Abstract

A new cod fish tissue certified reference material, NMIJ CRM 7402-a, for methylmercury analysis was certified by the National Metrological Institute of Japan in the National Institute of Advanced Industrial Science and Technology (NMIJ/AIST). Cod fish was collected from the sea close to Japan. The cod muscle was powdered by freeze-pulverization and was placed into 600 glass bottles (10 g each), which were sterilized with γ-ray irradiation. The certification was carried out using species-specific isotope dilution gas chromatography inductively coupled plasma mass spectrometry (SSID–GC–ICPMS), where 202Hg-enriched methylmercury (MeHg) was used as the spike compound. In order to avoid any possible analytical biases caused by nonquantitative extraction, degradation and/or formation of MeHg in sample preparations, two different extraction methods (KOH/methanol and HCl/methanol extractions) were performed, and one of these extraction methods utilized two different derivatization methods (ethylation and phenylation). A double ID method was adopted to minimize the uncertainty arising from the analyses. In order to ensure not only the reliability of the analytical results but also traceability to SI units, the standard solution of MeHg used for the reverse-ID was prepared from high-purity MeHg chloride and was carefully assayed as follows: the total mercury was determined by ID–ICPMS following aqua regia digestion, and the ratio of Hg as MeHg to the total Hg content was estimated by GC–ICPMS. The certified value given for MeHg is 0.58 ± 0.02 mg kg−1 as Hg.

NMIJ CRM 7402-a: cod fish tissue for MeHg analysis

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In order to prevent the outbreak and recurrence of Minamata disease (Kumamoto, Japan), Japanese regulation authorities have been monitoring total mercury and organomercuric species in a variety of industrial, environmental, biological and food samples. Recently, the Ministry of Health, Labour and Welfare of Japan issued guidelines for pregnant women regarding fish consumption in relation to mercury intake [1]. Around the world, several national and international regulatory bodies have also issued guidelines on the consumption of fish and shellfish [2, 3] based on the recommendation for the provisional tolerable human consumption of methylmercury (MeHg) by the Joint FAO/WHO Expert Committee on Food Additives [4]. Long-term monitoring of a wide area is required to implement these regulations, and thus certified reference materials for MeHg analysis are needed to ensure comparability between the monitoring results as well as the measurement methods used.

The National Metrology Institute of Japan (NMIJ) has developed a new cod fish tissue reference material (NMIJ CRM7402-a) for the analysis of MeHg. Its certification was carried out by species-specific isotope dilution gas chromatography inductively coupled plasma mass spectrometry (SSID–GC–ICPMS), where two different extraction methods (KOH/methanol and HCl/methanol extractions) and two different derivatization methods (ethylation and phenylation) were performed to ensure the reliability of the certification. Although the SSID–MS method can correct most systematic errors in the analysis, it can not compensate for nonquantitative extraction from the sample and/or for species reconformation during sample pretreatment [3–10]. Several researchers have reported that the decomposition of MeHg to inorganic Hg and the methylation of inorganic Hg may occur during the extraction and derivatization processes [5–10]. The conversion of MeHg to other mercury species can be compensated for by SSID–MS after achieving isotopic equilibrium [5, 6], but the artificial formation of MeHg from other mercuric species gives a positive bias to the analytical results [7–10]. The artificial formation of MeHg was particularly observed when TMAH was used in the extraction [7–10]. On the other hand, no significant artificial formation of MeHg was observed when KOH/methanol [9] or HCl/methanol [9, 10] was used in the extraction. Therefore, KOH/methanol and HCl/methanol extractions were applied in this certification. Furthermore, no significant artificial formation of MeHg during the sample pretreatment was indicated by the ratio of 200Hg/202Hg in the MeHg in the extracts when inorganic 200Hg2+ was added as a tracer before the extractions. A double ID method [11, 12] was also adopted during the certification, where an assay of the MeHg standard solution used in the double ID method was carefully carried out to ensure not only the reliability of the analytical result but also its traceability to SI units. In the present paper, the analysis for the certification of MeHg in NMIJ CRM 7402-a cod fish tissue by the SSID–GC–ICPMS is described.

