Abstract

A direct competitive enzyme-linked immunosorbent assay (ELISA) based on a monoclonal antibody has been developed and optimized for detection of aflatoxin B1 (AFB1), and an ELISA kit has been designed. This immunoassay was highly specific, sensitive, rapid, simple, and suitable for aflatoxin monitoring. AFB1 concentrations determinable by ELISA ranged from 0.1 to 10 μg L−1. The IC50 value was 0.62 μg L−1. Recovery from spiked rice samples averaged between 94 and 113%. The effect of different reagents on the stability of HRP–AFB1 conjugate solution was studied. The performance of a stabilized enzyme tracer in ELISA was determined and compared with that of a freshly prepared control solution of HRP–AFB1 conjugate. The results showed that stabilizing media containing 0.02% BSA, 0.1% Kathon CG, and 0.05 mol L−1 calcium chloride in 0.05 mol L−1 Tris-HCl buffer (pH 7.2) maintained the activity of HRP–AFB1 at a dilution of 1:1000 for a period of at least 12 months at room temperature whereas the reference conjugate solution without the additives lost its activity within a few days. Several additives were tested for their stabilizing effect on a monoclonal antibody (MAb) immobilized on the surface of polystyrene microtitre plates. It was shown that immobilized MAb, treated with post-coating solutions containing PVA, BSA, and combinations of these substances with trehalose, retained its activity for at least 4 months at 4°C, whereas the untreated MAb-coated plate lost its activity within 2 days.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Aflatoxins are toxic fungal metabolites that contaminate a wide range of agricultural products. There is an increasing awareness of the hazards to both human and animal health of aflatoxins present in food and feed. They are listed as group I carcinogens by the International Agency for Research on Cancer (IARC) [1]. Aflatoxin B1 (AFB1) is the most significantly occurring and toxic compound. Aflatoxins are regulated in many countries and legal limits ranging from 0 to 50 ng g−1 have been established for the compounds [2]. Maximum levels stipulated vary from country to country and depend on the commodity and its intended use. The current maximum levels set by the European Commission are 2 ng g−1 for AFB1 and 4 ng g−1 total aflatoxins for groundnuts, nuts, dried fruits, and cereals [3].

The discovery of serious aflatoxicosis in farm animals and the presence of aflatoxins in many food products triggered a worldwide effort to develop analytical methods for these compounds. Current analysis of aflatoxins is performed by a variety of methods [4] including mainly thin-layer chromatography [5], high-performance liquid chromatography (HPLC) [6, 7], overpressured-layer chromatography [7, 8], and enzyme-linked immunosorbent assay (ELISA) [9–11]. TLC is a relatively economical method of aflatoxin detection, with little equipment required, and is still used broadly in developing countries where limited or no facilities exist for monitoring these toxins in foods and feeds. Chromatographic analysis is widely accepted as an official method for aflatoxin determination. HPLC (normal and reversed-phase) have been applied in conjunction with UV absorption, fluorescence, mass spectrometry, and amperometric detection, with different clean-up procedures such as solid-phase extraction (SPE), supercritical-fluid extraction (SFE), matrix solid-phase dispersion (MSPD), and immunoaffinity chromatography [5, 6, 12–16]. The application of cyclodextrins in HPLC analysis of aflatoxins has also been described [17]. Recently, the use of a flow system coupled with capillary electrophoresis has been reported [18]. Although sensitive and accurate, most of the chromatographic methods developed are laborious, expensive, time-consuming, and unsuitable for analysis of many samples; they also require sophisticated equipment and extensive clean-up procedures. The development and application of biosensors for the detection of aflatoxins has also been described [19–21]. The main limitation of the use of biosensors is regeneration of the receptor surface.

