Abstract

Bacillus amyloliquefaciens strain LP03 isolated from soil, produced an antagonistic compound that strongly inhibited the growth of plant-pathogenic fungi and a lipopeptide biosurfactant. Also, isolated strain LP03 had a marked crude oil-emulsifying activity as it developed a clear zone around the colony after incubation for 24 h at 37°C. LP03 was identified as Bacillus amyloliquefaciens by analysis of partial 16 S rRNA gene and partial gyrA gene sequence. The lipopeptide was purified by acid precipitation of cell-free culture broth, extraction of the precipitates with methanol, silica gel column chromatography, and reverse-phase, high-pressure liquid chromatography. The purified biosurfactant was analyzed biochemical structure by matrix-assisted laser desorption/ionization time-of-flight mass spectrometry (MALDI-TOF) and electrospray ionization mass spectrometry/mass spectrometry (ESI-MS/MS). The masses of the two peaks were observed by HPLC chromatography. Their masses were determined to be 1,044 and 1,058 m/z with MALDI-TOF mass spectrometry. As constituents of the peptide and lipophilic part of the m/z 1,022.6, seven amino acids (Glu-Leu-Met-Leu-Pro-Leu-Leu) and β-hydroxy-C13 fatty acid were determined by ESI-MS/MS. The lipopeptide of 1,022.6 Da differed from surfactins in the substitution of leucine, valine and aspartic acid in positions 3, 4, and 5 by methionine, leucine, and proline, respectively. Novel lipopeptide was designated as bamylocin A.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biosurfactants are amphipathic molecules with both hydrophilic and hydrophobic moieties biosynthesized by diverse microorganisms such as bacteria, fungi, and yeasts. Due to their special characteristics, they are used in various fields such as in environmental, food, cosmetic, and agricultural chemical fields (Banat et al. 2000). In field of environment, biosurfactants are used for bioremediation and dispersion of oils, enhanced oil recovery, and transfer of crude oil (Noudeh et al. 2005). Many biosurfactants have these properties compared with chemical surfactants, including a lower toxicity, higher biodegradability, better environmental compatibility, and higher specific activity at extreme temperatures, pH level, and salinity (Zajic et al. 1977; Banat 1995; Kretschner et al. 1982).

The kinds of biosurfactants that have been reported include glycolipids, lipopeptides, fatty acids, lipids, polysaccharides, and protein complexes (Ron and Rosenberg 2001; Rosenberg and Ron 1999). Lipopeptides are produced by member of genera Bacillus, Pseudomonas, and Arthrobacter. Lipopeptides produced by bacteria are reported iturin families (iturin, mycosubtilin, and bacillomycin), fengycin, surfactin from Bacillus sp. and arthrofactin form Arthrobacter sp. and putisolvin from Pseudomonas sp. (Yakimov et al. 1995; Roongsawang et al. 2002; Steller and Vater 2000). Lipopeptides are important because they have many applications including bioremediation and oil recovery. The lipopeptides do not have oil-degrading activity themselves but can enhance oil degradation by increasing the apparent solubility of hydrocarbons.

Surfactin is a family of lipopeptide group produced by Bacillus species (Tsuge et al. 1996; Nakayama et al. 1997). It is well known as powerful biosurfactant; moreover surfactin has diverse biological activities such as anti-fungal, anti-bacterial, and anti-viral activities. Surfactin is a cyclic heptapeptide, which contains a β-Hydroxy fatty as hydrophobic moiety (Kalinovskaya et al. 2002; Vater et al. 2002). The closely related isoforms of surfactin differ in the length and branching of fatty acid side chains (C13–C15) and in the amino acid substitutions in the peptide ring. Surfactin A, B, and C are Leu, Val, and Ile (Fig. 5), respectively, as the seventh amino acid in peptide portion of the molecule (Steller and Vater 2000; Vater et al. 2002). Halobacillin is like surfactin in having Gln and Ile, respectively, as the first and seventh amino acids (Trischman et al. 1994). Pumilacidin has Leu and Val, as the fourth and seventh amino acids (Naruse et al. 1990).

