Abstract

l-Lysine (l-Lys) in living bodies is critical for metabolism; therefore, determination of its levels in food is important. Most enzymatic methods for l-Lys analysis are performed using l-lysine oxidase (LyOx), but commercially manufactured LyOx is generally not highly selective for l-Lys among amino acids. We previously isolated LyOx as an antibacterial protein secreted from the skin of the rockfish Sebastes schlegeli. In the present study, we developed an optical enzyme sensor system for rapid and continuous determination of l-Lys using this LyOx. The system comprised an immobilized LyOx membrane, an optical oxygen probe, a flow system, and a personal computer. The amount of l-Lys was detected as a decrease in the oxygen concentration due to the LyOx reaction. The specificity of the sensor was examined against various amino acids. The sensor response was specific for l-Lys. Good reproducibility was obtained in 58 assays. The response of the sensor using commercially prepared LyOx was unstable compared with the response using LyOx isolated in our laboratory. Our sensor system could be used for 5 weeks without our having to change the enzyme membrane. The calibration curve for a standard l-Lys solution was linear from 0.1 to 3.0 mmol L−1. One assay could be completed within 2 min. The sensor was applied to determine the l-Lys content in food samples such as bonito cooking water and scallop hepatopancreas. The values obtained using the sensor and conventional high-performance liquid chromatography methods were well correlated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Many amino acids have an important role in metabolism. l-Lysine (l-Lys) is an essential amino acid that is necessary for growth and for maintaining the nitrogen balance. l-Lys cannot be synthesized in the body and must therefore be supplied by the diet. It helps the body absorb and conserve calcium and thus might be involved in both osteoporosis and fractures or bone defects. l-Lys is given to patients with osteoporosis and fractures because it stimulates intestinal calcium absorption and renal conservation [1], and increases the cross-linking process of bone collagen [2]. l-Lys is used as a feed additive at a rate of over 600,000 t year−1. It is exclusively produced in a bioprocess using coryneform bacteria [3]. The efficiency of l-Lys utilization has recently received much attention in the field of aquaculture. l-Lys is frequently the first limiting amino acid in plant protein, which has an increasingly important role in fish feed. Significant amounts of crystalline l-Lys or l-Lys-rich ingredients need to be incorporated in feeds formulated with high levels of plant proteins to meet the l-Lys requirement of fish [4]. Thus, methods to efficiently and accurately determine l-Lys levels in research fields such as food, medical, and fishery sciences is very important.

Although l-Lys concentrations can be measured using an automatic amino acid analyzer, the procedure is complicated. To establish a rapid and simple analysis, various biosensor systems, including a microbial sensor and an enzyme sensor, consisting of immobilized biocatalysts and an electrochemical device, were recently developed to determine l-Lys concentrations [5–10]. Akyilmazaet et al. [5] developed a microbial biosensor system to determine l-Lys concentrations using microbial cells (Saccharomyces cerevisiae) and an oxygen electrode. The assay procedure of the microbial sensor is based on differences in cell respiration activity detected by the oxygen electrode in the absence and presence of l-Lys. The sensor response is linear for l-Lys concentrations between 1.0 and 10.0 mmol L−1 and has a 1-min response time. The microbial sensor, however, has low selectivity for l-Lys among other amino acids, because the microbial cells act as biocatalysts in the sensor system. The most popular techniques for determining l-Lys concentrations use enzymes such as l-lysine oxidase (LyOx). Kelly et al. [7] reported an enzyme biosensor system for measuring l-Lys concentrations that consisted of LyOx purified from the fungicolous fungus Trichoderma viride and a ruthenium/rhodium-coated glassy carbon electrode covered with 1,2-diaminobenzene polymer. Because the sensor system uses an immobilized enzyme membrane as the biocatalyst, the specificity for l-Lys is higher than that of sensors using microbial cells. This system has a linear response to l-Lys in the range from 2 to 125 mmol L−1 and the detection limit was 2 mmol L−1 [7]. The sensor, however, was not specific and responded to several amino acids, such as l-phenylalanine (l-Phe), l-arginine (l-Arg), and l-cysteine (l-Cys). Most enzymatic biosensors for l-Lys analysis use commercially manufactured LyOx, but the LyOx used in these systems lacks specificity for l-Lys.

