Abstract

Bacterial cyclopropane fatty acid synthases (CFA synthases) catalyze the transfer of a methyl group from S-adenosyl-l-methionine (AdoMet) to the double bond of a lipid chain, thereby forming a cyclopropane ring. CFAs contribute to resistance to acidity, dryness, and osmotic imbalance in many bacteria. This work describes the first biochemical characterization of a lactic acid bacterium CFA synthase. We have overexpressed Oenococcus oeni CFA synthase in E. coli in order to purify the enzyme. The optimum cyclopropanation activity was obtained at pH 5.6 and 35.8 °C. The high K m (AdoMet) value obtained (2.26 mM) demonstrates the low affinity of O. oeni enzyme toward the L. lactis subsp. cremoris unsaturated phospholipids. These results explain the partial complementation of the L. lactis subsp. cremoris cfa mutant by the O. oeni cfa gene and suggest a probable substrate specificity of the O. oeni enzyme. The current study reveals an essential hypothesis about the specificity of O. oeni CFA synthase which could play a key function in the acid tolerance mechanisms of this enological bacterium.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lactic acid bacteria (LAB) are Gram-positive, low GC bacteria that produce lactic acid as their primary catabolic end product (Carr et al. 2002). They play an essential role in the preservation of agricultural resources and in the improvement of the nutritional and organoleptic properties of human foods. Moreover, at present these organisms are increasingly used to obtain health-promoting probiotics and enzymes, as well as being used as metabolite factories and vaccine delivery vehicles (Escamilla-Hurtado et al. 1996; Tarahomjoo 2012). Regardless of their natural habitat, bacteria are exposed to constant fluctuations in their growth conditions. Thus, during food processing or ingestion and storage, LAB experience adverse environmental conditions such as oxidative, heat, cold, acid, and osmotic stresses. To respond to these different stress conditions, bacteria must coordinate their gene and protein networks to counteract the perturbations caused by specific environmental stressors (van de Guchte et al. 2002; Spano and Massa 2006; Spano et al. 2007).

Several LAB species are important industrial microorganisms, which are employed as starters in most fermented foods. In particular, Oenococcus oeni is of fundamental importance in enology because of its ability to perform malolactic fermentation in wine (Liu 2002). O. oeni tolerates the presence of ethanol associated with a high acidity in wine; thus, it is an ideal candidate to improve our knowledge of the stress response in LAB. Indeed, many studies have highlighted the molecular and physiological bases of the stress response in O. oeni. Several mechanisms allow O. oeni to withstand stress conditions, including the activation of malolactic fermentation to generate a proton-motive force and maintain intracellular pH (Salema et al. 1996a, b; Tourdot-Marechal et al. 1999), activation of membrane-bound H+-ATPases (Carrete et al. 2002; Fortier et al. 2003), stress protein synthesis (Guzzo et al. 2000; Bourdineaud et al. 2003; Beltramo et al. 2004; Bourdineaud et al. 2004; Grandvalet et al. 2005; Beltramo et al. 2006; Bourdineaud 2006; Cecconi et al. 2009; Maitre et al. 2014), and membrane fluidity including changes in lipid composition (Tourdot-Marechal et al. 2000; Da Silveira et al. 2003; Grandvalet et al. 2008).

The modification in fatty acid composition of the cytoplasmic membrane represents one of the most important adaptive microbial responses to stress, where the bacterial response includes modifications in the degree of saturation (Hazel and Williams 1990), carbon chain length, branching position (Kaneda 1977), cis/trans isomerization (Heipieper et al. 1992; Loffeld and Keweloh 1996), and the conversion of unsaturated fatty acids (UFAs) into cyclopropane fatty acids (CFAs) (Broadbent and Lin 1999; Teixeira et al. 2002; Grandvalet et al. 2008; Pini et al. 2009). These CFAs are formed in situ via post-synthetic modification, which involves the transfer of a methyl group from S-adenosyl-l-methionine (AdoMet) to the double bond of a UFA in a phospholipid molecule (Grogan and Cronan 1997). CFA synthase catalyzes this reaction, and it is encoded by the cfa gene (Taylor et al. 1981; Grogan and Cronan 1984, 1986). Early studies of CFA-producing bacteria have shown that these modified fatty acids first appear during the late exponential or early stationary phases of growth (Wang and Cronan 1994). This conversion plays a major role in the adaptation of bacteria in response to a drastic perturbation of the environment. In particular, it has been shown that the CFA content increases in response to a low pH in various bacteria (Brown et al. 1997; Alvarez-Ordonez et al. 2008; Grandvalet et al. 2008; Montanari et al. 2010), as well as in response to high temperature (McGarrity and Armstrong 1981; Dubois-Brissonnet et al. 2001), osmotic (Guillot et al. 2000), and ethanol stresses (Teixeira et al. 2002; Grandvalet et al. 2008; To et al. 2011). Physiological studies based on the construction of cfa-deficient cells in Escherichia coli, Salmonella enterica serovar Typhimurium, and Brucella abortus have demonstrated that the formation of CFAs in the membrane is a major factor that protects bacteria from low pH (Grogan and Cronan 1986; Kim et al. 2005; Palacios-Chaves et al. 2012). Moreover, an increased CFA content in the membrane of Clostridium acetobutylicum enhances resistance to acid and butanol (Zhao et al. 2003).

Oleic acid (C18:1n-9), which is the UFA precursor of the CFA lactobacillic acid (cycC19:0n-7), is often supplemented in the medium under the form of Tween 80 (polyethylene glycol sorbitan monooleate), and it is known to stimulate LAB growth as well as to protect cells toward stress (Williams and Fieger 1946; Goldberg and Eschar 1977; Guerrini et al. 2002; Corcoran et al. 2007). The CFAs lactobacillic acid and dihydrosterculic acid (cycC19:0n-9), which are derived from oleic acid and vaccenic acid (C18:1n-7), respectively, are regarded as key fatty acids for stress tolerance in LAB (Goldberg and Eschar 1977; Johnsson et al. 1995; Broadbent and Lin 1999; Montanari et al. 2010). Thus, Tween 80-supplemented cultures of O. oeni exhibit enhanced bacterial survival in wine which could be explained by a higher oleic acid and dihydrosterculic acid content and a lower level in palmitic (C16:0), vaccenic, and lactobacillic acids (Guerrini et al. 2002). Modifications of the CFA content have been demonstrated in O. oeni cells grown during sublethal stress conditions (Teixeira et al. 2002; Grandvalet et al. 2008). A previous characterization of the O. oeni cfa gene showed that the abundance of cfa transcripts increased when cells were harvested during the stationary phase and when cells were grown in the presence of ethanol or at low pH, thereby suggesting that transcriptional regulation of the cfa gene occurs under different stress conditions (Grandvalet et al. 2008). The function of the O. oeni cfa gene has been analyzed by cfa-deficient E. coli strain complementation where partial complementation was observed. In fact, the percentage conversion of UFAs into CFA by the complemented strain (18 %) was much lower than that by the parental strain (90 %). This may be attributed to some issues due to the expression of a heterologous gene in Gram-negative E. coli cells (protein misfolding) and/or to the intracellular pH of the host cell (7.2–7.8 for E. coli vs. 5.8–6.3 for O. oeni) unfavorable to the protein activity (Slonczewski et al. 1981; Salema et al. 1994; Augagneur et al. 2007). Alternatively, the substrate specificity of the O. oeni enzyme may also be involved.