In this study, we isolated and identified B. amyloliquefaciens LP03 that produces an effective biosurfactant. In addition, we purified and analyzed the structure of the biosurfactant. The isolated biosurfactant was designated as bamylocin A.

Materials and methods

Microorgaisms and culture media

Bacillus amyloliquefaciens LP03 was used throughout this work. LP03 was isolated from crop soil samples in Busan, Korea, and it strongly inhibited the growth of plant pathogenic fungi. Also, it was a well-degraded crude oil. The evidence for oil biodegradation is the clearing of agar plates that contain oil. This could also be due to the production of the biosurfactant, which would provide a clear zone on such medium. After LP03 was cultured LB (10 g/l casein peptone, 5 g/l yeast extract, 5 g/l NaCl, pH 7.0) medium at 37°C for 18 h and was stored at −70°C after 20% glycerol.

To isolate antagonistic bacterium, potato dextrose agar (PDA, Difco™; 4.0 g/l potato starch, 20 g/l dextrose, 15 g/l agar) medium was used and the fungi used were Botrytis cineria, Fusarium oxysporum, and Rhizoctonia solani, causing diseases such as gray-mold disease, Fusarium wilt, and damping-off, respectively, in plants.

The activity of crude oil-emulsifying was confirmed by LB agar plate containing crude oil produced by the United Arab Emirates. One milliliter of crude oil was smeared over the surface of an LB-agar plate (90 mm in diameter). LP03 was inoculated in the center of agar plate. After 24 h of incubation at 37°C, colonies surrounded by a halo zone on an oil-agar plate were indicated (Kim et al. 1997).

Surface tension of biosurfactant

The surface tension of the culture broth without cells was measured by the Ring Method (Magaritis et al. 1979) using a Du Nouy Tensiometer (Itoh Seisakusho, Ltd. Tokyo, Japan) every 6 h for 4 days. Also, the surface tension of the purified biosurfactant was determined by diluting until reaching the critical micelle concentration (CMC). To ensure that the results were reproducible, an average of three independent measurements were made.

Analysis of 16 S rRNA and gyrA nucleotide sequence

Bacterial genomic DNA was isolated using the method of Cutting and Vander (1990). The genomic DNA mixture was extracted with phenol, chloroform, and iso-amylalchol (25:24:1) and re-extracted with 4 ml of chloroform and iso-amylalchol (24:1). The DNA was precipitated with ethanol and 3 M sodium acetate (pH 5.2) and washed with chilled 70% ethanol and finally resuspended in 10 mM Tris–HCl (pH 8.0). The isolated DNA was used to template the polymerase chain reaction (PCR). PCR were carried out in the following mixture; 5 μl of 10× PCR buffer, extracted chromosomal DNA (0.1 μg), 20 pmol each of primers, 2.5 mM dNTPs (Takara Bio. Co., Japan) and 1.25 U of Ex Taq polymerase (Takara Bio. Co., Japan) in a total volume of 50 μl. Thermal cycling was carried out using a thermal cycler (Takara Bio. Co., Japan) as follows: initial denaturation at 95°C for 5 min followed by 30 cycles of denaturation at 95°C for 30 s, primer annealing at 55°C for 30 s, and primer extension at 72°C for 120 s.

The amplified 16 S rRNA and gyrA gene were extracted using Gel Extraction kit (Nuclegen Inc., Daejeon, Korea). PCR products of the amplified 16 S rRNA and gyrA gene were cloned into a pGEM-T-easy vector (Promega Co.) for sequencing. Their partial nucleotides sequences were determined with the primers M13F (5-CGC CAG GGT TTT CCC AGT CAC GA-3) and M13R (5-AGC GGA TAA CAA TTT CAC ACA GGA-3) in an automated DNA sequencer. These sequences were compared to rRNA and gyrA nucleotide sequences present in genebank, respectively (http://www.ncbi.nlm.nih.gov/BLAST/). Phylogenetic trees were constructed by Neighour Joining and the Clustal-X program.