We have developed several biosensor systems for use in food and environmental research fields [11–18]. In a previous study, we isolated a new type of LyOx as an antibacterial protein secreted from the skin of the rockfish Sebastes schlegeli [19]. The enzyme was purified to homogeneity by lectin affinity column chromatography, anion-exchange high-performance liquid chromatography (HPLC), and hydroxyapatite HPLC. This LyOx has antibacterial activity and strict substrate specificity, and exclusively catalyzes the oxidation of l-Lys to the corresponding α-keto acid [19, 20]. In the present study, we developed an optical enzyme sensor system for rapid and continuous determination of l-Lys using this isolated LyOx. The characteristics of the sensor system were investigated and the system was applied to determine l-Lys concentrations in real food samples.

Experimental

Enzyme and reagents

LyOx was purified to homogeneity by lectin affinity column chromatography, anion-exchange HPLC, and hydroxyapatite HPLC according to the method described previously [19]. Commercially prepared LyOx (L6150, EC 1.4.3.14) purified from Trichoderma viride was purchased form Sigma-Aldrich (St. Louis, MO, USA). Ultrathin dialysis membrane (part no. 157–0144–02; thickness 15 μm) was purchased from Technicon Chemical. (Orcq, Belgium). A photosensitive polymer (azide-unit pendant water-soluble photopolymer, AWP) was obtained from Toyo Gosei Kogyo (Tokyo, Japan). The amino acids and other reagents used for the experiments were commercial or laboratory grade. To prepare standard l-Lys solutions, l-lysine monohydrochloride was dissolved in 0.1 M phosphate buffer (PB; pH 7.5).

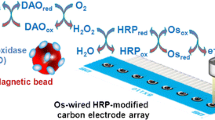

Enzyme sensor preparation

An enzyme-immobilized membrane was prepared using a photosensitive polymer (AWP) according to the method of Endo et al. [14]. Our prepared LyOx (0.6 U) was dissolved in 25 mL of 0.1 M PB (pH 7.0), and the resulting solution was mixed with 80 mg AWP. Next, a dialysis membrane soaked in distilled water was evenly spread over a glass plate without bubbles and then completely dried. The LyOx and AWP mixture prepared was evenly applied and rubbed into the dialysis membrane. After drying for 1 h in the dark, the membrane was placed under a fluorescent lamp for 15 min to prepare an immobilized enzyme membrane. AWP is a photosensitive polymer that hardens when exposed to light, immobilizing the enzyme. The resulting membrane was cut into 4 mm × 4 mm strips, and then closely attached onto the detection portion of a fiberoptic oxygen probe (Foxy-R-Flat, Ocean Optics, Dunedin, FL, USA) using Parafilm. The fiberoptic probe tip was composed of a ruthenium complex (Fig. 1). As a reference, commercially prepared LyOx, purified from Trichoderma viride (0.6 U), was also immobilized with AWP using the same method.

The enzyme sensor system. 1 carrier reservoir, 2 air, 3 sample injection port, 4 enzyme sensor, 5 microtube pump, 6 excitation light-emitting diode, 7 spectrometer, 8 personal computer, A fiberoptic probe tip composed of a ruthenium complex, a oxygen optical fiber probe, b Parafilm, c ruthenium complex, d immobilized enzyme membrane, e flow cell, f buffer solution

Apparatus and assay procedure

The enzyme sensor system was used in a flow-injection measurement system (Fig. 1). An excitation light-emitting diode (LED) light source (USB-LS-450, Ocean Optics), a spectrometer (UBS2000, Ocean Optics), and a personal computer (Dimension 4000, Dell, Round Rock, TX, USA) were connected to the enzyme sensor. Then, 0.1 M PB (pH 5.9–8.0) from the carrier reservoir was transferred to the flow cell equipped with the enzyme sensor. When light (475 nm) from the LED excites the ruthenium complex at the probe tip, the excited ruthenium complex fluoresces, emitting energy at 600 nm. If the excited ruthenium complex encounters an oxygen molecule, excess energy is transferred to the oxygen molecule in a nonradioactive transfer, decreasing or quenching the fluorescence signal. Energy is collected by the probe and carried through the optical fiber to the spectrometer. An analog-to-digital converter is used to convert the analog data to digital data, which are then recorded using computer software. The amount of dissolved oxygen in the flow cell can be measured on the basis of changes in fluorescence intensity. A 50-μL sample was injected into the flow system. The presence of l-Lys was measured as a decrease in the oxygen concentration associated with the oxidation of l-Lys by LyOx.