Experimental

Preparation of candidate material

Cod fish collected from the sea close to Japan was eviscerated and their muscles were stripped from the bone. The muscle was powdered by freeze-pulverization. The muscle powder that passed through a 250-μm sieve was homogenized using a V blender. Then the powder was placed into amber glass bottles (10 g each) and sterilized with γ-ray irradiation (60Co, 20 kGy). Finally, the bottles were sealed individually in aluminum packages. They were stored at room temperature.

Conversion to dry mass basis

The certified value of MeHg in the CRM7402-a is given on a dry-mass basis. A dry mass correction factor for sample humidity was evaluated by drying the sample at 102 °C. The cod muscle powder reached a constant weight after drying for 6 h, and thus a drying time of 6 h was selected for this experiment. The dry mass correction factor at the time of the certification was 0.9048 ± 0.0012 (average ± standard deviation, ten independent bottles).

Chemicals

Methylmercury chloride (purity 99.3%, as reported by the manufacturer) was purchased from Kanto Chemicals (Tokyo, Japan). The standard solution of MeHg was prepared by dissolving MeHgCl in methanol (pesticide analysis grade, Kanto Chemicals). The spiked solution of 202Hg-enriched MeHg (Me202Hg) was prepared by diluting ERM AE670 (Me202Hg in 2% ethanol solution) provided by the Institute for Reference Materials and Measurement (IRMM, Geel, Belgium) [13] with methanol. Both the standard and spiked solutions were stored at −20 °C. Sodium tetraethylborate (NaBEt4) and sodium tetraphenylborate (NaBPh4) were purchased from Wako Pure Chemical Industries (Osaka, Japan) and Aldrich (St. Louis, MO, US), respectively. 5% m/v NaBEt4 solution and 2% m/v NaBPh4 solution were prepared in a glove box that was purged with N2 gas. A standard solution of inorganic Hg (ca.1000 mg L −1, guaranteed by JCSS) was purchased from Kanto Chemicals (Tokyo, Japan). The enriched isotope 200Hg (96.44% enriched) in oxide form was purchased from Oak Ridge National Laboratory (TN, USA). It was dissolved in aqua regia solution and stored in a clean high-density polyethylene bottle. The nitric acid and hydrochloric acid used were of Ultrapur100 grade, and were purchased from Kanto Chemicals. The diethylmercury (Et2Hg) in toluene used for the mass discrimination correction in the GC–ICPMS measurements was prepared from the inorganic Hg standard solution using ethyl derivatization. Other chemicals used were of analytical reagent grade, and purchased from Kanto Chemicals. Pure water prepared by a Milli-Q water purification system (resistivity 18 MΩ cm, Nihon Millipore Kogyo, Tokyo, Japan) was used throughout the experiments.

Overview of the analytical procedure used for the certification

An overview of the analytical procedure used for the certification is shown in Fig. 1. A double ID method was adopted in this certification. The standard solution of MeHg used for the reverse-ID was assayed carefully to ensure the reliability of the analytical results and traceability to SI units. In order to avoid any possible analytical biases, two different extraction methods (KOH/methanol and HCl/methanol extractions) were performed, with one of the extraction methods utilizing two derivatization methods (ethylation and phenylation). The details of the procedures are described below.

Extraction procedure

KOH/methanol extraction

The cod muscle powder (ca. 0.5 g) was placed in a PFA centrifuge tube and spiked with an appropriate amount of the spike. Then 20 mL of 25%wt/v KOH methanol solution was added to the tube. The resulting mixture was ultrasonicated at 60 °C for 2 h and then mechanically shaken for 1 h. The solution was stored in a refrigerator overnight. Ten milliliters of sample solution were transferred into another PFA tube and neutralized with 6 M HCl methanol solution. Then 10 mL of saturated NaCl solution and 4 mL of toluene were added to the tube, and it was shaken again for 1 h and centrifuged at 3000 rpm for 5 min. Finally, the upper toluene layer was collected as the extract.

