Abstract

This paper describes a new and rapid method for accurate quantification of the six ergot alkaloids, ergometrine, ergotamine, ergosine, ergocristine, ergocryptine, and ergocornine, by liquid chromatography–tandem mass spectrometry (LC–MS–MS). The six ergot alkaloids studied have been defined by the European Food Safety Authority (EFSA) as among the most common and physiologically active ones. In addition, the method enables the quantification of the corresponding six epimers (ergo-inines) of these ergot alkaloids. This is of considerable importance in terms of the differences in toxicity of the isomeric forms. The method involves extraction under alkaline conditions using a mixture of acetonitrile and ammonium carbonate buffer followed by a rapid clean-up using dispersive solid-phase extraction with PSA (primary secondary amine) and a short chromatographic LC-run (21 min) with subsequent MS–MS detection. The method was developed and validated using ten different cereal and food samples. The major strength of the new method compared with previously published techniques is the simplicity of the clean-up procedure and the short analysis time. The limits of quantification were 0.17 to 2.78 μg kg−1 depending on the analyte and matrix. Recovery values for the 12 ergot alkaloids spiked into ten different matrices at levels of 5, 50, and 100 μg kg−1 were between 69 and 105% for 85 of 90 recovery measurements made over six days. Measurement uncertainty values were highly satisfactory. At a concentration level of 5 μg kg−1 the expanded measurement uncertainty ranged from ±0.56 to ±1.49 μg kg−1, at a concentration level of 100 μg kg−1 the expanded measurement uncertainty ranged from ±8.9 to ±20 μg kg−1. Both LOQs and measurement uncertainties were dependent on the analyte but almost independent of the matrix. The method performance was satisfactory when tested in a mini-intercomparison study between three laboratories from three different countries.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

General

Ergot alkaloids are mycotoxins produced by fungi of all species of the Claviceps genus, most notably by C. purpurea, which parasitizes the seed heads of living plants at the time of flowering. Fungal infections are most prevalent in rye and triticale that have open florets but wheat and other small grain are also potential hosts of these fungal species [1, 2]. The fungus replaces the developing grain or seed with the alkaloid containing wintering body, known as ergot, ergot body, or sclerotium. The sclerotia show significant differences in their total alkaloid content that can vary between 0.01 to 0.5% (w/w) [1, 3, 4] and show large differences in the patterns of alkaloids produced that are determined by the individual fungal strain in a geographical region and the host plant. The sclerotia are harvested together with the cereals or grass and can thus lead to contamination of cereal-based food and feed products with ergot alkaloids. Investigations in Germany indicate an increase in the occurrence of Claviceps purpurea infections in the last 10 years. This increase seems to be associated with the more extensive use of hybrid varieties of rye and perennial rye breeds [5, 6]. Despite effective cleaning procedures, ergot alkaloids have been detected in surveys of Swiss, Canadian, Danish, and German cereals and cereal products, at total levels of up to 7,255 μg kg−1 in German rye flours [7]. The most severe effects of ergot contaminated grain are described in the medieval literature as St Anthony’s Fire or Holy Fire, with respect to the intense pain resulting from vasoconstriction and subsequent gangrene with loss of fingers, hands, feet, and even entire limbs. Ergotism has nowadays practically been eliminated as a human disease but remains an important veterinary problem, particularly in cattle, horses, sheep, pigs, and chicken [8]. There are numerous reports of poisoning of farm animals by ergot-contaminated feed and by endophyte-infected grasses.

The main ergot alkaloids produced by Claviceps species which are contained in the sclerotia are ergometrine, ergotamine, ergosine, ergocristine, ergocryptine, and ergocornine, and the group of agroclavines, the latter being less toxic [9]. These ergot alkaloids are very similar, differing only in substituents on C-8 [7]. The amount and pattern of ergot alkaloids vary between fungal strains, depending on the host plant and the geographical region.

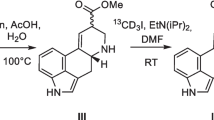

Ergot alkaloids containing a C9 = C10 double bond (known as ergolenes) readily exhibit epimerisation (Fig. 1), especially in the presence of alkalis, with respect to the centre of symmetry at C-8, with the formation of a series of right-hand rotation (S) isomers representing isolysergic acid (iso-LA) derivatives [10]. According to international classification the left-hand rotation isomers of ergot alkaloids representing LA derivatives (C-8-(R) configuration) are termed ergopeptines (e.g. ergotamine) and ergopeptames while the right-hand rotation diastereomers representing isolysergic acid (iso-LA) derivatives (C-8-(S) configuration) are termed ergopeptinines (e.g. ergotaminine). In nature, ergopeptinines always accompany ergopeptines. Considerable amounts of ergopeptinines may form during storage of raw materials over prolonged time or in improper conditions, or during extraction of ergot alkaloids from cereals.

Structure and epimerisation of ergot alkaloids containing a C9 = C10 double bond [7]

The EU Scientific Panel on Contaminants in the Food Chain of the European Food Safety Authority (EFSA) has reviewed the ergot issue recently [9]. The EFSA concluded that alkaloid concentrations are very variable and a consistent relationship between the amount of sclerotia and the total ergot alkaloid (ergoline) concentration cannot be established. Guideline limits recently discussed for ergot alkaloids in cereals for human consumption are 400–500 μg kg−1 and 100 μg kg−1 in Germany and Switzerland, respectively, [11, 12].