There has been an increasing demand for monitoring of aflatoxins in developing regions such as South-East Asia, Africa, and the Middle East where aflatoxin contamination is rampant. They are the exporters of food and food products which can suffer from aflatoxin contamination. Immunoassays provide a simple and economical alternative to instrumental methods for mycotoxin analysis. Application of immunochemical methods, especially enzyme-linked immunosorbent assay (ELISA), in the surveillance of aflatoxins is becoming more widespread, because of the sensitivity, specificity, rapidity, simplicity, and cost-effectiveness of the methods. Production and characterization of monoclonal and ultra-sensitive polyclonal antibodies to AFB1 and their application in enzyme immunoassay and immunoaffinity chromatographic methods for aflatoxins have been reported [22, 23]. Different immunoassay techniques for AFB1 have been developed rapidly in the past two decades. To give a few recent examples, radioimmunoassay (RIA) [24], a rapid colorimetric sequential injection immunoassay system (SIIA) [25], a surface plasmon resonance-based immunoassay [26], a strip liposome immunoassay (LIA) [27], an immunofiltration-based assay using an improved catalysed reporter deposition (Super-CARD) method of signal amplification [28], and a fluorescence polarization (FP) immunoassay [29] have been reported. The development of ELISA methods for AFB1 detection and their application to different matrices have also been described [11, 30–32]. In general, ELISA has several advantages for rapid screening of commodities for aflatoxins. The detection limits of ELISA can be comparable with or even lower than those obtained by use of instrumental methods, although matrix effects are a common problem in immunoassays.

The quality and stability of immunoreagents (antibodies, enzyme tracers) are important aspects of the performance of immunoassays and of their standardization. Stabilization of the biological components is an essential aspect of their lifetime, which is significant in practical applications such as on-line sample monitoring. Therefore, the long-term storage and stability of the reagents has to be ensured. This problem is of particular importance when introducing enzyme immunoassays for mycotoxin analysis to laboratories in different parts of the world, especially tropical and subtropical countries. A critical point remains the stability of protein and, in particular, enzyme reagents. Stabilizing an enzyme normally means suppressing the unfolding of the protein and retaining the catalytic activity. The most important methods for stabilizing enzymes are modification of the protein structure by direct site mutagenesis, immobilization to solid phases, chemical modification, or addition of stabilizing agents, for example substrates, products, inhibitors, cofactors, metal ions, proteins, sugars, and natural or synthetic polymers [33, 34]. Horseradish peroxidase (HRP) is most widespread of the enzymes used for immunoassays. It can be quantified by use of a variety of substrate systems ranging from colorimetric detection with tetramethylbenzidine (TMB) to chemiluminescent detection with luminol. The enzyme tracer is the most sensitive reagent in ELISA. They are used in high dilution and are often unstable. The development of ELISA kits requires that their composition be as simple as possible and that the number of dilution stages in the analysis should be minimal. Choice of the optimum environment is known to be one factor affecting enzyme stability. Several stabilizing media have been developed and many substances have been tested to stabilize solutions of HRP or its antigen-bearing conjugates and other ELISA kit components [35–38]. It was therefore important to determine the optimum conditions for storage of diluted HRP–AFB1 conjugate and to investigate the effect of different stabilizing agents on the ELISA for AFB1.

This paper reports the development of a direct competitive ELISA using monoclonal antibodies (MAb) for detection of aflatoxin B1, stabilization of ELISA kit components for long-term storage, and application of the method to the analysis of spiked and naturally contaminated grain samples.

Experimental

Materials

Aflatoxins and other mycotoxins used for cross-reactivity studies, bovine serum albumin (BSA; further purified fraction V, approx. 99%), Tween 20, 3,3′,5′,5-tetramethylbenzidine (TMB), 3,3′,5′,5-tetramethylbenzidine (TMB) liquid substrate system, poly(vinyl alcohol) (PVA, 30,000–70,000), glycine (minimum 99%), D-(+)-trehalose, N,N-dicyclohexylcarbodiimide (DCC), N-hydroxysuccinimide (NHS), and other chemicals used in the hapten synthesis, in immunization, and in ELISA, common solvents, and salts were purchased from Sigma (St Louis, MO, USA). Poly(ethylene glycol) (PEG 4000 in 75 mmol L−1 Hepes (PEG 50%, w/v), sterile, fusion tested) was purchased from Roche Diagnostics (Mannheim, Germany). Cell-culture media (DMEM), fetal calf serum and supplements were obtained from Gibco BRL (Paisley, Scotland). Kathon CG was supplied by Vendico Chemical AB (Malmo, Sweden). Dialysis membrane (Spectra/Por; MW cutoff 6,000–8,000) was obtained from Spectrum Laboratories (Rancho Dominguez, CA, USA). Thin-layer chromatography (TLC) plates (silica gel 60, fluorescent, 1 mm, 20 cm×20 cm) were purchased from Merck (Darmstadt, Germany). Maxisorp polystyrene 96-microwell plates were purchased from Nunc (Rockilde, Denmark), and Removawell Strips were purchased from Dynex Technologies (Chantilly, VA, USA). All chemicals and organic solvents were of reagent grade or better. Water used in all experiments was purified with a NANOpure system (Barnstead, USA).