HCl/methanol extraction

The cod muscle powder (ca. 0.5 g) was placed in a PFA centrifuge tube and spiked with an appropriate amount of the spike. Then 1 mL of methanol, 2 g of NaCl, and 1 mL of 6 M HCl were added to the tube. The resulting mixture was ultrasonicated at 60 °C for 5 min. After 4 mL of toluene had been added, the tube was mechanically shaken for 20 min. Then 1 mL of 6 M HCl and 10 mL of saturated NaCl solution were added to the tube, and it was shaken again for 20 min. The tube was centrifuged at 3000 rpm for 5 min. Finally, the upper toluene layer was collected as the extract.

Derivatization procedure

The extract was transferred into a PFA centrifuge tube, and 25 mL of the sodium acetate–acetic acid buffer (0.5 M, pH 5) was added to it. Then 0.2 mL of 5% NaBEt4 solution or 1 mL of 2% NaBPh4 solution was added, and the tube was mechanically shaken for 30 min. The tube was centrifuged at 3000 rpm for 5 min. Finally, the toluene layer was transferred to another tube and mixed with 2 g of anhydrous sodium sulfate to remove the residual water.

Determination of MeHg by ID–GC–ICPMS

The GC–ICPMS apparatus used was an Agilent 6890 GC coupled to an HP4500 ICPMS (Yokogawa Analytical Systems, Tokyo, Japan) by a manufactured transfer line (Yokogawa). The GC column used was HP 5msi (30 m × 0.25 mm i.d., 0.25 μm film thickness). The GC temperature programs were 70 °C (1 min hold) to 300 °C (30 °C min–1, hold 2 min) for the phenyl derivatization and 100 °C (1 min hold) to 300 °C (30 °C min–1, hold 2 min) for the ethyl derivatization. Other operating conditions and procedures used for GC–ICPMS were similar to those described elsewhere [4]. To correct for the mass discrimination in the GC–ICPMS measurements, Et2Hg in toluene was added to the sample solutions. The mass discrimination correction factor for MeHg was calculated from the ratio 200Hg/202Hg in Et2Hg at each chromatographic run.

The concentration of MeHg was calculated by the following equation, based on the double-ID method [11, 12]:

where C x is the analyte concentration in the sample (mol g−1), m x is the mass of sample (g) used for the sample–spike mixture, m y is the mass of spike solution (g) used for the sample–spike mixture, \(m^{\prime }_{y} \) is the mass of spike solution (g) used for the standard–spike mixture, m z is the mass of standard solution (g) used for the standard–spike mixture; R is the ratio 200Hg/202Hg in MeHg in the sample–spike mixture solution, R′ is the ratio 200Hg/202Hg in MeHg in the standard–spike mixture solution, R x is the ratio 200Hg/202Hg in MeHg in the sample solution, R y is the ratio 200Hg/202Hg in MeHg in the spike solution, R z is the ratio 200Hg/202Hg in MeHg in the standard solution, w the correction factor for dry mass, n the number of replicate measurements; K and K′ are the mass discrimination correction factors of the isotope ratios, C meth is the concentration of MeHg in the standard solution, B is the procedural blank, and E is the variation factor that was introduced by the extraction into the analytical results.

Assay of the MeHg standard solution

The concentration of the MeHg standard solution used for the reverse-ID was assayed by the following procedure. First, the total Hg in the standard solution was determined, and then the ratio of Hg as MeHg to the total Hg content was estimated.

The total Hg content was determined by double ID–ICPMS after microwave digestion with aqua regia. The microwave digestion procedure was as follows. The MeHg standard solution was weighed in a Teflon vessel, and then an appropriate amount of inorganic 200Hg2+ spike solution and 5 mL of aqua regia were added to it. Then microwave irradiation (ramp temperature to 180 °C over 30 min, and hold for 10 min) was performed. The solution in the vessel was diluted to ca. 50 g with Milli-Q (Millipore, Billerica, MA, USA) water. The double ID–ICPMS procedure employed was similar to that described elsewhere [14].