Determination of ergot alkaloids

pK a values of the ergo-ines vary from 5.5 (ergocristine) to 6.0 (ergometrine) and for the ergo-inines from 4.8 (ergocorninine) to 6.2 (ergometrinine) [7]. Ergot alkaloids are therefore positively charged at N-6 in acidic solutions and neutral at higher pH. In most methods for qualitative and quantitative determination of ergot alkaloids in cereals, extraction has either been performed with non-polar organic solvents under alkaline conditions or with polar solvents under acidic conditions. A mixture of dichloromethane, ethyl acetate, methanol, and 25% aqueous ammonia (50:25:5:1, v/v) was used by Scott et al. [13] and Müller et al. [14] whereas methanol–0.25% conc. phosphoric acid (40:60, v/v) was used by Ware et al. [15]. A wide variety of methods has been explored for the final determination of ergot alkaloids in grain, grasses, feed, and grain foods. Reviews of available analytical methods for the determination of ergot alkaloids including the most frequently employed LC–MS methods have been published by Scott [16, 17], Komarova and Tolkachev [18], and, most recently, by Krska and Crews [7].

The main column materials that have been employed for the LC separation of ergot alkaloids are C18 [19] and Phenomenex Gemini C18 [20, 21]. Various isocratic mobile phases and gradient systems have been used for reversed-phase LC of ergot alkaloids [17]. Acetonitrile has often been used mixed with either aqueous basic [22, 23] or acidic solutions [15].

Acidic mobile phases are often preferred because many silica-based LC phases are degraded at high pH. In addition, it is common practice to employ volatile weak acids for enhancing the ionisation of basic compounds in mass spectrometry operated in electrospray positive mode [24]. On the other hand those methods employing acidic phases do not enable detection of both epimers (ines and inines). Typical LC run times for the separation of ergometrine, ergotamine, ergosine, ergocristine, ergocryptine, and ergocornine and their corresponding epimers are around 45 min [14, 25]. LC coupled to mass spectrometry (LC–MS) and LC tandem MS (LC–MS–MS), usually with electrospray ionisation operated in the positive mode, ESI(+), has been employed for the quantification of ergot alkaloids as an alternative to FLD. The use of this technique provides, in addition, unequivocal identification of the alkaloids. Mohamed et al. [26] studied the fragmentation mechanism of six major ergot alkaloids by triple-quadrupole and ion-trap mass spectrometers operated in ESI(+). Characteristic product ions at m/z 223 and 208 were observed for peptide-type and lysergic acid derivatives. As a result precursor ion scanning of the most abundant m/z 223 ion was employed for survey studies of rye samples.

Lehner et al. [20] demonstrated the facility of using ESI(+) mass spectrometry with selected reaction monitoring (SRM) for screening grass and forage samples for novel ergot alkaloids. The same authors [21] have made a thorough study of the fragmentation patterns of selected ergot alkaloids by LC–MS–MS which allows the prediction of mass spectra of related compounds for which standards are not readily available.

Mohamed et al. [19] used LC–MS–MS with SRM after C18 clean-up for quantification of five ergot alkaloids (ergotamine, ergosine, ergocristine, α-ergocryptine, ergonovine, and ergocornine) in rye flour and obtained recoveries from 24% (ergonovine) to 92% (α-ergocryptine) and limits of quantification of 11–37 μg kg−1. Bürk et al. [11] reported an LC–MS–MS method capable of quantifying five ergot alkaloids down to 0.1–1 μg kg−1 (LOQ) with mean recoveries from 65 to 82% without the need for any clean-up. These methods do not determine both ines and inines, possibly because of the lack of available standards, and some [11] are unfortunate in using the undesirable dichloromethane as part of the extraction mixture[13].

Apart from LC methods the performance characteristics of most methods are not well known. None of the methods mentioned, including LC methods, has been validated by interlaboratory study and there are no certified matrix reference materials or proficiency studies available for the determination of ergot alkaloids. Recently, the European Food Safety Authority [9] concluded that validated analytical methods for the quantification of ergot alkaloids in feed materials are needed as a prerequisite for a survey on the occurrence of ergot alkaloids in feed materials in Europe. Analytical techniques should aim to detect the major ergot alkaloids and their corresponding biologically active metabolites formed in exposed animals.

The major goal of the study presented in this paper was to develop and validate an analytical method using HPLC–MS–MS for the rapid and simultaneous determination of the six major ergot alkaloids defined by the EFSA [9], namely ergometrine, ergotamine, ergosine, ergocristine, ergocryptine, and ergocornine and their corresponding epimers (inines), with an LOQ of 1 μg kg−1 for each of the ergot alkaloids analysed. The availability of such a method should, in the future, fulfil the recommendations of the European Food Safety Authority with regard to the monitoring of ergot alkaloids [9], and should enable further research and study of the ergot problem.

Experimental

Chemicals and materials

Crystalline ergot alkaloids ergocristine, ergotamine, ergocornine, ergosine, α-ergocryptine, and ergometrine (as ergometrine hydrogen maleate) and their corresponding six epimers ergocristinine, ergotaminine, ergocorninine, ergosinine, ergocryptinine, and ergometrinine were purchased from Professor Miroslav Flieger, Laboratory of Physiology and Genetics of Fungi of the Institute of Microbiology, Academy of Sciences of the Czech Republic, Prague. Studies on the purity of these standards will be described elsewhere. The purities were considerably above 96% apart from ergocristinine (94.2%), ergosine (96.4%), and ergosinine (95.5%). The purity of the ergot alkaloid standards was considered satisfactory, particularly in view of the limited sources and numbers of ergot alkaloid standards available, and the purity of other commercial mycotoxin standards, which is usually between 95 and 99% [27].

