Abstract

The manufacture and evaluation of a novel sensor built with a composite material, highly selective to nitrate ions using doped polypyrrole as a recognition agent, are presented. When the ratio of recognition agent to graphite was optimized at 1:1, and the sensitivities found closely approached nernstian behavior. The stability times attained were less than 14 min with response times also below 20 s. Batch characterization of the sensor displayed a sensitivity of 57.1 mV/decade of nitrate ion activity (\(a_{{\text{NO}}_3^ - }\)) and a detection limit of 5.37 × 10−5 M, which are comparable to those reported for commercial sensors. Evaluation of the selectivity coefficients showed high affinity to nitrate ion, superior to that of commercial sensors and others reported in the literature. The composite material gives the sensor a prolonged service life with the added capability of allowing the regeneration of its active surface. Coupling the sensor and a solid state, composite-type, reference electrode to a flow injection analysis system (FIA) permitted to achieve an effective overall assessment of the system. A nitrate determination test was conducted on real samples. A comparison of the results obtained, either with stationary measurements or with FIA, indicated that there were no significant differences from the values from manufacturer’s specifications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The nitrate ion is a chemical species commonly found in a diversity of natural processes, as part of the basic nitrogen cycle. Also, as of recently, mankind has used many nitrogen-based compounds for a wide diversity of applications, like in agriculture as an integral part of fertilizers and contemporary insecticides, in chemical synthesis as precursors of a large variety of chemicals, and in the food industry as preservers, savourings, and disinfectants. Also, several nitrate-based organic salts have found various applications in medicine and as pharmaceutical intermediates. Last but not least, they are used as explosives in the mining industry [1, 2].

Together with the extended use of nitrate salts, an alarming increase has been taking place in the concentrations of these ions in the biosphere, thus giving rise to a significant pollution problem, particularly in water bodies and soils. This last aspect has been an ongoing process simultaneously occurring with that of human consumption of nitrates through preserved meats, contaminated water, exposure to insecticides or pesticides, and ingestion of nitrate-based medicaments etc. This outlook is rather worrying mainly on consideration of the impending toxicity of these compounds, which is closely related to precursors of N-nitroso compounds that are potentially carcinogenic [3, 4]. It is well known that in infants and domestic animals an excess of these compounds produces so-called methemoglobinemia [5].

The aforementioned considerations constitute a real basis to develop systems to perform quantitative analysis and consequently facilitate the implementation of control methods for nitrate ions not only in the processes where they are currently used, but also in the monitoring of residual wastewaters, aquifers, for the production of diverse foodstuffs, fruits, and vegetables. In this respect, there are stringent standards to be complied with, such as that of the US Environmental Protection Agency (EPA) which specifies that the nitrate concentration in potable waters should be < 10 ppm.

Spectrophotometry has been the quantification method most frequently used to determine nitrates[6]; however, recently quite a significant effort has been put into improving and optimizing it, thus leaving behind other analytical methods. Nevertheless, this state of affairs has witnessed the gradual inception of flow injection analysis (FIA) to existing spectrophotometry detectors, aiming to further automate the analytical procedures [7–11].

An alternative to spectrophotometry is the use of amperometric biosensors; these devices take advantage of the reaction of nitrate reductase in the presence of a mediator, where nitrate is reduced to nitrite and the resulting current is measured as the analytical signal [12, 13]. Although the use of this enzyme increases the selectivity of the analytical analysis, these biosensors still present considerable disadvantages regarding enzyme immobilization and denaturalization, which produce low reproducibility and poor lifetimes, along with the fact that the biosensor contains chemical species that make it an expensive device [14].