Real food sample for determining the l-Lys content

Bonito cooking water and scallop hepatopancreas were used as model food samples. Bonito cooking water was collected from a Katsuwo-bushi (dried bonito) manufacturing company in Kagoshima, Japan, in September 2006. Scallop hepatopancreas was supplied by a sea scallop processing company in Hokkaido, Japan, in April 2006.

Enzyme sensor method

Bonito cooking water was used directly as the sample in the sensor assay. In the case of scallop hepatopancreas, 10 g of muscle or viscera was homogenized with a food mixer to extract l-Lys from the sample. The homogenate was centrifuged for 3 min at 4,000 rpm. The supernatant of the sample was diluted 150 times with 0.1 M PB (pH 7.5) and used for the sensor assay.

HPLC method

As a reference, conventional HPLC methods were also used to determine the amount of l-Lys in the food sample. The same amount of concentrated hydrochloric acid (11.6 M) was added to the bonito cooking water or scallop hepatopancreas and the sample was hydrolyzed at 115 °C under vacuum for 20 h. Upon hydrolysis, the sample was evaporated under reduced pressure and washed with distilled water several times until the acid had been completely removed. The sample was then brought to the appropriate concentration using sodium citrate buffer solution (pH 2.2, Wako Pure Chemicals) and filtered through an Omnipore PTFE membrane (Millipore) with a 0.2-μm pore size for amino acid analysis. The amino acid composition was measured with an HPLC system consisting of a Shimadzu LC-20AB pump (bigradient elution system), an RF-10AXL detector, a Shim-pack ISC-30/S0504 Na column, and a postcolumn OPA fluorescent reaction system at 60 °C. The mobile phase flow rate was 0.4 mL min−1 and each assay took 62 min.

Results and discussion

Typical response curve of the enzyme sensor system

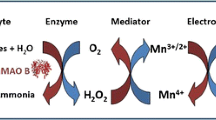

To determine the l-Lys content, a 50-μL aliquot of the sample was injected into the injection port of the sensor system at 38 °C and pH 7.5. The flow rate of the buffer solution was 0.3 mL min−1. Figure 2 shows a typical response curve of the enzyme sensor. After injecting the sample, the sensor output increased within 15 s, and maximum fluorescence intensity was obtained within 40 s. This response indicated that the l-Lys sample solution came into contact with the LyOx immobilized on the enzyme membrane. The enzyme oxidized l-Lys using the dissolved oxygen surrounding the immobilized enzyme membrane as shown in Scheme 1.

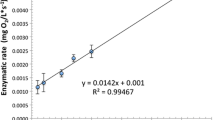

Oxygen consumption due to the oxidization caused a decrease in the amount of dissolved oxygen, resulting in an increase in the output of the sensor owing to increased fluorescence intensity. When the oxidation of l-Lys by the enzyme and the diffusion rate of the dissolved oxygen attained equilibrium, stationary fluorescence intensities were obtained. The difference in the increase in the fluorescence intensity between the base levels obtained from the buffer solution and from the sample solution was used for further calculations. One assay could be completed within 2 min. In our proposed method, an optical oxygen probe consisting of a ruthenium complex and an optical fiber was employed to measure dissolved oxygen. This probe has some advantages such as fast response time (1 s for dissolved oxygen) and long life (more than 1 year) compared with electrochemical electrodes. Moreover, good reproducibility could be obtained because the probe does not consume oxygen, allowing for continuous contact with the sample. Although the fluorescence intensity of the probe was influenced by several fluorides or halogenated compounds, this does not matter for the food samples in this study. We investigated the relationship between the sensor output and the concentration of the l-Lys standard solution. The calibration curve of the l-Lys concentration was linear from 0.1 to 3.0 mmol L−1 (correlation coefficient 0.9889; Fig. 3) and the detection limit was 0.1 mmol L−1.

Calibration curve for l-Lys standard solution. The assay conditions were the same as those described for Fig. 2

Specificity of LyOx for various amino acids

The specificity of the sensor system using our prepared LyOx was examined against various amino acids. As a reference, the response of the sensor system to commercially prepared LyOx was also investigated using the same samples. The ratio of the sensor response using various amino acids normalized to the response to l-Lys (response of l-Lys equivalent to 100%) is shown in Fig. 4. The concentration of each amino acid was 1.0 mmol L−1. Using commercially prepared LyOx, we obtained a sensor response for eight amino acids: l-Arg, l-histidine, l-luecine, l-Met (l-methionine), l-Phe, l-tryptophan, l-tyrosine, and l-Cys. Each response ratio was approximately 10% (Fig. 4). In contrast, our proposed sensor responded to only three of 20 amino acids: l-Arg, l-Met, and l-Cys. Moreover, each response ratio was less than 3%. Thus, our proposed sensor system was highly specific for l-Lys among various other amino acids.

