Abstract

An immunochromatographic lateral flow dipstick assay for the fast detection of microcystin-LR was developed. Colloid gold particles with diameters of 40 nm were used as red-colored antibody labels for the visual detection of the antigen. The new dipstick sensor is capable of detecting down to 5 µg·l−1 (ppb; total inversion of the color signal) or 1 ppb (observation of color grading) of microcystin-LR. The course of the labeling reaction was observed via spectrometric wave shifts caused by the change of particle size during the binding of antibodies. Different stabilizing reagents showed that especially bovine serum albumin (BSA) and casein increase the assays sensitivity and the conjugate stability. Performance of the dipsticks was quantified by pattern processing of capture zone CCD images. Storage stability of dipsticks and conjugate suspensions over 115 days under different conditions were monitored. The ready-to-use dipsticks were successfully tested with microcystin-LR-spiked samples of outdoor drinking- and salt water and applied to the tissue of microcystin-fed mussels.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The toxin microcystin-LR (MC-LR) is a cyclic heptapeptide causing liver damage and promoting tumor growth [1]. Contaminations of lakes and seafood with this toxin during the algal bloom of cyanobacteria in the summer season raise the need for a fast and easy-to-use detection method. Current analytical procedures are based on on-site sampling and the time-delayed analysis of the toxin via ELISA, HPLC, or MALDI-TOF [2]. ELISA methods have especially been of high interest and frequently published in recent years. Though having excellent detection limits ranging from 3 to 300 ng/L, the ELISA measurement requires one to several hours and has to be performed within a laboratory [3–9]. For quick on-site assessments of MC-LR contaminations, an immunochromatographic lateral flow dipstick assay for the detection of microcystin-LR has been developed. The lateral flow assay is an easy and fast to use detection method that is very reliable and cheap in production. The so called ‘dipsticks’ are based on the retention and visual detection of color-labeled antibodies during their flow through a defined capture zone in a membrane.

When running the assay, analyte solution is driven up the dipstick by capillary forces [10] and causes desorption and entrainment of the labeled antibodies. Very small antigens (like microcystin) do not allow the binding of more than one antibody. For their detection, competitive binding has to be applied [2]. Here, the dipsticks capture zone is composed of the antigen. If antigen is present in the sample, it will form a complex with the antibodies in the release pad of the assay. When reaching the capture zone, the already-complexed antibodies are not available for binding to the immobilized antigen.

For their irreversible binding as capture line, the antigens need polar groups for a preliminary binding to the polar nitrate-, carboxyl-, and hydroxyl-groups and hydrophic segments for the subsequent interaction with the cellulose surface [11]. As a consequence, the small haptenes have to be conjugated with a larger protein prior to their immobilization on a capture zone. The conjugated protein, typically BSA, thus will bind to the surface presenting the antigen away from the membrane for an interaction with the antibodies.

Labeling of antibodies for visual identification is usually done by colored nanoparticles. The here-applied labels are red-colored gold colloid particles. An advantage of gold is its excellent affinity for proteins. Furthermore, the particles have a very intense red color in their colloid form when produced with particle diameters above 20 nm; even getting more intense with increasing diameter [12]. Particle diameters above approximately 100 nm should not be chosen as the specific surface portion of the antibody as it gets very low and the interaction with the antigen can be sterically hindered. Due to the commonly applied reduction of gold chloride by citric acid, gold particles have a citrate-covered and thus negative-charged surface. A typical IgG (Immunoglobulin G) antibody has a pI between 9 and 10 [13]. The pH during binding is best chosen 0.5 below the isoelectric point for a slightly positive charge of the protein.

The stability of gold colloid solutions is extremely dependent on the ionic strength in the solution. High ionic strengths reduce the spherical expansion of the zeta potential thus decrease the repulsion of the colloids among each other [10]. Without prior stabilization, colloids would therefore flocculate at elevated salt concentrations [14]. The increase of the ionic strength within a colloid solution thereby provides the possibility of testing the particles stability.