Phosphate-buffered saline (PBS, 0.05 mol L−1, pH 7.4) was used in the experiments.

Standard solutions of aflatoxins were prepared by dilution of stock solutions of these compounds (1 mg mL−1, in methanol).

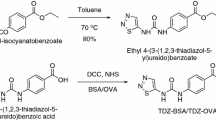

Preparation of AFB1-oxime

The chemical structures of AFB1 and its derivatives used for ELISA development are shown in Fig. 1. AFB1-oxime was prepared according to the method described elsewhere [39]. Briefly, 5 mg (20 μmol) AFB1 and 12 mg (60 μmol) carboxymethoxylamine hemihydrochloride were dissolved in 7 mL pyridine and incubated overnight at 37°C. Carboxymethoxylamine hemihydrochloride (12 mg, 60 μmol) was then added to the mixture, which was incubated again at 37°C for 6 h. Pyridine was evaporated and the product, a yellow–brown oil, was dissolved in 10 mL 0.1 mol L−1 NaOH. The reaction mixture was extracted twice with 5 mL dichloromethane. The aqueous phase was acidified to pH 2 with 5 mol L−1 HCl and formation of a white residue was observed. The crude compound was extracted thrice with 10 mL ethyl acetate. The combined organic phases were dried (2 g anhydrous sodium sulfate), filtered, and the solvent was evaporated. The product was separated by TLC using dichloromethane/methanol (4:1, v/v) as mobile phase. The yield of AFB1-oxime was 3.3 mg (7 μmol).

Synthesis of enzyme and protein conjugates of AFB1-oxime

AFB1–BSA and AFB1–HRP (Fig. 1) conjugates were synthesized using the activated ester method [40]. Briefly, 11.5 mg (100 μmol) NHS and 20.5 mg (100 μmol) DCC were dissolved in 2 mL absolute DMF; 1 mL of this solution (containing 50 μmol NHS and 50 μmol DCC) was added to 3.3 mg (7 μmol) AFB1-oxime and the reaction mixture was incubated overnight at room temperature. BSA (15 mg, 0.25 μmol) was dissolved in 2 mL 0.05 mol L−1 carbonate buffer (pH 9.6) and cooled at 4°C for 2 h. The solution of the active ester (300 μL) was slowly added (drop by drop, with shaking) to the protein solution. The reaction mixture was kept for 2 h at room temperature, then overnight at 4°C, and then centrifuged at 3,000 rpm for 10 min. Subsequently, dialysis against 2 L PBS, which was changed three times a day, was performed for 3 days.

The enzyme conjugate AFB1–HRP was prepared in a similar manner, but using 2 mg (0.05 μmol) HRP in 1 mL 0.05 mol L−1 carbonate buffer (pH 9.6) and 70 μL of activated ester solution.

Preparation of monoclonal antibodies

Monoclonal antibodies to AFB1 were produced in our laboratory by the standard procedure [41] using AFB1–BSA as immunogen.

Immunization

AFB1–BSA (200 μg) in 0.2 mL sterilized PBS was emulsified with an equal volume of Freund's complete adjuvant and given as two intraperitoneal injections, at two-week intervals, to each of several 7-week-old female BALB/c mice. Ten days later serum was collected from the caudal vein of each mouse and titres of antisera were determined by indirect ELISA. Three days before cell fusion the mice, which produced antisera with high titres, were given another intraperitoneal boost injection without the adjuvant.

Cell fusion and culture

Suspensions of 3.5×108 spleen cells from immunized mice were fused with 1.17×108 or 4.3×108 SP2 myeloma cells or 4.3×108 6.5.3 myeloma cells using 50% poly(ethylene glycol) 4000. After HAT selection [41] the supernatants of hybridoma cells were assayed by indirect ELISA. ELISA-positive hybridoma cells were cloned by the limiting dilution method. Cloned hybridoma cells (1.0×107 in PBS) were intraperitoneally injected into BALB/c mice, pre-treated with intraperitoneal injection of 1 mL pristane, and grown as ascite tumours. The immunoglobulin fraction was prepared from the ascitic fluids by precipitation with saturated ammonium sulfate.