Acetonitrile and water (fluorescence grade) were supplied by Fisher Scientific (UK). Ammonium carbonate (3.03 mmol L−1; pH 8.9 ± 0.3) was purchased from Fluka (ref. 74415). Varian Bondesil PSA (40 μm, 10 g, part no. 12213023) was employed as material for dispersive solid-phase extraction.

Amber sampling jars (60 mL) with PTFE caps (Qmx, reference S00108) were used as extraction bottles. The sample shaker was obtained from AQS Manufacturing (Cat. No. R100B). Whatman 12.5 cm No. 54 filter papers and a 1-mL plastic Luer-lock syringe (BD, Plastipak luer syringe, reference 300013) equipped with 13 mm × 0.22 μm PTFE plastic filters (Qmx, reference Klarity F10030) were employed for filtration after PSA clean-up in screw cap 2.0 mL amber vials (Qmx, reference V0048 or equivalent).

Instrumental conditions

HPLC–ESI(+)-MS–MS analysis of ergot alkaloid standards was carried out on a Waters Alliance 2695 HPLC equipped with a Phenomenex Gemini, C18 column, 2 mm × 150 mm × 5 μm particle size, including a 4 mm × 2 mm Gemini C18 guard column. Elution proceeded by means of a gradient with 0.5 mL min−1 flow rate using solvent C = ammonium carbonate buffer (200 mg L−1 = 3.03 mmol L−1), D = acetonitrile. Initially, the proportion of C was immediately increased from 5% to 17% within 1 min and further linearly increased to 47%, 54%, and 80% after 2 min, 10 min, and 15 min, respectively. Subsequently, the proportion of C was decreased to the initial conditions (5%) over 1 min followed by a hold-time of 5 min, to result in a total run-time of 21 min. The LC column temperature was 30° C. The autosampler temperature was kept at 15° C. The injection volume was 10 μL.

Analyses were performed on a Micromass (Waters, UK) Quattro Ultima and a Quattro Ultima Platinum tandem quadrupole instrument. MS–MS detection was performed in positive electrospray ionisation mode using selected reaction monitoring (SRM) acquisition mode. Nitrogen was used as nebulizer and collision gas.

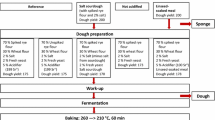

Procedure

Calibrants

Individual stock solutions of six ergot alkaloids, ergocristine, ergotamine, ergocornine, ergosine, α-ergocryptine, ergometrine (as ergometrine hydrogen maleate) and their corresponding six epimers ergocristinine, ergotaminine, ergocorninine, ergosinine, ergocryptinine, and ergometrinine were prepared in acetonitrile at levels of 50–200 μg mL−1.

From these individual stock solutions mixed calibrants of all 12 ergot alkaloids were freshly prepared, by dilution with acetonitrile, at levels of 0.1, 0.2, 1, 2, 4, 10, 20, and 40 ng mL−1. These concentrations correspond to concentrations of the individual ergot alkaloids in the sample between 0.5 and 200 μg kg−1. All solutions were stored in dark brown glass vials in a freezer at −24° C, in darkness, to prevent any isomerisation problems. Since minor precipitation was observed in the ergometrine calibrants at a level of 200 μg mL−1 after 4 weeks, immediate dilution of the stock solutions is recommended. Alternatively, stock solutions at lower levels or the use of a more polar solvent is possible.

The stability and epimerisation behaviour of ergot alkaloids in various solvents has been thoroughly studied by Hafner et al. [28].

Spiking

Ground samples (5 g) were spiked at four different concentrations (5, 50 and 100 μg of each of the 12 ergot alkaloids per kg sample) by adding 25, 250, and 500 μL, respectively, of a 1 μg mL−1 mixed calibrant containing all 12 ergot alkaloids under dim conditions. To avoid epimerisation the spiked samples were not stored overnight but extracted approximately 20 min after the spiking.

Extraction and clean-up

After 30 min extraction of 5 g ground sample with 25 mL acetonitrile–ammonium carbonate buffer (200 mg L−1), 84:16 (v/v), the extract was filtered through Whatman No. 54 filter paper and subsequently subjected to dispersive solid-phase extraction. For that purpose 1 mL of the filtered extract was vortex mixed in a 4-mL screw-capped amber glass vial containing 50 mg PSA material for 45 s and finally filtered through the PTFE syringe filter prior to injection of 10 μL into the LC–MS–MS system.

Data evaluation

Calibration curves for each analyte were constructed by plotting the analyte concentration versus the signal intensity (area) of the analyte using the Micromass MassLynx version 4.0 software. Resulting data were smoothed using the same software.

Validation design

The final validation was carried out for ten different matrices on six different days. The selected matrices (samples) were obtained from supermarkets and local farmers around York, UK, and included one baby food, four types of cereal, and five processed foods (Table 1). Due to the enormous effort which would have been required for full validation for ten different matrices on six different days, a special analytical scheme was developed. In total, four different concentrations were covered by this validation plan (5 μg kg−1, 50 and 100 μg of each of the 12 ergot alkaloids per kg sample plus very low level = blank samples). On each of the six independent validation days five of the matrices were analysed at levels 5 and 100 μg kg−1 and five of the matrices at the levels “blank” and 50 μg kg−1, respectively. Thus, during the whole validation period of six days, 120 measurements (20 on each day) were carried out for four different concentrations. In Table 1 the scheme for the measurements on day 1 is presented as an example. Whereas the matrices “oatbran flakes”, “pearl barley”, “oat meal”, and “wheat flour” contained ergot alkaloids at levels lower than the LOD of the method, the samples “multigrain crackers”, “rye flour”, “rye crispbread A”, “rye crispbread B”, and “baby rusk biscuits” contained levels of up to 5 μg kg−1. In “malted-milk biscuit” ergosine was present at a concentration of 21 μg kg−1 with a sum of ergot alkaloids of 95 μg kg−1.