Few bacterial CFA synthases have been well characterized, and the homologous enzyme from E. coli is the best known regarding synthesis and reaction mechanisms (Wang et al. 1992; Courtois et al. 2004; Courtois and Ploux 2005; Guianvarc’h et al. 2008; Guangqi et al. 2013). The E. coli CFA synthase is a peptide that comprises 382 amino acid residues, which is active in vitro as a homodimer (Wang et al. 1992). Similar to many methyltransferases, this enzyme has three motifs that comprise 8–10 amino acids, which are involved in the binding of AdoMet and S-adenosyl homocysteine (Kagan and Clarke 1994). Three cysteine residues are highly conserved, although mutations in these residues do not affect the enzyme activity significantly (Grogan and Cronan 1997). A previous biochemical analysis demonstrated the relative instability of the CFA synthase purified from E. coli, where its half-life was 16 h at 4 °C and only a few minutes at 37 °C (Grogan and Cronan 1984). This enzyme can be made relatively stable in vitro by adding lipid molecules to purified fractions. The addition of bovine serum albumin (BSA) or dithiothreitol (DTT) also stabilizes the enzyme in vitro (Courtois et al. 2004). The CFA synthase from E. coli has a K m with AdoMet of 80 μM and a k cat of 4 min-1 (Guianvarc’h et al. 2006).

Therefore, to understand the partial complementation of a cfa-deficient E. coli mutant previously reported (Da Silveira et al. 2003), we studied the activity of the CFA synthase from O. oeni in a Gram-positive bacterium. We complemented the cfa-deficient L. lactis subsp. cremoris MG1363 strain, which was constructed previously by To et al. (2011). Moreover, the enzyme was overproduced in E. coli strain BL21(DE3) using the pET expression system for purification, and the biochemical characteristics of the O. oeni CFA synthase were determined in vitro. In vitro enzymatic activity measurements were taken by monitoring product appearance using gas chromatography (GC). The in vitro characterization of a CFA synthase from a lactic acid bacterium was described for the first time.

Materials and methods

Strains, plasmids, and media

The bacterial strains and plasmids used in this study are listed in Table 1. E. coli strains were cultured in liquid Luria–Bertani (LB) medium (Bertani 1951) at 37 °C on a rotary shaker at 150 rpm. L. lactis subsp. cremoris MG1363 strains were cultured at 30 °C in modified M17 medium, which was adjusted to pH 7 (M17/7) or pH 5 (M17/5), and 6 % ethanol (vol/vol) was added (To et al. 2011). Kanamycin, spectinomycin, and ampicillin were used at concentrations of 50, 50, and 100 μg/ml, respectively, with E. coli. For the L. lactis subsp. cremoris MG1363 strains, 1 mg/ml of spectinomycin was added to the medium as necessary.

Complementation of the L. lactis subsp. cremoris cfa-deficient strain

Standard procedures such as purification, ligation, restriction analysis, and gel electrophoresis were performed as described by Sambrook and Pollack (1974). L. lactis subsp. cremoris chromosomal DNA was prepared as described previously (Leenhouts et al. 1989). The PCR products and restriction products were purified using a Gene Elute PCR kit (Sigma, St Quentin Fallavier, France). Conventional electroporation was used for E. coli. L. lactis subsp. cremoris was transformed by electroporation, as described by Dower (1990).

The entire cfa gene of O. oeni ATCC BAA 1163 (including the promoter region) was amplified by PCR with Platinum® Taq DNA Polymerase High Fidelity (Life Technologies, Saint-Aubin, France) using the primers cfa4MT (5′CCCGGATCCTTCATTTTAATTAAAAAAAATAAAATTTT3′) and cfa5MT (5′GGGGAATTCTCTTGTTTCCTTTTTTTAGAAAATT3′), which include BamHI and EcoRI restriction sites, respectively (the restriction sites are underlined). The PCR product was first subcloned into pUC18, and then the 1140-bp fragment isolated by BamHI and EcoRI (Life Technologies, Saint-Aubin, France) digestion was ligated into the corresponding sites of pDL278 to yield pGC20. After verifying the sequence of the cfa gene (Beckman Coulter Genomics, Essex, UK), the pGC20 recombinant vector was introduced into the L. lactis subsp. cremoris cfa-deficient strain as the heterologous expression system.

RNA extraction and analysis

L. lactis subsp. cremoris cells in the exponential growth phase were centrifuged and washed with 0.1 % dimethylpyrocarbonate-treated water before autoclaving to inactivate RNases. The cell pellets were resuspended in 1 ml TRI Reagent (Sigma-Aldrich, St Quentin Fallavier, France), and the cells were broken using a Precellys Disruptor (Bertin Technologies, Montigny-le-Bretonneux, France), with two cycles for 30 s at 6000 rotations per minute in the presence of 200 mg of glass beads (diameter 70–100 μm, Scientific Industries Inc., NY, USA). Next, the total RNA was extracted with phenol–chloroform, precipitated with isopropanol, and resuspended in RNase-free water. Reverse transcription-PCR was performed using the reverse transcriptase iScript™ (Bio-Rad, Marnes-la-Coquette, France), as recommended by the supplier. Quantitative real-time PCR (qRT-PCR) was performed using IQ™ SYBR® Green Supermix (Bio-Rad, Marnes-la-Coquette, France) on a Bio-Rad iCycler with the SYBR Green system. Thermal cycling conditions included the following steps: initial denaturation at 95 °C for 10 min, followed by 45 cycles at 95 °C for 15 s and 60 °C for 30 s. Fluorescence measurements were recorded during each annealing step. The primers used for amplification were 1163cfaF (5′GCTGGCAGCTTTTTGACTGATA3′) and 1163cfa (5′TATCGTAGTGACTTTGAACG3′) for the O. oeni cfa gene; MG1363cfaF (5′GGACAGTTTTTTAACTGACCAATC3′) and MG1363cfaR (5′CGAGATTGTTTTTGAGAATGATT3′) for the L. lactis subsp. cremoris cfa gene. The specificity of each primer pair was determined with a melting curve. The threshold cycle value (C T) was determined for each measurement. The mRNA levels were quantified using the threshold method (ΔΔC T), where the quantity of target cDNA was adjusted to a reference based on the amount of cDNA, as previously described (To et al. 2011). The results were normalized using the L. lactis subsp. cremoris butB gene, which encodes 2,3-butanediol dehydrogenase, as reference gene. Primers RTF-butB (5′GGATATCATGCTGTTGAACGTGC3′) and RTR-butB (5′TGAGCTTTGGCAACTGCAGCT3′) target an internal region of the butB coding sequence. Previously, we verified that butB gene transcription level was independent of the growth conditions tested in this study (To et al. 2011).