Concerning other alternatives, chemical sensors have become one functional, fundamental alternative choice with which to build analytical systems, because they have several advantages over conventional spectrophotometry or amperometric-based systems. First and foremost, it is possible to reduce significantly the overall dimensions of the system, and second, it becomes possible to undertake direct measurements of the analyte of interest while maintaining an operational coupling to other automated analytical systems; it must be underlined the latter affords a significant cost reduction [15]. In trying to capitalize on the benefits brought by these two features, several efforts have been undertaken during the last few years to build nitrate-selective sensors, which are largely based on supported liquid membranes that use various ionophores such as the tris(2,2′,2″-salicylideneimine)triethylamine and the bis(2-hydroxyacetophenone)ethylenediimine vanadyl(IV) among others [16–19]. This has resulted in greater availability of a commercial series of potentiometric sensors that nevertheless display serious disadvantages when used, such as a minimum capacity to reduce their size because they contain an internal solution, and even more importantly, they have a very small selectivity in the presence of other interfering anions such as perchlorates, thiocyanates, iodides, bromides, and chlorides [20, 21]. It is relevant to mention that in reality there have been meager efforts put into the development of chemical sensors for nitrates. That being the case, these are the two main problems currently displayed by chemical sensors that must be overcome if they are to be considered as an alternative, even more adequate method for quantification of nitrates.

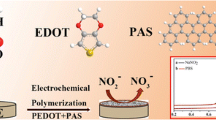

At the end of the 1990s, Jovanovic et al. [22], showed that conducting polymers based on polypyrrole (Ppy) doped with a given anion not only displayed a nernstian-type response toward the dopant anion, but that a molecular impression phenomenon was also induced that afforded a highly selective surface film. Such results encouraged the construction of sensors having a selective polypyrrole membrane doped with nitrates [23] and even bigger anions like dodecyl sulphate [24]. However, when these polymers are grown electrochemically on metal substrates or graphite, problems like dimensions reduction and eventual incorporation into automated analysis systems, like flow injection analysis (FIA), still have remained unsolved. One promising alternative to solve these limitations consists in using composite materials [25], containing a recognition agent in its matrix. This would in turn allow construction of a solid-state sensor, capable of miniaturization and with the added possibility of shaping it in accordance with the requirements of the FIA system into which it would be integrated.

Given the aforementioned arguments, the present research work gives continuity to previous results attained on the growth of polypyrrole in the presence of diverse ions, such as nitrates [26], incorporated into the graphite- and epoxy resin-based matrix composite, to develop a new nitrate-selective composite electrode (NSCE). Therefore, this development concerns a chemical sensor for nitrates that fully solves the selectivity problems associated with typical commercial produce, which additionally complies with the demands posed by modern chemical analyses.

Experimental

All solutions used were prepared with reagent-grade chemicals from Merck and deionized water type 1 with 18.2 MΩ resistivity, free from organic matter, obtained from a US Filter PURE- LAB Plus UV, deaereated with nitrogen, and freshly prepared prior to each determination. The nitrate activities within the different systems studied were determined using the extended Debye–Hückel consideration and molar activity coefficients.

Construction of the composite and the cylindrical NSCE

The composite comprises a mixture of the electrically conducting agent graphite powder, Alfa AESAR 99.9999%, the polypyrrole (Ppy) doped with nitrate that works as recognition agent, and the epoxy resin, Araldit-H.R, as agglomerating agent in a 1:0.4 proportion, respectively. The doped polypyrrole was electrochemically prepared using a BAS 100 potentiostat and the best experimental conditions, such as those reported in the literature [23, 27], in aqueous media over a stainless steel electrode to enable easy surface removal and subsequent powdering with mortar and pestle. The composite was then built with a 1:1 mixture of epoxy resin/graphite + polypyrrole; the amount of polypyrrole and graphite were varied in the composite keeping the said proportion.

The electrodes with a cylindrical configuration used for batch studies were typically built as shown in Fig. 1, using a 0.5-mm-OD PVC tube, and a round, thin copper plate, serving as connecting plate. Hardening of the composite was achieved during a period of 12 h at a constant temperature of 60 °C. Thereafter, the would-be working surface was polished by hand with successively smaller alumina grits. The sensor thus built is immersed in a 10−3 M nitrate solution to produce its activation.