Specificity of the sensor system for various amino acids. White bars l-lysine oxidase (LyOx) purified from the rockfish Sebastes schlegeli; black bars commercially available LyOx purified from the fungicolous fungus Trichoderma viride. The concentration of each amino acid was 1.0 mmol L−1. The experimental conditions were the same as those described for Fig. 2

Effects of analytical conditions on the sensor output

In general, the response of the enzyme sensor system was easily influenced by analytical conditions such as temperature, pH, and flow rate of the buffer solution. The effects of these parameters on the sensor output were investigated (Fig. 5). The effect of temperature on the response of the sensor system is shown in Fig. 5a. The response was constant up to 30 °C, but gradually increased at about 35 °C. The maximum response was obtained at 45 °C. A higher response is usually preferable for the operation of a sensor. As described later, however, the reproducibility of the sensor output was not good at 45 °C (Fig. 6a); therefore, the enzyme reaction was performed at 35 °C for subsequent experiments. The effects of pH and flow rate on the response of the sensor are shown in Fig. 5b and c, respectively. The maximum sensor output was achieved at pH 7.0–7.8; therefore, measurement of l Lys concentrations in real samples was performed at, pH 7.5. The sensor response decreased with an increase in the flow rate, as shown in Fig. 5c. When the buffer flow rate is fast, the sample might pass the immobilized enzyme membrane without reacting. Conversely, a slower flow rate results in a broadening of the peak because of diffusion in the cell. The sample solution should be injected into the flow line at the optimum flow rate. We therefore set the flow rate of the buffer solution to 0.3 mL min−1. On the basis of these results, the performance of the sensor system was optimum under the following conditions: temperature 35 °C, pH 7.5, flow rate 0.3 mL min−1.

Effect of the analytical conditions temperature (a), pH (b), and flow rate (c) on sensor output. Measurements were performed using a 1.0 mmol L−1 l-Lys standard solution. The experimental conditions were the same as those described for Fig. 2, except for each parameter being investigated, which was varied as indicated

Reproducibility and stability of the sensor system

Figure 6 shows the reproducibility of the sensor system. Measurements were performed at 30, 35, and 45 °C using l-Lys standard solution (1.0 mmol L−1). Good reproducibility was obtained in 58 assays at 30 and 35 °C (Fig. 6a). At 45°C, however, reproducibility of the sensor output was not good. The sensor response was higher at 45 °C than at 35 °C (Fig. 5a). Because the sensor response obtained at 35 °C was stable, subsequent experiments were performed with an operating temperature of 35 °C. As a reference, the reproducibility of a sensor made of commercially prepared LyOx was also investigated using the same samples (Fig. 6b). In assay conditions at 30 and 35 °C, good reproducibility was not obtained compared with that of our proposed sensor.

Reproducibility of the sensor system. a LyOx purified from the rockfish Sebastes schlegeli. b Commercially purified LyOx from the fungicolous fungus Trichoderma viride. Measurements were performed using a 1.0 mmol L−1 l-Lys standard solution. Other experimental conditions were the same as those described for Fig. 2

We also investigated the stability of our sensor to determine the probable practical operational lifetime. l-Lys concentrations were measured for approximately 5 weeks at 35 °C. At each time point, the calibration curve for the l-Lys standard solutions (0.1–2.0 mmol L−1) was determined and a correlation coefficient for the linear relationship was calculated. Table 1 shows changes in the correlation coefficient of the calibration curves over 36 days. The correlation coefficient remained extremely high, indicating that the sensor could be used for extended periods of time without exchanging the enzyme membrane. Enzyme activity therefore remained stable and the enzyme remained stable for at least 5 weeks.

