for calibration was SRM 1828b from the National Institute of Standards and Technology (Gaithersburg, MD, USA).

Synthesis of the ionic liquid derivatives

Bis-hydroxyethyl imidazolium trioxyethylene derivatives

Bis-hydroxyethyl imidazolium trioxyethylene bis-(trifluoromethylsulfonyl) imide, noted (HeIM)2PEG3, 2 NTf −2 was synthesized following a method previously reported [28]. Trioxyethylene dibromide was reacted with hydroxyethyl imidazole, in a one to two mole ratio, in isopropyl alcohol (IPA) at 83 °C under reflux overnight. The bromide ionic liquid obtained was dissolved in methanol with Li NTf2 and mixed for 2 h. The NTf2 ionic liquid was extracted with methylene chloride, washed with water and ether, and dried in a vacuum oven with P2O5. It was reacted with triethoxysilane ethylisocyanate in dry ACN in a one to one mole ratio for 4 h. The ethoxysilane derivative was bonded to half its weight of silica particles to give IL 1 (Fig. 1, top). The elemental analyses and coverage are listed in Table 1.

The second ionic liquid polar derivative was performed following the same protocol as for IL 1 but the bromide ions were exchanged for trifluoromethyl sulfate or triflate ions (TfO−) instead of NTf −2 ions giving IL-2-bonded particles (Table 1).

1,1′-(1,6-hexanediyl)bisimidazole derivative

A 250-ml round-bottom flask was filled with 100 mL anhydrous dimethylformamide (DMF) and 2.0 g sodium imidazole (22.2 mmol). Next, 3.8 mL of 1,6-dichlorohexane (3.8 mmol) were slowly added into the DMF solution and stirred overnight at room temperature. After filtering off remaining solids, the filtrate was concentrated under reduced pressure and the resulting crude product was purified by column chromatography (SiO2 20 μm, 60 Å; CH2Cl2/methanol 9:1) to yield the desired product 1,1’-(1,6-hexanediyl) bis imidazole (88 %; Fig. 1, bottom). 1H NMR (300 MHz, DMSO-d 6): δ, 7.56 (s, 1H), 7.12 (S, 2H), 6.84 (s, 2H), 3.89 (t, J = 7.2 Hz, 4H), 1.64 (m, 4H), 1.21 (m, 4H). Calculated analytical mass: C12H18N4: C, 66.02; H, 8.31; N, 25.67; found: C, 66.21; H, 8.49; N, 25.70.

Styrene dicationic imidazolium monomer

One gram of 1,1′-(1,6-hexanediyl) bisimidazole (4.6 mmol) was dissolved in 20 mL CH3CN in a 100-mL round-bottom flask. 4-chloromethylstyrene (1.5 g; 10.1 mmol) was added with a syringe and the reaction was heated at 65 °C overnight. The reaction was then allowed to cool to room temperature and was poured into 100 mL diethyl ether. A precipitate formed immediately, and the crude product was cooled to −10 °C in the freezer. Et2O was decanted and the product dissolved in 20 mL deionized water. The aqueous phase was washed with ethyl acetate (3 × 50 mL) and water was removed by reduced pressure to obtain the dicationic imidazolium monomer in the chloride form (Figure 1, bottom). 1H NMR (300 MHz, DMSO-d 6): δ 9.58 (s, 2H), 7.83 (s, 4H), 7.50 (dd, J = 8.26 Hz, 8H), 6.71 (dd, J = 11.0 Hz, 2H), 5.86 (d, J = 17.54 Hz, 2 H), 5.41 (s, 4H), 5.41 (s, 4H), 5.28 (d, J = 12 Hz, 2H), 4.15 (t, J = 7.2 Hz, 4H); 1.22 (m, 4 H). Calculated analytical mass: C30H36N4; C, 68.82; H, 6.93; N, 13.54; found: C, 68.91; H, 7.02; N, 10.94.

Synthesis of the silica-bonded polymer

To a suspension of 4 g of azobis-isobutyronitrile-derivatized silica (Supelco) in Toluene was added 1.0 g of the dicationic monomer and the mixture was heated to 80 °C for 6 h. Then it was allowed to cool to room temperature with continued stirring overnight. Next, the content was filtered through fine-pore-sintered glass filter. The collected silica-bonded polymeric product was successively washed with 100 mL of toluene, ethanol, acetone, methanol, and chloroform. The final product was dried under vacuum at 50 °C.