Apparatus

Measurements of optical density for 96-well microtitre plates were performed on a Bio-Rad (Richmond, CA, USA) Model 550 microplate reader. MPM software (Version 4.0, Bio-Rad Co., USA) was used for data processing.

Sample preparation

Rice samples were taken from fields in Gyeongnam and Kangwon provinces, South Korea. One gram of dried ground rice sample was spiked with AFB1 at different concentrations (0, 10, 20, 50, 200, and 500 ng g−1) and then extracted 5 ml with methanol–water, 70/30, for 0.5 h at room temperature with shaking at intervals. Each sample was extracted in duplicate. Extracts were centrifuged at 2000 rpm for 10 min and, after 20-fold dilution, were analyzed in triplicate by ELISA. Blank and naturally contaminated samples were prepared as described above but not spiked with aflatoxins.

ELISA procedure

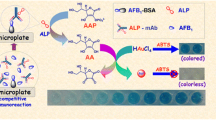

The wells of the plates were coated overnight at 4°C with 100 μL anti-AFB1 MAb 34 solution (1:1000 in PBS), then washed with PBS containing 0.05% Tween 20 (PBST) by using a Nunc-Immuno Wash 8 microplate washer (Nalge Nunc International, Rockilde, Denmark). AFB1 standards in 10% (v/v) methanol–PBS (50 μL), or samples (50 μL), and 50 μL enzyme tracer AFB1–HRP solution (1:10,000 in PBS) were added to the wells. After 30 min incubation at 37°C the plates were washed, and 100 μL per well of substrate solution was added (TMB liquid substrate system). After incubation for 10–15 min at room temperature colour development was stopped with 0.5 mol L−1 sulfuric acid (50 μL per well) and the absorbance was measured at 450 nm.

Standard curves were plotted as absorbance (A) vs. logarithm of analyte concentration.

Detection limit was determined as the concentration corresponding to 90% A/A 0.

Cross-reactivity (CR) for different mycotoxins was determined by performing competitive assays and comparing the analyte concentration resulting in half-maximum inhibition (IC50, μg L−1), and calculated as:

% CR=(IC50 for AFB1/IC50 for analyte) ×100.

Aflatoxin concentration in spiked samples was calculated after fitting the standard curve using the four-parameter logistic model.

Post-coating of plates

The plates were coated with MAb as described above, washed thrice with PBST, and post-coated with the solution of the additives in PBS for 2 h at 37°C. The wells were emptied and dried for 40 min at 37°C. The plates were sealed with a tape and stored at 4°C in closed plastic bags with silica gel. Every 2–3 weeks, ELISA was conducted to measure the activity of the coated plates and the effect of the post-coating reagents. The activity retained (%) was determined by comparing the activity of the aged MAb-coated microwell plates with that of a freshly coated plate.

Stabilization of the enzyme tracer

Several stabilizing solutions were prepared. Solution 1 contained 0.1% Kathon CG and 0.02% BSA in 0.05 mol L−1 Tris-HCl buffer (pH 7.2) supplemented with 0.05 mol L−1 calcium chloride (CaCl2) [38]; solution 2 contained 0.1% BSA and 0.2% Kathon CG in PBS; solution 3 contained 0.06 mmol L−1 TMB and 0.1% Kathon CG in PBS. AFB1–HRP conjugate was added to each solution (dilution 1:1000) and the solutions were stored in thoroughly closed brown glass vials in the dark at room temperature. A solution of HRP–AFB1 conjugate in PBS without any additives was tested as a reference. Every 2–4 weeks aliquots were tested in ELISA. The solutions of the enzyme tracer were further diluted 1:10 before the assay (final dilution 1:10,000). The performance of the enzyme tracer was determined by comparing the standard curves for the conjugate in different solutions. The absorption values of the standards were related to those of the control (freshly prepared solution of HRP–AFB1 conjugate), defined as 100% stabilization.