Mini-intercomparison study

To check the comparability of the measurement results obtained with the newly developed method (Participant 1, UK), a mini-intercomparison study with two other laboratories from Austria (BOKU/IFA-Tulln, Participant 2) and Germany (Chemisches und Veterinäruntersuchungsamt Stuttgart, Participant 3) was carried out.

Three samples were analysed by the three participants. They were a high-level barley containing an estimated level of 0.5–50 mg kg−1 ergot alkaloids, a mixture of this barley with wheat giving a low-level sample containing an estimated 5–500 μg kg−1 ergot alkaloids, and a low level sample of rye flour that contained less than 50 μg kg−1 ergot alkaloids.

Participant 1 employed the new method described in this report. Participant 2 used the same extraction solvent but no clean-up was used and a different type of LC–MS–MS instrument was used. Samples (10 g) were extracted with 40 mL mobile phase solvent (acetonitrile–ammonium carbonate buffer (200 mg L−1) 84:16). The column was a Phenomenex Gemini 150 × 4.6 mm, 5 μm particle size, and the mass spectrometer was an Applied Biosystems QTrap 4000.

Participant 3 used a method based on Müller et al. (2006) [14] which employs a completely different extraction solvent (Scott et al., 1992) [32] involving a chlorinated solvent and final separation and detection by HPLC–FLD. The use of a different extraction solvent by Participant 3 was an ideal way to reveal potential systematic errors.

The method employed by Participant 3 was to extract 20 g sample with 100 mL dichloromethane–ethyl acetate–methanol–aqueous ammonia (conc.) 50:25:5:1 (v/v). Extract (12 mL) was cleaned on a basic aluminium oxide SPE column. The eluate was evaporated and redissolved in 5 mL acetonitrile–water (50:50). The HPLC system used a Phenomenex Gemini, 5 μm 250–4 column with a precolumn and a mobile phase of acetonitrile–water containing ammonium carbonate. The detector was FLD with an excitation wavelength of 245 nm and an emission wavelength of 418 nm.

Results and discussion

Development of the analytical method

MS–MS detection

Each toxin’s mass spectrometric selected reaction monitoring (SRM) settings (mode, collision energy, and cone voltage) were optimized using syringe pump infusion. Ergot alkaloid calibrants (0.1 μg mL−1) were prepared for direct infusion ESI(+) MS analysis by dilution 1:100 of 10 μg mL−1 stock solution with ammonium carbonate buffer–acetonitrile, 1:1, and infused with a syringe pump (Harvard Apparatus, pump 11). In positive-ion mode, [M+H]+ ions yielded the strongest signal compared with [M+NH4]+ and [M+Na]+. Negative-ion mode did not result in useful signal intensities.

The most abundant SRM transition of the ergot alkaloids investigated was that to the product ion m/z 223. Cleavages involved in the release of the m/z 223 fragment and its demethylated counterpart at m/z 208 have been studied by Lehner et al. [21]. Exceptions were ergocornine and ergocristine where the most abundant transition was to m/z 268, although with a smaller range of maximum abundance. For ergometrinine the most abundant transition was to m/z 208.

SRM detection was carried out in a two-stage process with time window function 1 from 2.0 to 5.5 min, and function 2 from 5.2 to 16.0 min. As a compromise the transitions and optimised collision energies given in Table 2 were used in favour of the more important ines.

For all 12 ergot alkaloids tested the transitions from the protonated precursor ion [M+H]+ to m/z 223 was employed as quantifier ion. The transitions to m/z 208 served as qualifier ion for ergometrine, ergosine, ergocornine, and ergotamine, the transition to m/z 268 as qualifier for ergocryptine and ergocristine.

Ergot alkaloids were considered as positively identified in the samples when the following criteria were met:

-

1.

the chromatographic retention time of the analyte corresponded to that of the calibrants within a ±2% tolerance;

-

2.

the presence of a signal was identified at each of the two diagnostic transition reactions (quantifier and qualifier ion; Table 2); and

-

3.

the peak area ratio from these two channels was within the tolerance of ±20% which was set out in 2002/657/EC for the mean ratio from the calibrants.

Chromatographic separation

The autosampler temperature was kept at 15° C, which almost completely eliminated any epimerisation process during a chromatographic run. Poor HPLC separation can be expected for ergot alkaloids because of the possible protonation of the basic nitrogen in these compounds. To address this problem 3 mmol L−1 ammonium carbonate buffer and acetonitrile were used as solvents to avoid protonation and to improve separation. The Phenomenex C18 columns (pH range according to manufacturer 1 to 12) showed good stability at the chosen pH (8.9) and even at higher pH.