The ratio of Hg as MeHg to the total Hg content was estimated by GC–ICPMS after derivatization. In order to evaluate the uncertainty associated with derivatization, the MeHg standard solutions after ethylation and phenylation were measured. For each evaluation, three sets of the sample solution were prepared individually and were measured in triplicate.

The concentration of MeHg, C meth, was calculated using the following equation:

where C total is the total concentration of Hg in the standard solution, P is the ratio of Hg as MeHg to the total Hg content in the standard solution, f i is the response factor of mercuric impurities in GC–ICPMS measurements, and A i is the relative peak area of the mercuric impurities to that of MeHg. In this experiment, it was assumed that all of the responses of Hg for the organomercuric impurities during GC–ICPMS measurements are equal, and so the response factor f i =1.

Homogeneity study

The between-bottle homogeneity of the CRM7402-a was examined by analyzing subsamples taken from ten bottles selected from the lot of 600 bottles. The concentration of MeHg was determined by SSID–GC–ICPMS after the KOH/methanol extraction and phenylation. Analysis of variance (ANOVA) was performed on the data and the mean squares within a group (MS within) and among groups (MS among) were calculated. Then the standard deviations between bottles (s bb) were calculated using the following Eq. 3:

In the case of insufficient repeatability of the measurement method, the influence of analytical variation on the standard deviation between units (u bb) was calculated and used as the estimate for the inhomogeneity instead of s bb [15]. The u bb was calculated using the following Eq. 4:

where \(v_{{\text{MS}}_{{\text{within}}} } \) represents the number of degrees of freedom of MSwithin.

Results and discussion

Homogeneity study

Between-bottle inhomogeneity (s bb) was not observed, and thus the u bb value (0.3% relative) was used as the uncertainty derived from the inhomogeneity for MeHg. These results indicate that this material is homogeneous enough for the MeHg analysis.

Stability of MeHg in this material

There are previous reports on the stability of methylmercury in BCR CRMs 463 and 464 (tuna fish tissue certified reference materials; IRMM, Belgium) [16] and DORM-2 (dogfish muscle certified reference material; NRCC, Canada) [17]. Quevauviller et al. reported that BCR CRMs 463 and 464 were pasteurized at 100 °C during their preparation, and that the MeHg in them was stable when the material was stored at below −20 °C [16]. On the other hand, DORM-1 was radiation-sterilized after bottling, and the MeHg in it was stable at room temperature for over fifteen years [17]. The CRM7402-a was also radiation-sterilized, so it should be stable at room temperature. Indeed, no significant change in MeHg concentration in the CRM7402-a has been observed since 2005.

Assay of the MeHg standard solution

The concentration of the MeHg standard solution was assayed, since the double-ID procedure requires a standard solution with a well-defined concentration. An outline of the assessment procedure was provided in the “Experimental” section.

The total Hg content in the standard solution (C total) was determined by ID–ICPMS following microwave digestion with aqua regia. Since the presence of different species of Hg results in an error when determining the total Hg by ID–ICPMS [18], the complete conversion of MeHg to inorganic Hg must be performed. Figure 2 shows GC–ICPMS chromatograms of 200Hg obtained from the MeHg standard solution after the aqua regia digestion. It is clear that the MeHg in the standard solution was completely converted (>99.8%) to inorganic Hg by the aqua regia digestion. Therefore, the error in the isotope ratio measurement caused by the presence of different species was negligible. The value of C total obtained by ID–ICPMS was 0.446 ± 0.006 mg kg–1 (mean ± combined uncertainty, n = 4).