Results and discussion

Direct competitive ELISA for aflatoxin B1

ELISA conditions were optimized using two kinds of microwell plate (Removawell and Nunc) and different conditions and buffers for MAb immobilization. Nunc plates were chosen because they produced more stable results with better coefficients of variance (CV). Optimum concentrations of immunoreagents were established by titrating an enzyme conjugate against antibodies coated on microwell plates at different concentrations and determining the concentrations producing an optical density of 1–1.5. Two MAbs for AFB1 (MAb 34 and 78) were initially used in ELISA. The use of both antibodies gave sensitive and specific assay (Fig. 2). Cross-reactivity of the MAbs to different aflatoxins is shown in Table 1. No cross-reaction was observed with other mycotoxins such as ochratoxin, zearalenone, patulin, and T-2 toxin. MAb 78 gave more sensitive assay (IC50=0.196±0.008) compared with MAb 34 (IC50=0.62±0.07). Finally, MAb 34 was used for the analysis because it resulted in higher assay specificity and broader determinable range and gave a more stable standard curve. MAb 78 could also be used for detection of total aflatoxins, because of its broader specificity to other aflatoxins. MAb concentration of approximately 2 mg L−1 and AFB1–HRP conjugate dilution of 1:10,000 were found to be optimum. Studying different conditions for the competition step (temperature, shaking, incubation time) showed that 30 min incubation at 37°C was optimum for a sensitive and stable assay. An example of a typical standard curve for AFB1 ELISA performed by the standard procedure described above is given in Fig. 2(1) and the analytical performance of the assay is demonstrated in Table 2.

Stabilization of ELISA kit components

The long-term storage and stability of ELISA kit components is a matter of particular importance. For standardization and simplification of an assay it would be useful to separate the coating procedure from the conventional assay procedure. The activity of coated plates decreased substantially within a few days. After two days only very low absorptions of the standard curve were observed (<0.1). Therefore, several additives were tested for their stabilizing effect on MAb immobilized on the microwell plates. Some of the stabilizing effects rely on protection of immobilized Ab by addition of sugars, polymers, or BSA during the storage or drying process [37]. Such agents as trehalose, glycine, PVA, BSA, and their combinations were tested to improve the stability of MAb-coated microwell plates. Two series of experiments were performed:

-

1

MAb was diluted with the solution containing stabilizing reagents and then immobilized on the plate surface; or

-

2

MAb-coated plates were treated with a post-coating step (post-coating with stabilizing agents).

In the first of these the activity of the plates with MAb immobilized from solutions containing BSA and PVA decreased very fast. After storage for two weeks standard absorptions values were less than 0.1. Some stabilizing effect was observed for trehalose (3–6%) and glycine (1.5–3%)—after storage for two weeks absorption of the standard curve averaged 50% that of the control; although after 4 months only low absorption values were observed (<0.3). Thus, including stabilizing agents in the coating solution containing the Ab was not effective for long-term storage. If the coating solution contained additives such as PVA and BSA, no signal was observed in ELISA, in agreement with data reported previously [37]. Apparently, those additives occupy the binding sites of the polystyrene surface preventing Ab immobilization on the microwell plate. It is also possible that PVA can form films on the plate surface, which also prevents Ab immobilization. The viscosity of PVA solutions should also be taken into consideration as an important aspect of diffusion-controlled processes.

Post-coating with solutions containing glycine and trehalose (up to 6%) did not result in a tangible stabilizing effect—after two weeks absorptions of the standard curve were only 20–30% that of the control. Treating microwell plates with post-coating solutions containing PVA and BSA, and combinations of these substances with trehalose and glycine had a positive stabilizing effect. Interestingly, similar results were obtained by Heiss et al. [42] for stabilization of apoglucose oxidase in a dry matrix. The best results were obtained with 3% BSA and 6% PVA, their 1:1 combination, and combinations of these additives with 6% trehalose—after four months storage ELISA standard curves for MAb-coated microtitre plates treated with those solutions were almost identical with that for the control (data not shown). This means MAb-coated plates can be stored only if their surface is protected by addition of stabilizing reagents.

The enzyme tracer is commonly used at high dilutions in an ELISA procedure and is often not stable. Several possible stabilizing reagents were added to the AFB1–HRP conjugate solution to investigate their effect on the tracer stability. In our experiments the AFB1–HRP conjugate was diluted 1:1000 in a buffer and supplied with the additives. The prepared solutions were stored in thoroughly closed brown glass vials in the dark at room temperature. The ELISA was performed every 2–4 weeks as described above. A solution of HRP–AFB1 conjugate without additives was tested as reference. The performance of stabilized enzyme tracer in ELISA was determined and compared with that of a freshly prepared control solution of HRP–AFB1 conjugate. Solutions of the enzyme tracer were further diluted 1:10 before the assay (final dilution 1:10,000), and the standard curves were compared. The best stabilizing effect was observed with solution 1 (Fig. 3) containing 0.02% BSA, 0.1% Kathon CG, and 0.05 mol L−1 CaCl2, prepared as described in [38] for “protein-based” HRP-stabilizing media. In that work effects of different supplements on the catalytic activity, thermal stability, and secondary structure of HRP in diluted aqueous solutions were studied, and HRP-stabilizing media were developed. Stabilizing solution 1 maintained the activity of AFB1–HRP conjugate for 12 months at room temperature yielding 100% stabilization (Fig. 3). ELISA performed with the conjugate stored in that environment gave a standard curve similar to that of the control (Fig. 4).