In order to avoid peak-fronting experienced during preliminary LC conditions of 17% acetonitrile–83% ammonium carbonate buffer when 10 μL acetonitrile were injected, the run was started with 5% acetonitrile for the first minute. The peak fronting was clearly eliminated and the abundance of the ergometrine peak increased considerably. With the optimized elution gradient the six most prevalent ergot alkaloids ergometrine, ergotamine, ergosine, ergocristine, ergocryptine, and ergocornine [9] and their corresponding epimers could be baseline separated within less than 15 min with a total LC-run time of 21 min, which is about half the time required in previously published LC methods for these ergot alkaloids [25]. Figure 2 shows an ESI(+)LC–MS–MS SRM chromatogram of blank wheat spiked at 5 μg kg−1; this clearly demonstrates both the performance of the chromatographic separation and the sensitivity of the method.

ESI(+) LC–MS–MS SRM chromatogram of blank wheat spiked at 5 μg kg−1 with (ergocristine/inine, ergotamine/inine, ergocornine/inine, ergosine/inine, ergocryptine/inine, and ergometrine/inine) and total ion chromatogram of the ergopeptides (lowest trace). For all 12 ergot alkaloids tested the quantifier transitions from the protonated precursor ion [M+H]+ to m/z 223 were employed (see Table 2 for details)

During SRM of the transition m/z 576 → 223 for α-ergocristine (R t = 7.64 min) an additional peak occurred at R t = 7.92 min for low-level naturally contaminated rye samples. We propose that this peak corresponds to the presence of the ergocryptine β-isomer [14], for which, however, no standard is available. Figure 3 shows an LC–ESI-MS–MS SRM chromatogram of this particular transition obtained from naturally contaminated rye flour, rye crispbread, and multi grain crackers and from an ergocryptine inine calibrant. Despite the close elution of both isomers, Fig. 3 clearly demonstrates the good separation, even of these similar analytes.

Optimization of extraction solvent

In most methods for qualitative and quantitative determination of ergot alkaloids in cereals, extraction has either been performed with non-polar organic solvents under alkaline conditions or with polar solvents under acidic conditions [7]. In this work, for the first time, a mixture of acetonitrile–alkaline aqueous solvent in the ratio 84:16 (v/v) was employed for extraction of the ergot alkaloids. This ratio has already successfully been applied in mycotoxin analysis and particularly for trichothecene mycotoxins [29].

The extraction efficiency of the acetonitrile–ammonium carbonate buffer 84:16 (v/v) was compared with acidic mixture MeOH–0.25% H3PO4 40:60 [15] and with neutral acetonitrile–ammonium acetate 1:2 [19] at a sample-to-solvent ratio of 5 g:25 mL and an extraction time of 30 min with three replicate measurements each. Naturally contaminated barley (high level, up to 25 mg kg−1 ergot alkaloids) and a low level contaminated rye product (rye crispbread, up to 16 μg kg−1) were used as commodities in this study. The extracts obtained were only diluted (rye 1:1, barley 1:50) and filtered but no clean-up was performed prior to determination by LC–MS–MS. Extraction with acetonitrile–ammonium acetate 1:2 required subsequent centrifugation at 15,000 rpm at 4° C for 30 min to enable separation of the sample from the solvent.

The highest concentrations of the 12 ergot alkaloids tested were found after extraction with acetonitrile–ammonium carbonate buffer 84:16 (v/v) as shown in Fig. 4 for naturally contaminated barley. To prove that the higher concentrations were the result of higher extraction efficiency rather than the result of matrix effects in mass spectrometry, standard additions at a contamination level of 10 mg kg−1 ergot alkaloid for the highly contaminated barley were carried out. Reasonable recoveries for all 12 ergot alkaloids of 91–121% were obtained for these spiked samples and confirmed the high efficiency of the selected extraction mixture.

Optimization of clean-up

Initial SPE experiments were mainly carried out with 40 ng mL−1 calibrants of the 12 ergot alkaloids (corresponding to a concentration of 200 μg kg−1 ergot alkaloids in cereals) and blank wheat extracts spiked at a level of 200 μg kg−1. Hydrophilic–lipophilic balance reversed-phase sorbent (Oasis, HLB, 200 mg) and mixed-mode cation-exchange and reversed-phase cartridges for bases (Oasis MCX, 150 mg) were evaluated. Calibrants containing the six ergot alkaloids (ergometrine, ergosine, ergotamine, ergocornine, ergocryptine, ergocristine) were prepared in acetonitrile–ammonium carbonate buffer (200 mg L−1) 1:2. HLB (200 mg) cartridges were pre-conditioned, in sequence, with 3 mL methanol and 3 mL ammonium carbonate buffer (200 mg L−1). After having loaded 3 mL of the calibrant, the cartridges were washed, in sequence, with 3 mL water and 3 mL acetonitrile–water (1:10). Finally, ergot alkaloids were eluted with 6 mL methanol–acetonitrile (1:2). The recovery of each analyte was calculated from the ratios obtained from peak areas in these experiments to those for calibrants at the same concentration injected directly into the LC–MS–MS. Almost no epimerisation occurred and convenient average recoveries of almost 100% were obtained with the HLB column for all ergot alkaloids except the most polar ergometrine. The latter was not sufficiently retained on the column and was already completely eluted during the washing step with water.