Application of the sensor system for the determination of l-Lys in a real sample

The sensor system was used to determine the amount of l-Lys in a real food sample such as bonito cooking water and scallop hepatopancreas. We examined the correlation between data obtained with the sensor and conventional HPLC (Fig. 7). l-Lys concentrations were calculated from the calibration curve shown in Fig. 3. All scallop hepatopancreas samples were diluted 150 times with 0.1 M PB (pH 7.5) to adjust the concentration to between 1.0 and 3.0 mmol L−1 for use with the sensor. As shown in Fig. 7, there were strong correlations between the values determined using the sensor and HPLC (correlation coefficient for bonito cooking water of 0.9953 and for scallop hepatopancreas of 0.9845). Assays were completed within 2 min and it was possible to determine the concentrations of the sample continuously. Thus, the system could be used for rapid determination of l-Lys in a real food sample.

Relationship between the proposed sensor and conventional high-performance liquid chromatography (HPLC) methods for assaying l-Lys in a real sample: a bonito cooking water, b scallop hepatopancreas. The assay conditions were the same as those described for Fig. 2

Conclusions

The sensor system we developed to determine the amount of l-Lys using our isolated LyOx was highly selective for l-Lys. The sensor response was specific for l-Lys, and not for other amino acids. The calibration curve for l-Lys was linear in the range from 0.1 to 3.0 mmol L−1. Each assay could be completed within 2 min. The response of the sensor was very stable for at least 5 weeks when the sensor was operated at 35 °C. When the sensor was applied to determine the amount of l-Lys in an actual food sample, there was a very strong correlation between the values determined by the sensor and conventional HPLC methods. Further studies in our laboratory towards the application of the system for various food samples are ongoing.

References

Civitelli R, Villareal DT, Agneusdei D, Nardi P, Avioli LV, Gennari C (1992) Nutrition 84:400

Oxlund H, Barckman M, Ortoft G, Andreassen TT (1995) Bone 2:365S

Pfefferle W, Mockel B, Bathe B, Marx A (2003) Adv Biochem Eng Biotechnol 79:59

El-Haroun ER, Bureau DP (2007) Aquaculture 262:402

Akyilmaza E, Erdoğanb A, Öztürka R, Yaşac İ (2007) Biosens Bioelectron 22:1055

García-Villar N, Saurina J, Hernández-Cassou S (2003) Anal Chim Acta 477:315

Kelly SC, O’Connell PJ, O’Sullivan CK, Guilbault GG (2000) Anal Chim Acta 412:111

Karalemasa ID, Georgioub CA, Papastathopoulos DS (2000) Talanta 53:391

Lavagnini MG, Moscone D, Palleschi G, Compagnone D, Cremisini C (1993) Talanta 40:1301

Vrbová E, Marek M, Ralys E (1992) Anal Chim Acta 270:131

Hibi K, Mitsubayashi K, Ushio H, Hayashi T, Ren H, Endo H (2007) Biosens Bioelecton 22:1916

Ohnuki H, Saiki T, Kusakari A, Endo H, Ichihara M, Izumi M (2007) Langmuir 23:4675

Hibi K, Abe A, Ohashi E, Mitsubayashi K, Ushio H, Hayashi T, Ren H, Endo H (2006) Anal Chim Acta 573–574:158

Endo H, Yonemori Y, Musiya K, Maita M, Shibuya T, Ren H, Hayashi T, Mitsubayashi K (2006) Anal Chim Acta 573–574:117

Minamide T, Mitsubayashi K, Jaffrezic-Renault N, Hibi K, Endo H, Saito H (2005) Analyst 130:1490

Endo H, Hayashia T, Ren H, Muramatsu H (2005) Int J Environ Anal Chem 85:807

Mitsubayashi K, Kubotera Y, Yano K, Hashimoto Y, Kon T, Nakakura S, Nishi Y, Endo H (2004) Sens Actuators B 130:463

Endo H, Maita M, Takikawa M, Ren H, Hayashi T, Urano N, Mitsubayashi K (2003) Fish Sci 69:1194

Kitani Y, Tsukamoto C, Zhang GH, Nagai H, Ishida M, Ishizaki S, Shimakura K, Shiomi K, Nagashima Y (2007) FEBS J 274:125

Kitani Y, Kikuchi N, Zhang GH, Ishizaki S, Shimakura K, Shiomi K, Nagashima Y (2008) Comp Biochem Physiol B 149:394

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Endo, H., Hayashi, Y., Kitani, Y. et al. Optical enzyme sensor for determining l-lysine content using l-lysine oxidase from the rockfish Sebastes schlegeli . Anal Bioanal Chem 391, 1255–1261 (2008). https://doi.org/10.1007/s00216-008-1847-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-008-1847-9