Metathesis reaction

The bonded silica is in the chloride form. One gram of silica-bonded ionic liquid polymer in chloride form was mixed with 3 g of sodium triflate (NaTfO) and stirred overnight. After filtration, it was washed with deionized water until no white precipitate was seen testing the filtrate with dilute silver nitrate. The resulting silica-bonded polymer was vacuum dried overnight to obtain the bonded silica in the triflate form. Similar metathesis was carried out to obtain the silica-bonded ionic liquid polymer in its bis-trifluoromethanesulfonimide (NTf −2 ) form.

The (StyrIM)2C6, 2 TfO− ionic liquid was prepared on a similar manner exchanging the bromide ions for triflate ions before polymerization and bonding on silica particles. Table 1 lists the elemental carbon analyses of the bonded silica particles.

Equipment

Solid-phase microextraction

For all headspace extractions, a Supelco SPME fiber assembly and holder Model 57330 was used with a 57357-U sampling stand, a 57358-U heater block holding eight 15-mm vials of 4.0 mL and a Corning PC420-D heat/stir plate, all provided by Supelco (Sigma-Aldrich). Immersion extractions were done using the Supelco fiber assembly and a Varian CX 8200 autosampler (Varian Inc. Palo Alto, CA, USA) using 2 mL mini-vials. The ionic-liquid-derivative-bonded silica particles were sent to Supelco Bellefonte to be glued as a 50-µm layer onto SPME flexible core wire fitting the holder (Supelco® proprietary protocol). Figure 2 shows scanning electron microphotographs of Fiber 3. A very porous 50 µm layer is coated on the solid core. At high magnification (Fig. 2, bottom), it is possible to see the polymeric IL bonded onto each silica particle.

Scanning electron microphotographs of Fiber 3. Top left Side view of the fiber. Top right Granular structure of the coating due to the silica particles. Bottom right Enlargement of the coated layer showing the porous structure of the Stableflex® layer holding the bonded silica particles. The left inset is an enlargement of a single silica particle showing the IL polymeric coating as white spots covering the particles. bottom right For comparison, the same procedure was followed with bare silica particles. The IL coating is not seen

For comparison, commercial fibers were used in the same conditions as the newly developed fibers. They were a 65-µm polydimethylsiloxane / divinylbenzene fiber (PDMS/DVB) Stableflex 57326-U, a 60-µm polyoxyethylene glycol (PEG) 57354-U, a 100-µm PDMS 57300-U and an 85-µm polyacrylate fiber (PA) fused silica 57304 (Supelco). Before use, all the fibers were conditioned at 220 °C in the GC injection port under a flow of helium for 15 min.

Gas chromatography

An Agilent GC 6850 was used with a split injector and FID detector both set at 300 °C. A Chemstation software (Agilent, Palo Alto, CA, USA) was used to drive the chromatograph and process the chromatograms. The column for polar compounds and headspace analysis was a 30 m, 250 µm i.d., 0.25 µm film thickness Supelcowax™ 10 capillary column (Supelco). The stationary phase is a polyethylene glycol polymer of about 20 million molecular weight (Carbowax® 20 M). The column for polar and amine compounds analyzed by immersion was a 30 m, 320 µm i.d., 4 µm film thickness SPB-1 Sulfur PDMS capillary column (Supelco). Both columns were operated with helium as the carrier gas.

SPME protocol

Headspace analysis

A known amount of the polar test compounds: ACN, methanol, ethanol, n-propanol, IPA, n-butanol, acetone, and ethyl acetate, were added to 2.5 mL distilled water in a Teflon®-capped 4 mL vial. Seven hundred fifty milligrams of sodium chloride and a magnetic stir bar were added to the solution. The fiber holder needle was then inserted in the vial headspace. The fiber was exposed for 15 min to the headspace vapors obtained at 50 °C under fast 1,000 rpm stirring. After 15 min, the fiber was retracted inside the needle and the fiber holder was withdrawn from the vial. The needle containing the fiber was next inserted into the GC split injector set with a low split ratio of 5 to 1. The fiber was immediately exposed for thermal desorption of the adsorbed compounds at 200 °C for 2 min. After 2 min, the fiber was retracted inside the needle, the latter being simultaneously withdrawn from the injector. The sample was analyzed with the 30-m capillary column maintained at 50 °C for 4 min followed by a temperature gradient of 15 °C/min for 6 min and 40 s up to 150 °C, with 1 min at 150 °C. The helium carrier gas linear velocity was 35 cm/s (hold-up time 1.45 min) with an average flow rate of 1.0 mL/min. The FID solute peak areas were used for quantitation rather than the peak heights (see a typical GC chromatogram in supplemental information).