Optimization and analytical characterization of an optimum NSCE

The NSCE is optimized on consideration of the sensitivity maximization towards the ideal Nernst value of 59.16 mV/decade \(a_{{\text{NO}}_3^ - }\); in order to proceed it becomes necessary to test various polypyrrole/graphite formulations in the composite. Activities are then measured with various standard solutions to have the corresponding calibration plots. The sensitivity parameters, the detection limits, and quantification limits will be obtained from the said calibration plots through linear fitting by least-squares regression. The electrode potential changes as a function of time, stored with the use of a Mettler Toledo MP250 potentiometer linked to a PC, and will be used to evaluate the response and stabilization times. Also, the IUPAC-recommended mixed solution method will be used to determine the selectivity coefficients for diverse anions typically found in real samples, keeping the concentration of the interfering ion constant at 10−3 M [32]. To enable evaluation of the NSCE once the analytical parameters have been obtained, these will be compared with those reported in the literature for other types of sensors.

Direct quantification of nitrates in a medicament using an NSCE

The sensor is tested with a real sample, namely for the determination of isosorbide mononitrate, which is the active ingredient of the medicament Elantan. The contents of one capsule (50 mg of the active ingredient) was dissolved in 25 mL phosphate buffer at pH = 6.8, and 10 direct measurements were taken with the NSCE. All the results were statistically analyzed to evaluate the differences between the values registered and those reported by the manufacturer.

Construction and characterization of a tubular NSCE coupled to an FIA system for nitrates quantification

In order to proceed with continuous flow determinations, it becomes necessary to couple the NSCE to a FIA system: given the characteristics obtainable with versatile composite designs, it is not complicated to attain an analytical system with a tubular configuration. To support the composite, cylindrical, 0.4-mm-ID sections made from poly(methyl methacrylate) were filled with the composite mix and fitted with the copper lead contact, such as depicted in Fig. 2a; the material thus cast was left to harden during 12 h at 60 °C. The opposite ends were ground flat and covered by a thin layer of epoxy resin to isolate them from the rest of the body. To undertake the quantitative determination of nitrates through the use of the coupled FIA cylindrically configured system, the NSCE was coupled to a solid composite reference electrode developed by our research team [28], such that it becomes possible to implement a full potentiometric, tubular, miniaturized system. The scheme depicting this experimental set up is shown in Fig. 2b.

An ISMATEC peristaltic pump was used to build the FIA system, together with an OMNIFIT 6-way injection valve and 0.7-mm-ID PTFE tubes. The simplest FIA system to determine nitrates is shown in Fig. 3. The initial parameters were as follows: flow rate of 841 μL min−1, transfer volume of 174 μL plus an injection volume of 77 μL.

In order to register the response of the detection system a Mettler Toledo potentiometer MP250 was used. Having established the initial parameters of the FIA system, the response profile is then established when injecting various solutions with increasing nitrate activity. The determination of the analytical features of the NSCE within the FIA system is obtained by means of the linear least-squares fitting of the various calibration plots obtained; the parameters of the FIA system are then optimized through maximization of the sensitivity recorded. To assess the usefulness of a FIA system during quantification of nitrates, the same study was carried out as when batch studying the isosorbide mononitrate in Elantan (50 mg), only that presently the sample is injected directly into the FIA system.

Results and discussion

Optimization of the NSCE

In order to optimize various NSCEs built, it became necessary to proceed with their individual calibration plots, through the least-squares fitting procedures as commonly used. Table 1 presents the results obtained for each case as well as the detection limits and linear range. It is important to note that the response of the composite containing only graphite is very poor compared to those that contained doped Ppy; thus, it becomes possible to assert that the response of the sensors built is due to the recognition agent and not the conducting agent. Furthermore, in order to determine the best NSCE, a comparison of the sensitivities attained was necessary.

From the results presented in Table 1, it becomes possible to appreciate that even when the detection limits are of the same order of magnitude, the best response is given by the composite containing only doped polypyrrole (100:0), although it is the one exhibiting the poorest sensitivity. When comparing the results of the sensitivity of the NSCE built, it was found that the composite built with a ratio doped Ppy/graphite of 50:50 exhibited the best response with an almost nernstian slope. Generally speaking, when choosing a sensor, it should be better to pick those displaying nernstian-type sensitivities; in order to continue the study, it is reasonable to base the selection of the NSCE on such a criterion, i.e., the latter proportion was used. It seems worthwhile to mention that, aside the ratio 40:60, there were no other proportions tried having greater graphite amounts because as previously said, this would certainly induce stronger interferences by other ions in solution; in the case of the ratio 40:60, the sensitivity obtained and the detection limit were equivalent to those of the 50:50 NSCE; however, because it had a greater amount of graphite, the latter ratio is preferred.

