Abstract

The respirometric BOD OxiTop method was used to monitor the biodegradation of different chain oils (mineral, rapeseed and tall oils) over 28 days in groundwater, as well as in standard conditions described by OECD 301 F. The aim of the study was to gather more information about the biodegradability of forestry oils in groundwater, as well as about the suitability of the automatic OxiTop method for biodegradation measurements. The BOD OxiTop method proved to be a precise and reliable technique for determining the biodegradations of different oils. Some comparative studies were also made using a traditional IR method in order to clarify the total oil concentrations. The results show that if biodegradation only is to be monitored, the OxiTop method is preferable. This is due to the influence of other reactions aside from biodegradation on total hydrocarbon concentrations when using the IR method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Environmentally sound operations are demanded in modern forestry. Because groundwater is often used as a drinking water source, the protection of forestry soil and especially groundwater areas against contamination from oil hydrocarbons is an important issue. The potentially harmful effects of different oils on nature and on forestry workers have been discussed recently [1]. Assuming that a total of 50 million cubic meters of wood a year are logged in Finland, it has been calculated that the total annual amount of chain oil discharged into Finnish forests is as much as two million liters [2]. The demand for the use of biodegradable oils in wood procurement is therefore justified from an environmental viewpoint. However, some harmful effects of biodegradable oils on forest machines have been reported [1]. Therefore, there is obviously a need to study the behavior of forestry oils in nature. Our research group has previously studied the environmental effects of forestry hydraulic and chain oils using biodegradation studies and tree planting experiments [1]. Biodegradation of oils has been traditionally evaluated using different IR methods [3, 4]. However, IR measurements are laborious and often contain sampling problems. They also sometimes require a poisonous extraction solvent, such as CCl4. In addition, evaporation of volatile compounds and foaming can cause errors in determination.

The aim of the present study is to find good methods of simulating the biodegradations of different types of forestry oils—hydraulic, motor and chain oils—in a groundwater environment and in forest soil. The aim of this work was to evaluate the applicability of the respirometric BOD OxiTop method for monitoring oil biodegradation in groundwater, using different chain oils as model compounds. In addition, we also wanted to gather more information on the biodegradations of forestry oils. A comparative study was carried out using the traditional IR method. Correspondingly and simultaneously, we have already used different forestry hydraulic oils as model compounds in an earlier study [5]. As far as we know, the BOD OxiTop method is a highly reliable method for determining the BODs of chemicals. The BOD OxiTop method can be used to study aerobic biodegradation. Other phenomena affecting the total concentrations of the studied chemicals do not affect this measurement (chemical degradation, evaporation, foaming), or they can be prevented (anaerobic biodegradation, nitrification). However, published information on the use of the BOD OxiTop method in environmental studies is still scarce [6–8].

It is worth noting that various studies regarding the biodegradations of oils and petroleum products have been carried out with methods other than BOD OxiTop over the past few years. To mention a few, research has been carried out by studying contaminated site bioremediation [9–13], method development [14, 15], comparison of aerobic and anaerobic biodegradation [9], and comparison of different physical properties of oils and oil biodegradation [16–18].

Experimental

Studied substances

The studied samples were common forestry chain oils. Some of them were bio oils (rapeseed oils and tall oils) and some were traditional mineral or recycled mineral oils. The exact chemical compositions of the studied oils were not determined. We examined the effect of oil type (bio oil/mineral oil) on its biodegradation in groundwater. A smaller comparative study was carried out between the use of the IR method (SFS 3010) [4] and the BOD OxiTop method. Extra information on the behaviors of these oils was gathered by carrying out tests in conditions described by the OECD 301 F standard [19].

Groundwater experiments

A certain amount of oxygen is consumed during aerobic biodegradation reactions of organic compounds. Carbon dioxide is produced at the same time and readily absorbed by solid sodium hydroxide pellets. The respirometric WTW BOD OxiTop method is based on very accurate pressure measurement, and the consumption of oxygen can be observed as diminished pressure. The exact procedure for the BOD OxiTop method is described in more detail in our previous article [5]. The BOD value is calculated by the OxiTop instrument, by applying the following equation:

M(O2) is the molecular weight of oxygen (32,000 mg/mol), R is the gas constant (83.144 l hPa mol−1 K−1), Tm is the measuring temperature (K), T0 is 273.15 K, Vtot is the bottle volume (ml), V l is the liquid phase volume (ml), α is the Bunsen absorption coefficient (0.03103) and Δp(O2) is the change in partial oxygen pressure (hPa).