Purification of biosurfactant

The biosurfactant-producing bacterium, LP03, was cultured in 2 l of LB medium containing 0.1% glucose at 37°C with constant shaking at 180 rpm for 5 days. To remove the bacterial cells, culture broth was centrifuged with 13,000×g at 4°C for 15 min. and the supernatant was acidified to pH 2.0 with conc. HCl, after the formation of a precipitate at 4°C overnight. The precipitates were collected by centrifugation (13,000×g, 4°C, 15 min), washed three times with acidic water (pH 2.0 with 12 N HCl), and dried by vacuum. The dried surfactant was extracted three times with methanol (100%) for 3 h. The methanol was removed with the aid of an EYELA rotary evaporator (Tokyo Rikakikai Co. Ltd., Tokyo, Japan) under reduced pressure. The crude biosurfactant was obtained as a brown-colored material using an EYELA rotary evaporator. The crude biosurfactant was dissolved in butanol and was loaded onto a column of silica gel 60 (Merck Co. Inc., Damstadt, German; 2.5 × 30 cm, 230–400 mesh) which had been previously equilibrated with butanol. The column was then washed with the same solvent. The biosurfactant was eluted with a liner gradient of 100% butanol. Fractions (10 ml) were collected at a flow rate of 2 ml/min. Active fractions were pooled and then concentrated by evaporator. Further purification was achieved using a reverse-phase HPLC system.

Oil film-collapsing assay of biosurfactant

An oil film-collapsing assay was measured using a modified method (Kim et al 1997). Twenty microliters of crude oil was placed on the surface of 20 ml of distilled water in petri dishes (90 mm in diameter). A thin oil film was formed immediately. Then, 10 μl of eluents by HPLC were gently placed in the center of the oil film. A clear halo became visible under light, and the diameter of this circle was measured.

Thin-layer chromatography

Thin-layer chromatography was carried out on pre-coated silica gel 60 F254 plates (Merck Co. Inc., Damstadt, German). TLC plates were spotted with the sample purified biosurfactant and developed using the following mobile phases: chloroform/methanol/water (65:25:4, by vol.). The plates that developed were then sprayed with water and dried with air (Symmank et al. 2002).

Reverse phase high-pressure liquid chromatography

High-pressure liquid chromatography was performed using a reverse-phase liquid chromatography system, Waters 400 HPLC (Waters, USA) equipped with a BDS C18 column (Thermo Hypersil Ltd., Cheshire, UK; 5 μ, 4.6 × 250 mm) at room temperature. The system was operated at a flow rate of 2.0 ml/min with a solvent of 90% methanol as the mobile phase. HPLC spectra were detected by a UV monitor at 210 nm. Each peak fractions were harvested to MALDI-TOF mass spectrometry analysis.

Mass spectrometry analysis

The purified biosurfactant mixture was mixed with an equal volume of matrix solution (10 mg/ml α-cyano-4-hydroxycinnamic acid matrix in 70% acetonitrile containing 0.1% (v/v) TFA) and the mixture was analyzed on a Voyager-DE PRO instrument of Perkin–Elmer Cetus (Foster City, CA, USA). Ionization was achieved using a nitrogen laser (337 nm beam, 3 ns pulse width, 3 Hz) set at attenuation between 80 and 95. Peptide masses (M + Na and M + H) in the range 800–3,000 Da were measured. Samples were infused with a syringe. The electro spray source was operated at a capillary voltage of 32 V, a spray voltage of 5 kV and a capillary temperature of 320°C.

Results

Isolation and identification of biosurfactant-producing B. amyloliquefaciens LP03

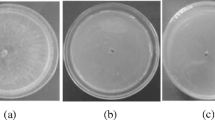

LP03 was isolated from crop soil due to its ability to control phyto-pathogenic fungi: it showed strong antifungal activity against B. cinera, R. solani, and F. oxsporum (Fig. 1). Antagonistic bacterium LP03 also had a marked crude oil-emulsifying activity, as visualized by the clear zone that developed around the colony after 24-h incubation at 37°С (Fig. 2). LP03 had the ability to reduce surface tension from 58 to 27 mN/m of culture broth (data not shown).