Cloning of the O. oeni cfa gene into the pET-28a(+) vector

The O. oeni cfa gene was cloned and expressed in E. coli in order to raise antibodies production and biochemical characterization. To facilitate the purification of CFA synthase, a His-tag was added to the N-terminal using the pET expression system. The entire coding sequence of the O. oeni cfa gene was amplified by PCR using the primers cfa1M (GGGGCCCCCATATGTTAGAGAAAACCATTTATCG) and cfa2 (CCCGAATTCTTAACTTAATTCATGTTCATAAATAT), which contain NdeI and EcoRI restriction sites, respectively (the restriction sites are underlined). The PCR product was subcloned into pUC18, before the 1180-pb fragment isolated by NdeI and EcoRI (Life Technologies, Saint-Aubin, France) digestion was ligated into the corresponding sites of pET-28a(+) to yield the pETcfa1-2 plasmid. The sequence of O. oeni cfa gene was verified by DNA sequencing (Beckman Coulter Genomics, Essex, UK).

CFA synthase overproduction and purification

The pETcfa1-2 plasmid was transformed into E. coli BL21(DE3) (Novagen-Merck KGaA, Darmstadt, Germany). The recombinant E. coli was grown aerobically at 37 °C into 1 liter of LB broth supplemented with 50 μg/ml kanamycin for 2 h (OD600 = 0.7). Expression of the cfa gene was induced by adding 50 μM isopropyl-β-d-1-thiogalactoside (IPTG), and the cells were incubated for 19 h at 16 °C on a rotary shaker at 150 rpm. The cells were harvested by centrifugation (6000×g, 15 min at 4 °C), washed with lysis buffer (KH2PO4/K2HPO4 50 mM, pH 7.4; NaCl, 300 mM), and resuspended in the same buffer (20 UDO600nm/ml). The cells were then disrupted using a One Shot Cell Disrupter (Z plus Series Cell, Constant Systems Ltd, Northants, UK) with one cycle at 1.4 kbar. Cell debris were removed by centrifugation (7000×g, 30 min at 4 °C), and the supernatant was applied directly to a 2-ml nickel-nitrilotriacetate column (Ni-NTA agarose, Qiagen, Courtaboeuf, France), which had been pre-equilibrated with 10 column volumes of wash buffer (NaH2PO4/Na2HPO4, 100 mM; Tris–HCl, 10 mM; pH 8, NaCl 300 mM) at a flow rate of 1 ml/min using a peristaltic pump. The column was washed with 10 column volumes of wash buffer, and the recombinant protein was eluted with four column volumes gradient of 10–400 mM imidazole in wash buffer (NaH2PO4/Na2HPO4 100 mM, pH 8; Tris–HCl, 10 mM; NaCl, 300 mM). The flow rate was 0.5 ml/min for loading, washing, and eluting. The eluate was collected in 2-ml fractions, and 10-µL aliquots of each fraction were subjected to SDS-PAGE (12.5 % polyacrylamide) to verify the purity and apparent molecular mass of the eluted protein. The protein content was quantified using the Bradford method (Bradford 1976). Fractions that produced a single intense band on the gel (fractions eluted by the imidazole gradient from 100 to 200 mM) were pooled and dialyzed to remove imidazole and salts using an Amicon Ultra filter 15 kDa (Merck Millipore, Darmstadt, Germany). The purification yield obtained was around 4 μg/mg wet cell pellet. After adding glycerol (50 %, vol/vol) and BSA (80 μM), the enzyme was stored at −20 °C until use.

Western blotting experiments

L. lactis subsp. cremoris stationary phase cells were harvested by centrifugation at 6300×g for 10 min, washed with lysis buffer (10 mM Tris–HCl, pH 8; 300 mM NaCl), and resuspended in 1/100th of the volume of original culture volume using lysis buffer. The cells were disrupted using a Precellys Disruptor, with four cycles for 30 s at 6500 rotations per minute in the presence of 200 mg of glass beads (diameter 70–100 μm; Scientific Industries Inc., NY, USA). The lysate was centrifuged at 17,900×g for 20 min at 4 °C, and the protein concentration of the supernatant (crude extract) was determined using the Bradford method (Bio-Rad reagent, Richmond, CA, USA) with BSA as the standard (Bradford 1976). SDS-PAGE (12.5 % polyacrylamide) was performed according to Laemmli’s method (1970). The proteins were transferred to an Amersham Hybond-ECL membrane (GE Healthcare Life Sciences, Velizy-Villacoublay, France) using a Trans-Blot SD semi-dry Transfer Cell (Bio-Rad, Marnes-la-Coquette, France) and the following buffer: 25 mM Tris; 192 mM glycine; and 20 % methanol. O. oeni CFA synthase protein was detected using serum from a rabbit (AGRO-BIO, La Ferté Saint-Aubin, France) immunized with the O. oeni CFA synthase–His-tag purified protein and the Amersham ECL detection system (GE Healthcare Life Sciences, Velizy-Villacoublay, France).

Preparation of phospholipids

L. lactis subsp. cremoris cells (80 UDO600nm) collected in the stationary growth phase after growth in M17 media were washed and resuspended in NaCl 0.9 %. Cell suspension was used to extract cellular lipids with chloroform/methanol (1:2) according to Bligh and Dyer (1959).

For the in vitro enzymatic assay, lipids were extracted from stationary phase L. lactis subsp. cremoris ∆cfa cells grown in M17/7 medium. A film of extracted lipids was obtained by evaporation of chloroform with a rotavapor at 65 °C (Rotary Evaporator RE100 Bibby, Odil) under nitrogen-reduced pressure for 45 min followed by rehydration with pre-warmed buffer 20 mM potassium phosphate buffer (pH 7.4) at 65 °C. The liposome suspension was gently mixed and sonicated 2 × 30 s (ELMA D-78224, VWR) prior to its use as the substrate in the CFA synthase assay.

Esterification of fatty acids and gas chromatography (GC) analysis

The fatty acid of total lipids and phospholipids was directly transesterified with methanol/H2SO4 (95/5, v/v) at 80 °C for 2 h. The fatty acid methyl esters (FAMEs) were extracted with hexane and analyzed by GC using a Chrompack CP 9002 chromatograph equipped with a Varian FactorFour™ capillary column (30 m × 0.32 mm) (Middelburg, the Netherlands). The detector and injector temperatures were 230 and 220 °C, respectively. Initially, the oven temperature was 160 °C for 10 min, before increasing to 180 °C at 2 °C/min. The FAMEs were identified by comparing retention times with those of authentic standards (Nu Check Prep., Elysian, MN, USA). The percentage of each component was calculated based on the peak area obtained (peak area of component/total area of all peaks). The absolute quantification of each component was achieved by using a defined amount of pentadecanoic acid (C15:0) as an internal standard.