The OECD 301F standard [19] is based on the idea of providing the biodegradation process with favorable conditions due to the relatively high concentration of the chemical compared to that present in the environment. Therefore, it is believed that if a chemical degrades significantly in a laboratory-scale experiment, it will most likely degrade in the environment too. We simulated the conditions of a natural groundwater resource, and so no nutrients, inoculum or nitrification inhibitors were added to the groundwater. The OECD standardization organization has labeled these tests as “simulation tests” [19]. The medium used in our studies was groundwater supplied by the Paavola water treatment station [5]. A blank test was always carried out when a new batch of groundwater was used. The measurements were made at a constant temperature of 20.0±0.2 °C.

Oil concentrations of 80–140 mg/l were used in the groundwater experiments. The carbon contents of the samples were determined in order to calculate the degree of biodegradation. Two different methods were used: use of a Perkin Elmer 2400 series II CHNS/O analyzer based on combustion and determination of carbon as carbon dioxide, and a COD method based on oxidation with potassium dichromate.

Conditions described by OECD 301 F

Measurements were carried out in a nutrient solution which contained KH2PO4, K2HPO4, NaHPO4· 2H2O, NH4Cl, CaCl2, MgSO4· 7H2O and FeCl3· 6H2O in concentrations given in OECD 301 F [19]. Waste water was added as a microbe source, and nitrification was prevented with n-allylthiourea. Oil concentrations of 90–140 mg/l were used.

Infrared spectroscopy

Samples were prepared by mixing oils and groundwater to obtain 50 mg/l solutions. A small amount of Triton X-100 surfactant was added to the samples. Three replicates were made from the oils. The sample bottles were held in an incubation cabinet at 20.0 °C during the test period. Measurement of total oil hydrocarbon concentration was carried out according to the Finnish standard SFS 3010 [4]. The samples (50 ml) were extracted using carbon tetrachloride (25 ml), and smaller subsamples were taken straight from the CCl4 layer for IR measurements, which were carried out with a Bruker IFS 66 infrared spectrometer. Absorbances at wavenumbers 2,960 and 2,925 cm−1 were detected and integrated. Calibration solutions were made from the same oils as the samples.

Results and discussion

Carbon contents of the oils studied

The carbon contents of the oils, as determined by different methods, are presented in Table 1. The COD method gave somewhat different carbon contents to the CHNS/O analyzer. The biggest differences can be seen with mineral oil 1, tall oil 1 and mineral oil 3; 7.92, 3.96 and 2.97%, respectively. In our opinion, the CHNS/O analyzer is a more suitable method for determining carbon content.

Effect of oil type on biodegradation in groundwater

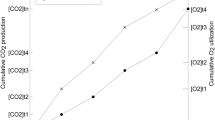

The biodegradations of different chain oils (mineral, tall and rapeseed oils) were determined using the OxiTop method in a groundwater environment. The biodegradations of mineral oils and bio oils (tall and rapeseed oils) are presented in Figs. 1 and 2; respectively. The degree of biodegradation is defined as the ratio of the biological oxygen demand (BOD) to the theoretical oxygen demand (ThOD).

The degrees of biodegradation of the mineral chain oils studied were mainly lower than those of the bio oils studied in ground water. However, tall oil 1 biodegraded only slightly better than mineral oil 2; the values of BOD/ThOD after 28 days were 9.5 and 8.9%, respectively. Mineral oil 2 was surprisingly biodegradable, although it is not sold as an easily biodegradable oil! Mineral oils 1 and 3 hardly biodegraded over 28 days. Mineral oil 1 is almost non-biodegradable over the short time period of 28 days; its degree of biodegradation was as low as 0.7%. There were no big differences between the biodegradability of tall oil 2 and rapeseed oils 2 and 3, for which the values of BOD/ThOD were 14.2, 12.9 and 11.9%, respectively. The biodegradation was still effective after 28 days. In the same time period, rapeseed oil 1 reached a BOD/ThOD value of 26.2% (Fig. 2).

The differences between the biodegradations of the different oils can be explained by the different chemical compositions of the oils, and therefore their different biodegrading components. The slow biodegradation of mineral oils shows that these oils contain components that are difficult to biodegrade and even possibly hazardous to the microbial population or a part of the population (especially mineral oil 1), at least over a short time period. Therefore, it is suggested that mineral oils cause a substantially higher risk of endangering the environment by contamination than bio oils do. However, mineral oil 2 is a moderately biodegrading oil. It is a recycled oil which is produced from collected waste mineral oils. This might have some effect on its biodegradability; some of its compounds degrade easily. The reason for the better biodegradation of rapeseed oil 1 may be connected to its method of production (for instance, no antioxidants are used). Although fast biodegradation is preferred from a natural point of view, it can be harmful during use.