The ratio of Hg as MeHg to the total Hg content in the MeHg standard solution, P, was estimated by GC–ICPMS after the derivatizations. Figure 3 shows the GC–ICPMS chromatograms of 200Hg obtained from the MeHg standard solution after phenylation. Three mercuric impurities were observed. Et2Hg and ethyl-Hg (EtHg) were identified from their retention times during GC–ICPMS measurements. The other impurity could not be identified, but it does not introduce a significant error into the ratio estimation because the Hg responses for the organomercuric impurities in the GC–ICPMS measurements would be nearly equal. The ratios of each mercuric impurity to the total Hg content were calculated as 0.36% for Et2Hg, 0.13% for EtHg, and 0.13% for the unknown. The ratio of Hg as MeHg to the total Hg content obtained by phenylation, P phenyl, was 99.38 ± 0.05% (mean± SD, n = 3). In order to reduce the possible analytical bias arising from the derivatization efficiency of each mercuric species, the MeHg standard solution after ethylation was also measured. Only the peak from Et2Hg was observed in the chromatogram as the impurity. EtHg was derivatized as Et2Hg with the ethylation and was included in the peak of Et2Hg. On the other hand, the unknown peak was not observed for the MeHg standard solution after ethylation. The ratio of Hg as MeHg to the total Hg content obtained by ethylation, P ethyl, was 99.46 ± 0.03% (mean ± SD, n = 3). The difference between the P phenyl and P ethyl values reflect the difference between the derivatization efficiencies of each mercuric species under phenylation and ethylation. Therefore, the median of the maximum range of the P phenyl and P ethyl values was used as the P value (99.41%). The uncertainty of the P value was evaluated by combining the following two uncertainty factors. One is the uncertainty associated with the difference in the derivatization efficiencies, which was estimated as the maximum distance between the P phenyl and P ethyl values. The other is the uncertainty arising from nonderivatized mercury species, and this was evaluated empirically to be 0.1%. The P value was estimated as 99.41 ± 0.13% (value ± combined u). Finally, the concentration of the MeHg standard solution was assayed as 0.445 ± 0.006 mg kg−1 (value ± combined u).

Evaluation of the conversion of MeHg during the extraction and derivatizations

In the SSID–MS method, it is important to consider the interconversion of species during sample preparation [4–10]. Although the conversion of MeHg to other mercury species can compensate for the conversion to MeHg if an isotopic equilibrium is achieved [5–7], the artificial formation of MeHg from other mercuric species can give a positive bias to the analytical results. Therefore, before the certification analysis, the artificial formation of MeHg from Hg2+ during the extractions and derivatizations was evaluated from the ratio 200Hg/202Hg in the MeHg in extracts when inorganic 200Hg2+ had been added as a tracer before the extractions. The 200Hg/202Hg ratios in the MeHg in the test solutions obtained for all three pretreatment procedures closely matched the ratio obtained from the MeHg standard solution. In addition, as is shown later, the analytical results obtained with the three combinations of the extractions and derivatizations were in quite good agreement and each was within the range of its uncertainty. These results indicate that the analytical biases caused by the artificial formation of MeHg during the pretreatment procedure are negligible for this certification.

Analytical results obtained by each method

The concentration of MeHg in the candidate reference material was determined by the three analytical methods. Figures 4 and 5 show the GC–ICPMS chromatograms obtained from the sample extract spiked with the 202Hg-enriched MeHg and Et2Hg (natural abundance). An adequate sensitivity for MeHg was obtained for the SS–IDMS analysis.

The correction for mass discrimination during the isotope ratio measurement is one of the important procedures in the IDMS method. In this experiment, the mass discrimination in the GC–ICPMS measurement was corrected in each chromatographic run, and the mass discrimination correction factor was calculated from the ratio 200Hg/202Hg for the natural abundance Et2Hg that was added to the sample solutions before the measurement. This correction approach not only saves analytical time but also provides a better mass discrimination correction [19] than conventional bracketing correction [20, 21], in which the correction factor is calculated from the isotope ratios obtained from a natural isotopic standard measured every few chromatographic runs.