MCX SPE cartridges were pre-conditioned, in sequence, with 3 mL methanol and 3 mL ammonium carbonate buffer (200 mg L−1). After having loaded 4 mL of the calibrant, the cartridges were washed, in sequence, with 4 mL water and 3 mL methanol. Finally, ergot alkaloids were eluted with 6 mL 5% NH3 in methanol or in acetonitrile. All ergot alkaloids tested were recovered completely from the column with no matrix interferences evident in the MS detection. In order to avoid epimerisation, the applied calibrants were not acidified and thus not positively charged at N-6, which does not favour retention by the ion-exchange mechanism. Nevertheless, all analytes were retained on the column. This might be due to the slight amount of reversed-phase contribution from the MCX column phase and/or due to some charge which may have been introduced into the molecules even under neutral/slightly alkaline conditions. Final elution under the described alkaline conditions (5% NH3), however, strongly promoted epimerisation to the inines of up to 27% for ergosinine. In contrast with this, no epimerisation was observed for freshly prepared and properly stored ergot alkaloids in acetonitrile.

Finally, dispersive SPE using primary secondary amine (PSA) was studied as a rapid one-step clean-up for the selected ergot alkaloids. Dispersive SPE is based on the SPE methodology, but the sorbent is directly added to the extract, vortex mixed and subsequently filtered or centrifuged. PSA is a weak anion exchanger sorbent with the ability to remove fatty acids, sugars, and some other matrix co-extractives that form hydrogen bonds. This procedure omits many time-consuming steps such as conditioning or washing, commonly employed in traditional SPE methods. Dispersive SPE using PSA is known from a multiresidue method developed by Anastassiades et al. [30] for pesticide analysis. In this work, the potential of dispersive SPE using PSA was, for the first time, studied for the determination of the selected ergot alkaloids. Although preliminary experiments employing PSA clean-up for the six major ergot alkaloids indicated minor epimerisation (maximum 12% for ergotamine and ergosine) the validation study which also involved the epimers (inines) of these alkaloids did not reveal any significant epimerisation. Moreover, convenient recoveries at higher precision were obtained with the new PSA clean-up. Interestingly, using PSA as normal SPE column material (HF BondElut LRC PSA, 500 mg) gave recoveries significantly higher than 100% during preliminary studies and were rejected for this reason and also for the higher cost compared with the dispersive PSA material.

The best results were obtained after vortex mixing 1 mL of the filtered extract for 45 s in a 4 mL screw-capped amber glass vial containing 50 mg PSA material and subsequent filtering through a PTFE syringe filter prior to LC–MS–MS detection.

Evaluation of matrix effects

In order to evaluate the influence of the matrix on mass spectrometric detection, PSA-cleaned and non-cleaned extracts of blank wheat and malted-milk biscuits were each spiked at nine different concentrations in the μg L−1 range with a relative concentration of 1:2:4:10:25:50:100:250:500 (each in duplicate) which correspond to concentrations between 5 and 250 μg ergot alkaloid per kg matrix. As zero level the extract of the blank matrix was employed. The resulting linear calibration functions were compared with that of a calibrant containing no matrix. The signal suppression/enhancement (SSE) was calculated according to the equation:

This procedure was used to reveal and to compare the effects/losses arising from ion suppression/enhancement in cleaned and non-cleaned sample extracts. Figure 5 shows the results obtained for SSE (%) for the spiked extracts of malted-milk biscuit. Ideally, a ratio of 1 is obtained which corresponds to an SSE of 100% and indicates no matrix effects over the tested concentration range.

For neither wheat nor malted-milk biscuits were severe matrix effects for any of the 12 ergot alkaloids found. However, a tendency toward underestimation of the ergot alkaloid concentration can be observed for both matrices. For non-cleaned wheat, underestimations of 3–21% were revealed (SSE = 80–86%) for seven analytes including ergometrine, ergosine, and ergocornine. For PSA-cleaned samples SSEs were mostly approximately 100% with slight enhancement effects for ergometrinine, ergosinine, and ergocryptinine (SSEs ∼110%).

For malted-milk biscuits a different picture was observed (Fig. 5): Whereas no significant differences between cleaned and non-cleaned extracts were observed for most ergot alkaloids, signal reductions for non-cleaned samples of 24% and 47% compared with cleaned samples were obtained for ergotamine and ergotaminine, respectively. In contrast with these underestimations, an SSE of 139% was obtained for ergometrinine.

Summarising, it can be concluded that although only minor matrix effects were generally observed, the positive effect of the PSA clean-up was clearly visible from calculations of the SSE for cleaned and non-cleaned-up extracts of wheat and malted-milk biscuits.

Method validation

Calibration results

Calibration curves for all the analytes were linear over the working range 0.1–40 ng mL−1, which corresponds to a concentration of 0.5–200 μg ergot alkaloid per kg matrix. Squared correlation coefficients (r 2) for the eight-point calibration curves ranged from 0.9888 (for ergocorninine) to 0.9985 (for ergosine).

Recoveries

Figure 6 depicts the mean recoveries obtained for each of the 12 ergot alkaloids in the 10 different matrices at the spiking levels 5, 50, and 100 μg kg−1. Of 90 recovery measurements 85 were between 69 and 105%. Only five recovery results—four for ergometrine and one for ergocristinine—were below 69%, with only two values for ergometrine in rye crispbread lower than 60%. Besides this exception, the results demonstrated that, as a whole, recoveries were independent of the analyte and the matrix, which proves the validity of the approach of pooling 10 different matrices of all 12 ergot alkaloids during the validation study.