In a previous publication, Pyo et al. presented a dipstick system capable of detecting microcystin. In their work [15], the detection limit is defined as the color grading still distinguishable by the bare eye. As coloration cannot be absolutely determined by the human eye, this form of concentration determination would require the analysis of a complete dilution row of the sample and is based on subjective estimations. Typically, a dipstick provides the user with a clear yes-or-no signal as commonly known from pregnancy tests. As described by Pyo et al., the color signal vanishes somewhere within a concentration range of 10–100 µg·l−1 representing the justifiable detection limit.

Furthermore, the study by Pyo et al. presented colloidal gold labels were not impregnated on the dipstick but applied as a suspension shortly before using the assay. This does not seem very user-friendly as the dipstick assay is supposed to be in an on-site ready-to-use-state. This paper presents an enhanced assay setup. By different optimization steps in label manufacturing and the application of the label on the dipsticks, an increase in sensitivity and applicability was accomplished. Furthermore, assay application with real water and mussel samples and the storage stability have been examined.

Materials and methods

Chemicals and reagents

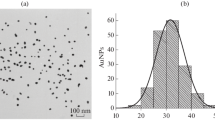

For a precise and reproducible dipstick assay, the particle labels have to be monodisperse [16]. Monodisperse (diameter ±8%) nanoparticles were purchased at British Biocell International, Cardiff, UK. The colloid has a gold concentration 0.01% (w/v) and a mean particle diameter of 40 nm. Axxora Deutschland GmbH, Grünberg, Germany, provided the Microcystin-LR (purity ≥ 95%).

Anti-Microcystin-LR (clone MC10E7, mouse IgG isotype) at a concentration of 1 mg∙ml−1 was purchased from Alexis Biochemicals, Lausen, Switzerland. For further details concerning the antibody, consult [17, 18]. The above antibodies were all derived from mice. The anti-mouse antibody for the control line at a concentration of 2.5 mg∙ml−1 was purchased from Sigma-Aldrich, Munich, Germany. BSA, fraction V, >98 %, casein, glycerol (99 %) and buffer components were purchased from Sigma-Aldrich as well. Polyethylene glycol and gelatin were purchased from Fluka, Buchs, Switzerland. Triethanolamine (purity GV ≥ 99%) was purchased from VWR, Darmstadt, Germany. As release pad, a Reemay 2040 spun-bound polyester fleece from BBA Fiberweb, Nashville, USA, was used. The Unisart 140 CN nitrocellulose membrane was kindly supplied by Sartorius AG, Göttingen, Germany.

Labeling of antibodies

The described labeling and storage procedures were first established with a pregnancy hormone assay as reference systems are commercially available. The derived protocols could be transferred for the implementation of an anti-microcystin antibody without any change.

For immobilization of antibodies on the gold surface, a 5-mM pH 9.2 borate buffer was applied. When necessary, 150 mM of sodium chloride was added to the buffer. For storage, the above buffer was supplemented with 150 mM NaCl, 1% BSA, and 0.05 % NaN3 (sodium azide). Freeze storage required addition of 20% (w/v) of glycerol to the storage buffer. Antigen standards were prepared in a 100-mM phosphate buffer (pH 6.9) with 150 mM NaCl.

Conjugation of microcystin

Microcystin has to be conjugated with BSA molecules, which easily adhere to CN-membranes. The coupling protocol is following the procedure for coupling horseradish peroxidase to MC-LR described by Zeck et al. [17].The conjugation was done by activating 500 µL of BSA (20 g∙L−1) with 150 µL 2-iminothiolan hydrochloride (4 g∙L−1) in a pH 8 0.05 mol∙l−1 triethanol amine buffer containing 0.15 mol∙l−1 sodium chloride and 0.001 mol∙l−1 EDTA in a nitrogen atmosphere at room temperature. The activated BSA was then cleaned over a Sephadex PD-10 G25 column with a PBS buffer (0.09 M, 0.145 M NaCl, pH 7.6), added to the microcystin (1.8 g∙L−1) in an acetonitrile/DMSO solution (9% v/v DMSO) and stirred over night at room temperature.