CFA synthase assay

The CFA synthase GC-based assay was adapted from the radiometric method described previously by Taylor et al. (Taylor et al. 1981) for E. coli enzyme characterization, with the following modifications. The assay consisted in 1 mg/ml phospholipids extracted from L. lactis subsp. cremoris ∆cfa cells, 0.5 mg/ml bovine serum albumin (BSA), 10 % (vol/vol) glycerol, 2 mM dithiothreitol (DTT), 0.75 mM AdoMet, 20 mM potassium phosphate buffer, pH 5.6, in a final volume of l00 µl. After pre-incubation at 35 °C for 5 min, the reaction was initiated by adding the CFA synthase (20 µg/ml) and incubated at 35 °C for a maximum of 45 min. The reaction was stopped by adding 1 ml 10 % (vol/vol) trichloroacetic acid. The total lipids were extracted and transesterified directly after adding 200 μg of pentadecanoic acid (C15:0, Sigma-Aldrich, St Quentin Fallavier, France) as an internal standard in each assay. The methyl esters obtained were then quantified by GC. The activity measured under these conditions was linear with time over a period of 1 h and linear with enzyme concentration up to 100 μg/ml of protein (data not shown).

Experimental design and statistical analyses

The experiments were designed using NEMRODW (LPRAI, University of Marseille, France) to determine the maximal rate of CFA conversion in the enzymatic reaction at different pH values (5–6) and temperatures (30–37 °C). We employed a square domain and a second-degree polynomial model in this study. Data are represented as mean ± SD for replicate experiments. To determine whether two sets of data were significantly different, paired Student’s t tests were performed using the T.TEST function in Excel. A value of p < 0.05 was considered statistically significant.

Results

The O. oeni cfa gene partially complemented the L. lactis subsp. cremoris MG1363 cfa-deficient strain

The L. lactis subsp. cremoris MG1363 cfa-deficient strain constructed previously by To et al. (2011) was complemented with the pGC20 plasmid derived from the low-copy number vector pDL278 (Chen and LeBlanc 1992), which carried the entire O. oeni cfa gene under the control of its own promoter. Analysis of total phospholipids revealed that in the presence of pGC20, we detected cycC19:0n-7 and we observed a slight decrease in the level of its precursor C18:1n-7 in the L. lactis subsp. cremoris complemented strain, MG1363 Δcfa pGC20 compared to cfa-deficient strain (Table 2).

In optimal growth conditions (M17/7), we observed that only 3.7 % of the CFA was converted by the complemented strain, whereas 36 % was converted by the parental strain MG1363. Although there were multiple copies of the vector, complementation of the L. lactis subsp. cremoris MG1363 strain did not restore the amount of CFA converted compared with that obtained with the parental strain. Based on transcriptional fusion constructions, Budin-Verneuil et al. (2005) reported the induction of the L. lactis subsp. cremoris MG1363 cfa gene under moderate acidity. Similarly, we observed almost 90 % CFA conversion when the cells were cultured in acidic conditions. In agreement with Budin-Verneuil et al. (2005), our results confirm that there was a significant increase in C18:1n-7 cyclization by the parental strain in acidic conditions (M17/5). We also observed an increase in the CFA conversion rate by the complemented strain. However, the level of CFA conversion in the complemented strain (15 %) was still lower than that in the parental strain. In acidic conditions, the CFA conversion level increased by four times in the complemented strain compared with that in the optimal conditions, whereas the CFA conversion level increased by 2.5 times in the parental strain. Previously, we reported that the addition of ethanol (6 %) to the medium increased the CFA level in L. lactis subsp. cremoris MG1363 by two times (To et al. 2011). The CFA level increased three times in the complemented strain. These results confirm that the O. oeni cfa gene complemented the L. lactis subsp. cremoris cfa-deficient strain in terms of its fatty acid composition, although the CFA level was partial. Moreover, in stressful conditions (growth at pH 5 or with 6 % ethanol) we observed an increase in the CFA conversion ratio in the complemented strain, which suggests an induction of the O. oeni cfa gene expression in L. lactis subsp. cremoris complemented strain.

Expression of the O. oeni cfa gene in the complemented L. lactis subsp. cremoris strain compared with the endogenous cfa gene in L. lactis subsp. cremoris

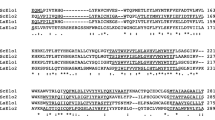

To understand the partial complementation of the cfa-deficient mutant, qRT-PCR experiments were performed in order to compare the expression level of the cfa gene in O. oeni with that of the cfa gene in L. lactis subsp. cremoris (Table 3). In optimal growth conditions (pH 7), the O. oeni cfa expression was increased sixfold in the complemented strain compared with the cfa transcript level in the parental strain. In acidic growth conditions (pH 5), the cfa transcript level was increased by over 36 times in the complemented strain, compared with an increase of only 3.5 times in the parental strain. However, these results did not explain the partial complementation of the cfa-deficient mutant because the O. oeni cfa transcript levels were six times and 71 times higher than that of L. lactis subsp. cremoris cfa in the optimal growth condition and acidic conditions, respectively. However, the incomplete cyclization of UFAs in the complemented cfa-deficient strain may be attributable to a low translation level or to the suboptimal enzymatic activity of O. oeni CFA synthase in the heterologous host. The production of heterologous CFA synthase in L. lactis subsp. cremoris strains was estimated by immunodetection using specific antibodies directed against O. oeni CFA synthase. As shown in Fig. 1 (lane 2), an overproduced protein was detected in the complemented strain. No protein corresponding to the same molecular size was displayed in the wild-type and the cfa-deficient strains (Fig. 1, lanes 1 and 3), indicating that this band represents the O. oeni CFA synthase. The anti-CFA synthase antibodies detected another minor band for the L. lactis subsp. cremoris wild-type strain, which was not detected in the cfa-deficient strain (Fig. 1, lane 1). This band, corresponding to a slightly smaller size protein, was probably attributable to a cross-reaction with the CFA synthase from L. lactis subsp. cremoris. Thus, an enzymatic approach was employed to further study the in vitro CFA synthase activity of O. oeni.