Stabilization time, response time, and drift of the NSCE

The optimum potential recorded as a function of time by means of the NSCE was analyzed in terms of the changes that took place when the chemical environment surrounding the electrode was changed upon varying the nitrate concentration in the media. Figure 4 is a typical plot depicting the time evolution of the study undertaken.

Upon performing the calculations, the stabilization time found was 14 min with a response time varying between 4 and 20 s, depending on the nitrate activity in the system. Thus, it is possible to observe from Fig. 5 that the NSCE exhibits a negative potential drift constant, and the least-squares regression indicated that the drift was 0.1 mV min−1, which should be taken into account for determinations that take considerable time to achieve.

Sensitivity, detection limit, and quantification range of the NSCE

Figure 5 shows a typical calibration plot for the NSCE studied. An equation can be obtained for the best straight line by using the least-squares fitting procedure of the data points having a linear trend. From the calibration plots done, the following general equation was obtained:\(E = \left( { - 57.1 \pm 0.3} \right)\log \,a_{{\text{NO}}_3^ - } - \left( {36.9 \pm 0.6} \right)\) from which it can be observed that the sensitivity of the NSCE is −57.1 ± 0.3 mV/decade \(a_{{\text{NO}}_3^ - }\), a value taken to be practically nernstian. Using the IUPAC method [33] to determine the detection limit and the quantification range, it was found that the former lied at a nitrate activity of (5.37 ± 0.07)×10−5, while the lower quantification limit lied at a concentration (1.56 ± 0.01)×10−4 M and the higher limit was greater than 0.1 M, which was the greatest concentration studied. To evaluate the analytical quality parameters of the NSCE, the results obtained are compared with those reported in the literature and presented in Table 2.

As can be observed in Table 2, the results obtained with the NSCE are practically equivalent to those reported for other commercial or recently proposed sensors.

Selectivity of the NSCE

In order to evaluate the NSCE with respect to the presence of some common interfering inorganic anions, the mixed solutions method was used, as recommended by IUPAC, to find the selectivity coefficients [32]. Using a fixed 10−3 M concentration of each interfering anion under study, several calibration plots are carried out for the nitrate ion. Table 3 shows the results obtained and the comparison of the selectivity coefficients reported for other commercial sensors, as well as the selectivity coefficients found for a nitrate-doped polypyrrole membrane over a glassy carbon electrode, to corroborate the effect of graphite over the response of the sensor.

As can be observed from Table 3, the selectivity coefficients are significantly diminished in the systems using doped polypyrrole as recognition agent, even when the NSCE exhibits selectivity coefficients slightly better than those reported when directly using a film of the polymer, which is though to be due to adsorption of interfering anions on the graphite present in the composite.

Influence of the pH on the response of the NSCE

To determine the influence of the pH on the response of the NSCE, the potential of the sensor was monitored in a 10−3 M nitrate solution, varying the pH by means of hydrochloric acid or sodium hydroxide additions. As shown in Fig. 6, the potential remained constant within the pH range 4.3–7.4. The explanation for this is based on the use of graphite, because the pH changes are mostly due either to adsorption of protons at acid pH or to hydroxide at basic values.

Repeatability and lifetime of the NSCE

The repeatability of the measurements performed with the NSCE is evaluated and interpreted as the relative percentage error; thus fifty consecutive measurements were carried out with a constant 10−3 M nitrate concentration solution. The results of the statistics indicated an error of 1.72%, which is quite adequate for a sensor of this kind.