Immersion analysis

Stock solutions of the volatile analytes were prepared at concentration in the g/L range in water. A volume of 1.2 mL of buffer at different pH and containing 30% w/v NaCl was introduced in a 2-mL vial. Spiking additions using the stock solutions were made to prepare the mixture with known concentrations of the desired analytes at the selected pH. A total of five to six extractions by fully immersing the fiber in the liquid mixture for 10 min with strong agitation (50 Hz vibration) at room temperature were made with each sample. In all cases, the first extraction was excluded because results from the first extraction were usually not consistent with the remaining extractions. After 10 min, the vibration-agitation is stopped; the fiber is retracted inside the needle and withdrawn for the vial for immediate GC analysis. The needle is inserted into the GC injector at 220 °C or 250 °C and the fiber is exposed in splitless condition for 45 s then the split is opened at a ratio of 20 to 1 (total helium flow is ∼30 mL/min) for 1 min 15 s before being retracted into the needle and withdrawn from the injector. The chromatogram was developed with the capillary column maintained at 45 °C for 1.5 min followed by a temperature gradient of 8 °C/min for 4 min and 22 s up to 80 °C, followed by a faster gradient of 20 °C per min for 8 min and 30 s up to 250 °C with a 5-min hold at 250 °C. The helium carrier gas linear velocity was 30 cm/s (hold-up time 1.67 min) with an average flow rate of 1.5 mL/min. The FID detector was set at 290 °C. The solute peak areas were used for quantitation rather than the peak heights.

Results and discussion

Ethoxylated and polymeric alkylated ionic liquid derivatives

Polar analytes are hydrophilic. As such, they are more difficult to extract by the SPME protocol even maximizing the salting-out effect of adding sodium chloride close to the saturation concentration (359 g/L or 28% w/v at 25 °C) [2]. SPME was used to identify the fuel used in arson cases and was very effective with gas or petroleum derivatives but was much less so when alcohols were used as fuel source igniters [3, 29]. Thus, enhancing the capabilities of SPME with new adsorbents that have a high affinity for polar compounds is of considerable interest. The specific affinity of ionic liquids for alcohols and polar compounds may be used for this purpose. Considering the problems due to ionic-liquid-coated fibers (liner contamination in the GC injector and irreproducibility) [25], bonded IL silica materials were tailored for the task. Oxyethylene adducts were also selected to enhance to polarity of the ionic liquid derivative.

The 1 and 2 derivatives were bonded as oxyethylene adduct monomers onto the silica particle surface (Fig. 1, top and Table 1). The carbon loading and moiety molecular weight (Table 1) allows for an estimate of the bonding density as 1.2–1.5 µmol/m2. Such bonding density would be somewhat low for bonded silica particles used as the sorbent in stationary phase HPLC. The 8.5% to 9.2% carbon loading makes it acceptable for SPME extraction. Derivatives 3 and 4 were designed to increase substantially the carbon load by polymerizing a styrene bonded di-imidazolium monomer. The significantly higher carbon loads between 21 and 23% cannot be related to a coverage density since the additional carbon is strictly the result of the chain lengthening polymerization reaction up to the point that spots can be seen on the silica particle surface (Fig. 2, bottom).

The specific role of the anion in selectivity was pointed out previously [28, 30–32]. Specifically, linear solvation energy relationship (LSER) studies found that the triflate anion had less proton acceptor ability than the bis-(trifluoromethylsulfonyl)imide anion (lower b coefficient in the Abraham LSER regression equation) [28, 30, 32]. This is not surprising since triflic acid is one of the strongest acids known. TfO− also had a significantly higher a parameter (basicity) than NTf −2 [28, 30, 32]. It is then interesting to compare the effect of the anion in our ionic liquid sorbent derivatives.