Western blot analysis of Lactococcus lactis subsp. cremoris Δcfa complemented by Oenococcus oeni cfa gene. Crude extracts from the L. lactis subsp. cremoris MG1363 strain harboring pDL278 (lane 1), L. lactis subsp. cremoris Δcfa strain complemented by pGC20 (lane 2), and L. lactis subsp. cremoris Δcfa strain harboring pDL278 (lane 3) were separated on a 12.5 % SDS-polyacrylamide gel. The separated proteins were transferred onto a Hybond membrane, and the immunoblot was probed with antibodies raised against O. oeni CFA synthase. Equal amounts of protein (20 μg) were applied to each lane. The molecular mass markers are indicated on the left

Overproduction and purification of the CFA synthase

As described by Courtois et al. (2004) in E. coli, the O. oeni CFA synthase was overproduced as an N-terminal His6-tagged recombinant protein using the plasmid pET28a(+). Overexpression in E. coli BL21(DE3), which harbored the recombinant plasmid pETcfa1-2, was optimized in the following conditions: induction at OD600nm = 0.7, with 50 mM IPTG; and overnight incubation at 16 °C. The enzyme was purified by immobilized metal affinity chromatography using a Ni-NTA agarose column. As shown in Fig. 2, the O. oeni protein product had the expected molecular mass of ca 45 kDa.

Overproduction and purification of Oenococcus oeni cyclopropane fatty acid synthase. SDS-PAGE analysis of crude extract from E. coli BL21 λ DE3 carrying pETcfa1-2 (lane 2), the protein fraction not retained on Ni-NTA agarose (lane 3), and the fractions eluted with purification buffer containing 10 (lane 4), 20 (lane 5), 50 (lane 6), 100 (lane 7), 200 (lane 8), and 400 mM imidazole (lane 9). The protein samples were separated on a 12.5 % SDS-polyacrylamide gel, which was stained with Coomassie Brilliant Blue after electrophoresis. Ten micrograms of protein crude extract (lane 2) or 10 µl aliquots of each fraction (lanes 3–9) were loaded. The molecular mass standards were loaded in lane 1

Biochemical characterization of the recombinant CFA synthase

The conditions described previously (Guianvarc’h et al. 2008) were adapted to the CFA synthase GC assay (see “Materials and methods”). To determine the effects of pH and temperature on the activity of CFA synthase, the experimental design of the complete model was generated using NEMRODW. The constraints on the two parameters were predetermined experimentally, i.e., the temperature ranged from 30 to 37 °C and the pH ranged between 5.0 and 6.0. The second-degree polynomial model was calculated. We generated a response surface that displayed the variation in the two factors. The response surface and the corresponding projection with iso-response curves are shown in Fig. 3. The numbers along the curves indicate the predicted response, and the circle delimits the experimental domain where the prediction is reliable. Analyzing these iso-response surfaces showed that a pH value of 5.6 and a temperature of 35.8 °C would obtain the highest CFA conversion rate.

Biochemical characterization of the activity of Oenococcus oeni CFA synthase using the iso-response method. Two-dimensional curves (a) and a three-dimensional response surface (b) showing CFA synthesis (μg/ml of cycC19:0n-7) as functions of temperature and pH. Enzymatic assays were performed as described in “Materials and methods”

O. oeni CFA synthase exhibited saturation kinetics with AdoMet in the presence of a saturating concentration of phospholipids (1 mg/ml), where K m = 2.26 mM for AdoMet, V max = 64.5 μM/min, and k cat = 6000/min. Compared with the values reported previously for E. coli CFA synthase (Taylor et al. 1981; Courtois et al. 2004; Iwig et al. 2004; Guianvarc’h et al. 2006), the O. oeni enzyme exhibited a lower cyclization activity with the unsaturated phospholipids from L. lactis subsp. cremoris in the test conditions. These results explain the partial cyclization of the UFAs in the L. lactis subsp. cremoris cfa-deficient mutant complemented with the O. oeni cfa gene.

Discussion

Our characterization of O. oeni CFA synthase was driven by the need to explain the previously described partial complementation of an E. coli cfa-deficient mutant (Grandvalet et al. 2008). This partial complementation was possibly caused by the use of a Gram-negative bacterium as the host, the identity of the homologous CFA synthase, or the reduced substrate specificity of the O. oeni enzyme. Thus, we complemented a L. lactis subsp. cremoris cfa-deficient strain with the O. oeni cfa gene, which encodes a protein that shares a 62 % amino acid sequence identity with the homologous protein in L. lactis subsp. cremoris MG1363 (versus a 29 % shared identity with E. coli CFA synthase). Unfortunately, CFA cyclization remained partial in the complemented strain under optimal as well as stressful conditions (Table 2). This partial complementation was not a consequence of the faulty expression of the expression gene in L. lactis subsp. cremoris. Moreover, the immunodetection assay confirmed the presence of the heterologous CFA synthase in the complemented strain. Furthermore, in a previous study, the L. lactis subsp. cremoris cfa-deficient strain was totally complemented by its homologous cfa gene using the same expression vector (pDL278) and 100 % CFA conversion was obtained (To et al. 2011). Thus, differences in the fatty acid precursor levels may have been responsible for the partial conversion observed in the complemented strain. Surprisingly, although the complemented strain grown on Tween 80-supplemented medium incorporated a large amount of C18:1n-9 (30 %), only a small amount of cycC19:0n-9 (dihydrosterculic acid) was produced compared with cycC19:0n-7 (data not shown). The predominance of cycC19:0n-7 (lactobacillic acid) instead of cycC19:0n-9 (dihydrosterculic acid) suggests that the partial cyclization was not linked to the tails of the fatty acids or to the position of the double bond. Finally, the biochemical characterization of O. oeni CFA synthase was performed in vitro. For the first time, we purified and characterized a recombinant CFA synthase from a lactic acid bacterium with an N-terminal His6-tag based on a previous observation that the presence of a His6-tag did not perturb the catalytic activity of the E. coli CFA synthase (Courtois et al. 2004). The recombinant enzyme was produced in E. coli BL21(DE3) using the pET expression system, and nickel affinity chromatography facilitated the rapid purification of O. oeni CFA synthase. The enzymatic activity measurements were taken in vitro using GC. The highest CFA conversion rate was obtained at pH 5.6 and 35.8 °C (Fig. 3). Thus, the behavior of this enzyme differs from that of the recombinant CFA synthase of E. coli, which has an optimal pH of 7.5 (Courtois et al. 2004). However, previous biochemical characterizations of many intracellular enzymes in O. oeni, such as glucosidase (Michlmayr et al. 2010), arabinofuranosidases (Michlmayr et al. 2011), esterase (Matthews et al. 2007), ornithine decarboxylase (Bonnin-Jusserand et al. 2011), and malolactic enzyme (Schumann et al. 2013; Wang et al. 2014), have determined optimum pH values between 5 and 6, which match the intracellular pH (pHi) found in O. oeni cells (5.8–6.3 in optimal conditions) (Salema et al. 1994; Augagneur et al. 2007). Given the differences between the pHi values determined for the hosts used for complementation and O. oeni (7.73 in E. coli and 7.24 in L. lactis subsp. cremoris with an external pH of 7.0), the partial complementation may be explained by a weak activity due to an excessively basic environment (Slonczewski et al. 1981; Hickey and Hirshfield 1990; O’Sullivan and Condon 1997; Olsen et al. 2002).