It is important to note that all the oils studied exhibit some degree of biodegradation in groundwater over the 28 day period (except mineral oil 4). This is desirable, because all of the power chain oils used are deposited directly into the environment during use. Because they even biodegrade in a groundwater environment, it is obvious that they should biodegrade more effectively in forest soil, where there are more minerals and microbes. This means that only small amounts of the chain oils will reach the groundwater layer, and that diminishes the risk of contaminating groundwater. However, it has been noted that fast biodegradation can produce some harmful degradation products in high concentrations, which can cause a contamination risk [20], but this requires more structural research on the degradation products to provide proof in each case.

Precision of the respirometric BOD OxiTop method

We determined the precision of the BOD OxiTop method earlier with hydraulic oils, and the relative standard deviation of the degrees of biodegradation of three replicates of the same hydraulic oil was only 1.06% [5]. The precision of the WTW BOD OxiTop method was tested and it also proved to be good enough when determining the biodegradabilities of chain oils (Table 2). The RSD values of two or three replicates were generally small. The only large difference between the results was observed with rapeseed oil 3. The reasons for the high precision of the BOD OxiTop method are accurate pressure measurements, relatively homogenous groundwater, accurate temperature control, and no problems with sample-taking.

Determining the biodegradations of chain oils in conditions described by OECD 301 F

Standardized biodegradation tests, like OECD 301 F [19], demand the use of extra minerals and microbes in order to speed up biodegradation. We wanted to study the biodegradation of chain oils in more optimal conditions (Fig. 3). It is apparent from Figs. 1, 2 and 3 that faster biodegradations occur for all of the chain oils in conditions where extra microbes and minerals are present. Rapeseed oils biodegrade most effectively. The rapeseed oils 2 and 4 had BOD/ThOD values of 60 and 63% after 28 days, and rapeseed oils 1 and 3 biodegraded even quicker, with a BOD/ThOD value of 70% after 28 days. Rapeseed oil 1 had not even reached the stable phase after 28 days. Tall oils also biodegrade effectively in these conditions. Their degrees of biodegradation after 28 days varied between 47 and 54%. Tall oils 1 and 2 are products from the same company, and they probably have quite similar compositions, producing similar biodegradations in these conditions. However, the degrees of biodegradation of these oils are not as close to each other in groundwater conditions; significant differences can be seen between the behaviors of these oils. Mineral oil 2 is also moderately biodegradable under these conditions, and this strengthens the observations made in the groundwater tests. Mineral oil 4 also biodegrades in these conditions, whereas it does not biodegrade at all in groundwater.

Abiotic degradation can also be a significant method of degradation, especially with rapidly degrading substances. This property was previously tested with hydraulic oils [5] and observed to be only minor. The most rapidly biodegradable chain oil (rapeseed oil 1) was selected for the abiotic degradation test. A test sample of rapeseed oil 1 in distilled water was boiled for 15 min in overpressure to kill microbes. This water–oil sample was cooled to room temperature overnight and then a BOD OxiTop measurement was carried out at 20 °C for 28 days. The degree of abiotic degradation of rapeseed oil 1 was 7.6% after 28 days. So, abiotic degradation can have some influence on degradation, but it is not major and it is probable that abiotic degradation is significantly minor for oils that degrade more slowly than rapeseed oil 1.

Comparison of the BOD OxiTop method with the traditional IR method

One traditional way to measure biodegradation of substances is to use IR spectroscopy. However, the substances studied should not contain volatile or foaming compounds, because they can cause loss of the studied substance without biodegradation. A standardized method for determining the biodegradation of oils in optimal conditions using IR is CEC L-33-T-82 [3]. However, in our IR measurements we used the Finnish standard SFS 3010 [4], which has been developed for determining the amount of oil and grease in water and soil. Extra microbes were not added, which is why the CEC standard was not used in our measurements. Three chain oils (mineral, rapeseed and tall oil) were used as test substances to compare the traditional IR method (Fig. 4) with the OxiTop method (Fig. 5).

It is apparent from the results that the change in the hydrocarbon content was much bigger than the degree of biodegradation over the same time. The reason for this observation is quite obvious; these two methods do not measure exactly the same parameter. The OxiTop method gives the degree of biodegradation: the amount of oxygen used in the degradation of organic carbon compared with the theoretical oxygen consumption, in percent. The biodegradation observed is only due to aerobic biodegradation. The IR method gives the total concentration of hydrocarbons in the samples. It gives no information about why the hydrocarbon content has diminished. The IR method does not separate aerobic and anaerobic biodegradation, evaporation of volatile compounds, nitrification, and so on. This is very obvious with the mineral oil sample. Mineral oil 4 did not biodegrade at all in groundwater over 40 days when the measurement was performed with the OxiTop method. However, the hydrocarbon content of the mineral oil diminished by about 25% at the same time. The BOD values of the groundwater and mineral oil 4 were almost the same; the BOD value of mineral oil 4 was even slightly smaller. Therefore, no degree of biodegradation could be calculated for mineral oil 4, whereas tall oil 3 and rapeseed oil 4 are moderately biodegradable, having BOD/ThOD values of over 12% after 28 days in groundwater. Of course, if no volatile compounds are present and reactions other than aerobic biodegradation are not probable, then the IR method is however suitable for determining the biodegradation of samples.