Headspace analyses

Effect of the fiber exposure time

The same trend was observed for all studied new SPME fiber coated sorbents used in headspace extractions. The adsorbed amount of all analytes increases up to a plateau value reached after about 15 min of headspace exposure at 50 °C. A small decrease may be observed for some compounds exposed for times greater than 20 min. Figure 3 shows the results obtained with the polymeric IL sorbent 3 using the relative response value: {peak area (p.a.) at time t} over {p.a. at time 15 min}. The trend is the same for all compounds in this study. The absolute response in concentration depended on the nature of the solute as shown by the inset of Fig. 3. Similar sorption-time profiles were obtained for polymeric IL-coated fibers (30 min plateau time at 25 °C) [26] or IL-coated fibers for amphetamine detection (20 min plateau time at 50 °C) [27].

Profiles of the relative sorption expressed as [p.a. (t) over p.a. (15 min)] versus headspace exposure time for the polymeric ionic liquid 3 SPME fiber. The insert shows the corresponding raw data with peak areas (p.a.) expressed as FID picoampere time second. All solute concentrations were 5 µg/ml (ppm). Exposure temperature 50 °C, 3 g NaCl added to 10 mL as salting-out agent

Extraction parameter optimization

NaCl salting-out agent

Sodium chloride is added to the solution as a salting-out agent. Previous work showed that the maximum amount of added NaCl produced the highest partial pressure of volatile analytes in the headspace volume and, consequently, the highest amount of analytes extracted by the fiber [1–4, 23–27]. This result was confirmed with our fibers. A saturated NaCl solution at 20 °C contains 316 g/L and has a density of 1.20 g/mL. To avoid any precipitation and/or solubility problems, the amount of NaCl added to all solutions was 30% w/v (750 mg NaCl in 2.5 mL water) just below the saturation concentration.

Extraction temperature

Temperature is another parameter increasing the partial vapor pressure of the analytes in the headspace volume. However, it also increases the vapor pressure of water making the pressure of the headspace volume higher than atmospheric pressure. If leaks occur, the concentration of the extracted analytes may be biased. The working extraction temperature for all headspace experiments was set at 50 °C.

Analytical figures of merit

Table 2 lists the analytical figures of merit of the four fibers made with silica-coated ionic liquid particles (as listed in Table 1), along with those of two commercial fibers: a polyacrylate (PA) fiber and a polydimethylsiloxane/divinylbenzene (PDMS/DVB) fiber. The listed sensitivity value is the slope of the calibration line for the given analyte extracted by the given fiber. It is expressed in {units of GC peak area} per {analyte ppm (= microgram per milliliter) concentration}. The limits of detection (LOD) listed are given in microgram per liter or parts per billion. They were computed as the ratio of three times the baseline noise over analyte sensitivity. The curves regression coefficient and calibration ranges are also listed.

The sensitivities obtained with the two monomeric IL fibers (#1 and #2, Tables 1 and 2) are clearly lower than the corresponding sensitivities obtained with the polymeric IL fibers #3 and #4. The two polymeric-bonded IL fibers have a better absolute sensitivity than the commercial PA and PDMS–DVB fibers for the three lightest polar analytes: acetonitrile, methanol, and ethanol. The commercial fibers PA and especially PDMS–DVB have better sensitivities than the new IL-based fibers for all other tested polar compounds. Fiber #4 (bonded polymeric [(StyrIM)2C6, 2 TfO−] n , Table 1) showed higher absolute sensitivities than its NTf –2 Fiber #3 counterpart for all analytes (Table 2). It should be noted that with the IL-coated fibers, both the binder and silica used to prepare the adsorbing layer take a significant percentage of the coating volume having limited extraction capabilities. Furthermore, the coating volume of the IL-based fibers with a coating thickness of around 50 µm (Fig. 2) is itself lower than the coating volume of the commercial PA fiber (85 µm) and the PDMS–DVB fiber (65 µm). To take into account these composition and volume differences, we used ethyl acetate as an internal standard to normalize the results.

Figure 4 presents the Table 2 absolute results as relative results, i.e., plotting for each analyte the ratios of the analyte absolute response over the same fiber ethyl acetate response. This representation shows that the IL fibers have a better relative response for all selected analytes. For the polymeric-bonded IL fibers #3 and #4, the short-chain alcohols' relative response can be twice higher than that of the commercial fibers. For n-butanol that shows the highest absolute response for all fibers, the polymeric IL #3 (NTf2 anion) relative response is 20% higher than the other fiber response (Fig. 4).