Preparation of lateral flow membranes

Nitrocellulose membrane sheets with the immobilized antibodies respectively antigens were printed with a BioJet XYZ 3000 Dispenser at the Sartorius AG, Göttingen, Germany. For protein immobilization on the membrane sheets, 0.87 µl∙cm−1 of protein solution with a concentration of 1 mg∙ml−1 was dispensed. Before use, the release pads were treated with 0.25% (w/w) Tween 20© and 0.5% (w/w) BSA. Furthermore, sucrose solution was added to the release pad with a subsequent short drying period before application of the antibody–gold conjugates.

Application of the labeled antibodies

Prior to the labeling procedure, 2 ml of the nanoparticle suspension were adjusted to a pH value of 9.2 with a 0.1-M potassium carbonate solution. One hundred fifty microliters of the antibody solution (4.35 µg∙ml−1) were set to pH 9.2 as well and subsequently slowly dropped into 1 ml of the colloid solution under shaking. The suspension was vortexed and stored at room temperature for 40 min. Afterwards, 100 µl of a 1% (w/v) BSA solution were added to the suspension, vortexed, and stored for a further 20 min. After the reaction, the suspension was centrifuged at 6,000–8,000 rpm (3,900–7,000×g) for 30 min at 4°C. The pellet was isolated and resuspended in 100 µl storage buffer, sonicating the samples for a few seconds if necessary. The suspension was then washed six times by centrifugation at 4°C, 6,000–8,000 rpm and 15 min with resuspension in 100 µl storage buffer each time. The centrifugal speed could be reduced to approximately 4,000 to 5,000 rpm (1,800–2,700×g) during the process. After the washing procedure, the labeled antibodies could be applied to the lateral flow assay. After the assembly of the different assay components and cutting of dipsticks, the label was applied to the release pad and allowed to dry for 1–2 h. The dipsticks were used with 200 µl sample volume.

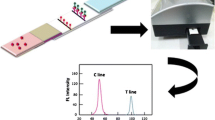

Semi-quantitative analyte detection

The detection of the captured labeled antibody is usually done by qualitative visual inspection of the dipstick. In the presented work, the dipsticks were semi-quantitatively evaluated by taking digital pictures of the capture line and evaluating the color intensity by a pattern-processing software (Optimas© 6.5). The pictures were taken in a screened black box with a constant illumination of a halogen bulb [19]. Markers of defined length in the background of the dipsticks picture made a size calibration possible. Thereby, the color intensity of the dipstick capture line could be compared in relative units per measured area, here noted as RU∙mm−2. The semi-quantitative nature of this detection method derives from the incomplete acquisition of the labels color intensity, as a digital photographic picture has no depth resolution. Furthermore, the capture lines can have irregular shapes not analyzable by the software. Repeated measurements showed that an error of 11.3 % has to be assumed for the measurement values.

Course of the gold–antibody conjugation reaction

Increase of colloid surface covering and dipstick sensitivity during the binding reaction with the gold label were compared by stopping the reaction after different reaction times. The interruption of the binding reaction was done by addition of 100 µl of a 10% (w/v) BSA solution and immediate centrifugation. Subsequently, the suspension was washed, applied to a dipstick, and tested with 200 µl of antigen solution.

To monitor the actual course of the reaction as comparison, a photometric detection was done by monitoring the shift of the wavelength at which the maximal absorption during a period of 60 min was measured.

Storage stability of the conjugates

Storage of the conjugate suspensions was done at 4°C and −20°C in a borate storage buffer, whereas the frozen conjugates previously were stabilized by addition of 20% (w/w) glycerol.

Storage stability of the dipsticks

The storage stability of the ready-to-use dipsticks was compared after storage at room temperature, 4°C and −20°C over a period of 112 days. All dipsticks were stored in the dark and sealed in plastic bags. Dipstick sensitivity determination was done with 200 µl of antigen solution.