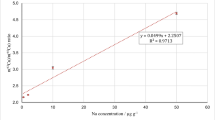

The combined standard uncertainties for the analytical results obtained by each method, u c, were calculated using Eq. 1. Direct estimation of the uncertainty of the validation factor that was introduced by the extraction into the analytical results E is a difficult task. Therefore, the relative standard deviation of the analytical results obtained after independent extractions (n = 4) was used as the uncertainty of E, although this includes the inhomogeneity of the sample. A typical uncertainty budget for the analytical results for MeHg obtained by SSID–GC–ICPMS after KOH/methanol extraction and phenylation is shown in Table 1. The uncertainty of the standard solution (uncertainty of C meth in Eq. 1) was not combined into u(x) because the same standard solution was used for both analyses. It was combined when the uncertainty of the certified value was calculated. The major contributors to the u(x) were the uncertainty of the ratio 200Hg/202Hg in the standard solution, R z (25.2% of u(x)), and the uncertainty of the extraction, E (26.3% of u(x)). The procedural blank B was quite low throughout the certification and hardly affected the analytical results and their uncertainties.

The analytical results along with their uncertainties obtained by the three analytical methods are summarized in Table 2. The values were calculated as mass fractions (based on dry mass). The analytical results obtained by the three analytical methods were in good agreement, and this agreement indicates that there were no significant analytical biases between the extractions and between the derivatizations. Therefore, all of the analytical results obtained were treated equally when the certified value and its uncertainty were calculated.

Establishing the certified value and its uncertainty

The certified value is the weighted mean of the analytical results obtained by the three combination methods, where 1/u i (u i : uncertainty of each result) was used as the weight. The certified value was obtained for the concentration of MeHg as mercury, as shown in Table 3.

The uncertainty of the certified value included the combined effects of method imprecision, possible bias among methods, and material inhomogeneity. Since the same standard solution was used for all measurements, the uncertainty of the standard solution (u std) was combined into the uncertainty of the certified value, as described above. The components of the uncertainty of the certified value are listed in Table 3. Since the certified value was the weighted mean of the three results, the combined uncertainty of each analytical result (u anal) was given by the following equation:

where x i is the result obtained by each of the three combination methods, and w i is the weight. The between-methods variance (u method) was calculated by performing an ANOVA on the data from the three techniques, and was not observed in this certification. The uncertainty derived from the inhomogeneity of the material (u bb) was estimated in the homogeneity study. We did not include the uncertainty from the stability, since the MeHg in the CRM7402-a is stable for at least fifteen years at room temperature, as described above. The expanded uncertainty of the certified value U is equal to ku c, where u c is the combined standard uncertainty with coverage factor k = 2, corresponding to a 95% confidence interval. The certified value given for MeHg is 0.58 ± 0.02 mg kg−1 as Hg.

Conclusion

The concentration of MeHg in the CRM 7402-a cod fish tissue was certified by using SSID–GC–ICPMS. No artificial formation of MeHg was observed in any of the three pretreatment procedures, and all of the analytical results obtained were in quite good agreement. These results indicate that any possible analytical biases caused by nonquantitative extraction, degradation and artificial formation of MeHg in the sample preparations were negligible. The MeHg standard solution was assayed to minimize the uncertainty related to the double-ID method. The material homogeneity was quite good, so the uncertainty derived from material inhomogeneity hardly contributed to the uncertainty of the certified value. The certified value of MeHg in the CRM7402-a is 0.58 ± 0.02 mg kg−1 as Hg (dry mass basis). The total Hg concentration has also been certified for the NMIJ CRM7402-a, and its certified value is 0.61 ± 0.02 mg kg−1 [23]. Thus, ca. 95.1% of the total Hg content is present as the MeHg species. The certified value of MeHg in the CRM7402-a is the same order of concentration as determined in NIST SRM1947 Lake Michigan fish tissue (0.233 ± 0.10 mg kg−1 as Hg on a wet mass basis, NIST, USA) [24] and is one order of magnitude lower than that of the MeHg determined in BCR CRM 463 (3.04 mg kg−1 as MeHg), CRM 464 (5.50 mg kg−1 as MeHg), and DORM-2 (4.47 mg kg−1 as Hg). If these CRMs are used properly, they can cover a wide concentration range during routine analyses of MeHg in fish tissue samples.

