Abstract

After deposition in the respiratory tract, nanoparticles exhibit acute, neutrophil-driven inflammatory and oxidative reactions, fibrotic responses and in chronic studies under overload conditions carcinogenic effects, more severely than the microscaled materials of the same chemistry. Besides these effects also known to be induced by microsized particles, nanoparticles principally can translocate from the site of exposure to circulation and become systemically available. This may either increase the toxic outcome (e.g. cardio-vascular effects and potential responses in remote organs) or facilitate an elimination of nanomaterials. For example, in combination with partial dissolution, a strong lung response after a short-term inhalative exposure may be followed by a rapid recovery effect. Mechanistically, in vitro and in vivo tests demonstrated that nanoparticles induce inflammation and oxidative stress after interaction with macrophages and lung epithelial cells; consequently, a cytotoxic and genotoxic potential may exist. The deposition, retention and clearance behaviour of inhaled nanomaterials and the toxic effects observed are decisively dependent on the particle agglomeration status of the aerosol. Two principally different experimental approaches are used for inhalative exposure to nanoparticles: either (1) a basic research-oriented approach using very small aerosol mass concentrations or particle formulations that result in at least partially nanoscaled aerosols; in this way, the potential hazard and the translocation potential for individual nanoparticles can be followed effectively; or (2) exposure scenarios mimicking the occupational situation (risk-oriented) with mostly agglomerated nanoparticles; consequently, the probable risk deriving from incidental/accidental exposure can be assessed more adequately.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

After a decade of intense development, a huge number of new engineered nanomaterials are to date marketed and already in use. Thus, the human respiratory tract as the main portal of entry is potentially exposed to a manifold of nanomaterials, incidentally in the occupational field during manufacture and processing, or intentionally if those are administered for therapeutic purposes (Oberdörster et al. 2005). The majority of nanomaterials for technical applications are low soluble, non-biodegradable substances, whereas those for drug delivery preferably are designed as biodegradable and biocompatible materials. As the toxicity of nanomaterials is mostly mediated by the surface, its physico-chemical characterisation is crucial for a predictive hazard assessment. A minimum set of data as recommended by the OECD Sponsorship Programme (OECD 2010), for example ζ potential, size distribution, agglomeration status, water solubility, specific surface area, etc., are obligatorily needed. Only this information allows a profound evaluation of in vitro and in vivo toxicity tests as well as the intercomparability of different tests with the same test materials.

Nanoparticles are not necessarily new chemicals as compared to their microscaled correspondents. However, a unique molecular identity of a new nanoparticle may define a new substance, for example carbon nanotubes (CNT) with fibrous and fullerenes with granular morphology as an example for elemental carbon that has two microscaled varieties in addition, that is diamond and graphite. This under regulatory aspects important consideration is raising the question whether principal differences exist between nano- and microscaled particles regarding the interaction with biological surfaces and cells. Both types of the same chemical composition have in common that after uptake in lungs typical particles effects are observed, for example the release of pro-inflammatory proteins, the production of reactive oxygen species and in the long run the damage of DNA, in particular under lung overload conditions. Differences are observed in the toxicokinetic behaviour: in contrary to microscaled particles, the clearance of nanoparticles from lungs is not predominantly mediated by macrophages, and the probability to translocate from lungs is increased (Borm and Kreyling 2004; Oberdörster et al. 2007).

Various approaches for inhalation toxicity testing

Deposition characteristics of nanoparticles

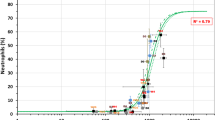

In Fig. 1, the deposition fraction of particles in human lungs is given for various mass median aerodynamic diameter (MMAD) ranging from 1 to 10 μm. The values for the deep lung (alveolar compartment) show a maximum of 50 % at approx. 20 nm, whereas the microscaled particles show values of approx. 10 % only. This substantial difference demonstrates that the inhalative deposition of nanoparticles on the lung-lining fluid following uptake in the respiratory tract and the toxicological impact depends decisively on the agglomeration status of the airborne particulate.

Deposition of particles in the human respiratory tract (impaction, sedimentation, diffusion; ICRP 1994)

The actual MMAD values in an inhalation experiment with nanoparticles are dependent on the aerosol generation techniques used and lead to very different deposition rates and clearance mechanisms.