Results and discussion

Optimal antibody concentrations and media conditions

The lowest stabilizing antibody concentration preventing coagulation of the colloids had to be determined. Deliberate coagulation was caused by the addition of 100 µl of a 10% NaCl (w/v) solution. The coagulation could be observed by a color-shift from red to blue. The lowest stabilizing concentration was hereby determined at 3.9 ± 0.4 µg antibody/ml gold colloid solution [19].

The optimal pH value was ascertained by the photometric measurement at a wavelength of 580 nm allowing the detection of any blue color indicating coagulation. Using the previously determined optimal protein concentration, gold colloid samples were adjusted to pH values between 6 and 10. By measurement of the absorbance at pH values from 6 to 10, a full stabilization of the labeled particles at pH 9 to 10 could be determined. The results seem very reasonable, as a typical value of IgG antibodies isoelectric point lies near 9.0 [20]. Lowering the pH beneath this point more than 0.5 units causes a positive charge up of the antibodies resulting in an increase of attraction to uncovered colloid surface and multiple bonding resulting in subsequent flocculation.

Course of the gold–antibody conjugation reaction

The determination of the minimal time requirement for the labeling reaction can be considered in different ways. Although theoretically, one antibody per nanoparticle would be sufficient for an antigen reaction, the surface of the particles usually will be coated by a massive amount of IgG antibodies having a mean size of only 14 × 10 × 4 nm [21]. Full saturation of the surface increases the chance of an antibody–antigen reaction after collision with the antigen and improves the particle stability by shielding its surface against coagulation [10].

The dipsticks sensitivity after different colloid-antibody binding reaction times from 1.5 to 60 min showed almost no change in sensitivity. In reference to the very high affinity of the gold surface to proteins, it seems reasonable that an immediate binding after the addition of the proteins to the colloid suspension occurs.

Slight shifts in the absorption maximum at 530 nm of a gold colloid suspension can be observed when the colloids change their size in a range from 10 to 50 nm [22]. As the antibodies with a length of 14 nm increase the diameter of the colloid from 40 up to 54 nm (35 %), a measurable change can be expected. Scans of wavelengths between 450 to 650 nm in intervals of 30 s were done and the absorption maximum for each scan determined. The plot in Fig. 1 shows an increase of the maximal wavelength from 526 to 532 nm during a period of 30–40 min. After this time, no further change can be observed indicating that the covering of the nanoparticles is complete.

Detection limit of the assay

Immunochromatographic microcystin detection in a concentration range from 0–10 µg∙l−1 was done. Figure 2 shows a drop of the capture line intensity from 57,550 to 19,810 to 11,220 RU∙mm−2 at concentrations of 0, 1, and 2 µg∙l−1. A visual detection of a colored capture line is barely possible at the last noted concentration. According to several test persons, absolute no coloring can be seen by the human eye below a coloring intensity of 10,000 RU∙mm−2. As can be seen in Fig. 2, the intensity falls below this value at using a dipstick at a concentration of 5.0 µg∙l−1. This value corresponds to the detection limit of the assay. After application of analyte concentrations of 0, 1, and 2 µg∙l−1 a distinction of the color grading by comparison of the dipsticks is easily possible.

Detection of microcystin in real samples

Tap water, water samples from a pond, and salt water were taken and spiked with different concentrations of microcystin-LR. Turbidity, conductivity and pH value of the samples were measured. The turbidity varied in a range of 0.31 to 22.46 NTU, the conductivity from 391 to 48,500 µS∙cm−1 and the pH values from 5.6 to 8.7.

The dipsticks were applied to the spiked samples as described before. A comparison of the response signals with microcystin-dotted standard potassium phosphate buffer at pH 7 is shown in Fig. 3. Even though the sample parameters vary in a wide range, the signal course of the capture zone is very similar with all applied samples. The microcystin-LR detection limit of the assay remains at 5 µg∙l−1 for buffer, salt, and pond water. Tap water shows an inhibiting effect at low microcystin concentrations, but the detection limit is still reached at a concentration of 5 µg∙l−1.