Relative response ratios of analytes in headspace analyses with four ILs and two commercial fibers. The Table 2 sensitivity factors for each analyte and each fiber are expressed as their ratio over the ethyl acetate corresponding factor to take into account the differences between adsorbent masses

However, the relative representation of the results in Fig. 4 shows that, except for n-butanol, there is no significant difference between the NTf2 and TfO− IL fiber response. The higher absolute values obtained for Fiber #4 (Table 2) compared to Fiber #3 may be due to a higher silica particle density formed during the coating procedure. The relative response in headspace analysis for the two polymeric IL fibers is very similar being somewhat better than the two monomeric IL fibers. The enhanced affinity of ILs for short-chain alcohols observed with IL gas chromatography stationary phases [20–22] is confirmed in headspace analysis with IL-based adsorbents.

Use of the polymeric IL fiber for ethanol determination in beverages

The headspace analysis process was validated using the reference material NIST SRM 1828b and it was used with Fiber #4 to assess the ethanol content of several alcoholic beverages. A calibration curve was prepared between 5 and 100 ppm in volume (microliters of ethanol per liter of water). The NIST reference material is calibrated in mass. The beverage items were all labeled in ethanol % v/v. Considering the low concentrations involved, the water density was taken as 1 g mL−1 and the ethanol density (0.789 g mL−1) was used to establish the correspondence: 1,000 ppm in mass = 0.1% w/w = 0.1267% v/v. Table 3 lists the results obtained comparing them with the beverage labels. The relative standard deviation (RSD) on four experiments were between 6% and 12%. These RSDs may appear high for an analytical technique; they are the usual RSD values obtained in quantitative SPME experiments [2–5, 7, 8]. The average values obtained for the SPME ethanol extraction of the two reference materials with certified 0.02% and 0.1% w/w values, were respectively 0.0193 ± 0.0013% w/w and 0.097 ± 0.0079% w/w validating the method with an 8% RSD.

Five different beers and two liquors were analyzed for their ethanol content. The samples were diluted using the label indication in percent v/v so that the ethanol content for SPME analysis was around 50 ppm in volume, a value in the middle of the calibration curve. With ethanol being rapidly eluted in gas chromatography, no interferences were encountered in the sample analyses. Except for the beer sample containing the highest ethanol percentage, all SPME results, including the two certified samples, were found slightly below the label values (Table 3). SPME headspace extraction could be used to estimate the ethanol content of blood samples in a non-destructive way.

Immersion extractions

The protocol for immersion extractions is necessarily different from the headspace protocol (see “Experimental” section). Only the two polymeric fibers #3 and #4 were evaluated. Six extractions were performed successively for each sample at room temperature. The very first extraction of a new sample always gave results that differed significantly from the five following extractions, it was discarded. Ion-exchange could be responsible for this phenomenon. Since the cationic part of the IL is chemically attached to the fiber and the anion is bound by electrical interaction only, the fiber can behave as an anion-exchanger. Ion-exchange can occur between the high ionic strength solution and the fiber anions. The fiber can exchange its triflate or bis-triflylimide anions for chloride and/or phosphate anions in the sample.

Extractions at pH 2

Since bonded silica is known to be sensitive to pH, extractions at pH 2 and pH 11 were done with different analytes. Table 4 lists the results obtained for nine selected typical solutes with the two polymeric IL fibers #3 and #4, two commercial fibers: a 60-µm thick PEG fiber and a 100-µm thick PDMS fiber, and the same compounds that were used in headspace analyses plus a variety of other less volatile compounds. A more complete table listing 19 compounds can be found in supplemental material. The listed values are the average of five successive experiments. The low percent RSD for most of the extracted analytes indicate that the fibers are quite stable. The relatively higher RSD for methanol was associated to a slowly declining response with repeated extractions. This may be due to an experimental artifact (slow evaporation during sampling). The same trend was observed with phenol and butyric acid (see supplemental material).