Effect of stabilizing additives on the performance of the enzyme tracer in ELISA. Solution 1 (squares) contained 0.1% Kathon CG and 0.02% BSA in 0.05 mol L−1 Tris-HCl buffer (pH 7.2) supplemented with 0.05 mol L−1 calcium chloride [38]; solution 2 (triangles) contained 0.1% BSA and 0.2% Kathon CG in PBS; solution 3 (hexagons) contained 0.06 mmol L−1 TMB and 0.1% Kathon CG in PBS. Control solution (filled circles) was a freshly prepared solution of AFB1–HRP conjugate; reference solution (empty circles) was a solution of AFB1–HRP conjugate in PBS without additives. The absorption values of the standards were related to those of the control defined as 100% stabilization

Standard curves for AFB1 ELISA using the enzyme tracer in different stabilizing solutions after storage for 12 months at room temperature. Solution 1 (squares) contained 0.1% Kathon CG and 0.02% BSA in 0.05 mol L−1 Tris-HCl buffer (pH 7.2) supplemented with 0.05 mol L−1 calcium chloride [38]; solution 2 (triangles) contained 0.1% BSA and 0.2% Kathon CG in PBS; solution 3 (hexagons) contained 0.06 mmol L−1 TMB and 0.1% Kathon CG in PBS. Control solution (filled circles) was freshly prepared solution of AFB1–HRP conjugate; reference solution (empty circles) was a solution of AFB1–HRP conjugate in PBS without additives

BSA was shown to have a strong stabilizing effect on HRP in buffer solution without any additives [38]. The stabilizing effect of BSA relies on an increase in soluble protein concentration, which is known to be a general principle of protein stabilization, and may be achieved as a result of protein–protein interactions after aggregation of BSA and the conjugate. In our work absorption values for the standard curves obtained by use of AFB1–HRP conjugate in a solution 2 containing 0.1% BSA and 0.2% Kathon CG, were much higher than the control during all storage period (Fig. 3). By altering the conjugate environment, the additives may affect protein solvation and result in significant changes in activity and stability. HRP activity higher than that of the control was also observed in [37] after addition of some stabilizing reagents to the solution of HRP conjugate. Kathon CG, which is a 1.5% aqueous solution of 5-chloro-2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin-3-one in the ratio 1.15:0.35 [38], was used as a preservative to prevent microbial degradation of the enzyme tracer. A stabilizing effect of TMB on HRP solutions has also been reported [35]. Because TMB is a substrate of HRP, it can bind to the active site of the enzyme and may therefore be able to suppress its denaturation or oxidative damage. After storage of AFB1–HRP conjugate for six months in solution 3 containing 0.06 mmol L−1 TMB and 0.1% Kathon CG, absorptions of standard curve were ca. 70% that of the control. It was, however, observed that after this period absorbance and, therefore, stabilization decreased and after 12 months absorbance was only ca. 25% that of the control (Figs. 3 and 4). Enzyme tracer stored in PBS without any additives lost its activity within a few days and even after only five days very low absorptions of the standard curve were observed (Fig. 4).

To investigate the stability of AFB1 standards, solutions of the mycotoxin at standard concentration of 0, 1, 3, 10, 30, and 100 μg L−1 were prepared in 100% methanol and 70% (v/v) methanol–PBS. They were stored in thoroughly closed brown glass vials in the dark at 4°C. Before assay the solutions were diluted 1:10 with PBS and standard curves were compared with those for the control (freshly prepared standard solutions). AFB1 standards in 100% methanol remained stable for at least 4 months (the standard curve was almost identical with that of the control, Fig. 5), whereas using standard solutions stored in 70% methanol affected assay performance.

The analytical performance of ELISA kit components stored for several months was similar to that for the control (Fig. 2(1)). Intra-assay CVs for AFB1 standards ranged from 0.9 to 8.7%.