Microcystin-fed mussels and microcystin-dotted mussel flesh were applied to the dipstick as well. The high content of solid particles in the pulpy samples led to a blocking of the membrane capillaries. A simple preceding cake filtration of the mussel flesh with a one-handed manual press was sufficient to avoid blocking. The filtrate was applied to the dipstick and a detection of microcystin with a detection limit of 90 µg in 1 kg of mussel flesh was achieved.

Color development during the dipstick assay

The ready-to-use gold–antibody-conjugate suspension should usually be applied on the release pad in a volume range from 1 to 10 µl, whereas higher volumes applied to release pads of typical dimensions would result in their complete ‘soaking’ and cause ingress of the conjugate into the CN-membrane. To determine the necessary amount of conjugate and the course of the color development, the color intensities of dipsticks with 1, 2, and 3 µl of conjugate on their release pad were evaluated over 85 min (Electronic Supplementary Material; Fig. S1). There is almost no color increase after the application of only 1 µl conjugate, while with 2 and 3 µl, a visually detectable coloring over a period of 50–60 min can be observed. For the human eye, a red-colored line can be seen in the range 10,000–15,000 RU∙mm−2 and a deep red line at values above 20,000 RU∙mm−2. This value is reached within 15−20 min. The difference in color intensity after 15 min between 2 and 3 µl applied conjugate merely lies at 18%, so that 2 µl would be adequate. However, in regard of the low production cost of the conjugates, 3 µl were applied further on.

Stabilization of the conjugates

Further stabilization of the conjugates after the labeling reaction concerning centrifugal washing and storage effects is preferable. Although stabilized against salt interactions, the conjugates did form thin gold films on the tube wall after harsh centrifugation during the washing steps. Different stabilizing reagents described in literature ([23–25]) were applied to the reaction solution after 40 minutes reaction time. The following washing steps were done under harsh centrifugation at 10,000 rpm (5,400×g). Figure 4 shows the color intensity of dipsticks used with the differently stabilized conjugates. BSA- and casein-stabilized conjugates showed very high intensities after their application on dipsticks, whereas the BSA-conjugates were slightly better in performance. Furthermore, the BSA-stabilized pellets could be very easily resuspended after centrifugation, whereas casein-stabilized conjugates had to be ultrasonically agitated. Addition of up to 0.5 M NaCl to the BSA-stabilized conjugate suspensions showed no tendency of flocculation or performance decrease even at very high ionic strengths.

Sonication

Storage of the conjugates at 4°C over several days resulted in their sedimentation. For their use on a release pad, the conjugates previously had to be dispersed by ultrasonic agitation for approximately 30 s. Without previous ultrasonic agitation, a decrease of 28% of the color intensity on the capture line could be observed. To monitor the effect of the energy input on the antibodies antigen-binding capability during ultrasonic agitation, aliquots of the conjugate were sonicated for different periods and the capture line intensity evaluated after their application to dipsticks. Sonication over 100×, the highest in this work, applied for a period of 30 s did not change the performance of the conjugates, specifically, the dipstick assay.

Storage stability of the conjugates

Monitoring of storage in a physiological KPP buffer (potassium phosphate buffer) at pH 7 instead of the pH 9 storage buffer showed that the capture line intensity dropped 72% in comparison with new conjugate applied in the KPP pH 7 buffer. The dipstick sensitivities of at pH 9 stored conjugate solution were evaluated over a period of 120 days. A continuous good performance of the gold-conjugate at 4°C and −20°C over a period of 120 days could be observed (Electronic Supplementary Material; Fig. S2). The frozen conjugate had a slightly lower but constant immunologic response compared to the cooled one. This can be explained due to the dilution effect of the glycerol freezing stabilizer.

Storage stability of the dipsticks

After longer periods of storage at room temperature and 4°C, an irreversible adsorption of fractions of the conjugate to the release pad could be observed. This resulted in a rapid decrease of the dipstick sensitivities within a week of storage at room temperature and 4°C. After 2 weeks storage at room temperature, the signal intensity dropped by 74% and hereby below the color detectable by the human eye. Storage at 4°C caused an intensity drop of 49% within this time. After 21 days, the loss amounted to 70% and is not visible to the eye anymore. Despite the signal fluctuation, the dipsticks stored at −20°C show no decrease in their sensitivity at all (Electronic Supplementary Material; Fig. S3).