The IL fibers were compared to a polar 60-µm PEG-coated fiber and to a non-polar 100-µm PDMS coated fiber. Table 4 lists the sensitivity obtained for each fiber expressed as GC peak area per parts per million (micrograms per milliliter) of analyte concentration. As observed in the headspace extraction study, the amount of extracting material has a great influence on the experimentally observed fiber sensitivity. Therefore, in the immersion extraction study also, ethyl acetate was used as an internal standard. Figure 5 presents the relative response ratios for each analyte and each fiber expressed as the absolute value for analyte on a given fiber (from Table 4) divided by the corresponding ethyl acetate value.

Relative response ratios of analytes in immersion analyses at pH 2 with two ILs and two commercial fibers. The Table 4 sensitivity factors for each analyte and each fiber are expressed as their ratio over the ethyl acetate corresponding factor to take into account the differences between adsorbent masses

In absolute terms, Fiber #3 (polymeric IL with NTf2 anion) gave higher sensitivity factors for all studied analytes compared to its counterpart Fiber #4 with the triflate anion (Table 4). The sensitivity factors for the PEG fiber were also higher than these obtained with the two IL fibers for all analytes. The picture is completely different when considering the relative fiber responses. Figure 5 shows that the two ILs fibers gave similar results in this relative representation. The IL fibers results compare well with the polar PEG fiber. Both results are clearly superior to the PDMS results except for MTBE (Fig. 5). The relative results obtained in headspace extraction (Fig. 4) and immersion extraction (Fig. 5) are quite coherent. Compared to the two IL fibers, the PEG fiber seems to be slightly more efficient in immersion extractions than in headspace extractions in acidic media.

Extractions at pH 11

Phosphate buffer was used to obtain a matrix of pH 11 allowing an evaluation of fiber stability. Since the polymeric ionic liquids are bonded to silica particles, alkaline solutions could damage the particle and/or deteriorate the bonding. Many of the pH 2 neutral analytes and seven basic analytes were used as test solutes. Table 4 lists all the results in the two rightmost columns.

The first observation is that there is ample stability and good reproducibility of the results at pH 11. The RSDs of the experiments were similar to those obtained at pH 2. Experiments at different pHs were repeated with the same fibers over several months to study different mixtures. The reproducibility of the silica-based fibers was comparable to that of the polymer-based commercial fibers.

Table 4 also lists the sensitivity factors obtained for seven small amines at pH 11. The two polymeric IL fibers were able to extract all of the tested amines with sensitivity factors equal or higher to those obtained for short-chain alcohols at both pHs (Table 4). The amine sensitivity factors are however significantly lower than the corresponding factors obtained with the three commercial fibers. It must be pointed out that the 65-µm PDMS/DVB commercial fiber was specially designed to extract basic compounds. It did produce sensitivity factors for amines higher than those of all other fibers except for trimethylamine.

When considering these extractions in relative terms, the picture is different. Figure 6 (top chart) shows the relative response ratios (ethyl acetate reference compound) of the amines extracted by immersion at pH 11. The IL fiber sensitivities for the amine compounds seem significantly better than the commercial fibers sensitivities. This figure will not be commented on any further because it was not obtained with a true internal standard. The internal standard, ethyl acetate, used to prepare Figs. 4 and 5 is not stable at pH 11 as it slowly decomposes to ethanol and sodium acetate. So its sensitivity factor was specially measured at pH 7 meaning that the standard was not present with the amine compounds as a true internal standard should be. This could induce a bias in Fig. 6 (top chart). Figure 6 (bottom chart) shows the same Table 4 data using n-propanol as an internal standard. n-Propanol is not the same standard as the one used in Figs. 4 and 5 but is was present with the amine compounds since it is stable at pH 11. Figure 6 top and bottom show very similar results for the two IL fibers compared to one another and also compared to the commercial PEG fiber. The PDMS and PDMS/DVB commercial fiber relative responses look very different and much higher than those of the two IL fibers when the true internal standard n-propanol is the reference compound. Polar n-propanol is not as good as the less polar ethyl acetate as an internal standard. Since n-propanol adsorbs more on the polymeric IL fibers and PEG fiber than on the less polar PDMS/DVB fiber (Fig. 5), used as the internal standard, it tends to produce underestimated relative sensitivity factors for the IL fibers and/or overestimated values for the PDMS-based fibers. There is no definitive conclusion comparing the new polymeric IL fibers to the commercial PDMS and PDMS/DVB fibers; however, there is no doubt that the IL fibers are able to extract short amines effectively.