Mean recoveries obtained for each of the 12 ergot alkaloids in the ten different matrices. The spiking levels were 5, 50, and 100 μg kg−1. In each “ergot alkaloid column” of the figure each point represents the recovery achieved in one of the ten matrices. (MET = ergometrine/inine, OS = ergosine/inine, TAM = ergotamine/inine, COR = ergocornine/inine, CRYPT = ergocryptine/inine, CRIS = ergocristine/inine)

Standard uncertainty and expanded uncertainty

The performance of the method was assessed by estimating the relationship between analyte concentration and standard uncertainty. Hence the relationship between analyte concentration and expanded uncertainty and estimates of limit of detection and limit of quantification were derived for each analyte. Thus, a linear regression of within-product standard deviation associated with each alkaloid against concentration was used to gain estimates of variation at low concentrations (expressed as a standard deviation (s 0) and variation at high concentrations (expressed as a relative standard deviation RSD). s 0 was used to estimate standard uncertainty at low concentrations (u 0). An estimate of the relative standard uncertainty associated with results from measurement of high concentrations of alkaloids (RSU) was gained by combining RSD for each alkaloid with the uncertainty associated with the purity of standards and the uncertainty associated with the mean recovery (\(\overline R \)) of each alkaloid in each product.

An estimate of the standard uncertainty u(x) associated with a particular measurement result x is given by [31]:

An estimate of the expanded uncertainty U(x) equivalent to a confidence interval of approximately 95% is given by [31]:

A summary of the expanded measurement uncertainties for each of the 12 ergot alkaloids in the 10 different matrices at 5 μg kg−1 is depicted in Fig. 7 which also shows that the observed measurement uncertainties are dependent on the analyte but almost independent of the matrix. In summary, at a concentration of 5 μg kg−1 the expanded measurement uncertainty ranged from ±0.56 to ±1.49 μg kg−1; at a concentration of 100 μg kg−1 the expanded measurement uncertainty ranged from ±8.9 to ±20 μg kg−1 (see Fig. S1 of the electronic supplementary material).

Limit of Quantification (LOQ)

The LOQ is the smallest amount of analyte in a test sample that can be quantitatively determined with suitable precision and accuracy under previously established method conditions (AOAC 2006) [32]. Given a fitness for purpose criterion that the relative standard uncertainty associated with results should be less than RSUMAX, (relative standard uncertainty encompasses precision and accuracy), and the relationship between concentration and standard uncertainty shown in Eq. 1, a limit of quantification (LOQ) is given by:

Figure 8 and S2 of the electronic supplementary material show estimates of LOQ where the maximum acceptable standard uncertainty is equal to 0.25. The limit of detection is defined as the lowest concentration that will be detected with probability 1 − β given a false positive rate α (ISO 1997). For α = β = 0.025 and given the relation between standard uncertainty and analyte concentration shown in Equation 1,

Convenient LOQs between 0.17 and 2.78 μg kg−1 were obtained, depending on the ergot alkaloid and the matrix, with LODs almost equalling the LOQs. A summary of all LOQs is depicted in Fig. 8, which demonstrates that the achieved LOQ is dependent on the analyte but almost independent of the matrix. This also proves the validity of the approach of pooling 10 different matrices for all 12 ergot alkaloids during the validation study.

For most analyte–matrix combinations the LOQ was close to or equal to LOD. This means that results with sufficiently low uncertainty can be produced for all concentrations down to the point where they are censored and reported as “not detected”. This is a feature of trace analyses in which the upper limit for fit for purpose relative standard uncertainties is relatively large (>20%). The lowest and highest LOQs which were obtained for the ine ergot alkaloids range from 0.45 μg kg−1 (ergometrine in wheat rusk biscuits) to 2.78 μg kg−1 (ergosine in rye crispbread).

Comparability

Typical results obtained by the three participants of the mini-intercomparison study for the three different samples are depicted in Fig. 7 for barley. Good comparability of measurement results with almost all deviations within the measurement uncertainties of the respective methods could be demonstrated. The only exceptions are ergocristine in “rye flour” (Participant 3: ca. 100% above mean value) and ergosine in “rye flour” (Participant 1: ca. 90% above the mean value). Minor deviations were also obtained for ergocristine in “barley high level” (Participant 3: ca. 25% above the mean value) and ergosine “barley wheat low” (Participant 1: ca. 25% above the mean value). Overall, and in view of the lack of collaborative trials in the area of ergot alkaloids detection, the agreement of results is surprisingly good. Moreover, the results emphasise that the comparability of the newly developed method even with well established methods (Participant 3) is satisfactory. However, the reasons for the deviations obtained for ergosine and, particularly, for ergocristine should be further investigated.

Conclusion

For the first time a rapid method has been developed and validated for ten different cereal and food samples which enabled the quantification of the six major ergot alkaloids defined by EFSA (ergometrine, ergotamine, ergosine, ergocristine, ergocryptine, and ergocornine) and their corresponding epimers (inines). A fast novel clean-up based on dispersive SPE using PSA material followed by a short chromatographic run (15 min for separation, total run time 21 min) and SRM in ESI(+) mode resulted in convenient LOQs of 0.17–2.78 μg kg−1 depending on the analyte and matrix. Eighty-five of 90 recovery measurements over six measurement days, which were carried out for the 12 ergot alkaloids in ten different matrices at the spiking levels 5, 50, and 100 μg kg−1, were between 69 and 105%. Three more values were greater than 60%. Figure 9

Moreover, highly satisfactory measurement uncertainties were obtained during the validation study which involved six measurement days with 120 independent measurements: At a concentration of 5 μg kg−1 the expanded measurement uncertainty ranged from 5 ± 0.56 to 5 ± 1.49 μg kg−1; at a concentration of 100 μg kg−1 it ranged from 100 ± 8.9 to 100 ± 20 μg kg−1. Both LOQs and measurement uncertainties of the method were dependent on the analyte but almost independent of the matrix which proves the validity of the approach of pooling 10 different matrices of all 12 ergot alkaloids during the validation study.