Advances in storage at room temperature have been made by adding 3% sucrose to the conjugate suspension and laminating the release pad with a layer of sucrose before the application of the conjugate. Furthermore, lyophilizing the ready-to-use dipstick at −80°C before their storage in evacuated sealed plastic bags was done. A stable dipstick color intensity over 19 days followed by a slow but continuous decrease in intensity during the following month could be observed as consequence of this preparation method (Electronic Supplementary Material; Fig. S4).

Conclusion

An optimized antibody labeling protocol with gold colloid nanoparticles for the detection of microcystin-LR could be established. As detection limit, a value of 5 µg∙l−1 microcystin was achieved. Further dilution of the label applied on the dipsticks causes a loss of signal intensity (the capture line color turns from red to pink) but can lower the detection limit to 1–2 µg∙l−1. The dipstick shows a clear signal after an assay time of 15 min. Despite the easy transport and usage, this makes the dipstick assay a very fast on-site method for the toxin detection.

The development of this dipstick allows the user a fast and easy estimation of a potential contamination of water or foodstuff. This could find implementation in the fields of water protection and as on-site seafood testing for fishermen. After microcystin indication by the presented dipstick, quantitative measurements via HPLC or ELISA have to be done in the lab.

For the previously published dipstick assay by Pyo et al. [15], the authors derived their detection limit from the distinguishability of the color grading. From our point of view, the bare eye is not capable of absolute color detection and can, at best, compare different shadings. A comparison of different dipsticks is contrary to the primary use of these assays, which should provide the user with a simple yes-or-no-answer. Based on a total absence of the capture zone coloring, the sensitivity of the dipstick was improved by a factor of at least 2 in comparison to the dipstick presented by Pyo et al. Furthermore, the dipstick assay was produced in a ready-to-use form and successfully tested with different real samples. A summary of the enhancements is given in Table 1.

Determination of dipstick sensitivities over storage periods of approximately 115 days showed that the conjugate suspension maintains its sensitivity over the whole time. Ultrasonic agitation as means to restore the conjugates dispersity proved to be well applicable and had no negative impact on the antibodies performance. The ready-to-use dipsticks storage protocol still can be improved in respect to the irreversible adsorption of the labeled antibodies to the release pad and has to be enhanced in further studies.

Despite the obvious advantages of the lateral flow assay, they are inexpensive in material costs. Even at high antibody prices of approximately 100–250 € per 200 µl vial (1 mg∙ml−1) only approximately 0.20 € have to be spent for one dipstick. Taking the commercial gold colloid (approx. 0.14 € per dipstick) and membrane materials into account, material cost of less than 0.50 € can be estimated for one dipstick.

References

Ueno Y, Makita Y, Nagata S, Tsutsumi T, Yoshida F, Tamura S, Sekijima M, lTashiro F, Harada T, Yoshida T (1999) No chronic oral toxicity of a low dose of microcystin-LR, a cyanobacterial hepatotoxin, in female BALB/c mice. Environmental Toxicology 14(1):45–55

Weller MG (2002) Algengifte im Wasser. Nachrichten aus der Chemie 50(7):700–705

Lindner P, Molz R, Yacoub-George E, Durkop A, Wolf H (2004) Development of a highly sensitive inhibition immunoassay for microcystin-LR. Analytica Chimica Acta 521(1):37–44

Pyo D, Lee J, Choi E (2005) Trace analysis of microcystins in water using enzyme-linked immunosorbent assay. Microchem J 80(2):165–169

Sheng J-w, He M, Yu S-q, Shi H-c, Yi Q (2006) Detection of microcystin-LR in waters using indirect competitive ELISA. Huan Jing Ke Xue 27(6):1166–70

Sheng JW, He M, Shi HC, Qian Y (2006) A comprehensive immunoassay for the detection of microcystins in waters based on polyclonal antibodies. Analytica Chimica Acta 572(2):309–315