Experimental set-ups for aerosolisation

Principally different aerosolisation techniques can be used to investigate the inhalative toxicity of nanoscaled particles. For scientific approaches, focusing on the toxicokinetic migration potential of nanoparticles, extremely small aerosol concentrations may be established with spark generators to trace single nanoparticles (e.g. aerosol concentration of approx. 1 mg/m3).

In contrary, exposure scenarios mimicking workplace situations should use realistic aerosols consisting usually of particle agglomerates. As the main exposure route during nanomaterial production and handling is the inhalation path and as a lot of nanomaterials are used as the bulk powders, the dry dispersion technique, for example using pressurised air, can be well justified for simulating the occupational situation.

A considerable number of nanomaterials are handled and marketed as stable particle suspension in aqueous formulations and thus should be aerosolised directly from the aqueous suspension. This means that a droplet aerosol is generated that is evaporated rapidly. In the result, solid airborne particles are inhaled.

This approach can also be adapted for originally powdrous bulk materials with nanoscaled primary particle diameters. Aqueous suspensions with at least small moieties of effectively existing nanoscaled particles can be nebulised to generate relatively high aerosol concentrations (e.g. aerosol concentrations of approx. 10 mg/m3). Mechanical energy applied in the combination of homogenisers (shear forces), vortexes and stirrer as well as additives facilitating the de-agglomeration of bulk material (buffers, proteins, detergents) can help to achieve those well-dispersed nanoparticle suspensions.

Thus, various aerosolisation techniques are justified to be used depending on the purpose of the corresponding experiment.

Materials and methods

Animals

Adult Wistar rats [strain: Crl:WI(WU); Charles River Deutschland, Germany] aged approx. 8–10 weeks were used for the inhalation experiments. Before exposure start, rats were trained to become accustomed to the tubes of a nose-only inhalation unit (Fig. 4).

Aerosol generation using the spark generator

For direct exposure to constantan (alloy of copper and nickel) aerosols, the spark generator was operated with an argon flow rate of 3.5 l/min. For case i (without ageing), this stream was immediately diluted with approximately 31 l/min compressed air and was directly fed into the nose-only inhalation chamber.

The aerosol atmosphere in the exposure chamber was controlled continuously using an electrical mobility spectrometer (Model 3071/3025, TSI, Germany) for the particle number-size distribution at 15-min intervals. During exposure to the nanoscaled constantan, the average number concentration was for example 9.6 × 106 [1/cm³] (Fig. 2). The average size distribution was characterised by a mean mobility diameter of 43 nm and a geometric standard deviation (GSD) of 1.9. Assuming a respiratory minute volume of 0.2 l/min, a surface area of 0.4 m² and a deposition efficiency of 50 % the particle loading of the lung surface after 6 h of exposure is 108 [1/cm²] = 1 [1/μm²] (Koch 2010). Exposure duration was once a 6-h period.

Using an ageing step of the aerosol in the experimental set-up (case ii), the mean mobility diameter could be increased to for example 130 nm.

Aerosol generation by nebulisation of an aqueous TiO2 P25 particle suspension in a 21-day short-term repeated dose toxicity test

A combination of mechanical and ultrasonic energy was applied to prepare a suspension with nanoscaled moiety within the total particle size distribution (Table 1; Fig. 3):

Characterisation of stock suspension TiO2 P25 on day of administration—Number-based particle size distribution of a TiO2 P25 dispersion (stock suspension). The aerosol re-suspended in an impinger filled with water showed the same particle size distribution suggesting a rapid disintegration of TiO2 P25/phosphate particles. An analogical behaviour can analogically be well expected for the interaction of the mixed-type particles with lung-lining fluid upon deposition in lungs

-

Suspension of TiO2 P25 (0.1 wt%) in a 0.15 wt% Na2HPO4 buffer

-

30-min treatment with Ultra-Turrax (high shear forces)

-

30-min ultrasonic treatment (high de-agglomeration forces).

As an example, a 21-day inhalation test (3 consecutive weeks) with subsequent 90-day recovery period was conducted (Creutzenberg et al. 2009) to investigate the lung toxicity and the toxicokinetics of TiO2 P25® (i.e. a hydrophilic, uncoated TiO2 marketed by Evonik Co.). The aerosolisation procedure (Fig. 4) used the following steps:

-

Preparation of test item: 0.1 wt% TiO2 suspension in 0.15 wt% phosphate-buffered solution (ultrasonic treatment, vortexing)

-

Nebulisation of the particle suspension with pressurised air

-

Following rapid evaporation deposition of a dry aerosol (MMAD: approx. 0.8 μm; GSD: 1.8; concentration 10 mg/m3; 40 % TiO2/60 % phosphate mixed-type particles) in the rat lung.