Application of the assay to the analysis of spiked and naturally contaminated grain samples

The ELISA method was used to detect aflatoxin in grain. Samples were extracted with methanol–water, 70:30 (v/v). Near-optimum standard curves could be obtained with buffer containing up to 10% (v/v) methanol, and little or no matrix effect was observed when samples, extracted with 70% (v/v) methanol, were 5–10% of the final assay volume.

Rice samples were spiked with AFB1 at different concentrations. These samples were extracted with five volumes of methanol–water, 70:30 (v/v); each sample was extracted in duplicate. The extracts were subsequently diluted 20-fold with PBS and analyzed in triplicate by ELISA using ELISA kit components stored for several months. Recoveries averaged between 94 and 113% (Table 3). The results were in a good agreement with the amounts spiked, demonstrating the applicability of the developed assay to practical problems. ELISA was characterized by good reproducibility; intra-assay and inter-assay CVs ranged from 3.9 to 16.4% and from 5.8 to 19.2%, respectively.

Samples from naturally contaminated grain (barley, 20 samples, rye, 20 samples, rice, 63 samples) were treated as described above and submitted in triplicate to ELISA. In four rye samples and in five barley samples AFB1 concentration was found to be below the detection limit, all other rye and barley samples were regarded to be negative. Trace amounts of AFB1 (below 5–10 ng g−1) were detected in 25 rice samples; one sample contained 12.8 ng g−1 and other samples were found to be negative, according to ELISA. Rice samples were also analyzed by HPLC. AFB1 was detected by HPLC in two samples at concentrations of 4.2 and 10.4 ng g−1, which corresponded to 5.6 and 12.8 ng g−1, respectively, determined by ELISA. Probably, ELISA tended to overestimate some results, although good recoveries were observed from spiked samples; this could be attributed to matrix interferences in some samples. Further validation and confirmation of the assay results is needed for naturally contaminated samples.

Conclusions

A direct competitive ELISA method based on a monoclonal antibody has been developed and optimized for detection of AFB1. ELISA kit components were checked for a long-term stability. Successful use of stabilizing additives for ELISA was demonstrated. High stability of immunoassay reagents, especially antibodies and enzyme tracer, is very important for prolonged shelf life and enzyme immunoassay standardization. MAb-coated microwell plates can be stored only if their surface is protected by addition of stabilizing reagents. MAb-coated plates treated with post-coating solutions containing PVA, BSA, and combinations of these substances with trehalose, retained their activity for at least four months. The activity of enzyme tracer in diluted aqueous solutions decreased drastically in a few days. This could be prevented by formulation of stabilization media for HRP solutions. Stabilizing solution used in our study, containing 0.02% BSA, 0.1% Kathon CG, and 0.05 mol L−1 CaCl2, maintained the activity of AFB1–HRP conjugate for 12 months at room temperature, i.e. resulted in 100% stabilization. The analytical performance of the assay kit after storage for several months was similar to that of the control. AFB1 spikes in rice extracts were determinable by ELISA with excellent recovery and CV. Further research is needed to validate the assay for naturally contaminated samples. Development of immunoassay techniques for mycotoxin detection appears to have practical advantages in rapidity and simplicity over existing conventional instrumental methods. On the basis of the results of this study, the assay developed seems to be suitable for aflatoxin residue screening of grain samples without complicated clean-up.

References

International Agency for Research on Cancer (1993) IARC monograph on the evaluation of carcinogenic risk to humans, vol 56. IARC, Lyon, France

Food and Agriculture Organisation of the United Nations (1995) FAO Food and Nutrition Paper. FAO, Rome, Italy

European Commission (1998), Commission Regulation 1525/98 Off J L201, 0093

Scott PM (1993) Trends Anal Chem 12(9):382–386

Stroka J, van Otterdijk R, Anklam E (2000) J Chromatogr A 904:251–256

Jaimez J, Fente CA, Vazquez BI, Franco CM, Cepeda A, Mahuzier G, Prognon P (2000) J Chromatogr A 882:1–10