Mhadhbi H, Ben-Rejeb S, Cleroux, Martel A, Delahaut P (2006) Generation and characterization of polyclonal antibodies against microcystins - Application to immunoassays and immunoaffinity sample preparation prior to analysis by liquid chromatography and UV detection. Talanta 70(2):225–235

Sun W, Huang B, Shi J, Jiang T (2007) The use of ultrasensitive time-resolved fluoroimmunoassay for rapid detection of microcystin LR. Wei Sheng Yan Jiu 36(2):187–9

Sheng JW, He M, Shi HC (2007) A highly specific immunoassay for microcystin-LR detection based on a monoclonal antibody. Analytica Chimica Acta 603(1):111–118

Chandler J, Robinson N, Whiting K (2001) Handling false signals in gold-based rapid tests. IVD Technology 7(2):34–45

Pristoupil TI, Kramlova M, Sterbikova J (1969) On mechanism of adsorption of proteins to nitrocellulose in membrane chromatography. J. Chromatog. 42:367–375

Chandler J, Gurmin T, Robinson N (2000) The place of gold in rapid tests. IVD Technology 6(2):37–49

Baschong W, Wrigley NG (1990) Small colloidal gold conjugated to Fab fragments or to immunoglobulin-G as high-resolution labels for electron-microscopy—a technical overview. J Electron Microsc Tech 14(4):313–323

Horisberger M, Rosset J, Bauer H (1975) Colloidal gold granules as markers for cell-surface receptors in scanning electron-microscope. Experientia 31(11):1147–1149

Pyo D, Choi J, Hong J, Oo HH (2006) Rapid analytical detection of microcystins using gold colloidal immunochromatographic strip. J Immunoassay Immunochemistry 27(4):291–302

Slot JW, Geuze HJ (1985) A New method of preparing gold probes for multiple-labeling cyto-chemistry. Eur J Cell Biol 38(1):87–93

Zeck A et al (2001) Highly sensitive immunoassay based on a monoclonal antibody specific for [4-arginine]microcystins. Anal Chim Acta 441:1

Weller MG et al (2001) Development of a direct competitive microcystin immunoassay of broad specificity. Anal Sci 17:1445

Stückmann H (2007) Entwicklung immunchemischer Schnelltestverfahren. PhD Thesis, University of Hanover

Cuello AC (1983) Immunohistochemistry, International Brain Research Organisation. 1200

Silverton EW, Navia MA, Davies DR (1977) 3-Dimensional structure of an intact human immunoglobulin. Proc Natl Acad Sci USA 74(12):5140–5144

Chow MK, Zukoski CF (1994) Gold sol formation mechanisms—role of colloidal stability. J Colloid Interface Sci 165(1):97–109

Hodgkinson JL, Steffen W (2001) Direct labeling of components in protein complexes by immuno-electron microscopy. Meth. Molec. Biol., vol. 161 Cytoskeleton Methods and Protocols, ed. R.H. Gavin, Humana Press Inc., Totowa, NJ, 133-139

Kawaguchi H, Sakamoto K, Ohtsuka Y, Ohtake T, Sekiguchi H, Iri H (1989) Fundamental-study on latex reagents for agglutination tests. Biomaterials 10(4):225–229

Al-Yousif Y, Anderson J, Chard-Bergstrom C, Kapil S (2002) Development, evaluation, and application of lateral-flow immunoassay (immunochromatography) for detection of rotavirus in bovine fecal samples. Clin Diagn Lab Immunol 9(3):723–724

Acknowledgments

This research project was supported by the "Otto von Guericke" e.V. AiF (Association of Industrial Research Organisations; AiF-No. KF0479001KMD3).

We thank Sartorius AG for providing material and equipment for the preparation of the dipsticks.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary Material Figs. S1–S4

(PDF 217 kb)

Rights and permissions

About this article

Cite this article

Tippkötter, N., Stückmann, H., Kroll, S. et al. A semi-quantitative dipstick assay for microcystin. Anal Bioanal Chem 394, 863–869 (2009). https://doi.org/10.1007/s00216-009-2750-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-009-2750-8