The pHi decreased in a linear manner as the extracellular pH decreased. In L. lactis subsp. cremoris, the pHi decreased from 7.24 to 5.19 as the extracellular pH declined from 7.0 to 4.0 (O’Sullivan and Condon 1997). Thus, with the M17/5 medium, the pHi value of the complemented strain was closer (pHi 5.9) to the optimum pH required for the activity of O. oeni CFA synthase. Therefore, independent of the transcriptional regulation of the cfa gene, the modulation of the pHi value explains why the CFA conversion rate of the complemented strain increased by four times in acidic conditions compared with that in optimal conditions, whereas that of the parental strain only increased by 2.5 times (Table 2).

In optimal conditions (pH 5.6 and 37 °C), the activity of O. oeni CFA synthase was low compared with that of E. coli CFA synthase, although the same expression system was employed and the same purification method was used for enzyme characterization (Courtois et al. 2004; Iwig et al. 2004; Guianvarc’h et al. 2006). We suggest that the affinity for the substrate could be linked to the phosphoric acid head groups of the membrane phospholipids. The lipid content varies among bacterial species. For example, in B. subtilis, phosphatidylglycerol (PG) accounts for 75 % of the total membrane lipid content and the remainder mainly comprises lysyl-PG and cardiolipin, whereas up to 38 % of the membrane lipid is lysyl-PG in S. aureus (Peschel et al. 2001). There is a great difference between the phosphoric acid head groups in the O. oeni membrane and those of L. lactis (Exterkate et al. 1971; Teixeira et al. 2002). The O. oeni membrane contains approximately 40 % phosphatidylethanolamine (PE), 20 % sphingomyelin, and 20 % PG (Teixeira et al. 2002). The L. lactis membrane contains 65 % PG, 4 % diphosphatidylglycerol (DPG), and 23 % lysyl-PG, but no PE (Exterkate et al. 1971). In fact, the phospholipids differ in terms of the substituents attached to phosphoric acid, which determine the charges of the phospholipids. Moreover, Gram-positive bacteria can reduce the overall negative charge on cell membranes by producing positively charged lysine esters of PG, i.e., lysyl-PG (Lennarz et al. 1967; Peschel et al. 2001; Oku et al. 2004). Steric hindrance and the hydration capacity of the substituent can also determine the characteristics of the phospholipid. For example, ethanolamine has a low steric hindrance and low hydration, thereby implying that a PE head group is smaller than a glycerol group, which has the same steric hindrance but greater hydration. Thus, PE has a cone shape and PG has a cylindrical shape. The wide variety of polar and nonpolar components is responsible for the high diversity of phospholipids and their physical properties. We suggest that differences in the phosphoric acid head groups in the O. oeni lipid bilayer and that of the host bacterium could hinder accessibility to O. oeni CFA synthase. Further investigations are needed to identify the specificity of different phospholipids with various substrates to optimize the CFA synthase activity in this LAB. O. oeni CFA synthase enzyme seems to be strongly tailored to its native membrane environment and should not be suitable for expression in other microorganisms. The use of phospholipids from O. oeni as positive control could support this hypothesis. Preliminary tests for obtaining phospholipids devoid of CFAs from O. oeni cells harvested in early log phase were not conclusive. The construction of O. oeni cfa-deficient strain would increase the extraction rate of phospholipids devoid of CFA. However, tools to delete genes in O. oeni are currently under development.

References

Alvarez-Ordonez A, Fernandez A, Lopez M, Arenas R, Bernardo A (2008) Modifications in membrane fatty acid composition of Salmonella typhimurium in response to growth conditions and their effect on heat resistance. Int J Food Microbiol 123:212–219

Augagneur Y et al (2007) Dual effect of organic acids as a function of external pH in Oenococcus oeni. Arch Microbiol 188:147–157

Beltramo C, Grandvalet C, Pierre F, Guzzo J (2004) Evidence for multiple levels of regulation of Oenococcus oeni clpP-clpL locus expression in response to stress. J Bacteriol 186:2200–2205

Beltramo C, Desroche N, Tourdot-Marechal R, Grandvalet C, Guzzo J (2006) Real-time PCR for characterizing the stress response of Oenococcus oeni in a wine-like medium. Res Microbiol 157:267–274

Bertani G (1951) Studies on lysogenesis. I. The mode of phage liberation by lysogenic Escherichia coli. J Bacteriol 62:293–300

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917

Bonnin-Jusserand M, Grandvalet C, David V, Alexandre H (2011) Molecular cloning, heterologous expression, and characterization of ornithine decarboxylase from Oenococcus oeni. J Food Prot 74:1309–1314

Bourdineaud JP (2006) Both arginine and fructose stimulate pH-independent resistance in the wine bacteria Oenococcus oeni. Int J Food Microbiol 107:274–280

Bourdineaud JP, Nehme B, Tesse S, Lonvaud-Funel A (2003) The ftsH gene of the wine bacterium Oenococcus oeni is involved in protection against environmental stress. Appl Environ Microbiol 69:2512–2520

Bourdineaud JP, Nehme B, Tesse S, Lonvaud-Funel A (2004) A bacterial gene homologous to ABC transporters protect Oenococcus oeni from ethanol and other stress factors in wine. Int J Food Microbiol 92:1–14

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Broadbent JR, Lin C (1999) Effect of heat shock or cold shock treatment on the resistance of Lactococcus lactis to freezing and lyophilization. Cryobiology 39:88–102

Brown JL, Ross T, McMeekin TA, Nichols PD (1997) Acid habituation of Escherichia coli and the potential role of cyclopropane fatty acids in low pH tolerance. Int J Food Microbiol 37:163–173

Budin-Verneuil A, Maguin E, Auffray Y, Ehrlich SD, Pichereau V (2005) Transcriptional analysis of the cyclopropane fatty acid synthase gene of Lactococcus lactis MG1363 at low pH. FEMS Microbiol Lett 250:189–194

Carr FJ, Chill D, Maida N (2002) The lactic acid bacteria: a literature survey. Crit Rev Microbiol 28:281–370

Carrete R, Vidal MT, Bordons A, Constanti M (2002) Inhibitory effect of sulfur dioxide and other stress compounds in wine on the ATPase activity of Oenococcus oeni. FEMS Microbiol Lett 211:155–159

Cecconi D, Milli A, Rinalducci S, Zolla L, Zapparoli G (2009) Proteomic analysis of Oenococcus oeni freeze-dried culture to assess the importance of cell acclimation to conduct malolactic fermentation in wine. Electrophoresis 30:2988–2995

Chen YY, LeBlanc DJ (1992) Genetic analysis of scrA and scrB from Streptococcus sobrinus 6715. Infect Immun 60:3739–3746

Corcoran BM, Stanton C, Fitzgerald GF, Ross RP (2007) Growth of probiotic lactobacilli in the presence of oleic acid enhances subsequent survival in gastric juice. Microbiology 153:291–299

Courtois F, Ploux O (2005) Escherichia coli cyclopropane fatty acid synthase: is a bound bicarbonate ion the active-site base? Biochemistry 44:13583–13590