Relative response ratios of analytes in immersion analyses at pH 11 with two ILs and three commercial fibers. The Table 4 sensitivity factors for each analyte and each fiber are expressed as their ratio over, top figure the ethyl acetate corresponding factor (obtained at pH 7) and, bottom n-propanol factor to take in account the differences between adsorbent masses

Durability of the IL fibers

The headspace procedure is a very gentle process for the fibers and did not pose any durability problems. The immersion procedure put much more mechanical strain on the fiber itself since the Varian 8200 auto sampler uses a strong vibrator similar to that used in an electrical razor. It is extremely harsh on the fiber coating vibrating it at about 50 Hz. However, a single triflate Fiber #4 was used to do all the more than 50 immersion experiments done in this study. If two Fiber #3 were needed, it is because one broke due to improper installation into the auto sampler. The fibers were very durable. The thickness of the fiber coating remained the same. The fiber coloration did change after the initial 220 °C conditioning but remained stable and consistent after all immersions and GC analyses done for the study. No indications of visual fiber coating deterioration were noted throughout the study.

Peak tailings were observed on the GC peaks of amines. A 30 °C desorption temperature increase was tried to improve the peak shape increasing the amine desorption rate. The GC injector temperature was raised to 250 °C. No significant changes were observed in either the analyte sensitivities or the GC peak shapes. However, the IL fibers withstood this temperature increase without damage further showing their durability.

Conclusion

Ionic liquids were found to have an intermediate polarity analogous to that of ethanol [15]. Upon polymerization and bonding to silica particles, the liquid state of ILs is lost but the other unique properties, such as low volatility and polarity associating apolar and charge–charge interactions, are maintained. It was demonstrated that the polymerized IL-bonded silica particles could be coated on SPME fibers to be used for the extraction of small and polar molecules. The headspace, as well as the immersion SPME protocols, was used to quantitate short-chain alcohols down to the 10 ppb level. The efficacy of the method was tested by checking the ethanol content of a variety of beverages and a NIST standard material. Small amines were extracted using the immersion procedure at pH 11 demonstrating the stability of the polymerized IL-coated silica particles. The nature of the anion, triflate or bis-triflyl amide, could influence the overall polarity of the IL. However, no clear differences were found between the two fibers made respectively with these two anions.

References

Arthur CL, Pawliszyn J (1990) Solid-phase microextraction with thermal desorption using fused silica optical fibers. Anal Chem 62:2145–2148

Pawliszyn J, Pawliszyn B, Pawliszyn M (1997) Solid phase microextraction (SPME). The Chemical Educator. doi:10.1333/s00897970137a

Pawliszyn J (1997) Solid phase microextraction theory and practice. Wiley, New York, NY, USA

Scheppers Wercinsky SA (1999) Solid phase microextraction. A practical guide. CRC Press, Boca Raton, FL, USA

Hinshaw JV (2003) Solid phase microextraction. LC&GC (Europe) 16:803–807; (North America) 21:1056–1061

Majors R (2008) The role of polymers in solid-phase extraction and sample preparation. LC&GC (North America) 26:1074–1090

Venkatachalam M. (1999) Properties of Commercial SPME Coatings. In: Pawliszyn J (ed) Applications of SPME. RSC Chromatography Monographs, Ch. 5, pp 57–72

Anonymous (1998) SPME: theory and optimization of conditions, Supelco bulletin 923. Supelco, Bellefonte, PA, USA

Mullett VM, Pawliszyn J (2003) The development of selective and biocompatible coatings for SPME. J Sep Sci 26:251–260

Jiang G, Huang M, Cai Y, Lv J, Zhao J (2006) Progress of SPME coatings and coating techniques. J Chromatogr Sci 44:324–332

Dietz C, Sanz J, Cámara C (2006) Recent developments in SPME coatings and related techniques. J Chromatogr A 1103:183–192

Earle MJ, Seddon KR (2000) Ionic liquids: green solvents for the future. Pure Appl Chem 72:1391–1398

Olivier-Bourbigou H, Magna L (2002) Ionic liquids: perspectives for organic and catalytic reactions. J Mol Catal A: Chem 182–183:419–437