To evaluate the lifetime of the NSCE, the sensitivity of one of the sensors is recorded while in constant use (this means continuous use for at least 2–4 h daily and two calibrations per day); it was found that by imposing 95% confidence limits on the average sensitivity values, the lifetime was around 6 months. Now, it is relevant to strongly emphasize that this lifetime should be referred to one particular surface of the composite exposed and that when the analytical features begin to be lost, then they may well be regenerated on a new clean surface, done relatively simply by grinding and polishing the old surface down to a sufficiently small abrasive grit, of the order of a fraction of a micron. In this way, the optimum analytical characteristics are recovered, such that the overall lifetime of the sensor is far superior than the 6 months previously stated.

Direct quantification of nitrates in a medicament using the NSCE

The sensor was tested for the determination of isosorbide mononitrate, which is the active ingredient of Elantan (50 mg), a pharmaceutical commonly used to treat chest angina, myocardial infarction, and congestive cardiac insufficiency, by increasing the amount of oxygen to the myocardium and the coronary flow. A compariso between the expected activity of the nitrate ion in the medicament sample, as stated by the manufacturer’s specifications, and the average obtained through several direct measurements performed with the NSCE is summarized in Table 4.

The Student’s t coefficient calculated turned out to be smaller than the critical t coefficient at a 95% confidence level; therefore, it can be concluded that there are no significant differences between both values, thus showing the usefulness of the NSCE for this sort of analyses.

Characterization and optimization of the FIA system for the quantification of nitrates

Using the parameters initially suggested, we obtained the response profile shown in Fig. 7, known as a fiagram, where the response peaks of the electrode potential are proportional to different nitrate concentrations injected into the system at different times. Also, it becomes possible to observe that the profile is typical of a diffusive-convective controlled-transport process, which is the adequate sort of regime for FIA studies.

Considering that the analytical response is a potential difference, ΔE, expressed as the baseline potential minus the minimum potential from the response, various calibration plots are obtained by injecting nitrate solutions of various ion activities into the system. Figure 8 depicts a typical plot obtained.

When performing the statistical analysis the sensitivity found was 26.6 ± 2.2 mV/decade \(a_{{\text{NO}}_3^ - }\) and a detection limit of (7.08 ± 0.62) × 10−3 with a lower quantification limit of (9.84 ± 0.91) × 10−3 M. The values obtained happen to be quite below those obtained from the batch studies, which is due to the hydrodynamic variables of the FIA system that affect the analytical characteristics. Another study was carried out to improve the sensitivity of the system at various flow rates; the results obtained are shown in Table 5.

At high flow rates the sensor is not capable of attaining a sufficiently rapid equilibrium to generate an adequate analytical response. Conversely, if very slow flow rates are used the injected sample becomes diluted in the carrier and reproducibility is adversely affected. The flow rate that gave the best sensitivity and detection limit to the analytical system was 510 μL min−1 at which a minimum quantification limit of (3.05 ± 0.42)×10−4 M is also obtained. Figure 9 shows a typical calibration plot for the system using the corrected flow rate.

Quantification of nitrates in a medicament using FIA

When the nitrate ion activity, as specified by the manufacturer of the medicament Elantan, was compared with the average obtained with the NSCE, then it is determined if there are meaningful differences resulting through application of the Student’s t test; the results obtained are summarized in Table 6.

The calculated t coefficient was smaller than the critical t at a 95% confidence level, which allows us to conclude that there are no meaningful differences between both values, showing the usefulness of the FIA system for the in situ and in-field determination of nitrates in various systems.

Conclusions

From the result obtained during the characterization of the NSCE it became evident that its analytical response in terms of the parameters studied were equivalent to that of commercial electrodes and of some ionophores recently reported in the literature. The evaluation of the selectivity coefficients indicated a superior behavior of the NSCE compared to commercial electrodes. Coupling of the NSCE in an FIA system is a fairly simple task, which proved versatile because of the composite-type reference electrode used. The usefulness of such system has been demonstrated for the determination of nitrate ions, which opens up an array of possibilities for such kinds of systems devoted to quantification of diverse samples, in either in situ or in-field studies.