Courtois F, Guerard C, Thomas X, Ploux O (2004) Escherichia coli cyclopropane fatty acid synthase. Eur J Biochem 271:4769–4778

Da Silveira MG, Golovina EA, Hoekstra FA, Rombouts FM, Abee T (2003) Membrane fluidity adjustments in ethanol-stressed Oenococcus oeni cells. Appl Environ Microbiol 69:5826–5832

Dower WJ (1990) Electroporation of bacteria: a general approach to genetic transformation. Genet Eng (N Y) 12:275–295

Dubois-Brissonnet F, Malgrange C, Guerin-Mechin L, Heyd B, Leveau JY (2001) Changes in fatty acid composition of Pseudomonas aeruginosa ATCC 15442 induced by growth conditions: consequences of resistance to quaternary ammonium compounds. Microbios 106:97–110

Escamilla-Hurtado ML, Tomasini-Campocosio A, Valdes-Martinez S, Soriano-Santos J (1996) Diacetyl formation by lactic bacteria. Rev Latinoam Microbiol 38:129–137

Exterkate FA, Otten BJ, Wassenberg HW, Veerkamp JH (1971) Comparison of the phospholipid composition of Bifidobacterium and Lactobacillus strains. J Bacteriol 106:824–829

Fortier LC, Tourdot-Marechal R, Divies C, Lee BH, Guzzo J (2003) Induction of Oenococcus oeni H+-ATPase activity and mRNA transcription under acidic conditions. FEMS Microbiol Lett 222:165–169

Goldberg I, Eschar L (1977) Stability of lactic acid bacteria to freezing as related to their fatty acid composition. Appl Environ Microbiol 33:489–496

Grandvalet C, Coucheney F, Beltramo C, Guzzo J (2005) CtsR is the master regulator of stress response gene expression in Oenococcus oeni. J Bacteriol 187:5614–5623

Grandvalet C et al (2008) Changes in membrane lipid composition in ethanol- and acid-adapted Oenococcus oeni cells: characterization of the cfa gene by heterologous complementation. Microbiology 154:2611–2619

Grogan DW, Cronan JE Jr (1984) Cloning and manipulation of the Escherichia coli cyclopropane fatty acid synthase gene: physiological aspects of enzyme overproduction. J Bacteriol 158:286–295

Grogan DW, Cronan JE Jr (1986) Characterization of Escherichia coli mutants completely defective in synthesis of cyclopropane fatty acids. J Bacteriol 166:872–877

Grogan DW, Cronan JE Jr (1997) Cyclopropane ring formation in membrane lipids of bacteria. Microbiol Mol Biol Rev 61:429–441

Guangqi E, Drujon T, Correia I, Ploux O, Guianvarc’h D (2013) An active site mutant of Escherichia coli cyclopropane fatty acid synthase forms new non-natural fatty acids providing insights on the mechanism of the enzymatic reaction. Biochimie 95:2336–2344

Guerrini S, Bastianini A, Granchi L, Vincenzini M (2002) Effect of oleic acid on Oenococcus oeni strains and malolactic fermentation in wine. Curr Microbiol 44:5–9

Guianvarc’h D, Drujon T, Leang TE, Courtois F, Ploux O (2006) Identification of new inhibitors of E. coli cyclopropane fatty acid synthase using a colorimetric assay. Biochim Biophys Acta 1764:1381–1388

Guianvarc’h D, Guangqi E, Drujon T, Rey C, Wang Q, Ploux O (2008) Identification of inhibitors of the E. coli cyclopropane fatty acid synthase from the screening of a chemical library: in vitro and in vivo studies. Biochim Biophys Acta 1784:1652–1658

Guillot A, Obis D, Mistou MY (2000) Fatty acid membrane composition and activation of glycine-betaine transport in Lactococcus lactis subjected to osmotic stress. Int J Food Microbiol 55:47–51

Guzzo J et al (2000) Regulation of stress response in Oenococcus oeni as a function of environmental changes and growth phase. Int J Food Microbiol 55:27–31

Hazel JR, Williams EE (1990) The role of alterations in membrane lipid composition in enabling physiological adaptation of organisms to their physical environment. Prog Lipid Res 29:167–227

Heipieper HJ, Diefenbach R, Keweloh H (1992) Conversion of cis unsaturated fatty acids to trans, a possible mechanism for the protection of phenol-degrading Pseudomonas putida P8 from substrate toxicity. Appl Environ Microbiol 58:1847–1852

Hickey EW, Hirshfield IN (1990) Low-pH-induced effects on patterns of protein synthesis and on internal pH in Escherichia coli and Salmonella typhimurium. Appl Environ Microbiol 56:1038–1045

Iwig DF, Grippe AT, McIntyre TA, Booker SJ (2004) Isotope and elemental effects indicate a rate-limiting methyl transfer as the initial step in the reaction catalyzed by Escherichia coli cyclopropane fatty acid synthase. Biochemistry 43:13510–13524

Johnsson T, Nikkila P, Toivonen L, Rosenqvist H, Laakso S (1995) Cellular fatty acid profiles of lactobacillus and lactococcus strains in relation to the oleic acid content of the cultivation medium. Appl Environ Microbiol 61:4497–4499

Kagan RM, Clarke S (1994) Widespread occurrence of three sequence motifs in diverse S-adenosylmethionine-dependent methyltransferases suggests a common structure for these enzymes. Arch Biochem Biophys 310:417–427

Kaneda T (1977) Fatty acids of the genus Bacillus: an example of branched-chain preference. Bacteriol Rev 41:391–418

Kim BH, Kim S, Kim HG, Lee J, Lee IS, Park YK (2005) The formation of cyclopropane fatty acids in Salmonella enterica serovar typhimurium. Microbiology 151:209–218

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Leenhouts KJ, Kok J, Venema G (1989) Campbell-like integration of heterologous plasmid DNA into the chromosome of Lactococcus lactis subsp. lactis. Appl Environ Microbiol 55:394–400

Lennarz WJ, Bonsen PP, van Deenen LL (1967) Substrate specificity of O-l-lysylphosphatidylglycerol synthetase. Enzymatic studies on the structure of O-l-lysylphosphatidylglycerol. Biochemistry 6:2307–2312

Liu SQ (2002) A review: malolactic fermentation in wine—beyond deacidification. J Appl Microbiol 92:589–601

Loffeld B, Keweloh H (1996) cis/trans isomerization of unsaturated fatty acids as possible control mechanism of membrane fluidity in Pseudomonas putida P8. Lipids 31:811–815

Maitre M, Weidmann S, Dubois-Brissonnet F, David V, Coves J, Guzzo J (2014) Adaptation of the wine bacterium Oenococcus oeni to ethanol stress: role of the small heat shock protein Lo18 in membrane integrity. Appl Environ Microbiol 80:2973–2980