According to CEN Report CR 13505: 1999 Food Analysis – Biotoxins - Criteria of analytical methods of mycotoxins, the recoveries obtained and the calculated measurement uncertainties are highly satisfactory. For example, the performance characteristics required for fumonisin B1 and B2 are: recoveries 60–120% with RSDr < 30% for c < 500 μg kg−1 and for deoxynivalenol 70–110% with RSDr < 20% for c > 100 μg kg−1.

The comparability of the measurement results was finally investigated within a mini-intercomparison study which involved three laboratories. In general, results from the newly developed method showed good comparability with the results obtained by the other two participants.

References

Lorenz K (1979) CRC Crit Rev Food Sci Nutr 11:311–354

Řeháček Z, Sajdl P (1990) Ergot alkaloids—chemistry, biological effects, biotechnology. Elsevier, Amsterdam

Schoch U, Schlatter C (1985) Mitt Gebiete Lebensm Hyg 76:631–644

Wolff J (1989) Getreide Mehl Brot 43:103–108

Amelung D (1999) Getreide Magazin 5:138–145

Engelke T (2002) Dissertation, Universität Göttingen

Krska R, Crews C (2007) Food Addit Contam (in press)

Bennet JW, Klich M (2003) Clin Microbiol Rev 16:497

EFSA (2005) EFSA J 225:1–27

Komarova EL, Tolkachev ON (2001) Pharm Chem J 35:504–513

Bürk G, Höbel W, Richt A (2006) Mol Nutr Food Res 50:437–442

Lampen A, Klaffke H (2006) J Verbraucherschutz Lebensmittelsicherheit 1:148–149

Scott PM, Lombaert GA, Pellaers P, Bacler S, Lappi J (1992) J AOAC Int 75:773–779

Müller C, Klaffke HS, Krauthause W, Wittkowski R (2006) Mycotoxin Res 22:197–200

Ware GM, Price G, Carter L Jr, Eitenmiller RR (2000) JAOAC Int 83:1395–1399

Scott PM (1995) Food Addit Contam 12:395–403

Scott P (2007) Mycotoxin Res 23:113–121

Komarova EL, Tolkachev ON (2001) Pharm Chem J 35:542–549

Mohamed R, Gremaud E, Richoz-Payot J, Tabet JC, Guy PA (2006) J Chromatogr A 1114:62–72

Lehner AF, Craig M, Fannin N, Bush L, Tobin T (2005) J Mass Spectrom 40:1484–1502

Lehner AF, Craig M, Fannin N, Bush L, Tobin T (2005) J Mass Spectrom 39:1275–1286

Baumann U, Hunziker HR, Zimmerli B (1985) Mitt Gebiete Lebensm Hyg 76:609–630

Scott PM, Lawrence GA (1980) J Agric Food Chem 28:1258–1261

Peng L, Rustamov I, Loo L, Farkas T (2007) Phenomenex Application Note TN-1031 (www.Phenomenex.com/TechnNotes/1031)

Lauber U, Schaufer R, Gredziak M, Kiesswetter Y (2005) Mycotoxin Res 21:258–262

Mohamed R, Gremaud E, Richoz-Payot J, Tabet JC, Guy PA (2006) Mass Spectrom 20:2787–2799

Krska R, Welzig E, Berthiller F, Molinelli A, Mizaikoff B (2005) Food Addit Contam 22:345–353

Hafner M, Sulyok M, Schuhmacher R, Crews C, Krska R (2007) World Mycotoxin J (in press)

Krska R (1998) J Chromatogr A 815:49–57

Anastassiades M, Lehotay SJ, Stajnbaher D, Schenck FJ (2003) J AOAC INT 86:412–431

Eurachem (2000) Quantifying uncertainty in analytical measurement. CITAC Guide number 4. http://www.measurementuncertainty.org/mu/QUAM2000–1.pdf

Scott PM, Lombaert GA, Pellaers P, Bacler S, Lappi J (1992) J AOAC Int 75:773–779

Acknowledgements

The authors would especially like to thank the UK Food Standards Agency for financial support of the project. Dr Uwe Lauber from the Chemisches und Veterinäruntersuchungsamt Stuttgart in Germany is acknowledged for his willingness to participate in the mini-intercomparison study. Rudolf Krska wants to thank Martin Hafner, Michael Sulyok, Rainer Schuhmacher (all BOKU/IFA-Tulln), Patrick Hough, and, especially, Simon Hird (both CSL) for advice and tuition in LC–MS–MS. This article was written during a secondment year of the first author at the Central Science Laboratory in Sand Hutton, York, which would not have been possible without the great support of Professor John Gilbert, Dr Laurence Castle (both CSL), Dr Rainer Schuhmacher, Professor Mathias Müller (IFA-Tulln), the Christian Doppler Research Association, and the University of Natural Resources and Applied Life Sciences, Vienna.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 22.3 kb)

Rights and permissions

About this article

Cite this article

Krska, R., Stubbings, G., Macarthur, R. et al. Simultaneous determination of six major ergot alkaloids and their epimers in cereals and foodstuffs by LC–MS–MS. Anal Bioanal Chem 391, 563–576 (2008). https://doi.org/10.1007/s00216-008-2036-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-008-2036-6