Results

Although this paper is focusing on the juxtaposing of various exposure approaches, in short also some results of the inhalation tests are given.

Constantan

The single 6-h exposure of rats to a nanoscaled constantan aerosol resulted in a very small particle load in lungs (by calculation in the range of approx. 100 μg/lung). Analytical detection of particles using transmission electron microscopy (TEM) was difficult because of the small particle amount deposited. Detection of some particles qualitatively showed a tendency to agglomerate formation in lungs.

TiO2 P25®

During the 21-day inhalation, masses of approx. 1.4 mg TiO2 P25®/lung were retained. Analysis of lungs by histopathology and bronchoalveolar lavage (BAL) resulted in very slight inflammatory findings 3 days after end of exposure that were not statistically significant as compared to controls. In contrary, a prior intratracheal instillation test administering the same total dose in two aliquots had shown a strong inflammatory effect on day 3 after treatment.

Discussion

Sometimes disputes can be observed in scientific discussions on the right way to investigate nanoscaled bulk materials in inhalation testing. The various methods of particle aerosol generation presented above raise the question whether a clear recommendation can be given.

What is the “best” experimental approach for nanoparticle toxicity testing?

Should the aerosol to be tested consist of individual nanoparticles?

What is the consequence of nanoparticle agglomerate formation in the exposure atmosphere on the fate after deposition, that is the translocation behaviour?

These questions cannot be answered absolutely. In contrary, this paper is a pleading that experimentators in nanoparticle research should be open-minded for different approaches and should reflect the experimental set-up under the purpose of the given experiment.

Basic research

Aerosols really existing of airborne nanoparticles can be produced in very small mass but high number concentrations using a spark generator (erosion of metal electrodes). For certain time periods (minutes), these nanoaerosols are stable; however, an ageing process is starting resulting in an increase of the agglomerate size. The experimental set-up of fresh particle generation together with ageing allows to expose the respiratory tract of animals to nanoscaled aerosols of a well-defined size. The approach is often used in the basic research field to deposit analytical, that is not toxicologically relevant masses of nanoparticles in lungs (Geiser et al. 2005; Oberdörster et al. 2004). In this set-up, only very small mass aerosol concentrations are feasible (≤10 mg/m3); however, the probability is increased to analyse successfully the toxicokinetic behaviour of nanoparticles including the translocation to remote organs and other compartments besides the primary target organ respiratory tract.

Occupational safety

For generation of data of workplace scenarios, mostly the inhalative exposure of airborne solid particles and a standardisation along existing guidelines should be preferred. This facilitates the acceptance of study results by regulatory authorities, and on the other hand, this approach includes the existence of nanoparticle agglomerates in the exposure atmospheres. The deposition of agglomerates is simply determined by the actual mass median aerodynamic diameters (MMAD) and the agglomerate density in the given experiment. The potential disintegration of those agglomerates is often discussed; however, it seems that the tendency for disintegration is weak (Maier et al. 2006).

Another approach is the nebulisation of stable aqueous suspensions of nanoparticles where a small percentage is in fact existing at the nanoscaled size range. As an example, this can be achieved using phosphate buffers for formulation. The dispersion status of nanoparticles in aqueous media principally depends on the surface properties of the given nanoparticle (e.g. hydrophilic particles are better dispersable than hydrophobic ones). Studies (Meissner et al. 2009; Schulze et al. 2008; Sager et al. 2007; Limbach et al. 2005) revealed that dispersions of nanoparticles in protein-free culture mediums are often unstable and larger agglomerates are rapidly formed, but that an agglomeration is in most cases inhibited or at least reduced in media containing proteins. As the ζ potential of the nanoparticles in media with added proteins is rather small, the observed stabilisation of the dispersions cannot be explained by electrostatic effects. Instead, the stabilisation indicates a coating of the particles by proteins, leading to steric effects that stabilise the dispersion (Schulze et al. 2008). The atmospheres consist of microscaled particles of the mixed type (nanoparticle plus phosphate) that can disintegrate after deposition on the aqueous lung-lining fluid.