Matthews A, Grbin PR, Jiranek V (2007) Biochemical characterisation of the esterase activities of wine lactic acid bacteria. Appl Microbiol Biotechnol 77:329–337

McGarrity JT, Armstrong JB (1981) The effect of temperature and other growth conditions on the fatty acid composition of Escherichia coli. Can J Microbiol 27:835–840

Michlmayr H et al (2010) A beta-glucosidase from Oenococcus oeni ATCC BAA-1163 with potential for aroma release in wine: cloning and expression in E. coli. World J Microbiol Biotechnol 26:1281–1289

Michlmayr H, Schumann C, Kulbe KD, del Hierro AM (2011) Heterologously expressed family 51 alpha-l-arabinofuranosidases from Oenococcus oeni and Lactobacillus brevis. Appl Environ Microbiol 77:1528–1531

Montanari C, Sado Kamdem SL, Serrazanetti DI, Etoa FX, Guerzoni ME (2010) Synthesis of cyclopropane fatty acids in Lactobacillus helveticus and Lactobacillus sanfranciscensis and their cellular fatty acids changes following short term acid and cold stresses. Food Microbiol 27:493–502

Oku Y, Kurokawa K, Ichihashi N, Sekimizu K (2004) Characterization of the Staphylococcus aureus mprF gene, involved in lysinylation of phosphatidylglycerol. Microbiology 150:45–51

Olsen KN, Budde BB, Siegumfeldt H, Rechinger KB, Jakobsen M, Ingmer H (2002) Noninvasive measurement of bacterial intracellular pH on a single-cell level with green fluorescent protein and fluorescence ratio imaging microscopy. Appl Environ Microbiol 68:4145–4147

O’Sullivan E, Condon S (1997) Intracellular pH is a major factor in the induction of tolerance to acid and other stresses in Lactococcus lactis. Appl Environ Microbiol 63:4210–4215

Palacios-Chaves L et al (2012) Identification and functional analysis of the cyclopropane fatty acid synthase of Brucella abortus. Microbiology 158:1037–1044

Peschel A et al (2001) Staphylococcus aureus resistance to human defensins and evasion of neutrophil killing via the novel virulence factor MprF is based on modification of membrane lipids with L-lysine. J Exp Med 193:1067–1076

Pini CV, Bernal P, Godoy P, Ramos JL, Segura A (2009) Cyclopropane fatty acids are involved in organic solvent tolerance but not in acid stress resistance in Pseudomonas putida DOT-T1E. Microb Biotechnol 2:253–261

Salema M, Poolman B, Lolkema JS, Dias MC, Konings WN (1994) Uniport of monoanionic L-malate in membrane vesicles from Leuconostoc oenos. Eur J Biochem 225:289–295

Salema M, Capucho I, Poolman B, San Romao MV, Dias MC (1996a) In vitro reassembly of the malolactic fermentation pathway of Leuconostoc oenos (Oenococcus oeni). J Bacteriol 178:5537–5539

Salema M, Lolkema JS, San Romao MV, Lourero Dias MC (1996b) The proton motive force generated in Leuconostoc oenos by L-malate fermentation. J Bacteriol 178:3127–3132

Sambrook J, Pollack R (1974) Basic methodology for cell culture–cell transformation. Methods Enzymol 32:583–592

Schumann C et al (2013) Malolactic enzyme from Oenococcus oeni: heterologous expression in Escherichia coli and biochemical characterization. Bioengineered 4:147–152

Slonczewski JL, Rosen BP, Alger JR, Macnab RM (1981) pH homeostasis in Escherichia coli: measurement by 31P nuclear magnetic resonance of methylphosphonate and phosphate. Proc Natl Acad Sci USA 78:6271–6275

Spano G, Massa S (2006) Environmental stress response in wine lactic acid bacteria: beyond Bacillus subtilis. Crit Rev Microbiol 32:77–86

Spano G, Lonvaud-Funel A, Claisse O, Massa S (2007) In vivo PCR-DGGE analysis of Lactobacillus plantarum and Oenococcus oeni populations in red wine. Curr Microbiol 54:9–13

Tarahomjoo S (2012) Development of vaccine delivery vehicles based on lactic acid bacteria. Mol Biotechnol 51:183–199

Taylor FR, Grogan DW, Cronan JE Jr (1981) Cyclopropane fatty acid synthase from Escherichia coli. Methods Enzymol 71(Pt C):133–139

Teixeira H, Goncalves MG, Rozes N, Ramos A, San Romao MV (2002) Lactobacillic acid accumulation in the plasma membrane of Oenococcus oeni: a response to ethanol stress? Microb Ecol 43:146–153

To TM, Grandvalet C, Tourdot-Marechal R (2011) Cyclopropanation of membrane unsaturated fatty acids is not essential to the acid stress response of Lactococcus lactis subsp. cremoris. Appl Environ Microbiol 77:3327–3334

Tourdot-Marechal R, Fortier LC, Guzzo J, Lee B, Divies C (1999) Acid sensitivity of neomycin-resistant mutants of Oenococcus oeni: a relationship between reduction of ATPase activity and lack of malolactic activity. FEMS Microbiol Lett 178:319–326

Tourdot-Marechal R, Gaboriau D, Beney L, Divies C (2000) Membrane fluidity of stressed cells of Oenococcus oeni. Int J Food Microbiol 55:269–273

van de Guchte M, Serror P, Chervaux C, Smokvina T, Ehrlich SD, Maguin E (2002) Stress responses in lactic acid bacteria. Antonie Van Leeuwenhoek 82:187–216

Wang AY, Cronan JE Jr (1994) The growth phase-dependent synthesis of cyclopropane fatty acids in Escherichia coli is the result of an RpoS(KatF)-dependent promoter plus enzyme instability. Mol Microbiol 11:1009–1017

Wang AY, Grogan DW, Cronan JE Jr (1992) Cyclopropane fatty acid synthase of Escherichia coli: deduced amino acid sequence, purification, and studies of the enzyme active site. Biochemistry 31:11020–11028

Wang P, Aixia L, Mei D, Fan M (2014) Induction, purification and characterization of malolactic enzyme from Oenococcus oeni SD-2a. Eur Food Res Technol 239:827

Williams VR, Fieger EA (1946) Oleic acid as a growth stimulant for Lactobacillus casei. J Biol Chem 166:335–343

Zhao Y et al (2003) Expression of a cloned cyclopropane fatty acid synthase gene reduces solvent formation in Clostridium acetobutylicum ATCC 824. Appl Environ Microbiol 69:2831–2841

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Djamel Drider.

Rights and permissions

About this article

Cite this article

To, T.M.H., Grandvalet, C., Alexandre, H. et al. Cyclopropane fatty acid synthase from Oenococcus oeni: expression in Lactococcus lactis subsp. cremoris and biochemical characterization. Arch Microbiol 197, 1063–1074 (2015). https://doi.org/10.1007/s00203-015-1143-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00203-015-1143-y