The isolated LP03 was identified as B. amyloliquefaciens by an analysis of the partial 16S rRNA and partial gyrA nucleotide (NT) sequences. The partial 16S rRNA gene of B. amyloliquefaciens LP03 exhibited over 98% homology with most Bacillus species, but the partial gyrA gene showed greater homology with B. amyloliquefaciens (95%) than other Bacillus species (less than 83%). The gyrA NT sequences are the source of significantly higher genetic variation than the 16S rDNA sequences.

Purification of biosurfactant from B. amyloliquefaciens LP03

The biosurfactant was purified from the culture filtrate of B. amyloliquefaciens LP03 grown in an LB-medium, as described in “Materials and methods”. The purification procedure consisted of four steps: HCl fractionation, methanol treatments, silica gel column chromatography, and HPLC. Finally, active fractions were collected, concentrated, and dissolved in methanol to estimate their purity by reverse phase HPLC. The HPLC analysis showed two major peaks and retention times were 5.482 and 6.358 min, respectively (data not shown). Eluents by HPLC showed oil film-collapsing activity, and the diameters of the halo zone were 65 and 60 mm, respectively. Two biosurfactants reduced surface tension from 72 to 25 mN/m of water (data not shown). They showed weak antifungal activity against B. cinera, R. solani, and F. oxsporum. The purified biosurfactants were identified as one spot (R f value 0.71) of white color on the TLC plates sprayed with water (data not shown).

Structural characterization of the purified biosurfactant

The molecular mass of the purified compounds was measured using MALDI-TOF mass spectrometry, giving main peaks at m/z 1,044.7 and 1,058.8 as [M + Na] (Fig. 3a, b). Two peaks, at m/z 1,044.7 and 1,058.8, revealed differences of 14 Da, suggesting that the purified compound had a different carbon chain length (–CH2–). The MS spectra of A and B are shown at m/z 656, 1,512, and 1,514 (Fig. 3). Two peaks, at m/z 1,512 and 1,514, were similar to fengycin, but m/z 656 did not correspond with any other lipopeptide.

The m/z 1,044.7 of ion was used as precursor ion for further ESI-MS/MS analysis. The product patterns of m/z 1,022.63 [M + H] of yMax, determined by ESI-MS mass spectrometry, are shown in Fig. 4. Ion at m/z 1,004.62 of bMax found in the spectrum corresponded to losses of H2O (−18 Da) from m/z 1,022.63. Figure 4 also shows b ion and y ion series in accordance with molecular mass and fatty acid-Glu. As constituents of the lipophilic part and peptide of the m/z 1,022.63, β-hydroxy-C13 (213.22) and seven amino acids (Glu-Leu-Met-Leu-Pro-Leu-Leu, 809.41) were determined by ESI-MS/MS. The structures of surfactin A, B, C, and bamylocin A are shown in Fig. 5. Structurally, the novel lipopeptide of m/z 1,022.63 Da was similar to surfactin, but the components of the amino acids differed in the substitution from Leu to Asp residue in positions 3, 4, and 5 by Met, Leu, and Pro, respectively. We therefore designated the compound of 1,022.63 Da with molecular mass as bamylocin A.

ESI-MS/MS spectra of the precursor ion m/z 1,044.7 from MALDI-TOF. Peaks of y ion were showed 342.20, 455.30, 586.39, 699.48, 796.53 and 909.60 on ESI-MS/MS spectra. Peaks of b ion were showed 227.18, 324.22, 437.31, 568.39, 681.47, and 810.54 on ESI-MS/MS spectra. A bamylocin A was calculated of y ions and b ions by ESI-MS/MS

Discussion

In this study, we collected bacterial isolates from crop soil samples. B. amyloliquefaciens LP03, an antagonistic bacterium, strongly inhibited growth of the phyto-pathogenic fungi B. cinerea, F. oxysporum, and R. solani. LP03 also emulsified the crude oil in the agar plate and reduced surface tension in culture broth. B. amyloliquefaciens LP03 was therefore selected to produce the biosurfactant. B. amyloliquefaciens are reported to inhibit the growth of the phyto-pathogenic fungi B. cinerea, B. elliptica, and R. solani (Yu et al. 2002; Sun et al. 2006; Chiou and Wu 2003). In order to identify LP03, we analyzed the nucleotide (NT) sequences of the partial 16S rRNA gene and partial gyrA and identified as B. amyloliquefaciens. The partial gyrA sequences were compared with those other Bacillus species, an approach that has proven useful in the past (Chun and Bae 2000).