Toxicokinetics of nanomaterials

The potential of individual nanoparticles to translocate through the lungs following deposition is a realistic scenario suggesting effects on remote organs or systemical availability (Borm and Kreyling 2004). The probability is often controversionally discussed, in particular the question whether integer particles or dissolved material are the active agent responsible for the observed biological effect.

Approaches focusing on basic research and the theoretical migration potential of nanoparticles may use the spark generation of individual nanoparticle aerosols or radioactively tagged aerosols as highly sensitive aerosol models.

However, focusing on occupational safety and assessing the risk in workplace scenarios, the dry aerosolisation of nanoscaled bulk materials is the appropriate mode to investigate the translocation behaviour under consistent conditions.

References

Borm PJA, Kreyling W (2004) Toxicological hazards of inhaled nanoparticles—potential implications for drug delivery. J Nanosci Nanotech 4:1–11

Creutzenberg O, Pohlmann G, Hansen T, Rittinghausen S, Ziemann C (2009) Nano- and microscaled titanium dioxide: comparative study on the inflammatory and genotoxic effects after a 3-week inhalation in rats. In: Poster presentation at the 46th congress of the European Societies of Toxicology (EUROTOX), Dresden, Germany, September 13–16, 2009

Geiser M, Rothen-Rutishauser B, Kapp N, Schürch S, Kreyling W, Schulz H, Semmler S, Im Hof V, Heyder J, Gehr P (2005) Ultrafine particles cross cellular membranes by nonphagocytic mechanisms in lungs and in cultured cells. Environ Health Persp 113:1555–1560

ICRP (1994) Human respiratory tract model for radiological protection. ICRP Publication 66. Ann ICRP 24(1–3)

Koch W (2010) BAuA project F2133: dispersion and retention of dusts consisting of ultrafine primary particles in lungs

Limbach LK, Li Y, Grass RN, Brunner TJ, Hintermann MA, Muller M, Gunther D, Stark WJ (2005) Oxide nanoparticle uptake in human lung fibroblasts: effects of particle size, agglomeration and diffusion at low concentrations. Environ Sci Technol 39:9370–9376

Maier M, Hannebauer B, Holldorff H, Albers P (2006) Does lung surfactant promote disaggregation of nanostructured titanium dioxide? J Occup Environ Med 48:1314–1320

Meissner T, Potthoff A, Richter V (2009) Physico-chemical characterization in the light of toxicological effects. Inhalation Tox 21:35–39

Oberdörster G, Sharp Z, Atudorei V, Elder A, Gelein R, Kreyling W, Cox C (2004) Translocation of inhaled ultrafine particles to the brain. Inhalation Tox 16:437–445

Oberdörster G, Oberdörster E, Oberdörster J (2005) Nanotoxicology: an emerging discipline evolving from studies of ultrafine particles. Environ Health Persp 113:823–839

Oberdörster G, Stone V, Donaldson K (2007) Toxicology of nanoparticles: a historical perspective. Nanotoxicology 1:2–25

OECD (2010) Environment, health and safety publications, series on the safety of manufactured nanomaterials No. 27, list of manufactured nanomaterials and list of endpoints for phase one of the sponsorship programme for the testing of manufactured nanomaterials: revision. Environment Directorate, ENV/JM/MONO(2010)46

Sager TM, Porter DW, Robinson VA, Lindsley WG, Schwegler-Berry DE, Castranova V (2007) Improved method to disperse nanoparticles for in vitro and in vivo investigation of toxicity. Nanotoxicology 1:118–129

Schulze C, Kroll A, Lehr C-M, Schäfer UF, Becker K, Schnekenburger J, Schulze Isfort C, Landsiedel R, Wohlleben W (2008) Not ready to use—overcoming pitfalls when dispersing nanoparticles in physiological media. Nanotoxicology 2:51–61

Conflict of interest

The author declares that he has no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published as a part of the Special Issue “Nanotoxicology II” on the ECETOC Satellite workshop, Dresden 2010 (Innovation through Nanotechnology and Nanomaterials + Current Aspects of Safety Assessment and Regulation).

Rights and permissions

About this article

Cite this article

Creutzenberg, O. Biological interactions and toxicity of nanomaterials in the respiratory tract and various approaches of aerosol generation for toxicity testing. Arch Toxicol 86, 1117–1122 (2012). https://doi.org/10.1007/s00204-012-0833-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00204-012-0833-3