Papp E, Otta KH, Záray G, Mincsovics E (2002) Microchem J 73:39–46

Otta KH, Papp E, Bagócsi B (2000) J Chromatogr A 882:11–16

Escobar A, Regueiro OS (2002) J Food Prot 65(1):219–221

Park JW, Kim EK, Kim YB (2004) Food Addit Contam 21(1):70–75

Lee NA, Wang S, Allan RD, Kennedy IR (2004) J Agric Food Chem 52:2746–2755

Roch OG, Blunden G, Coker RD, Nawaz S (1995) Food Chem 52:93–98

Holcomb M, Thompson HC Jr, Cooper WM, Hopper ML (1996) J Supercrit Fluids 9:118–121

Elizalde-González MP, Mattusch J, Wennrich R (1998) J Chromatogr A 828:439–444

Sharma M, Márquez C (2001) Animal Feed Sci Technol 93:109–114

Blesa J, Soriano JM, Moltó JC, Marín R, Maòes J (2003) J Chromatogr A 1011:49–54

Chiavaro E, Dall'Asta C, Galaverna G, Biancardi A, Gambarelli E, Dossena A, Marchelli R (2001) J Chromatogr A 937:31–40

Peòa R, Alcaraz MC, Arce L, Ríos A, Valcárcel M (2002) J Chromatogr A 967:303–314

Marrazza G, Chianella I, Mascini M (1999) Anal Chim Acta 387:297–307

Maragos CM, Thompson VS (1999) Nat Toxins 7:371–376

Van der Gaag B, Spath S, Dietrich H, Stigter E, Boonzaaijer G, van Osenbruggen T, Koopal K (2003) Food Control 14:251–254

Devi KT, Mayo MA, Reddy KLN, Delfosse P, Reddy G, Reddy SV, Reddy DVR (1999) Lett Appl Microbiol 29:284–288

Gathumbi JK, Usleber E, Märtlbauer E (2001) Lett Appl Microbiol 32:349–351

Korde A, Pandey U, Banerjee S, Sarma HD, Hajare S, Venkatesh M, Sharma AK, Pillai MRA (2003) J Agric Food Chem 51:843–846

Garden SR, Strachan NJC (2001) Anal Chim Acta 444:187–191

Daly SJ, Keating GJ, Dillon PP, Manning BM, O'Kennedy R, Lee HA, Morgam MRA (2000) J Agric Food Chem 48:5097–5104

Ho J-AA, Wauchope RD (2002) Anal Chem 74:1493–1496

Pal A, Dhar TK (2004) Anal Chem 76:98–104

Nasir MS, Jolley ME (2002) J Agric Food Chem 50:3116–3121

Bhattacharya D, Bhattacharya R, Dhar TK (1999) J Immunol Methods 230:71–86

Lipigorngoson S, Limtrakul P, Suttajit M, Yoshizawa T (2003) Food Addit Contam 20(9):838–845

Gathumbi JK, Usleber E, Ngatia TA, Kangethe EK, Märtlbauer E (2003) Poult Sci 82(4):585–590

Ó'Fágáin C (1995) Biochim Biophys Acta 1252:1–14

Ó'Fágáin C (2003) Enzyme Microb Technol 33:137–149

Schütz AJ, Winklmair M, Weller MG, Niessner R (1997) SPIE 3105:332–340

Kühlmeyer C, Klein J (2002) Enzyme Microb Technol 6196:1–8

Dankwardt A, Müller J, Hock B (1998) Anal Chim Acta 362:35–45

Eremin AN, Budnikova LP, Sviridov OV, Metelitsa DI (2002) Appl Biochem Microbiol 38(2):151–158

Chu FS, Hsia MTS, Sun PS (1977) J AOAC Int 60:791–794

Langone JJ, Van Vunakis H (1975) Res Commun Chem Pathol Pharmacol 10:163–171

Kolosova AYu, Park JH, Eremin SA, Kang SJ, Chung DH (2003) J Agric Food Chem 51:1107–1114

Heiss C, Weller MG, Niessner R (1999) Anal Chim Acta 396:309–316

Acknowledgements

This research was partially supported by the National Toxicology Program of the National Institute of Toxicological Research, Brain Korea 21 Program from the Ministry of Education and the Environmental Biotechnology National Core Research Centre (grant R15-2003-012-01001-0) from KOSEF/MOST, Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kolosova, A.Y., Shim, WB., Yang, ZY. et al. Direct competitive ELISA based on a monoclonal antibody for detection of aflatoxin B1. Stabilization of ELISA kit components and application to grain samples. Anal Bioanal Chem 384, 286–294 (2006). https://doi.org/10.1007/s00216-005-0103-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-005-0103-9