It is well known that Bacillus species produce lipopeptides such as bacillomycin, fengycin (or plipastatin), iturin, lichenysin, mycosubtilin, and surfactin (Steller and Vater 2000), and B. amyloliquefaciens produces fengycin, iturin, and surfactin (Yu et al. 2002; Sun et al. 2006). High-surface activity and anti-fungal activity exhibited by strain LP03 is consistent with the known properties of surfactin-like molecules.

The seventh peptide position is Leu, Ile, and Val in surfactins A, B, and C, respectively (Kalinovskaya et al. 2002; Steller and Vater 2000). The molecular mass of the biosurfactant produced by B. amyloliquefaciens LP03 (m/z 1,044. 7 (M + Na) and 1,058.8 (M + Na) as determined by MOLD-TOF mass spectroscopy corresponds to that of surfactin (Vater et al. 2002); however, in our analysis of ESI-MS/MS, the lipopeptide of LP03 differed from surfactins A, B, and C and surfactins like halobacillin, lichenysin A, pumilacidin (Arima et al. 1968; Peypoux et al. 1991; Itokawa et al. 1994; Naruse et al. 1990; Kalinovskaya et al. 2002). The peptide sequence of lipopeptide producing LP03 is Glu-Leu-Met-Leu-Pro-Leu-Leu.

References

Arima K, Kakinuma A, Tamura G (1968) Surfactin, a crystalline peptidelipid surfactant produced by Bacillus subtilis: isolation, characterization and its inhibition of fibrin clot formation. Biochem Biophys Res Commun 31:488–494

Banat IM (1995) Characterization of biosurfactants and their use in pollution removal-state of the art. Acta Biotechnol 15:251–267

Banat IM, Makkar RS, Cameotra SS (2000) Potential applications of microbial surfactants. Appl Microbiol Biotechnol 53:495–508

Chun J, Bae KS (2000) Phylogenetic analysis of Bacillus subtilis and related taxa based on partial gyrA gene sequence. Antonie van Leeuwenhoek 78:123–127

Chiou AL, Wu WS (2003) Formulation of Bacillus amyloliquefaciens B190 for Control of Lily Grey Mould (Botrytis elliptica). J Phytopathol 151:13–18

Cutting SM, Vander HPB (1990) Genetic analysis. In: Harwood CR, Cutting SM (eds) Molecular biological methods for bacillus. Wiley, Chichester, pp 27–74

Itokawa H, Miyashita T, Morita H, Takeya K, Hirano T, Homma M, Oka K (1994) Structural and conformational studies of [Ile7] and [Leu7] surfactins from Bacillus subtilis natto. Chem Pharm Bull 42:604–607

Kalinovskaya NI, Kuznetsova TA, Ivanova EP, Romanenko LA, Voinov VG, Huth F, Laatsch H (2002) Characterization of surfactin-like cyclic depsipeptides synthesized by Bacillus pumilus from Ascidian Halocynthia aurantium. Mar Biotechnol 4:179–188

Kim HS, Lee CH, Suh HH, Ahn KH, Oh HM, Kwon GS, Yang JW, Yoon BD (1997) A lipopeptide biosurfactant produced by Bacillus subtilis C9 selected through the Oil film-collapsing assay. J Microbiol Biotechnol 7:180–188

Kretschner A, Bock H, Wagnee F (1982) Chemical and physical characterization of interfacial-active lipids from Rhodococcus erythropolis grown on n-alkane. Appl Environ Microbiol 44:864–870

Magaritis A, Kennedy K, Zajic JE, Gerson DF (1979) Biosurfactant production by Nocardia erythropolis. Dev Ind Microbiol 20:623–630

Nakayama S, Takahashi S, Hirai M, Shoda M (1997) Isolation of new variants of surfactin by a recombinant Bacillus subtilis. Appl Microbiol Biotechnol 48:80–82