References

Ministry of Health, Labour and Welfare of Japan (2003) Advice for pregnant women on fish consumption concerning mercury contamination. Ministry of Health, Labour and Welfare of Japan, Tokyo

European Food Safety Authority (2004) Opinion of the scientific panel on contaminants in the food chain on a request from the commission related to mercury and methylmercury in food. EFSA J 34:1–14

United States Environmental Protection Agency (2004) FDA/EPA Consumer Advisory: what you need to know about mercury in fish and shellfish (EPA-823-R-04–005). US EPA, Washington, DC

Inagaki K, Takatsu A, Watanabe T, Yarita T, Aoyagi Y, Okamoto K, Chiba K (2007) Anal Bioanal Chem 387:2325–2334

Monperrus M, Krupp E, Amouroux D, Donard OFX, Martin-Doimeadios RCR (2004) Trends Anal Chem 23:261–272

Demuth N, Heumann KG (2001) Anal Chem 73:4020–4027

Hintelmann H, Falter R, Ilgen G, Evans RD (1997) Fresenius J Anal Chem 358:363–370

Qvarnstrom J, Frech W (2002) J Anal Atom Spectrom 17:1486–1491

Tu Q, Qian J, Frech W (2000) J Anal Atom Spectrom 15:1583–1588

Ortiz AIC, Albarran YM, Rica CC (2002) J Anal Atom Spectrom 17:1595–1601

Henrion A (1994) Fresenius J Anal Chem 350:657–658

Ellison SLR, Rosslein M, Williams A (2000) EURACHEM/CITAC guide to quantifying uncertainty in analytical measurement, 2nd edn. EURACHEM, Teddington, UK, pp 89–96

Snell JP, Qúetel CR, Lambertsson L, Qvarstromöm J (2004) J Anal Atom Spectrom 19:1315–1324

Inagaki K, Narukawa T, Yarita T, Takatsu A, Okamoto K, Chiba K (2007) Anal Bioanal Chem 389:691–696

Linsinger TP, Pauwels J, van der Veen AMH, Schimmel H, Lamberty A (2001) Accred Qual Assur 6:20–25

Quevauviller Ph, Drabaek I, Muntau H, Griepink B (1994) The certification of the contents (mass fractions) of total and methyl mercury in two tuna fish materials CRMs 463 and 464 (BCR information reference materials). EC, Brussels

National Research Council Canada (1999) Certificate of DORM-2. National Research Council Canada, Ottawa, ON, Canada

Cambell MJ, Vermeir G, Dams R, Quevauviller P (1992) J Anal Atom Spectrom 7:617–621

Inagaki K, Takatsu A, Watanabe T, Yarita T, Aoyagi Y, Okamoto K (2002) Analyst 128:265–272

Yang L, Mester Z, Sturgeon RE (2003) J Anal Atom Spectrom 18:431–436

Snell JP, Qúetel CR (2005) J Anal Atom Spectrom 20:447–454

De Laeter JR, Bohlke JK, De Bievre P, Hidaka H, Peiser HS, Rosman KJR, Taylor PDP (2003) Pure Appl Chem 75:683–800

NMIJ (2006) Certificate of NMIJ CRM7402-a. National Metrology Institute of Japan (NMIJ), Tsukuba-shi, Ibaraki, Japan

Clay Davis W, Christopher SJ, Pugh RS, Donard OFX, Krupp EA, Point D, Horvat M, Gibičar D; Kljakovic-Gaspic Z, Porter BJ, Schantz MM (2007) Anal Bioanal Chem 387:2335–2341

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Inagaki, K., Kuroiwa, T., Narukawa, T. et al. Certification of methylmercury in cod fish tissue certified reference material by species-specific isotope dilution mass spectrometric analysis. Anal Bioanal Chem 391, 2047–2054 (2008). https://doi.org/10.1007/s00216-008-1957-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-008-1957-4