Wasserscheid P, Welton T (eds) (2003) Ionic liquids in synthesis. Wiley, Weinheim, Germany

Carda-Broch S, Berthod A, Armstrong DW (2003) Solvent properties of the 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid. Anal Bioanal Chem 375:191–199

Koel M (ed) (2009) Ionic liquids in chemical analysis. CRC, Boca Raton, FL, USA

Anderson JL, Armstrong DW, Wei GT (2006) Ionic liquids in analytical chemistry. Anal Chem 78:2893–2901

Berthod A, Ruiz-Angel MJ, Carda-Broch S (2008) Ionic liquids in separation techniques. J Chromatogr A 1184:6–18

Poole CF, Kollie TO (1993) Interpretation of the influence of temperature on the solvation properties of GC stationary phases using Abraham’s solvation parameter model. Anal Chim Acta 282:1–17

Armstrong DW, He L, Liu YS (1999) Examination of ionic liquids and their interaction with molecules when used as stationary phases in gas chromatography. Anal Chem 71:3873–3876

Anderson JL, Armstrong DW (2003) High stability ionic liquids: a new class of stationary phases for gas chromatography. Anal Chem 75:4851–4858

Anderson JL, Armstrong DW (2005) Immobilized ionic liquids as high selectivity/high temperature/high stability gas chromatography stationary phases. Anal Chem 77:6453–6462

Vidal L, Psillakis E, Domini CE, Grane N, Marken F, Canals A (2007) An ionic liquid for headspace single drop microextraction of chlorobenzenes from water samples. Anal Chim Acta 584:18–195

Aguilera-Herrador E, Lucena R, Cárdenas S, Valcárcel M (2008) Direct coupling of ionic liquids based single drop microextraction and GC/MS. Anal Chem 80:793–800

Hsieh YN, Huang PC, Sun IW, Whang TJ, Hsu CY, Huang HH, Kuei CH (2006) Nafion membrane supported ionic liquid solid phase microextraction for analyzing ultra-trace PAHs in water samples. Anal Chim Acta 557:321–328

Zhao F, Meng Y, Anderson JL (2008) Polymeric ionic liquid as selective coatings for the extraction of esters using solid-phase microextraction. J Chromatogr A 1208:1–9

He Y, Pohl J, Engel R, Rothman L, Thomas M (2009) Preparation of ionic liquid based solid-phase microextraction fiber and its application to forensic determination of methamphetamine and amphetamine in human urine. J Chromatogr A 1216:4824–4830

Huang K, Han X, Zhang X, Armstrong DW (2007) PEG-linked geminal ionic liquids as selective, high-stability GC stationary phase. Anal Bioanal Chem 389:2265–2275

Wu CH, Chen CL, Huang CT, Lee MR, Huang CM (2004) Identification of gasoline soot in suspect arson cases by using headspace solid phase microextraction-GC/MS. Anal Let 37:1373–1384

Anderson JL, Ding J, Welton T, Armstrong DW (2002) Characterizing ionic liquids on the basis of multiple solvation interactions. J Am Chem Soc 124:14247–14254

Berthod A, Ruiz-Angel MJ, Huguet S (2005) Nonmolecular solvents in separation methods: dual nature of room temperature ionic liquids. Anal Chem 77:4071–4080

Sprunger LM, Gibbs J, Proctor A, Acree WE, Abraham MH, Meng Y, Yao C, Anderson JL (2009) Linear free energy relationship correlations for room temperature ionic liquids: revised cation-specific and anion-specific equation coefficients for predictive applications covering a much larger area of chemical space. Ind Eng Chem Res 48:4145–4154

Acknowledgments

Daniel W. Armstrong acknowledges the Robert A. Welch foundation (Y-0026) for support of this work. Alain Berthod thanks the French Centre National de la Recherche Scientifique (UMR5180, Pierre Lanteri) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Eranda Wanigasekara and Sirantha Perera contributed equally to this paper.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM1

(PDF 44 kb)

Rights and permissions

About this article

Cite this article

Wanigasekara, E., Perera, S., Crank, J.A. et al. Bonded ionic liquid polymeric material for solid-phase microextraction GC analysis. Anal Bioanal Chem 396, 511–524 (2010). https://doi.org/10.1007/s00216-009-3254-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-009-3254-2