Naruse N, Tenmyo O, Kobaru S, Kamei H, Miyaki T, Konishi M, Oki T (1990) Pumilacidin, a complex of new antiviral antibiotics: production, isolation, chemical properties, structure and biological activity. J Antibiot 43:267–280

Noudeh GD, Housaindokht M, Bazzaz BSF (2005) Isolation, characterization, and investigation of surface and hemolytic activities of a lipopeptide biosurfactant produced by Bacillus subtilis ATCC 6633. J Microbiol 43:272–276

Peypoux F, Bonmatin JM, Labbe H, Das B, Ptak M, Michel G (1991) Isolation and characterization of a new variant of surfactin, the [Val7]surfactin. Eur J Biochem 202:101–106

Ron EZ, Rosenberg E (2001) Natural roles of biosurfactant. Environ Microbiol 3:229–236

Roongsawang N, Thaniyavarn J, Thaniyavarn S, Kameyama T, Haruki M, Imanaka T, Moriawa M, Kanaya S (2002) Isolation and characterization of a halotolerant Bacillus subtilis BBK-1 which produces three kinds of lipopeptides: bacillomycin L, plipastatin, and surfactin. Estremophiles 6:499–506

Rosenberg E, Ron EZ (1999) High- and low-molecular-mass microbial surfactants. Appl Microbiol Biotechnol 52:154–162

Steller S, Vater J (2000) Purification of the fengycin synthetase multienzyme system from Bacillus subtilis b213. J Chromatogr B 737:267–275

Sun L, Lu Z, Bie X, Lu F, Yang S (2006) Isolation and characterization of a co-producer of fengycins and surfactins, endophytic Bacillus amyloliquefaciens ES-2, from Scutellaria baicalensis Georgi. World J Microbiol Biotechnol. doi:10.1007/s11274-006-9170-0

Symmank H, Franke P, Saenger W, Bernhard F (2002) Modification of biologically activepeptides: production of novel lipohexapeptide after engineering of Bacillus subtilis surfactin synthetase. Protein Eng 15:913–921

Trischman JA, Jensen PR, Fenical W (1994) Halobacillin: a cytotoxic cyclic acylpeptide of the iturin class produced by a marine Bacillus. Tetrahedron Lett 35:5571–5574

Tsuge K, Ano T, Shoda M (1996) Isolation of a gene essential for biosynthesis of the lipopeptide antibiotics plipastatin B1 and surfactin in Bacillus subtilis. YB8 165:243–251

Vater J, Kablitz B, Wilde C, Franke P, Mehta N, Cameotra SS (2002) Matrix-assisted laser desertion ionization-time of flight mass spectrometry of lipopeptide biosurfactants in whole cells and culture filtrates of Bacillus subtilis C-1 isolated from petroleum sludge. Appl Environ Microbiol 68:6210–6219

Yakimov MM, Timmis KN, Wray V, Fredrickson HL (1995) Characterization of a new lipopeptide surfactant produced by thermotolerant and halotolerant subsurface Bacillus licheniformis BAS50. Appl Environ Microbiol 61:1706–1713

Yu GY, Sinclair JB, Hartman GL, Bertagnolli BL (2002) Production of iturin A by Bacillus amyloliquefaciens suppressing Rhizoctonia solani. Soil Biol Biochem 34:955–963

Zajic JE, Guignard H, Gerson DF (1977) Properties and biodegradation of a bioemulsifier from Corynebacterium hydrocarboclatus. Biotechnol Bioeng 19:1303–1302

Acknowledgments

This paper was partially supported by the Dong-a University Research Fund in 2006, Sang-cheol Lee, Sun-Hee Kim, and In-Hye Park was supported by Brain Korea 21 project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Erko Stackebrandt.

Rights and permissions

About this article

Cite this article

Lee, SC., Kim, SH., Park, IH. et al. Isolation and structural analysis of bamylocin A, novel lipopeptide from Bacillus amyloliquefaciens LP03 having antagonistic and crude oil-emulsifying activity. Arch Microbiol 188, 307–312 (2007). https://doi.org/10.1007/s00203-007-0250-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00203-007-0250-9