Conclusions

The respirometric BOD OxiTop method proved to be a reliable method for monitoring the biodegradations of power chain oils under different conditions. Our results support the known fact that plant-based bio oils are generally rapidly biodegradable. What should be noted is that almost all oils exhibit some kind of biodegradation in the groundwater environment, which is important, because all of the chain oils used pass into the environment during their use. It is a totally different case with hydraulic oils, which are only deposited into the environment by accident.

The results show that there is a need to study the biodegradation of forestry chain and hydraulic oils in typical forest soils, and to study drifting processes of forestry oils through the soil layer (using leaching experiments for example). Also, degradation products and microbial activity should be studied in more detail. These studies enhance our understanding of the behaviors of forestry oils spilled into the environment.

References

Lauhanen R, Kolppanen R, Takalo S, Kuokkanen T, Kola H, Välimäki I (2000) Effects of biodegradable oils on forest environment and forest machines. In: Proc Int Sci Conf—Forest Wood Tech vs Environ. Brno, Czech Republic, 20–22 Nov 2000, pp 203–206 (and references therein)

Takalo S, Lauhanen R (1994) Tall oil as a lubricant in forestry. In: Proc Soil, Tree, Machine Interactions—Interactive Workshop and Seminar. Feldafing, Federal Republic of Germany, 4–8 July 1994. EU, ECE, IUFRO Division P3.08, FAO, ILO. Paper 4p

CEC (1982) Test method CEC L-33-T-82: Biodegradability of two-stroke cycle outboard engine oils in water. Co-ordinating European Council, Leicester, UK

SFS (1980) SFS 3010: Determination of oil and grease in water. IR-method. Finnish Standards Association (SFS), Helsinki

Kuokkanen T, Vähäoja P, Välimäki I, Lauhanen R (2004) Int J Environ Anal Chem 84(9):677–689

Conzelmann F (1996) Melliand Textil 77(10):700–702

Mittenzwey R, Seidenstuecker T, Fritz H-G, Suessmuth R (1998) Starch/Staerke 50(10):438–443

Reuschenbach P, Pagga U, Strotmann U (2003) Water Res 37(7):1571–1582

Salminen J, Tuomi P, Suortti A-M, Jørgensen K (2004) Biodegradation 15(1):29–39

Gallego J, Loredo J, Vàsquez F, Sánchez J (2001) Biodegradation 12(5):325–335

Murygina V, Arinbarasov M, Kalyuzhnyi S (2000) Biodegradation 11(6):385–389

Cunningham J, Hopkins G, Lebron C, Reinhard M (2000) Biodegradation 11(2–3):159–170

Kirchmann H, Ewnetu W (1998) Biodegradation 9(2):151–156

Davis C, Cort T, Dai D, Illangasekare T, Munakata-Marr J (2003) Biodegradation 14(6):373–384

Hoffmann J, Řezníčèková I, Vaňòková S, Kupec J (1997) Int Biodeter Biodegr 39(4):327–332

Haus F, German J, Junter G-A (2001) Chemosphere 45:983–990

Haus F, Junter G-A, German J (2000) Biodegradation 11(6):365–369

Meredith W, Kelland S-J, Jones DM (2000) Org Geochem 31:1059–1073

OECD (1992) OECD guidelines for the testing of chemicals. Section 3: degradation and accumulation. Test 301: Ready biodegradability. Updated guideline, adopted 17 July 1992. OECD, Paris, France

Alexander M (1977) Transformation of hydrocarbons. In: Introduction to soil microbiology, 2nd edn. Wiley, New York, pp 203–222

Acknowledgements

The authors would like to thank to D.Sc. (Agr. and For.) Risto Lauhanen for many helpful discussions regarding forestry oils. Special thanks to M.Sc.(Chem.) Annukka Juntunen for the carbon content determinations. Pekka Vähäoja would also like to thank the Tauno Tönning Foundation and the Academy of Finland for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vähäoja, P., Kuokkanen, T., Välimäki, I. et al. Biodegradabilities of some chain oils in groundwater as determined by the respirometric BOD OxiTop method. Anal Bioanal Chem 381, 445–450 (2005). https://doi.org/10.1007/s00216-004-2887-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-004-2887-4