References

Jonson C, Cross BC (1990) Am J Ind Med 4:449–456

Kurser MS, Wollenhaupt J, Calloway DH (1981) Am J Clin Nutrition 34:1305–1313

Avery AA (2001) Cause Environ Health Perspect 109:A12–A14

Fraser P, Chilvers C, Beral V, Hill MJ (1980) Int J Epidemiol 9:3–9

George M, Wiklund L, Aastrup M, Thunholm B, Saldeen T, Wernroth L, Zaren B, Holmberg L (2001) Eur J Clin Invest 31:1–13

Nidal F (1976) Talanta 23:349–357

Feres MA, Reis FB (2005) Talanta 68:422–428

Huang K, Wang H, Guo Y, Fan R, Zhang H Talanta In Press Corrected Proof Available online 7 October 2005

Aydın A, Ercan Ö, Taşcıoğlu S (2005) Talanta 66:1181–1186

Suvardhan K, Suresh Kumar K, Hari babu S, Jayaraj B, Chiranjeevi P (2005) Talanta 66:505–512

Gao F, Zhang L, Wang L, She S, Zhu Ch (2005) Anal Chim Acta 533:25–29

Glazier SA, Campbell ER, Campbell WH (1998) Anal Chem 70:1511–1515

Silva SD, Shan D, Cosnier S (2004) Sens Actuators B 103:397–402

Quan D, Min DG, Cha GS, Nam H (2006) Bioelectrochemistry 69:267–275

Kellner R, Mermet J, Otto M, Widmer H (1998) Anal Chem. Wiley-VCH, New York

Mitrakas MG, Alexiades CA, Keremidas VZ (1991) Analyst 116:361–366

Aslan N, Kenar A, Atakol O, Kilic E (2001) Anal Sci 17:1269–1272

Mazloum M, Salavati M, Jamshidpoor M (2004) Sens Actuators B 101:302–307

Hassan SSM, Marzouk SAM, Sayour HEM (2003) Talanta 59:1237–1244

Badea M, Amine A, Palleschi G, Moscone D, Volpe G, Curulli A (2001) J Electroanal Chem 509:66–72

Nitrate electrode instrumental manual, model 9703, Thermo Orion

Jovanovic V, Markicevic L, Stankovic S, Stankovic R, Jovanovic M (1995) Electroanalysis 7:574–578

Hutchins R, Bachas LG (1995) Anal Chem 67:1654–1660

Álvarez-Romero G, Morales-Pérez A, Rojas-Hernández A, Palomar-Pardavé M, Ramírez-Silva MT (2004) Electroanalysis 16:1236–1243

Alegret S, Alonso J, Bartrolí J, Paulís JM ((1984)) Anal Chim Acta 164:147–152

Álvarez GA, Garfías E, Ramírez MT, Galán CA, Romero M, Palomar M (2006) Appl Surf Sci 252:5783–5792

Díaz AF, Kanazawa KK, Gardini GP (1979) J Chem Soc Chem Commun 635–642

Valdés G, Álvarez GA, Galán CA, Hernández PR, Ramírez MT (2005) Sens Actuators B 110:264–270

Ion selective electrodes manual. Vernier Software and Technology

Mazloum M, Salavati M, Jamshidpoor M (2004) Sens Actuators B 101:302–307

Bendikov TA, Kim J, Harmon TC (2005) Sens Actuators B 106:512–517

Pure Appl Chem (2000) 72:1851–2082

Inezédy J, Lengyel T, Ure AM (eds) (1997) Compendium of analytical nomenclature. Definitive rules, 3rd edn. International Union of Pure and Applied Chemistry

Acknowledgements

The authors are grateful to Dr. Mario A. Romero Romo from Departamento de Materiales, Universidad Autónoma Metropolitana-Azcapotzalco, for his valuable suggestions and the English translation of this paper. GAAR, MTRS, and MEPP thank the SNI for the distinction of their membership and the stipend received. GAAR also thanks CONACYT for the financial support given through the Institutional Consolidation program with number 050020 and to Departamento de Materiales, UAMA, for financial support thought projects 2260220, 2260225 and 2260231.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Álvarez-Romero, G.A., Palomar-Pardavé, M.E. & Ramírez-Silva, M.T. Development of a novel nitrate-selective composite sensor based on doped polypyrrole. Anal Bioanal Chem 387, 1533–1541 (2007). https://doi.org/10.1007/s00216-006-1021-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-006-1021-1